The Pizzeria's Guide to 27 Inch Pizza Prep Tables

Share

In the controlled chaos of a busy pizzeria, a 27-inch sandwich prep table is so much more than a piece of equipment. Think of it as the command center for speed and consistency, the one spot where the magic of pizza assembly happens efficiently. This compact unit creates a dedicated, refrigerated station for all your toppings, completely cutting down on wasted steps and streamlining the entire pizza-building process.

For any pizzeria where floor space is at a premium, this table isn't just a good idea—it's a strategic advantage.

Why Your Pizzeria Needs a 27 Inch Prep Table

Picture your pizza line during the Friday night dinner rush. Your crew is moving fast, reaching for cheese, pepperoni, and veggies. Without a single, organized station, this process quickly devolves into a messy scramble, leading to slower ticket times and wildly inconsistent topping portions. A 27-inch sandwich prep table puts an end to that chaos by creating a hyper-efficient workspace.

This unit brilliantly combines a refrigerated base for your bulk ingredients with a refrigerated pan rail right on top. This keeps everything from mozzarella to mushrooms perfectly chilled and literally within arm's reach. It's the kitchen equivalent of a pit crew station in a car race—small, perfectly organized, and stocked with exactly what you need for peak pizza-making performance.

The Strategic Advantage in a Compact Footprint

In most pizzerias, kitchen space is one of the most valuable resources you have. A 27-inch prep table is engineered to maximize every inch of that space without demanding a huge footprint, allowing you to set up a dedicated topping station even in the tightest kitchens.

The benefits are immediate and tangible:

- Reduced Wasted Motion: By keeping all your toppings in one spot, you eliminate the constant back-and-forth trips to the walk-in cooler. Those saved seconds add up fast over hundreds of pizza orders.

- Improved Consistency: With ingredients neatly organized in pans, your pizzaiolos can apply toppings with better precision, which means better portion control and a uniform, quality pizza for your customers every time.

- Enhanced Food Safety: The refrigerated rail ensures perishable ingredients like cheese and meats are held at a safe temperature (typically below 41°F), which is absolutely crucial for passing health inspections.

The growing demand for this kind of specialized equipment isn't just a hunch; it's a trend seen across the entire food service industry. The global market for food prep tables was valued at roughly USD 1.18 billion in 2023 and is on track to hit USD 1.62 billion by 2029. This growth shows just how vital these units have become for modern pizzerias that are serious about efficiency. You can explore more about these trends from market experts at Arizton.

A 27-inch prep table isn't just a piece of stainless steel; it’s a direct investment in your pizzeria's workflow. It empowers your team to build better pizzas faster, which has a real impact on your bottom line and keeps customers happy.

Translating Tech Specs Into Pizzeria Performance

A generic spec sheet rarely tells the whole story, especially when you're outfitting a high-speed pizza kitchen. The real value of a 27 inch sandwich prep table isn't just its size; it’s how its technical features directly boost your pizzeria's efficiency, food quality, and safety. Reading these specs through the lens of a pizza maker is the key to a smart investment.

Let's start with the heart of the unit: the refrigeration system. A powerful fan-cooling system isn't just a feature on a list—it's your frontline defense against wilted basil and unsafe cheese temperatures. This technology circulates a consistent curtain of cold air around every topping pan, keeping ingredients like pepperoni and mushrooms safely chilled below 41°F. That's crucial when the lid is open during a frantic dinner rush.

Decoding Features for Pizza Production

Beyond the core cooling, several other specs have a direct impact on your day-to-day pizza operations. For instance, the type of steel used matters more than you might think. A table built from durable stainless steel (like 304-grade) can stand up to the acidic nature of tomato sauce spills and the constant scraping of metal pizza peels without rusting or pitting.

Similarly, NSF certification is a non-negotiable seal of approval. It guarantees the unit is designed for easy cleaning and sanitization, a critical factor in any kitchen where flour dust and stray cheese can accumulate. This certification simplifies health inspections and shows you're serious about food safety.

A great pizza prep table is an active partner in your kitchen's success. Its features should solve real-world pizzeria problems, from keeping mozzarella perfectly chilled to standing up to the inevitable mess of a busy production line.

Refrigerated prep tables are a cornerstone of the modern pizzeria. The market for these units, including versatile 27-inch models, was valued at around USD 7.67 billion in 2024 and is expected to climb to USD 10.30 billion by 2031. This growth highlights their essential role in maintaining food safety with features like digital temperature controls that hold ingredients between 33°F and 41°F. You can find out more about these industry trends and what they mean for pizzeria owners.

Matching Pan Capacity to Your Topping Menu

Pan configuration is where you customize the table for your specific pizza menu. A standard 27-inch unit typically holds six to eight pans, which is perfect for classic pizza toppings like pepperoni, mushrooms, and mozzarella. However, if your pizzeria is known for its wide array of specialty ingredients, you might consider a "mega top" version. These add a third row for pans, significantly expanding your at-hand topping selection.

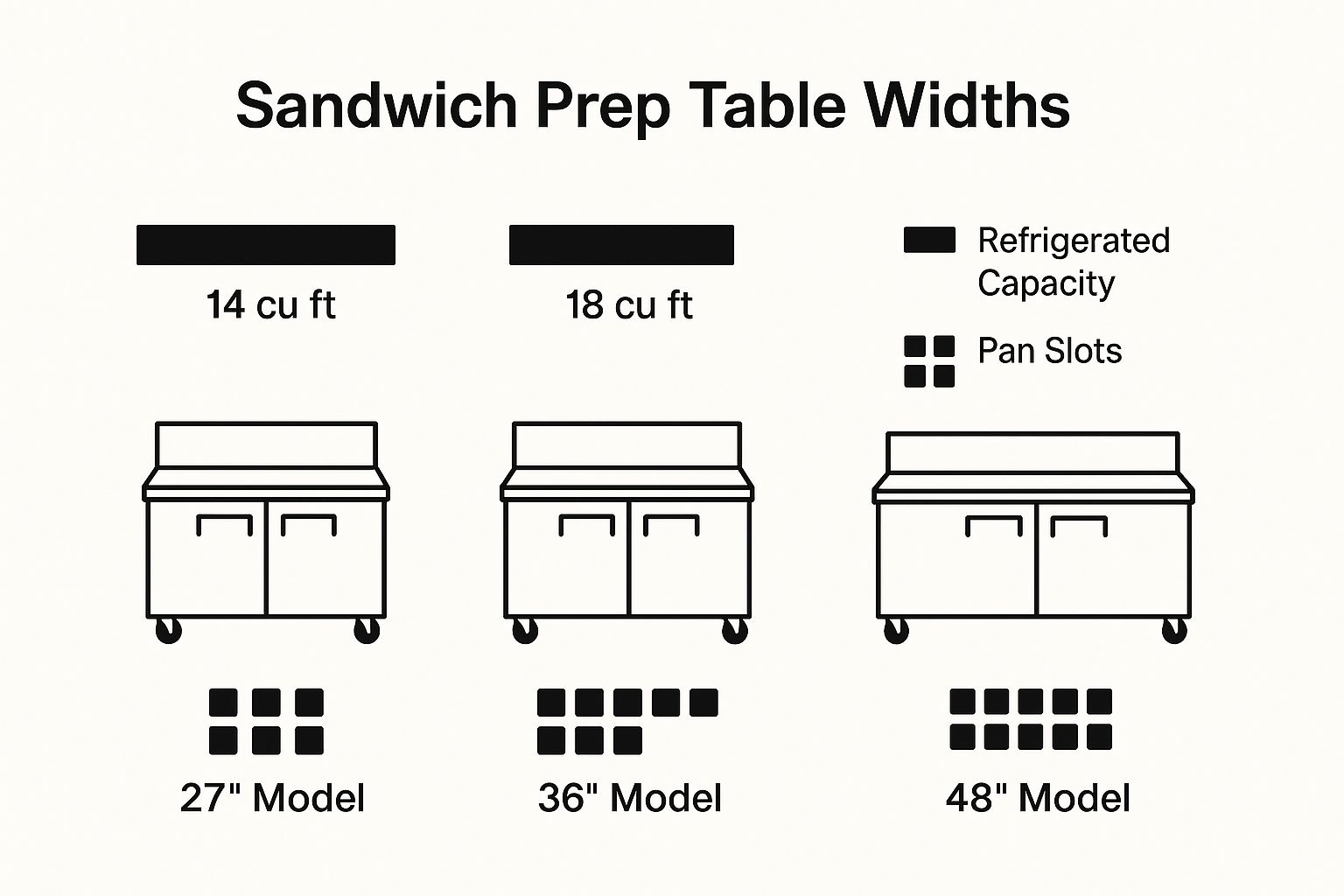

This image compares the pan and storage capacity of a 27-inch model against larger units to help you visualize the differences.

As you can see, while larger tables offer more storage, the 27-inch model provides an efficient balance of pan slots and refrigerated space for smaller pizzerias. For a deeper dive into selecting the perfect unit, you should check out our comprehensive guide on prep tables for restaurants.

Optimizing Your Pizzeria Layout and Workflow

Buying the right pizza prep table is only half the battle. Where you put it can make or break your kitchen's efficiency. A 27-inch sandwich prep table isn't just another piece of stainless steel—it's a strategic tool. Its placement directly impacts the flow of your staff, your ingredients, and ultimately, how fast a finished pizza gets to the oven.

Think of your kitchen layout as a roadmap. Every extra step a pizza maker takes is a detour that adds precious seconds to your ticket times. By thoughtfully integrating this compact prep table, you can eliminate those detours and create a straight, logical path from dough to topping to cooking.

This is all about turning your investment into a tangible improvement in speed and kitchen harmony. Proper placement reinforces a strong 'Mise en Place' system, where everything your team needs is exactly where it should be, when they need it.

Creating Strategic Pizza Prep Stations

The beauty of a 27-inch sandwich prep table is its versatility. Thanks to its compact size, it can play multiple roles within a pizzeria's workflow, each designed to solve a specific operational headache. The goal is to create defined zones that streamline pizza production, especially when the dinner rush hits.

Here are a few proven setups I've seen work wonders in pizzerias:

- The Specialty Pizza Station: Dedicate this table to your gourmet or specialty pies. By isolating unique ingredients like prosciutto, arugula, or specific cheeses, you prevent flavor transfer from high-volume items like pepperoni. This ensures your signature pizzas taste exactly as you intended, every single time.

- The Overflow Topping Area: During a rush, the main pizza line can become a serious bottleneck. Position a secondary 27-inch table as an overflow station for common toppings. This allows a second pizza maker to jump in and help, effectively doubling your topping capacity without creating chaos.

- The Finishing Station: Place the table near the oven exit to act as a final "finishing" station. This is the perfect spot for adding fresh, post-bake ingredients like basil, parmesan, or a drizzle of olive oil. It keeps the main assembly line clear and ready for the next wave of orders.

By strategically placing a smaller pizza prep table, you're not just adding more counter space. You are creating a purpose-built system that directs kitchen traffic, minimizes wasted motion, and empowers your team to work faster and smarter.

Impact on Kitchen Harmony and Speed

A well-organized layout does more than just save time; it dials down the stress in the kitchen. When your pizzaiolos aren't constantly crossing paths or reaching over one another to grab ingredients, the entire environment becomes calmer and more focused. A dedicated 27-inch pizza prep table helps establish clear, personal workspaces.

This organized approach translates directly into faster service and better pizza. With every ingredient chilled and within arm's reach, your pizza makers can build pies with consistent portioning and quality. The result is a more efficient pizzeria, a happier staff, and perfectly crafted pizzas delivered to your customers without delay.

Boosting Profits Through Smart Topping Management

Let's be honest, a 27 inch sandwich prep table isn't just a piece of stainless steel—it's a profit-generating machine hiding in plain sight. In the controlled chaos of a busy pizzeria, every last shred of cheese and slice of pepperoni adds up. This unit’s organized, refrigerated pan rail is your secret weapon for locking down portion control, which is ground zero for profitability.

Think of the pan rail as a perfectly organized command center for your pizza makers. Each ingredient has its own dedicated spot, chilled and ready to go. This kind of setup naturally builds consistency. When toppings are laid out neatly, it's just plain easier for your team to grab the right standardized scoop and stick to the recipe. No more guesswork, no more profit-killing over-topping.

Arranging Toppings for Speed and Savings

The way you lay out your topping rail directly impacts your bottom line. A logical ingredient setup can shave precious seconds off every single pizza order, and over a hectic dinner rush, that time saved translates into real labor cost savings. The trick is to put your heavy hitters within the easiest possible reach.

Here are a few practical tips to get your pizza line humming:

- Prime Real Estate for Core Toppings: Put your most popular ingredients—think mozzarella and pepperoni—right in the center. This is the sweet spot that minimizes hand movement and speeds up the assembly of your best-selling pies.

- Logical Grouping: It just makes sense to group similar ingredients. Keep all your veggies on one side and your meats on the other. This creates an intuitive workflow that helps your team move faster and make fewer mistakes.

- Less-Used Items on the Ends: Those ingredients for specialty pizzas or less common requests can live on the outer edges of the rail. They stay chilled and accessible but don't clutter up the main workspace.

There's a reason these units are so popular. The market for sandwich and salad prep tables was already pegged at USD 1.2 billion in 2024 and is on track to hit USD 1.8 billion by 2033. Their success in small and medium-sized pizzerias comes from that perfect blend of workspace and refrigeration, helping owners control costs without eating up floor space. You can find additional details on this growing industry to see just how essential these tables have become.

Maximizing Freshness and Minimizing Spoilage

Food waste is the silent killer of profit margins. An organized pizza prep table helps you fight back against spoilage with a simple, smart ingredient rotation strategy. The clear visibility of the pans practically begs your team to use the First-In, First-Out (FIFO) method.

By keeping older ingredients at the front of the pans, you make it second nature for your staff to use them up before they spoil. This simple habit, reinforced by the table's very design, directly cuts down on waste and protects your food cost percentages.

Proper ingredient management isn't just about saving money; it's about quality. Fresh toppings mean every pizza that leaves your kitchen meets your highest standards. That's what builds customer loyalty and keeps them coming back. For more tips, you might find our guide on Dukers pizza prep tables designed to keep your dough cool and customers happy useful. This systematic approach is how you turn a simple prep station into a genuine profit center.

Taking Care of Your Pizza Prep Table

In the whirlwind of a busy pizzeria, your 27 inch sandwich prep table is one of the hardest-working pieces of equipment you own. It runs relentlessly, shift after shift. But ignoring its basic needs is a guaranteed path to emergency repair calls and frustrating downtime. Think of regular maintenance as a cheap insurance policy—a few simple, consistent habits will protect your investment, lock in food safety, and keep your table humming along for years.

The refrigeration system is the engine of your prep table. Just like a car, it needs routine care to perform, especially when it’s battling the ambient heat from pizza ovens and a constant barrage of airborne flour dust. A maintenance schedule isn't just a friendly suggestion; it's a non-negotiable part of running a smart, successful pizzeria.

A Simple Maintenance Schedule for Pizzerias

A pizza kitchen has unique challenges, especially when it comes to flour and sauce. Flour dust is the number one enemy of a prep table's refrigeration system. It gets sucked in and clogs the condenser coils, forcing the unit to work overtime just to stay cool. This doesn't just make your energy bills skyrocket; it can lead to a total compressor failure—an expensive and completely avoidable disaster.

To help you out, here’s a maintenance schedule built for the realities of a pizza shop.

To keep your prep table in peak condition, a structured maintenance routine is key. We've broken down the essential tasks into a simple schedule that addresses the specific challenges of a pizzeria environment, from daily sanitation to crucial monthly checks.

Pizza Prep Table Maintenance Schedule

| Frequency | Task | Importance |

|---|---|---|

| Daily | Sanitize the cutting board and wipe down all stainless steel surfaces at the end of each shift. | High - Prevents bacteria buildup from dried sauce, dough, and cheese. |

| Weekly | Inspect the door gaskets for any tears or gaps that could cause cold air leaks. | High - A poor seal makes the compressor run constantly, wasting energy. |

| Weekly | Remove and deep clean all ingredient pans, not just the visible surfaces. | Medium - Ensures no hidden food particles are left behind. |

| Monthly | Clean the condenser coils by gently vacuuming or brushing away flour dust and grease. | Critical - Prevents overheating and premature compressor failure. |

Sticking to this schedule transforms your prep table from a potential problem into a reliable partner.

A well-maintained prep table is a sign of a well-run pizzeria. Consistent cleaning doesn't just prolong the life of your equipment; it reinforces high standards for food safety and operational excellence that your entire team can follow.

By dedicating just a few minutes each day and a bit more time each month, you're protecting your bottom line. You'll lower your energy bills and prevent the kind of breakdowns that always seem to happen during the Friday night dinner rush. For more tips on making your kitchen run like a well-oiled machine, check out our guide on how to prep pizza like a pro.

Common Mistakes to Avoid When Buying and Using

Learning from the mistakes of others is the cheapest tuition you can get in the restaurant business. Investing in a 27-inch sandwich prep table is a solid move for any pizzeria, but a few common slip-ups can turn a kitchen workhorse into a daily headache.

By knowing what these pitfalls are before you buy, you can make a smarter choice and get your new equipment humming along without any drama.

One of the biggest blunders I see is underestimating topping needs. A standard 27-inch model is fantastic for a classic pizzeria, but if you have a huge menu with lots of unique ingredients, you'll run out of pan space fast. This just leads to endless trips to the walk-in, which completely defeats the purpose of having a pizza prep table in the first place.

Another rookie mistake is forgetting about your kitchen's airflow when choosing a compressor. A rear-breathing unit needs a few inches of breathing room from the wall to work right. Shove it flush against the drywall, and you’re basically suffocating it. The unit will overheat, struggle to stay cool, and eventually, the compressor will give out.

Operational Errors to Sidestep

Once your pizza prep table is in place, a few bad habits can sabotage its performance and even create food safety nightmares. The absolute most common error, especially in pizzerias, is overfilling the ingredient pans.

It seems efficient to mound that shredded mozzarella high for a busy shift, but piling ingredients above the pan's rim blocks the flow of cold air.

This simple mistake stops the refrigerated air from circulating properly, creating a temperature "danger zone" where the toppings at the very top aren't kept safely chilled. It's a massive food safety issue that you can easily avoid just by keeping ingredients level with the edge of the pan.

The same logic applies to the refrigerated cabinet below. Cramming it full of dough boxes or topping containers blocks the internal vents, causing wild temperature swings and spoiled food. Treating your 27-inch sandwich prep table right means respecting its design.

Here are a few other common user errors I see all the time:

- Placing it next to heat sources: Setting up your prep table right beside the pizza oven forces the refrigeration system into overdrive. Your energy bills will skyrocket, and you'll put unnecessary strain on the compressor.

- Using the cutting board for raw dough: It's tempting, I get it. But using the main cutting board for raw dough can lead to cross-contamination unless it's sanitized perfectly between every single use. A dedicated dough station is always a safer bet.

- Neglecting coil cleaning: In a pizzeria, flour dust is the number one killer of condenser coils. Failing to clean them regularly is the fastest way I know to cause a complete system meltdown, usually on a busy Friday night.

Got Questions? We've Got Answers

When you're looking at a 27-inch sandwich prep table for your pizzeria, a few common questions always pop up. Let's get right to them with some straight answers.

Can I Use This Table for Proofing Dough?

That's a definite no-go. These pizza prep tables are refrigeration workhorses, engineered to maintain a strict cold zone between 33°F and 41°F. This is the sweet spot for keeping toppings like cheese, pepperoni, and veggies safe and fresh.

Dough, on the other hand, needs a warm, humid environment to rise properly—the exact opposite of what this unit is designed to do. Trying to proof dough in one of these tables is not only ineffective but could seriously damage the refrigeration system. Stick to a dedicated proofer for that job.

What's the Real-World Pan Capacity for Pizza Toppings?

A standard 27-inch model is typically set up to hold eight 1/6-size food pans along its top rail. For a classic pizzeria, this is plenty of space for your core lineup—think pepperoni, mushrooms, olives, onions, and peppers.

It's the perfect setup for an efficient pizza-making station, letting your team build the majority of pies on your menu without having to constantly run back to the walk-in cooler for refills.

For shops with a ton of topping choices, a mega-top version of the 27-inch sandwich prep table is a game-changer. It adds a whole extra row for pans, boosting your on-hand topping capacity by a massive 30-50%.

If your pizzeria is known for its specialty pies or you handle a high volume of custom orders, that extra pan space from a mega-top model will be your best friend. It keeps the line moving and makes those crazy busy Friday nights feel a whole lot smoother.

Ready to make your pizzeria more efficient? Check out our full lineup of professional-grade pizza prep tables at Pizza Prep Table and find the perfect unit for your kitchen. Head over to https://pizzapreptable.com to get started.