The Ultimate Guide to Comparing Planetary Mixers

Share

Why Planetary Mixers Are Essential for Commercial Kitchens

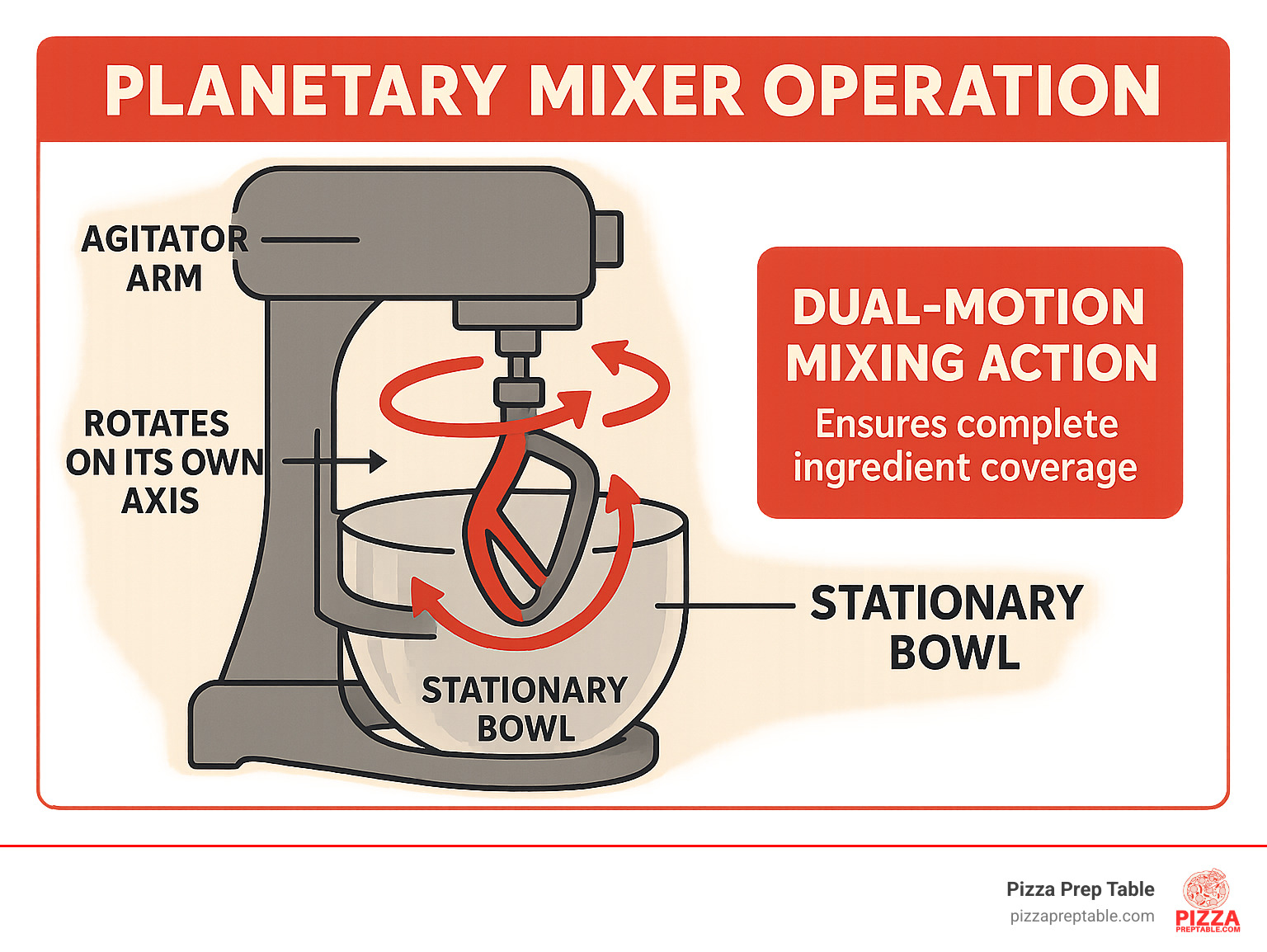

Planetary mixers are the workhorses of commercial kitchens, combining versatility with power to handle everything from pizza dough to whipped cream. These mixers get their name from their unique mixing action - the agitator rotates on its own axis while orbiting around a stationary bowl, just like planets moving around the sun.

Quick Overview: What Makes Planetary Mixers Special

- Unique mixing action: Agitator rotates and orbits for thorough blending

- Versatile attachments: Dough hooks, beaters, whips, and specialty tools

- Wide capacity range: From 5 to 140 quarts for any kitchen size

- Multiple applications: Dough, batters, frostings, sauces, and more

- Complete bowl coverage: Blades contact entire batch in just 36 revolutions

This complete mixing coverage means no dead zones and consistent results every time. Unlike other mixer types that excel at specific tasks, planetary mixers handle nearly everything you throw at them.

For pizzeria owners and small restaurant managers, planetary mixers offer the flexibility to prepare multiple menu items with one machine. Whether you're mixing pizza dough for tonight's dinner rush or whipping cream for tomorrow's desserts, these mixers adapt to your needs without breaking your budget.

I'm Sean Kearney, and my sales background has given me deep insight into how the right equipment transforms kitchen operations. Through years of helping restaurant owners choose planetary mixers, I've seen how these versatile machines boost efficiency and profitability in commercial kitchens.

Planetary mixers vocab explained:

What is a Planetary Mixer and How Does It Work?

Picture the solar system for a moment - planets spinning on their own axes while orbiting the sun. That's exactly how planetary mixers got their name and how they work their magic in commercial kitchens. The mixing attachment rotates on its own axis while simultaneously traveling around a stationary bowl, creating a thorough mixing action that's simply impossible to achieve by hand.

At its heart, a planetary mixer consists of a powerful motor, a stationary mixing bowl, and various attachments that connect to the agitator. The motor drives everything through either a gear-driven or belt-driven transmission system. What makes these machines so valuable is their incredible versatility - swap out attachments and the same machine that just kneaded your pizza dough can whip delicate cream or even grind meat for tomorrow's special.

This adaptability is why so many pizzeria owners consider planetary mixers their kitchen's MVP. Instead of buying separate equipment for each task, one well-chosen mixer handles multiple jobs efficiently.

For more detailed information about industrial-grade options, check out our guide on industrial mixers.

The Unique Mixing Action

The genius of planetary mixing lies in its dual-motion system. Just like how planets orbit the sun, the mixing blade rotates clockwise while the entire agitator assembly moves counterclockwise around the bowl. This opposite-direction movement creates a powerful shearing action that breaks down ingredients and ensures every bit gets properly mixed.

Here's a fascinating fact: the blades of a planetary mixer physically contact the entire batch in just 36 revolutions around the vessel. That means no hiding spots for unmixed flour or stubborn butter chunks. Every ingredient gets the attention it needs for consistent texture and quality.

This complete bowl coverage eliminates those frustrating dead zones where ingredients can hide. You won't need to stop mid-mix to scrape down the sides manually - a real time-saver during busy prep periods. The thorough mixing action delivers consistent results every single time, which is exactly what you need when customers expect the same great taste with every order.

Primary Functions and Applications

Planetary mixers truly shine when it comes to versatility. With the right attachments, these workhorses tackle an impressive range of kitchen tasks that would otherwise require multiple pieces of equipment.

Dough kneading is where many pizzeria owners first fall in love with their planetary mixer. The dough hook attachment handles heavy, sticky pizza dough with ease, developing gluten properly without overworking the mixture. Whether you're making thin crust or deep dish, the consistent kneading action ensures perfect texture every time.

Batter mixing becomes effortless with the flat beater attachment. Cake batters, muffin mixes, and pancake batter achieve perfect consistency through gentle folding action. The mixer incorporates all ingredients thoroughly while preventing the overmixing that can make baked goods tough.

For whipping cream, meringues, and frostings, the wire whip attachment creates light, airy textures that would take forever by hand. The planetary action incorporates maximum air while maintaining stability - perfect for those picture-perfect dessert toppings.

But wait, there's more! With specialty attachments, these mixers transform into meat grinders, vegetable slicers, and cheese graters. This incredible versatility makes them invaluable for kitchens with diverse menus or those looking to expand their offerings.

For more options and specifications, explore Hobart's planetary mixer selection to see just how many possibilities these machines offer.

Key Factors for Choosing the Best Planetary Mixers

Choosing the right planetary mixer can make or break your kitchen's efficiency. I've seen too many pizzeria owners rush into buying the first mixer they find, only to realize months later it doesn't meet their needs. The key is understanding your specific requirements before you start shopping.

Think about your current menu and production volume first. A cozy neighborhood pizzeria making 50 pizzas daily needs something completely different than a busy operation cranking out 500 covers. But here's the thing - don't just consider today's needs. Your business will grow, and your equipment should grow with you.

Budget matters, but smart buyers focus on the total cost of ownership. A $3,000 mixer that serves you faithfully for 15 years costs far less than a $1,000 model that needs replacing every five years. Plus, downtime from equipment failures during your dinner rush? That's expensive in ways you can't put a price on.

For comprehensive guidance on making the right choice, check out our ultimate professional mixer buying guide.

Capacity and Size: Countertop vs. Floor Models

Countertop models are the workhorses of smaller kitchens. These compact units typically handle 5 to 30 quarts and fit perfectly on your prep table. They're ideal for pizzerias that make smaller batches throughout the day - think fresh pizza dough for the evening rush or whipped cream for desserts.

Floor models are where things get serious. These powerhouses handle 30 to 140 quarts and require dedicated floor space, but they're built for high-volume operations. When you're mixing 60 pounds of pizza dough at once, you need the muscle that only a floor model can provide.

The capacity range for planetary mixers spans from 5 to 140 quarts, so there's truly something for every kitchen size. Most small pizzerias start with 20-quart models, while larger establishments or those planning expansion often choose 40-60 quart units. The beauty is that you can always add a second mixer later if your volume grows.

Space planning is crucial here. Measure your kitchen carefully and think about workflow. A countertop model might save floor space, but if you're constantly running out of mixing capacity during busy periods, a floor model might be worth the real estate.

Need help sizing your mixer perfectly? Our guide on choosing a large mixer that fits your kitchen and needs walks you through the process. Hobart also offers a handy capacity calculator to nail down exact requirements.

Power, Drive System, and Durability

Motor horsepower separates the weekend warriors from the daily workhorses. Light cake batters need minimal power, but thick pizza dough or heavy frostings demand serious muscle. Most commercial planetary mixers range from 1/2 HP for small countertop units up to 5 HP for large floor models.

Gear-driven transmission systems are the gold standard for commercial use. They deliver superior torque and durability compared to belt-driven alternatives. They cost more upfront, but they handle heavy loads day after day with minimal maintenance. Belt-driven systems work fine for lighter applications, but they'll need more attention in high-volume kitchens.

Look for overload protection - it's like having a guardian angel for your motor. This feature automatically shuts down the mixer if it encounters resistance beyond safe limits. Trust me, this little safety net can save you from costly repairs when someone accidentally tries to mix concrete-thick dough.

Essential Attachments for Your Planetary Mixer

The three standard attachments that come with most planetary mixers are your kitchen's holy trinity. The dough hook handles pizza dough and bread with the perfect kneading action - no overworking, just smooth, elastic dough every time. The flat beater is your go-to for cake batters, cookie dough, and frostings, scraping bowl sides while it mixes. The wire whip creates magic with meringues, whipped cream, and anything that needs air incorporated.

But here's where things get exciting - the #12 attachment hub opens up a world of possibilities. Your mixer transforms into a meat grinder for fresh sausage, a vegetable slicer for consistent prep work, or a cheese grater for fresh toppings. Some operations even add pasta makers for house-made noodles.

These attachments turn your mixer into a multi-purpose food prep station. Instead of buying separate equipment for each task, you're maximizing your investment and saving precious counter space. It's like having a Swiss Army knife for your kitchen.

Budget and Leading Brands

Planetary mixers span a wide price range - from around $200 for basic models to $5,000 or more for heavy-duty commercial units. This range reflects real differences in capacity, build quality, and features. While budget models work for occasional use, commercial kitchens benefit from investing in proven, durable equipment.

The return on investment calculation is straightforward. A quality mixer that lasts 15 years and handles your growing volume provides better value than cheaper alternatives that need frequent replacement. Factor in service availability, warranty coverage, and parts availability when making your decision.

Leading manufacturers each target different market segments. Hobart leads in reliability and service support, while brands like Avantco offer solid value for moderate use. Globe and Omcan serve specialized niches with unique features and competitive pricing.

Don't let budget constraints stop you from getting quality equipment. Programs like Five Star Financing make professional-grade mixers accessible with manageable monthly payments. Sometimes the difference between good and great equipment is just a few dollars per day.

Planetary Mixers vs. Other Mixer Types: What to Know

| Feature | Planetary Mixers | Spiral Mixers | Horizontal Mixers |

|---|---|---|---|

| Versatility | High - handles multiple tasks | Low - dough only | Medium - heavy mixing |

| Best For | General purpose, varied menu | Artisan bread, pizza | Large batches, dense dough |

| Dough Type | All types, small to medium batches | High-hydration, artisan | Heavy, dense dough |

| Heat Generation | Moderate | Low | High |

| Attachments | Extensive options | Limited | Few options |

| Noise Level | Moderate | Low | High |

When you're shopping for a commercial mixer, understanding the differences between planetary mixers and other types can save you thousands of dollars and countless headaches. Each mixer type has its sweet spot, and choosing the wrong one is like buying a sports car to haul lumber.

Spiral mixers are the specialists of the mixer world. They excel at one thing - mixing dough, especially high-hydration artisan breads and pizza dough. The spiral agitator gently develops gluten without generating much heat, making them perfect for bakeries focused on bread production. However, try to whip cream or mix cake batter in a spiral mixer, and you'll quickly realize why they're called specialists.

Horizontal mixers are the heavy lifters, designed for massive batches of dense products. These workhorses handle 100+ pound batches of thick dough or heavy mixtures that would bog down other mixer types. The trade-off? They generate significant heat, create more noise, and offer limited versatility beyond heavy mixing tasks.

Planetary mixers sit in the sweet spot for most commercial kitchens. They handle dough consistency well while offering the flexibility to tackle everything from delicate meringues to thick frostings. This versatility makes them ideal for restaurants with diverse menus who need one machine to do multiple jobs well.

For pizza-specific guidance, our article on choosing the best stand mixer for pizza dough breaks down the pros and cons of each type for pizzeria applications.

When to Choose a Planetary Mixer

Planetary mixers earn their reputation as all-purpose workhorses when versatility is your top priority. If your kitchen menu includes cookies one day, cakes the next, and heavy dough for pizza crusts, a planetary mixer adapts to each task with the right attachment.

These mixers shine in general-purpose kitchens where you're preparing multiple food types in moderate batches throughout the day. Rather than investing in separate machines for dough mixing, batter preparation, and whipping tasks, one planetary mixer handles all three jobs efficiently.

Pizzerias with diverse menus particularly benefit from this flexibility. You might mix pizza dough during prep time, whip cream for desserts during the afternoon lull, and prepare cake batter for tomorrow's special. The same machine handles all these tasks without missing a beat.

Consider a planetary mixer if you're planning menu expansion or seasonal offerings. The extensive attachment options mean you can add new capabilities without buying entirely new equipment. For pizza-focused operations, specialized options like Hobart's pizza mixer offer planetary action optimized specifically for dough preparation.

The key is matching the mixer type to your kitchen's workflow. If you're mixing one type of product in large volumes, a specialized mixer might serve you better. But if versatility and space efficiency matter more than specialization, planetary mixers deliver the flexibility most commercial kitchens need.

Frequently Asked Questions about Planetary Mixers

What size planetary mixer do I need for a small pizzeria?

The key to choosing the right size planetary mixer for your small pizzeria lies in understanding your daily production needs and planning for growth. Most small pizzeria owners find that 20-30 quart mixers hit the sweet spot for daily pizza dough production while keeping enough flexibility for other menu items.

Countertop models work beautifully if you're working with limited space and prefer preparing smaller batches throughout the day. These compact workhorses typically handle 10-15 pounds of dough per batch, making them perfect for pizzerias cranking out 50-100 pizzas daily. They're also great for operations that like to keep their dough fresh by mixing multiple small batches.

Floor models make more sense when you're planning for growth or need to tackle large batches during your prep periods. A 40-quart floor model can handle 25-30 pounds of dough in one go, which supports higher volume operations or helps you get ahead with batch preparation strategies.

Here's something many owners overlook: think about your peak hours when sizing your equipment. If you're the type who needs to prepare tomorrow's dough after service ends, a larger mixer will cut down your prep time and labor costs significantly. Your tired kitchen staff will thank you for making their end-of-shift routine smoother.

For detailed mixing techniques that'll help you get the most from whatever size you choose, check our guide on mastering pizza dough kneading in your stand mixer.

Can you use a planetary mixer for high-hydration pizza dough?

Absolutely! Planetary mixers can handle high-hydration pizza dough, but there are some important tricks to keep in mind. High-hydration doughs (those with 80-90% water absorption) can be sticky little troublemakers that love to climb the dough hook during mixing - and nobody wants dough decorating their mixer head.

The secret is using lower speeds to prevent that dough from climbing and potentially damaging your motor. Start mixing on the lowest speed and gradually increase as the dough develops structure. Think of it like coaxing a shy cat - patience and gentle handling work better than force.

Keep a close eye on the mixing process and don't hesitate to stop if the dough begins climbing excessively. It's better to pause and scrape things down than to risk damaging your equipment or creating a messy situation.

Now, if your operation specializes in high-hydration artisan breads or authentic Neapolitan pizza, you might want to consider whether a spiral mixer would better suit your needs. These mixers handle wet doughs more effectively and generate less heat during mixing, which can be crucial for maintaining dough quality.

For comprehensive guidance on choosing the right mixer for your specific pizza style, read our ultimate guide to choosing the best pizza dough mixers.

How do you properly clean and maintain a commercial planetary mixer?

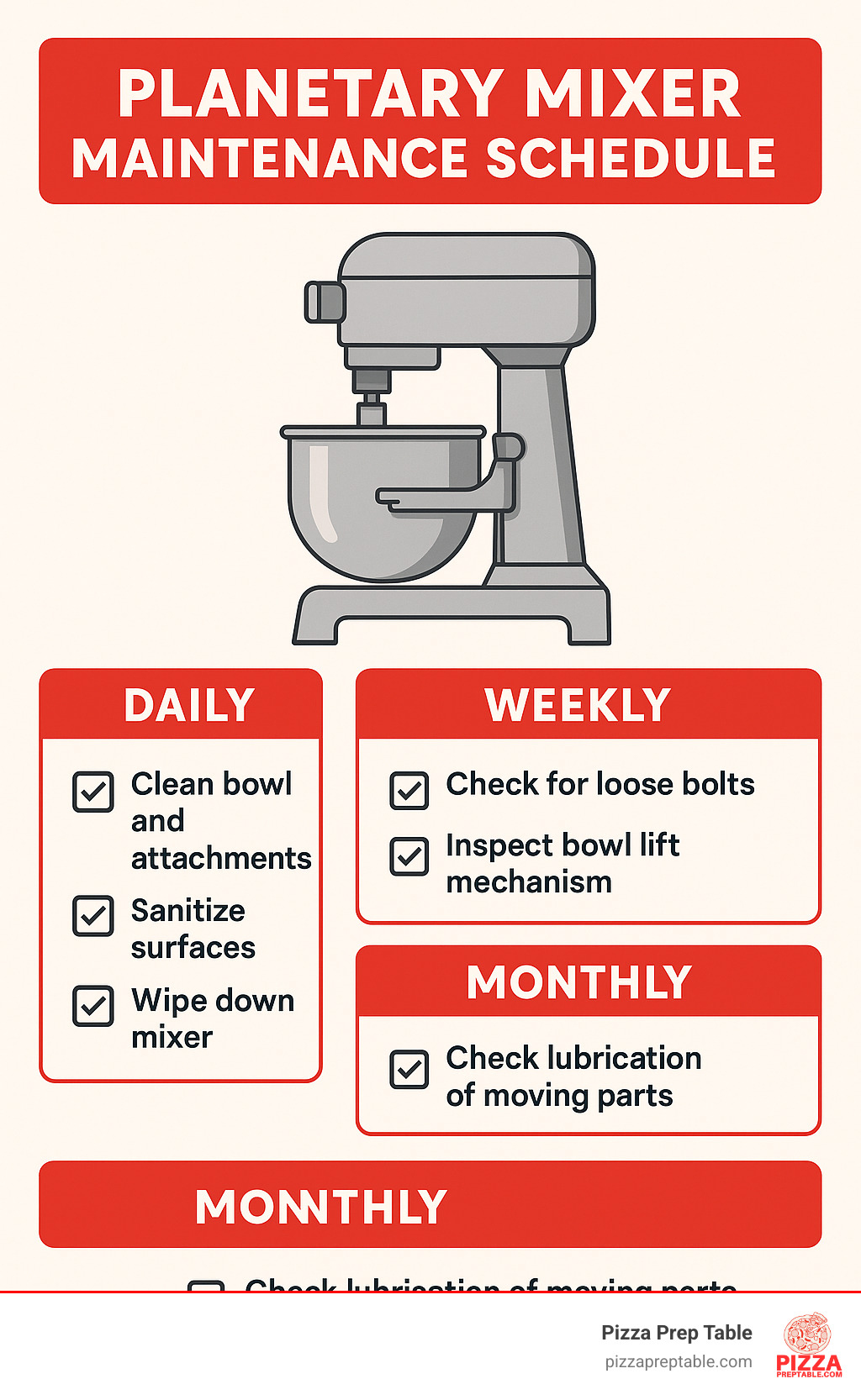

Proper cleaning and maintenance are what separate planetary mixers that last for decades from those that break down after a few years. The good news is that with a solid daily routine and some regular attention, these machines are built to be workhorses that keep on going.

Your daily cleaning routine should become as automatic as locking the front door. Start by disconnecting the power and removing all attachments - safety first! Wash the stainless steel bowl and attachments in warm, soapy water, then sanitize all food-contact surfaces. Don't forget to wipe down the mixer head and base with food-safe cleaner, and make sure everything's completely dry before reassembly.

Regular maintenance is where you'll save yourself headaches down the road. Check for loose bolts, inspect the bowl lift mechanism, and ensure proper lubrication of moving parts. Most commercial mixers need professional service every 6-12 months depending on how hard you work them - think of it as a health checkup for your equipment.

Watch for warning signs that indicate your mixer needs professional attention: unusual noises, grease leaking from the gear box, or decreased mixing performance. These issues often mean internal components need service or replacement, and catching them early saves money in the long run.

For professional service support, visit Hobart Service or contact your local dealer for maintenance scheduling. Trust me, a little preventive care goes a long way toward keeping your mixer running smoothly during those busy dinner rushes.

Conclusion

Choosing the right planetary mixer can transform your kitchen operations from chaotic to smooth-running. After helping countless pizzeria owners make this decision, I've seen how the right equipment becomes the backbone of efficient food preparation.

Planetary mixers offer that sweet spot between versatility and power that most commercial kitchens desperately need. Their unique mixing action ensures complete ingredient coverage in just 36 revolutions, while their extensive attachment options turn one machine into your entire prep station. Whether you're whipping delicate meringues for tonight's dessert special or kneading heavy pizza dough for tomorrow's lunch rush, these mixers adapt to whatever you throw at them.

The range of sizes from 5 to 140 quarts means there's a perfect fit for every kitchen - from the tiny counter space of a startup pizzeria to the high-volume demands of a busy restaurant. This flexibility makes planetary mixers a smart investment that grows with your business.

When making your final decision, think beyond today's needs. Assess your current menu requirements, but also consider where you want to be in two years. Evaluate your production volume during peak hours, not just average days. The mixer that handles your busiest Saturday night rush without breaking a sweat is the one that'll serve you well long-term.

At PizzaPrepTable.com, we've guided restaurant owners through this decision process hundreds of times. We understand that choosing equipment isn't just about specifications - it's about finding tools that support your vision and help your business thrive. That's why we offer flexible financing options that make quality equipment accessible, whether you're launching your first location or expanding your successful operation.

The right planetary mixer becomes more than just equipment - it becomes your kitchen's reliable partner, quietly doing the heavy lifting while you focus on creating amazing food and building your business. From our experience serving pizzerias across major cities, we know that investing in quality mixing equipment pays dividends in consistency, efficiency, and customer satisfaction.

Ready to find your perfect mixing solution? Explore our full range of pizza prep tables and equipment to complete your ideal commercial kitchen setup. Your future self will thank you for making the investment in equipment that truly works as hard as you do.