Under Counter Refrigerator: The Ultimate Pizza Prep Guide

Share

Let's be honest, in a pizzeria, an under counter refrigerator isn't just cold storage—it's the command center for the entire pizza-making line. When it’s built right into a pizza prep table, this workhorse keeps every critical ingredient perfectly chilled and literally at your fingertips. It dictates the entire pace and flow of your kitchen.

A great unit makes service feel like a well-oiled machine. A bad one? It just creates expensive bottlenecks and frustrated cooks.

The Heart of Your Pizzeria's Workflow

In the fast-paced world of a pizzeria, every single second counts, especially when the dinner rush hits. The right under-counter refrigerator, specifically a pizza prep table, becomes the central hub of your whole assembly line. It’s the spot where dough becomes dinner, and its design has a direct impact on your speed, consistency, and ultimately, your profits.

Think of it as the difference between a chaotic scramble for toppings and a smooth, synchronized kitchen ballet.

When every ingredient—from the mozzarella and pepperoni down to the fresh veggies—is perfectly organized and held at a food-safe temperature, your team can build pizzas faster and more efficiently. This kind of setup cuts out wasted steps and ensures every single pizza that goes out the door meets your quality standards.

Efficiency and Ingredient Freshness

A poorly thought-out kitchen layout forces chefs to constantly walk back and forth between a standard refrigerator and their prep station. All that wasted time adds up fast, slowing down how quickly orders get filled and frustrating both your staff and your customers. An integrated under-counter unit just erases that problem completely.

Here’s where a dedicated pizza prep station really shines:

- Streamlined Assembly: All your must-have ingredients are right below and in front of the chef. It’s a powerful, all-in-one workstation.

- Consistent Quality: Precise temperature control in both the refrigerated base and the topping rail means your ingredients stay fresh, preserving their taste and texture.

- Enhanced Food Safety: Keeping perishable items at the right temperature isn't just a good idea—it’s critical for preventing spoilage and flying through health inspections.

A pizzeria’s success really hinges on its ability to crank out a high volume of quality pizzas, fast. The pizza prep table isn't just another piece of equipment; it's the engine driving that production line. A bottleneck here can bring the entire restaurant to a screeching halt.

To really squeeze the most profit out of your operation, you need effective small business inventory management strategies, and your under-counter refrigerator is a key player. By keeping ingredients visible and organized, you naturally cut down on over-ordering and minimize waste. This single piece of equipment becomes the foundation for a lean, efficient, and profitable kitchen, which sets the stage perfectly for diving into how to choose the right model for your pizzeria.

Anatomy of a Pizza Prep Table

To really get why an under counter refrigerator is so essential in a pizzeria, you have to see it as part of a bigger machine: the pizza prep table. This isn't just a cold box with a cutting board glued on top. It's a purpose-built, all-in-one workstation where every single component is designed for speed and efficiency.

When you break it down, you start to see how all the pieces work together. The whole system is engineered to help your crew build flawless pizzas, faster. Understanding this anatomy shows you exactly how this piece of equipment impacts your pizzeria's speed, food safety, and the consistency of every pie that goes out the door.

The Refrigerated Base

The foundation of any pizza prep table is its refrigerated base. This is your main storage hub, built to hold the bulky stuff—boxes of dough, big containers of sauce, and backup blocks of cheese. You might not think much about the doors, but your choice here really matters.

- Solid Doors: These are the champions of energy efficiency. Because they're fully insulated, they do a much better job of trapping cold air. That means less work for the compressor and lower utility bills for you.

- Glass Doors: You trade a little insulation for a huge gain in visibility. Glass doors let your staff see what’s inside at a glance, making it faster to grab what they need and obvious when you're running low on something critical.

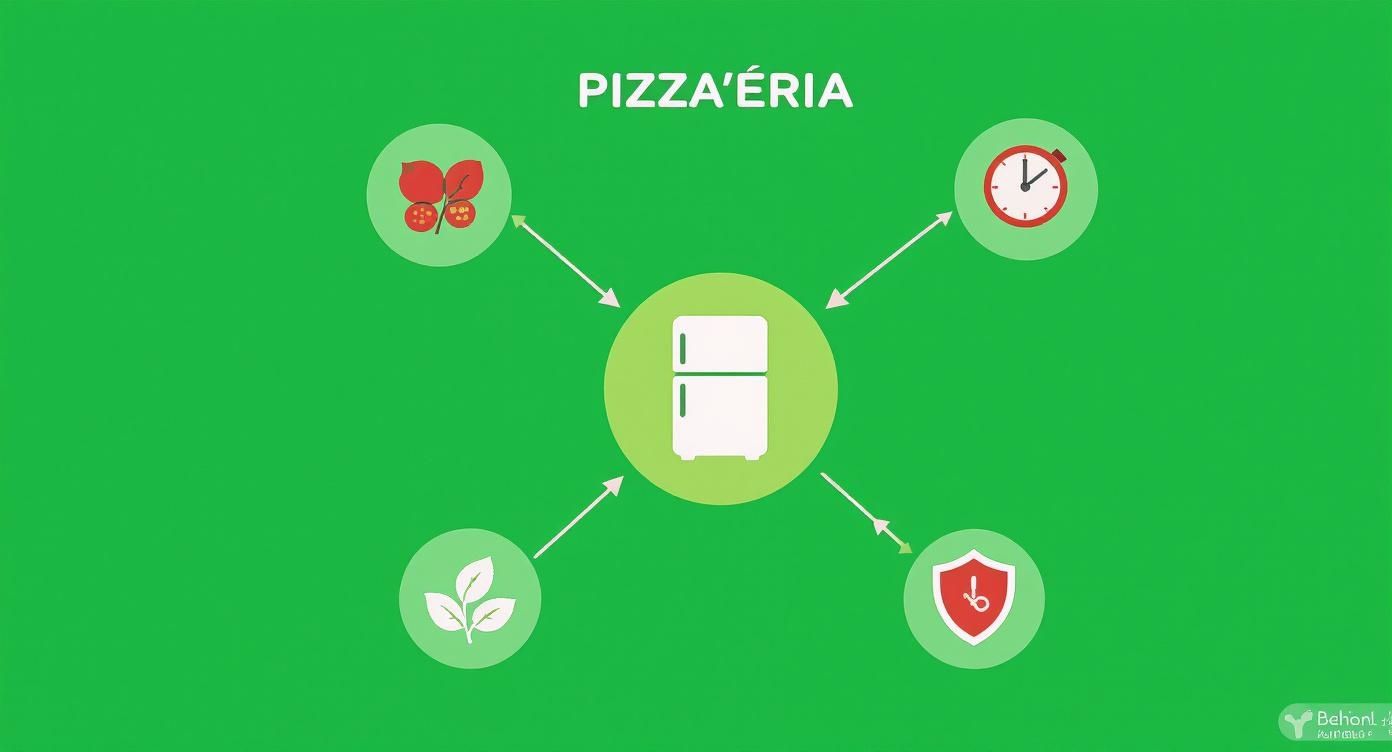

The infographic below shows how this refrigerated core is the starting point for a workflow that’s all about freshness and speed.

As you can see, the entire pizza-making process flows directly from this refrigerated base, which has a massive impact on the quality and efficiency of your final product.

To get a clearer picture of how these components come together, let's break down the key parts of a typical pizza prep table.

Key Components of a Pizza Prep Table

| Component | Primary Function | Key Consideration |

|---|---|---|

| Refrigerated Base | Bulk storage for dough, sauce, cheese, and backup ingredients. | Choose between energy-efficient solid doors or high-visibility glass doors. |

| Refrigerated Topping Rail | Holds pans of ready-to-use toppings at food-safe temperatures. | Proper cooling here is non-negotiable for food safety and reducing waste. |

| Cutting Board Work Surface | Provides a dedicated, sanitary space for stretching dough and building pizzas. | Material choice (polyethylene vs. marble) affects workflow and maintenance. |

| Compressor Unit | Powers the refrigeration system for both the base and the topping rail. | Bottom-mounted compressors are often easier to service and more efficient. |

Each of these parts plays a vital role in creating a seamless assembly line, turning a simple refrigerator into a high-performance pizza-making station.

The Refrigerated Topping Rail

Sitting right above the work surface, the refrigerated topping rail is arguably the most critical part of the entire setup. It's a series of chilled wells designed to hold food pans filled with all your go-to toppings—pepperoni, mushrooms, onions, olives, and of course, mountains of mozzarella.

This is the component that keeps perishable ingredients at a steady, food-safe temperature, even when you're in the middle of a chaotic dinner rush. Having proper cooling here isn't just a suggestion; it's what prevents spoilage, cuts down on waste, and guarantees every pizza is made with fresh, safe ingredients.

The topping rail is where the magic happens. Its ability to keep dozens of ingredients perfectly chilled and within arm's reach is what transforms a simple refrigerator into a high-performance pizza assembly line.

The importance of this kind of equipment is reflected in the market itself. The commercial undercounter refrigeration market was valued at USD 11.4 billion and is expected to hit USD 15.0 billion by 2032. This isn't just a niche product; it's a cornerstone of efficient pizzerias where space and reliability are everything.

The Cutting Board Work Surface

Finally, let's talk about the workspace itself. This is the large cutting board that runs the full length of the unit, giving you a dedicated surface for stretching dough and assembling pizzas. The material used for this board can make a huge difference in your day-to-day workflow.

Most modern pizza prep tables come with a durable, food-grade polyethylene cutting board. This stuff is tough enough to handle constant scraping and chopping, non-porous for easy cleaning, and won't dull your knives too quickly.

Some high-end or specialty pizza prep tables might feature marble surfaces, which are prized for keeping dough cool and preventing it from sticking. While they look great and work beautifully, marble requires a lot more care and is a much bigger investment upfront. To see how these different options fit into various models, you can check out our comprehensive guide on choosing a commercial pizza prep table.

Understanding Cooling Systems and Airflow

The real engine of your pizza prep table is its refrigeration system. Getting a handle on how it works—specifically how it breathes and circulates air—is absolutely critical for picking an under counter refrigerator that fits your pizzeria's layout and keeps ingredients perfectly fresh. It's the difference between a unit that works with you and one that constantly works against you.

Think of the cooling system like the lungs of your prep table. The way it pulls in and pushes out air dictates exactly where you can place it and how hard it has to work. This simple mechanical detail can have a massive impact on your kitchen's workflow and, you guessed it, your energy bills.

Front Breathing Versus Rear Breathing

One of the first technical details you'll run into is the location of the unit's ventilation. This is a big deal, as it determines how much clearance the refrigerator needs and where you can actually install it.

- Front-Breathing Units: These models pull in cool air and push out hot air from the front, usually through a grille right below the doors. This design is a game-changer for tight pizzeria kitchens because you can install the unit completely flush against a wall or between other pieces of equipment without worrying about it overheating.

- Rear-Breathing Units: These are the more traditional systems that vent from the back. They’re often a bit less expensive but demand several inches of clearance between the unit and the wall for proper airflow. If you block that space, the compressor will overwork itself, leading to sky-high energy bills and, eventually, a very expensive mechanical failure.

For most pizzerias where every square inch is prime real estate, a front-breathing under counter refrigerator is easily the smarter choice. It just gives you so much more flexibility.

Airflow in the Topping Rail

Beyond the main compressor, the way cold air gets distributed within the topping rail is make-or-break for food safety and quality. A poorly cooled rail can leave ingredients in some pans too warm while others start to freeze. Both scenarios lead to a ton of food waste in a pizza operation.

The goal of any topping rail is to create an uninterrupted "curtain" of cold air that blankets every single ingredient pan. Consistent temperature across the entire rail is non-negotiable for preserving the freshness of your toppings and sailing through health inspections.

Modern pizza prep tables use advanced forced-air refrigeration to make this happen. This system relies on fans to actively circulate cold air around and underneath each pan, guaranteeing a consistent temperature from one end of the rail to the other. It's a huge leap forward from older, static-cooled rails that were notorious for inconsistent cold spots.

The Rise of Eco Friendly Refrigerants

The type of refrigerant humming away inside your under counter refrigerator is another important piece of the puzzle, affecting both your environmental footprint and your operating costs. For years, older refrigerants like R134a were the industry standard, but thankfully, things have moved toward much greener alternatives.

The new gold standard is R290, which is essentially a natural propane refrigerant. Here’s why it’s a smart investment for any pizzeria:

- Higher Efficiency: R290 is fantastic at absorbing heat, which means the compressor doesn't have to work as hard or run as long to keep everything at the right temperature.

- Lower Energy Bills: That increased efficiency translates directly into lower electricity consumption. We're talking savings that can add up to hundreds of dollars per year. Our guide on energy-efficient commercial refrigeration dives deeper into this.

- Minimal Environmental Impact: R290 has an extremely low Global Warming Potential (GWP), making it a much more responsible choice for the planet.

Choosing a unit with R290 refrigerant is a forward-thinking decision. It benefits both your bottom line and your brand's commitment to sustainability.

Choosing the Right Size and Configuration

Picking the right under counter refrigerator for your pizzeria is about more than just finding a spot where it fits. It's about matching the machine's size and layout to the actual flow of your kitchen. The goal isn’t just to fill a space; it’s to find a unit that plugs directly into your pizza line, making you faster and more efficient when the tickets start flying.

Think of it like this: a pizza prep table that’s too small for your order volume is a guaranteed bottleneck. Your crew will waste precious minutes restocking toppings in the middle of a dinner rush. On the flip side, an oversized unit is just a space-hog that eats up valuable kitchen real estate and burns more electricity than you need. The sweet spot is a machine that feels like a natural extension of your pizza line.

Translating Dimensions into Pan Count

In the pizza world, the most practical way to size up a prep table isn't by its width in inches, but by its pan count. This simply means how many standard 1/3-size food pans it can hold in the refrigerated topping rail. This number instantly tells you how much production power you're getting.

A unit's pan count gives you a clear, real-world picture of how many different toppings you can keep chilled and ready to go at any moment. For a deeper dive into how different unit widths translate to specific pan configurations, check out our complete guide on under counter refrigerator dimensions.

- Small Slice Shop or Low-Volume Pizzeria: A compact 48-inch unit, which usually holds about 6 pans, is often the perfect starting point. It gives you enough variety for a core menu without taking over your whole kitchen.

- Medium-Volume Pizzeria: Stepping up to a 67-inch, 9-pan model is a serious upgrade. It’s the sweet spot for restaurants with a diverse menu and a steady stream of orders all day long.

- High-Volume Pizzeria: For the true powerhouses cranking out massive orders, a 93-inch, 12-pan beast is non-negotiable. This setup ensures your pizza team has every topping imaginable right at their fingertips to keep pace with relentless demand.

The right pan count is your buffer against chaos. When you're three tickets deep on a Friday night, it ensures your team isn't scrambling to refill the mozzarella—they're building and baking pizzas.

This demand for smart, space-saving refrigeration is a huge trend in pizzerias and commercial kitchens. The global undercounter refrigerator market was valued at around US$4.5 billion and is expected to hit US$7.1 billion by 2033. This growth is all about kitchens needing compact, high-performance gear to keep up. You can dig into more of this data over at reportsandinsights.com.

Doors Versus Drawers: The Great Debate

Once you've nailed down the width and pan count you need, the next big decision is what’s going on below the worktop. How you store your bulk ingredients in the refrigerated base of your pizza prep table will have a direct impact on your team's speed and organization.

Your two main choices are traditional swing-out doors or pull-out drawers. Each one has some clear pros and cons depending on how your pizzeria operates.

Making the Final Choice

So, how do you decide? Let’s put these two configurations head-to-head to see which one might be the better fit for your pizzeria's unique rhythm.

| Configuration | Best For | Primary Advantage | Key Downside |

|---|---|---|---|

| Doors | Storing bulky, oversized items in a pizzeria. | Maximum storage flexibility for large dough boxes, sauce buckets, and blocks of cheese. | Items can get lost at the back, requiring staff to shuffle contents to find what they need. |

| Drawers | Organizing smaller, prepped pizza toppings. | Superior organization with easy, at-a-glance access to portioned items like sliced meats and veggies. | Less accommodating for bulky containers and can be a more significant upfront investment. |

At the end of the day, the right setup comes down to your menu and prep style. If your pizzeria runs on big batches of dough and buckets of sauce, doors probably make the most sense. But if your operation thrives on meticulous organization and lightning-fast access to a wide variety of pre-portioned toppings, the efficiency boost from drawers might just be a game-changer.

Must-Have Features for Food Safety and Durability

What separates a workhorse under counter refrigerator from one that dies during a Friday night pizza rush? It all comes down to the details. Investing in a quality unit isn't just about getting a cold box; it’s about buying a reliable partner for your pizzeria, one built for the chaos of a busy kitchen.

When you're looking at different pizza prep tables, a few key features are simply non-negotiable. These are the elements that guarantee food safety, stand up to the relentless wear and tear of a commercial kitchen, and ultimately protect your investment and your reputation.

The Stainless Steel Standard

In a pizzeria environment filled with acidic tomato sauce, grease, and constant cleaning, your choice of material is everything. This is why commercial-grade stainless steel is the undisputed king. It’s not just about looking professional; it's about pure, rugged durability.

Stainless steel offers a non-porous surface that resists corrosion, stains, and the growth of bacteria. This makes it incredibly easy to clean and sanitize, which is a massive advantage for passing health inspections and keeping your workspace hygienic. While other materials might look good on day one, they just can't handle the daily abuse of a high-volume pizza operation.

Demystifying Food Safety Certifications

When you see logos like NSF and ETL on a piece of equipment, don't just gloss over them. These certifications are your assurance that the refrigerator meets strict standards for public health and safety. They are essential for compliance and for your own peace of mind in the pizzeria.

- NSF (National Sanitation Foundation): This mark certifies that the unit is designed and built in a way that promotes food safety. It means all surfaces are smooth, easy to clean, and resistant to harboring bacteria.

- ETL (Intertek Testing Services): The ETL Listed Mark tells you the product has been tested and meets North American safety standards. This often relates to electrical components, ensuring the unit operates safely in a commercial setting.

Think of NSF and ETL certifications as a seal of approval from health and safety experts. They confirm the pizza prep table is not just functional but is built from the ground up to protect your ingredients, your customers, and your business's reputation.

Essential Features for Peak Performance

Beyond the core construction and certifications, several other features can dramatically improve your pizzeria's efficiency and the lifespan of your unit. These are the practical add-ons that make a real difference during the daily grind.

A digital temperature controller is a must-have. It gives you a precise, at-a-glance reading of the internal temperature, letting you easily monitor and adjust settings to keep ingredients in the critical food-safe zone. This is miles ahead of an old-school analog dial in both accuracy and reliability.

Another incredibly useful feature is an insulated rail cover. This heavy-duty lid fits snugly over your topping rail when the pizzeria is closed. It traps cold air, forcing the compressor to work less overnight and significantly cutting down on your energy bills.

Finally, don't overlook the importance of heavy-duty casters. Having your pizza prep table on smooth-rolling, lockable wheels makes cleaning underneath it a breeze. Instead of a difficult, time-consuming chore, you can simply roll the unit out, clean the floor, and roll it back. This simple feature makes maintaining a sanitary kitchen so much easier.

Maintenance Tips to Maximize Your Investment

Your pizza prep table is a serious investment. Like any critical piece of machinery in your pizzeria, it needs consistent care to deliver the performance you depend on. Getting the installation right from day one and sticking to a routine maintenance schedule are the keys to protecting that investment.

Think of it as a small deposit of your time that pays huge dividends in equipment longevity and operational stability. A proactive approach keeps your under counter refrigerator humming along for years, preventing those dreaded breakdowns during a Friday night pizza rush.

Proper Installation is the First Step

Before you even plug the unit in, a correct installation sets the stage for a long, trouble-free life. Two things are absolutely critical here: ventilation and power. Most of these pizza prep tables are heavy-duty machines that throw off a good bit of heat, and they need room to breathe.

Always make sure there’s enough clearance around the unit for proper airflow, especially for the rear-breathing models. Just as important, your prep table should always be plugged into a dedicated electrical circuit. Trying to share a circuit with other high-draw appliances is a classic mistake that can fry the compressor over time.

The 15-Minute Weekly Maintenance Checklist

Just 15 minutes of focused upkeep each week can head off the vast majority of common equipment failures. This isn't just about preventing breakdowns; this simple routine keeps your unit running efficiently, lowers your energy bills, and helps you spot little problems before they become catastrophic ones for your pizzeria.

Here’s a simple but powerful checklist to follow:

- Clean the Condenser Coils: Dust and grease are the mortal enemies of your refrigeration system. When coils get clogged, the compressor has to work overtime to release heat, leading to higher energy bills and, eventually, total failure. A quick brushing is all it takes.

- Check and Clean Door Gaskets: The rubber seals around the doors are what keep the cold air in. Wipe them down weekly and check for any cracks or brittleness. A leaky gasket forces your unit to run constantly.

- Wipe Down Interior and Exterior Surfaces: This is about more than just looks. Regular cleaning prevents grime buildup and ensures you have a sanitary pizza prep environment. Use a food-safe cleaner on all stainless steel surfaces, handles, and the cutting board.

- Clear Drain Lines: Make sure the interior drain lines are free of food debris. This simple check prevents clogs and water backup inside the unit, which helps maintain proper humidity levels and prevents nasty odors from developing.

A clean condenser coil is the single most important thing you can do to extend the life of your compressor. A five-minute cleaning each week can save you from a multi-thousand-dollar repair bill and a kitchen shutdown.

Beyond your own daily cleaning, bringing in professional restaurant cleaning services can make a huge difference in the overall hygiene and longevity of your pizzeria's equipment. They have the tools and know-how to tackle the deeper cleaning tasks that are easy to miss during the chaos of daily operations. By making this simple maintenance schedule part of your weekly routine, you transform your pizza prep table from a potential headache into a reliable workhorse you can count on for years.

Common Questions About Pizza Prep Refrigerators

When you're investing in a piece of equipment that's the heart of your pizza line, you're going to have questions. And you should. Getting the right answers upfront helps you pick the perfect under counter refrigerator and keep it running like a champ for years. This is where we tackle the real-world questions we hear from pizzeria owners just like you.

Think of this as the practical, day-to-day stuff that really matters when you're in the middle of a dinner rush. We'll get into the details—from nailing your temperature settings to keeping things clean—so you can get the most out of your investment.

What Is the Ideal Temperature Setting?

Getting your temperatures right is non-negotiable for food safety and keeping your pizza ingredients tasting great. Your pizza prep table has two different cooling zones, and both need a close eye.

- Refrigerated Base: This is your bulk storage workhorse. You want to keep the main compartment set between 36°F and 38°F (2°C to 3°C). It’s the sweet spot for keeping things like dough, big blocks of cheese, and backup sauce perfectly chilled without any risk of freezing.

- Topping Rail: Health codes are strict here. Your topping rail needs to stay at or below 40°F (4°C), period. A good digital thermometer is your best friend for making sure every single pan, especially the ones at the ends, is holding that safe temperature.

Checking these temperatures consistently isn't just a good idea; it's a critical part of running a safe pizzeria.

How Often Should I Clean the Condenser Coils?

This is probably the single most important maintenance task you can do for your pizza prep table. You absolutely have to clean the condenser coils at least once every 90 days. But for a busy pizzeria? Monthly cleaning is the gold standard. In a pizza kitchen, grease and dust are just part of the environment, and they stick to those coils like a magnet, forming an insulating blanket.

Neglecting your condenser coils is like forcing your car's engine to run with no oil. It makes the compressor work way too hard, which means higher energy bills and a much, much higher risk of a breakdown that will cost you a fortune. A five-minute cleaning once a month is the best insurance you can get for your refrigerator’s health.

Can I Use Any Type of Food Pan in the Topping Rail?

Technically, most standard-sized food pans will fit, but the type of pan you use actually makes a difference in durability and how well your pizza toppings stay cold. We always recommend stainless steel pans. They last forever and are fantastic at conducting cold, which helps keep your ingredients at a consistent, safe temperature.

Polycarbonate (the plastic ones) are cheaper, sure, but they tend to get brittle and crack over time, especially with constant use in a pizzeria. They also just don't transfer cold as well as metal does. Sticking with high-quality stainless steel pans is a smart move that keeps your ingredients safe and your setup looking professional and reliable for the long haul.

Ready to build the perfect pizza line? At Pizza Prep Table, we specialize in high-performance refrigerated prep tables that streamline your workflow and guarantee freshness. Explore our curated selection of top-rated units and find the ideal fit for your pizzeria today. https://pizzapreptable.com