Mastering Temperature Control for Food Safety in Your Pizzeria

Share

When it comes to your pizzeria, temperature control for food safety isn't just another box to check—it's the most critical, yet invisible, ingredient you handle every day. For a pizza restaurant, getting this right is everything. It's how you stop harmful bacteria from turning your beautiful pepperoni, cheese, and veggies into a liability, ensuring every pie you serve is not only delicious but perfectly safe.

Frankly, it's the bedrock of your pizzeria's entire operation.

Why Temperature Control Is Your Most Critical Ingredient

Picture a slammed Friday night. The oven's roaring, your team is a blur of motion, slinging dough and topping pies like a well-oiled machine. But while all that visible chaos is under control, there’s a hidden battle raging inside your pizza prep table and walk-in cooler. It's a fight against microscopic enemies that love it when temperatures creep up, and losing this fight is not an option for any pizzeria that wants to stay in business.

This is where the infamous "Temperature Danger Zone" becomes a very real, very present threat in your pizzeria. It’s not just some term from a food safety poster; it’s a reality you have to manage every single shift.

The Bacterial Party You Must Prevent

Think of the temperature range between 40°F and 140°F (that’s 4°C to 60°C) as an open-bar invitation for a bacterial blowout. Within this zone, nasty characters like Salmonella and E. coli can literally double their numbers in just 20 minutes. Your pepperoni, your cheese, and those fresh-cut veggies become the perfect party spot for this rapid growth if you're not careful.

A pizzeria's reputation is built one slice at a time. Consistent temperature control protects not only your customers but also the trust you've worked so hard to build. It’s a silent guardian of your brand.

Proper refrigeration is the bouncer at the door, kicking these unwelcome guests out. By keeping a steady, cold environment in your pizza prep tables and walk-ins, you slow bacterial growth to a crawl. This preserves the quality, integrity, and—most importantly—the safety of every pizza topping you use. For a deeper look at the nuts and bolts, our complete restaurant food storage guidelines cover the whole process, from delivery to the prep line.

More Than Just Safety—It's Quality

Getting temperature control for food safety right does more than just keep people from getting sick. It has a direct, noticeable impact on the quality of every pizza that comes out of your oven. When your ingredients are held at their ideal temperatures, you guarantee:

- Flavor Preservation: That rich, tangy flavor in your pizza sauce stays bright and vibrant.

- Optimal Texture: Your shredded mozzarella stays perfectly fresh and doesn't get clumpy or oily.

- Freshness and Crispness: Veggies like bell peppers and onions keep that satisfying crunch your customers love.

At the end of the day, temperature control is the invisible thread connecting safety, quality, and your profitability. For larger pizzerias, this extends to the hot side, too; ensuring you have an uninterrupted heat source for your pizza ovens is crucial, making things like emergency natural gas solutions for critical heat-dependent operations a smart consideration. By mastering both your cold and hot holding, you’re actively protecting your customers, your reputation, and your bottom line.

Mastering Your Pizza Prep Table

Your refrigerated pizza prep table is the engine room of your entire operation. It’s the frontline warrior in the constant battle against the kitchen's ambient heat, working tirelessly to keep your pepperoni, cheese, and veggies perfectly chilled and safe. Mastering its function is a core part of effective temperature control for food safety in any pizzeria.

Think of your prep table like a high-performance car engine. For that engine to run efficiently, it needs clean fuel, unrestricted airflow, and regular maintenance. If you clog the air intake or put dirty fuel in the tank, it’s going to sputter and fail—likely at the worst possible moment. Your pizza prep table works on the same principles.

Optimizing Airflow and Organization

The biggest mistake pizzerias make is treating their prep table like an unorganized storage bin. Overstocking the ingredient wells or cramming the under-counter storage suffocates the unit. This blocks the cold air from circulating, creating dangerous warm spots where bacteria can thrive.

This common mistake forces the compressor to work overtime, which leads directly to premature failure and some seriously expensive repair bills.

Similarly, propping open the lid during a busy service might seem like a time-saver, but it's like leaving your car's AC on with all the windows down. All the precious cold air escapes, and the unit simply cannot keep up. The result is pizza toppings entering the temperature danger zone, compromising both safety and quality.

To avoid this, focus on strategic organization:

- Don't Overfill Pans: Fill ingredient wells only to the designated fill line. This ensures cold air can flow over the top of the food, keeping everything at a consistent, safe temperature.

- Rotate Stock Efficiently: Use the First-In, First-Out (FIFO) method for your pizza toppings. This not only reduces waste but prevents older products from sitting in the unit for too long.

- Keep Lids Closed: Train your staff to close the prep table lid after every single use. It’s a simple habit that makes a massive difference in maintaining a stable temperature.

For a detailed breakdown of different models and how they are designed for optimal workflow, our guide on choosing a commercial pizza prep table offers valuable insights that can help streamline your pizzeria's efficiency.

Daily Checks and Simple Maintenance

Effective temperature control relies on vigilance. You can't just assume your pizza prep table is working correctly; you have to verify it. Daily checks are non-negotiable and are your first line of defense against a potential food safety crisis.

Your temperature log is more than just paperwork for the health inspector—it's your prep table's daily health report. Consistent monitoring allows you to spot a failing compressor or a faulty thermostat long before it leads to a full-blown emergency.

Start by making temperature checks a mandatory part of your opening and closing procedures. Use a calibrated food thermometer to check the actual temperature of ingredients in different pans—especially the pepperoni and cheese—not just the unit's built-in thermostat. This gives you a true reading of your product's safety.

Beyond daily checks, simple maintenance can prevent 90% of equipment failures. The most critical task is cleaning the condenser coils. These coils, usually located at the back or bottom of the unit, are responsible for releasing heat. In a busy pizzeria, they quickly get clogged with grease, flour, and dust.

A clogged coil forces the compressor to work harder, consume more energy, and eventually burn out. Cleaning them once a month with a stiff brush takes just a few minutes but can save you thousands in repair bills and prevent a catastrophic breakdown during a Saturday night dinner rush. Consistent care ensures your prep table remains a reliable asset, not a ticking liability.

Navigating Food Safety Regulations and HACCP

Health codes and HACCP plans can feel like a mountain of confusing paperwork, but they don't have to be. For a busy pizzeria, think of these regulations not as obstacles, but as a clear roadmap for excellent temperature control for food safety. They provide a structured way to protect your customers and your business from preventable risks.

At its core, a Hazard Analysis and Critical Control Points (HACCP) plan is simply a proactive system. It’s not about reacting to problems after they happen; it’s about identifying potential food safety hazards in your pizzeria in advance and putting firm controls in place to stop them.

Imagine a pilot preparing for a flight. They don't just hope the plane is safe; they go through a detailed pre-flight checklist, verifying every critical system before takeoff. A HACCP plan is your pizzeria's pre-flight checklist, ensuring every topping is handled safely from the moment it arrives to the second it goes into the oven.

What Health Inspectors Are Really Looking For

When a health inspector visits your pizzeria, they're not there to find fault. They are there to verify that your systems are working to protect public health. For a pizza restaurant, their focus often boils down to a few key areas related to your pizza prep tables and processes.

They’ll be checking for very specific temperature points throughout your kitchen's workflow. This includes:

- Receiving Temperatures: Is that shipment of cheese and pepperoni arriving at or below 40°F (4°C)? A temperature gun check right at the delivery door is your first line of defense.

- Cold Storage Integrity: Are your walk-in and pizza prep table maintaining consistent, safe temperatures? They will check the unit's thermometer and may also probe food items directly.

- Final Cook Temperatures: They'll want to see that your pizzas are cooked to a temperature that kills harmful bacteria, typically 165°F (74°C) for any pies containing chicken or other reheated ingredients.

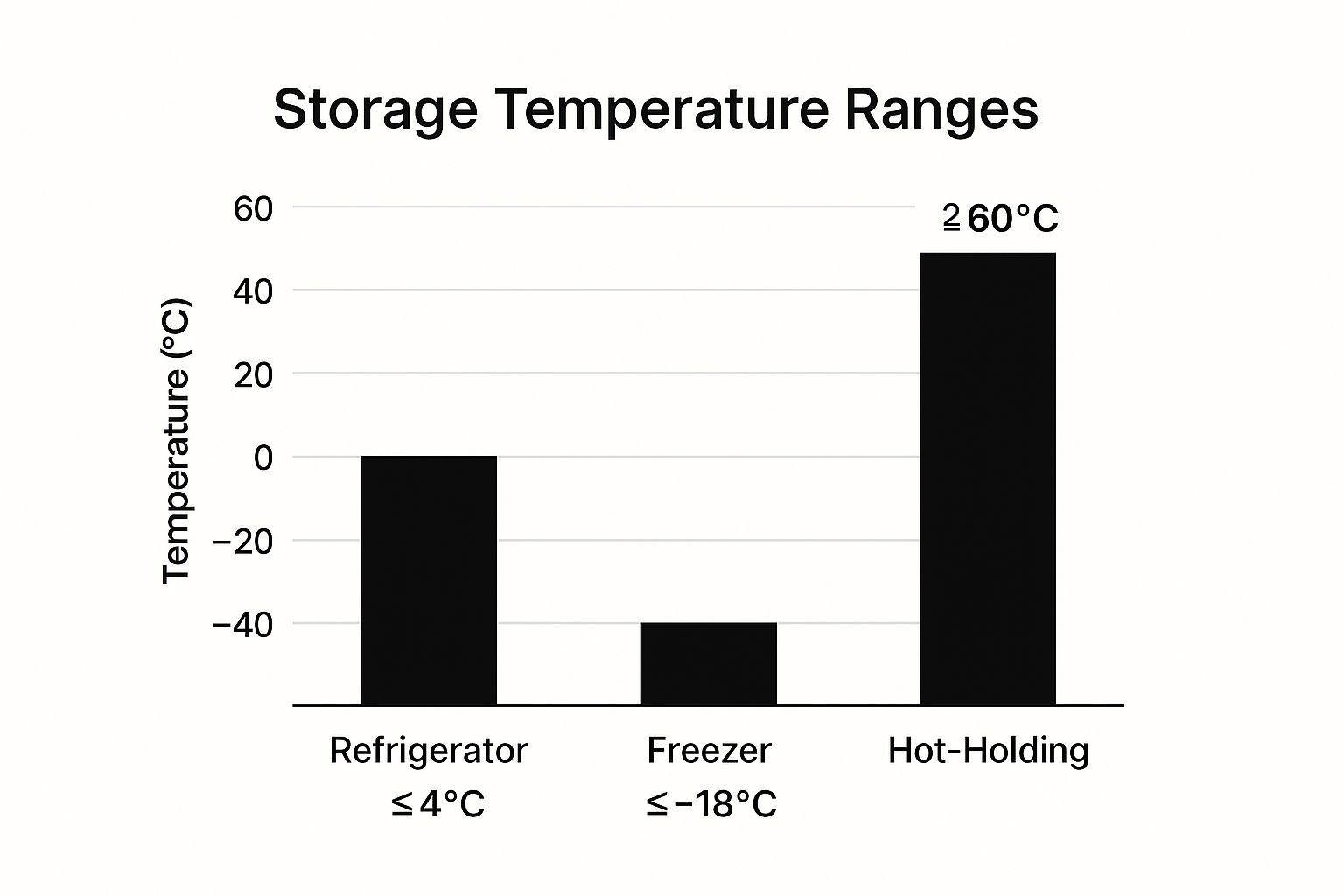

The following chart breaks down the essential temperature zones that health inspectors will verify for proper storage in your restaurant.

This visual guide makes it clear that maintaining distinct and consistent temperatures for refrigeration, freezing, and hot-holding is fundamental to compliance and, more importantly, food safety.

For pizzerias, this means being diligent about every topping. Here’s a quick-glance table to help you keep track.

Pizza Ingredient Temperature Requirements at a Glance

This table offers a quick reference for the critical temperature points you need to monitor for common pizza ingredients, from the moment they arrive to when they're ready to serve.

| Stage | Ingredient Type | Required Temperature (°F) | Purpose |

|---|---|---|---|

| Receiving | Refrigerated items (cheese, meats, sauce) | 40°F or below | Prevents bacterial growth from the start. |

| Cold Storage | All perishable toppings | 33°F - 40°F | Maintains freshness and safety in prep tables/walk-ins. |

| Freezer Storage | Frozen dough, meats | 0°F or below | Preserves quality and stops pathogen activity. |

| Cooking | Pizzas with meat/poultry toppings | 165°F (internal) | Ensures all harmful bacteria are destroyed. |

| Hot Holding | Slices for sale (e.g., in a display warmer) | 135°F or above | Keeps cooked food out of the temperature danger zone. |

Following these guidelines isn't just about passing an inspection; it's about serving pizza you can be proud of.

Temperature Logs: Your Best Defense

Keeping accurate temperature logs can sometimes feel like tedious work, but it’s one of the most powerful tools at your disposal. These logs are more than just paperwork; they are your pizzeria's documented proof of diligence and your best defense in any food safety discussion. They show a consistent, professional commitment to safety.

A well-maintained temperature logbook isn't a chore; it's your restaurant's safety diary. It tells the story of your commitment to quality and provides undeniable evidence that you are actively managing risks every single day.

This proactive approach is critical because the stakes are incredibly high. The U.S. Centers for Disease Control and Prevention estimates that about 1 in 6 Americans (48 million people) get sick from contaminated foods each year, leading to thousands of deaths. Programs like HACCP are designed specifically to prevent pathogen growth by establishing and monitoring these critical temperature points. You can learn more about the vital role of temperature in preventing foodborne pathogens and see how your diligence contributes to public health.

Ultimately, embracing these regulations turns compliance from a burden into a benefit. It builds strong habits within your pizza-making team, reinforces your commitment to quality, and provides peace of mind that you are serving the safest, most delicious pizza possible.

Essential Tools for Accurate Temperature Monitoring

Alright, let's move from the theory to the tools of the trade. Having the right gear is what turns the principles of temperature control for food safety into a daily reality in your pizzeria. Relying on the built-in thermostat of your pizza prep table is like driving a car without a speedometer—sure, you're moving, but you have no idea if you're doing it safely.

To get it right, you need a dedicated toolkit for accurate, reliable monitoring.

This is about equipping your pizza-making team with the right thermometers and, just as importantly, training them to use and calibrate them properly. Think of it as an investment in consistency, compliance, and your own peace of mind.

The Pizzeria Thermometer Trio

Not all thermometers are created equal, and any busy pizzeria needs a few different types to cover all the bases. Each one has a specific job, from spot-checking pepperoni deliveries to keeping a constant eye on your walk-in cooler.

- Probe Thermometers: This is your workhorse, the one you'll reach for most often. A good digital probe thermometer is non-negotiable for checking the internal temperature of ingredients like sausage or chicken, both when they arrive and after they're cooked. It’s also the only way to get a true reading on your pizza sauce.

- Infrared (IR) Thermometers: These are all about speed. Perfect for quick surface-level checks, an IR thermometer lets you instantly read the temperature of a pizza stone or a pizza oven deck without making contact. It's fantastic for fast checks, but remember its limitation: it can't measure the internal temperature of food. It's a great supplement, not a replacement, for a probe thermometer.

- Refrigerator/Freezer Thermometers: These are your simple, inexpensive sentinels. They live inside your equipment. Place one in your pizza prep table and another in your walk-in to get a constant, at-a-glance reading of the ambient temperature. They're your early warning system, helping you spot problems before they turn into disasters.

Proper calibration is what separates a useful tool from a liability. A thermometer that’s off by even a few degrees can give you a false sense of security, unknowingly putting your pizza toppings right in the middle of the Temperature Danger Zone.

Calibrating your probe thermometers weekly is a must-do. The ice-point method is the easiest way: just fill a glass with ice and a little water, stick the probe in, and make sure it reads 32°F (0°C). If it doesn't, you'll need to adjust it following the manufacturer's instructions.

The Rise of the Digital Guardian

Beyond the manual checks, modern tech offers a powerful way to ensure perfect temperature control for food safety around the clock. Automated monitoring systems act like a "digital guardian" for your most valuable assets—your pizza prep table and walk-in cooler.

Imagine a small sensor living inside your walk-in cooler that works 24/7, never taking a break.

This isn't just about making life easier; it's about eliminating human error and gaining some serious peace of mind. These systems create a continuous, unbroken record of your temperature data, which is a massive advantage when the health inspector walks in.

Even better, they're proactive. If a cooler door is left ajar after a late-night cleaning or a prep table compressor starts to fail overnight, the system doesn't wait for your morning crew to discover a crisis. It sends an instant alert straight to your phone. This allows you to intervene before a single topping is lost.

These systems ensure you’re always in control, protecting your inventory and your reputation even when you’re not physically in the pizzeria. For any pizzeria owner, choosing the right equipment is a foundational decision, and our guide on commercial fridge shopping made easy shows how modern features support these exact goals.

Common Pizzeria Temperature Mistakes to Avoid

Even the most buttoned-up pizzeria teams can fall into bad habits. When it comes to temperature control, these small slip-ups can snowball into serious issues, hitting everything from the quality of your pizza toppings to the health of your customers. The first step to building a rock-solid food safety culture is knowing where the weak spots are.

Let's be honest, most of these mistakes happen in the heat of the moment—that Friday night rush or an unexpected lunch slam—when getting pizzas out the door feels more important than following procedure to the letter. But spotting and fixing these common failures is what separates the pros from the amateurs. Let's break down the temperature control blunders I see most often in pizzerias and how to banish them from your kitchen for good.

The Overstuffed Prep Station Fiasco

One of the most frequent slip-ups is treating the pizza prep table's refrigerated wells like a bottomless pit of toppings. In an attempt to be efficient, staff will pile pepperoni, cheese, and veggies high above the fill line. It might save a few trips to the walk-in, but it's a food safety disaster waiting to happen.

Here’s the deal: refrigerated pizza prep tables are built to push cold air over the ingredients. When you mound that cheese up, it acts like a dam, completely blocking the airflow. The ingredients at the top of the pile are left hanging out in the warm kitchen air, quickly creeping into the temperature danger zone while the stuff at the bottom stays perfectly chilled.

The Fix:

Enforce a strict "level-fill" rule. It’s non-negotiable. Train your team to fill ingredient pans only to the marked line and never higher. It's far safer to use smaller, shallower pans that you refill more often than to overstuff big ones. This is the only way to guarantee every shred of mozzarella and every slice of mushroom is held at a consistent, safe temperature.

The Mid-Rush Lid Prop Habit

During a chaotic service, propping open the pizza prep table lid feels like a clever shortcut. It shaves a few precious seconds off making each pizza. But this seemingly harmless habit completely defeats the purpose of your refrigeration unit.

Think about it like leaving your home refrigerator door wide open. The compressor will chug along endlessly, fighting a losing battle against the pizzeria's ambient heat. This puts a massive strain on your equipment—leading to expensive breakdowns—and lets all that precious cold air spill out, causing your ingredient temperatures to climb.

A closed lid is your prep table's best friend. It traps the cold air right where it belongs—on your pizza toppings. Each time that lid is opened and closed, it's a small but vital act that upholds your pizzeria's food safety standards.

The Fix:

This one is all about training and discipline. Make closing the lid after every single pizza a hard-and-fast rule in your kitchen workflow. More importantly, explain the why behind the rule—it protects food quality, prevents equipment failure, and keeps customers safe. Once your crew understands the impact, the habit becomes second nature.

Thawing Pepperoni on the Counter

The classic "just leave it on the counter" move is a massive red flag in any commercial kitchen. Grabbing a frozen block of sausage or pepperoni and letting it thaw on a prep surface might seem easy, but it's one of the riskiest things you can do. The outer layers of the meat warm up fast, jumping right into the temperature danger zone where bacteria throw a party, all while the inside is still frozen solid.

This method creates the perfect storm for foodborne pathogens. Temperature slip-ups can occur at any point in the supply chain, but your pizzeria is the last line of defense. Sticking to proper protocols not only prevents spoilage and wasted money but also protects public health. In fact, research shows that better temperature control is a key factor in reducing food waste globally, which you can read more about here.

The Fix:

There are only three safe ways to thaw food, and "on the counter" isn't one of them. Stick to these health department-approved methods:

- In the Refrigerator: This is the gold standard for pizzerias. It requires planning, but it's the safest method by far. Just move your frozen items to the walk-in a day or two before you need them.

- Under Cold Running Water: For a faster thaw, place the sealed product in a sink under cold, running water that is 70°F or below. The key word here is running—the constant flow washes away surface bacteria.

- As Part of the Cooking Process: Some pizza toppings, like frozen sausage crumbles, can go straight from the freezer onto the pizza, as long as you ensure they reach the proper final internal temperature in the oven.

Your Pizzeria Temperature Safety Questions, Answered

Even with the best equipment and training, questions about the nuts and bolts of temperature control for food safety are going to pop up. In the middle of a Friday night rush, the details really matter. This is where we tackle the most common questions and real-world challenges pizzeria owners and managers face every day, giving you clear, direct answers to keep your kitchen running safely and smoothly.

Think of this as your go-to guide for those tricky situations that always seem to happen during the busiest pizza shifts.

How Often Should I Be Logging Temperatures For My Pizza Prep Table?

Consistency is king here, and it's what health inspectors are trained to look for. As a baseline, you absolutely must check and log the temperatures of your pizza prep table and other cold storage units at the start of every single shift. No exceptions. This gives you a clear starting point for the day.

From there, temperatures should be checked at least every 4 hours while you're open. However, for a busy pizzeria, I strongly recommend tightening that up to every 2 hours. This provides a much stronger safety net, especially during peak times when the prep table lid is opening and closing constantly.

This frequency ensures you'll catch a temperature problem long before it puts your pizza toppings—and your customers—at risk.

A detailed temperature log isn't just about appeasing the health department; it's a performance diary for your equipment. When you log consistently, you start to see patterns that can predict maintenance needs and prove you're doing your due diligence to run a safe pizzeria.

What's The Right Way To Cool A Big Batch Of Pizza Sauce Safely?

Whatever you do, never leave a big, hot pot of your signature pizza sauce to cool down on the counter. This is one of the most common—and most dangerous—mistakes a kitchen can make, as it lets the sauce sit for hours right in the middle of the temperature danger zone.

The only correct method is the two-stage cooling process that most health codes demand. It's a systematic approach designed to get food down to a safe storage temperature as quickly as possible.

Here’s the breakdown:

- Stage One: The goal is to cool the sauce from 140°F (60°C) down to 70°F (21°C) within two hours. The faster, the better. You can speed this up dramatically with an ice bath (placing the sauce pot into a larger container of ice water) or by using an ice paddle, which is a tool made specifically for this job.

- Stage Two: Once your sauce hits 70°F, you have another four hours to bring it all the way down to 40°F (4°C) or colder. Transfer the sauce into shallow metal pans to maximize the surface area, then get them into your walk-in cooler. Make sure there’s some space around the pans for air to circulate.

This two-step method is your most reliable defense against bacterial growth in large batches of pizza sauce.

My Pizza Prep Table Can't Seem To Stay Cold During A Rush. What Can I Do?

This is an incredibly common problem for busy pizzerias, and it's a critical one to solve. When your pizza prep table can't keep up, your ingredients are in jeopardy. The issue usually comes down to one of three things, and thankfully, they're all fixable.

First, check your team's habits. The most frequent culprit is leaving the lids open. Train your staff to keep them closed whenever possible. Every second a lid is open, cold air rushes out and warm kitchen air floods in, forcing the unit's compressor to work overtime.

Second, resist the urge to overfill the ingredient pans. This is a crucial part of proper temperature control for food safety. When you pile pizza toppings high above the rim of the pan, you're blocking the cold airflow that's designed to keep them chilled. It's far better to use smaller batches and refill them more often from the walk-in.

Third, handle the simple maintenance. Make sure the condenser coils are clean and free of dust, flour, and grease. Clogged coils can't dissipate heat properly, which cripples the unit's cooling power. Also, check that the unit has enough breathing room and isn't jammed up against a wall. If you've addressed all these points and the problem continues, it’s probably time to call a service professional or consider upgrading to a pizza prep table built for high-volume kitchens.

Ready to master your pizzeria's temperature control with equipment you can trust? Pizza Prep Table offers a wide selection of high-quality, NSF-compliant refrigerated prep tables designed for the demands of a busy kitchen. Explore our collection and find the perfect unit to keep your ingredients safe and fresh at https://pizzapreptable.com.