Your Guide to the 3 Compartment Sink Drain System

Share

In a busy pizzeria, the 3 compartment sink drain is the unsung hero of your sanitation system. It’s the essential plumbing that underpins the entire wash, rinse, and sanitize process. This isn't just about pipes; it’s a critical piece of infrastructure for keeping food safe, flying through health inspections, and avoiding the kind of clogs that can shut down your kitchen during a dinner rush.

Why Your 3 Compartment Sink Drain Is Crucial

Think of your 3 compartment sink as the assembly line for clean dishes in your pizzeria. It’s a constant cycle, taking a pizza pan covered in sauce and cheese and turning it into a clean, sanitized tool ready for the next order. Each station—Wash, Rinse, Sanitize—has a specific job, and the drain system is what keeps that entire line moving.

If one part of that system backs up, the whole operation grinds to a halt. For a pizzeria owner, that’s not just an annoyance; it’s a direct threat to your business.

The Pizzeria Drain's Unique Challenges

Pizzerias have a special kind of trouble when it comes to drains. The very ingredients that make your pizzas irresistible are the mortal enemies of a clear pipe. We're talking about a triple threat:

- Melted Cheese: When hot, greasy cheese from pizza pans hits the cold water in your drainpipes, it solidifies into a waxy, sticky mess that grabs onto every other bit of food debris.

- Dough Residue: Those little bits of flour and dough you wash off pans, pizza prep tables, and tools don't just go away. They swell up with water and can create a blockage as dense as cement over time.

- Grease and Oil: From olive oil to pepperoni grease, these fats are relentless. They coat the inside of your pipes, narrowing the passage until you’re dealing with slow drains and, eventually, a full-blown clog.

Let that 3 compartment sink drain go, and you’ll get foul odors, water that won’t go down during a Friday night rush, and potentially a messy, unhygienic backup right on your kitchen floor. These are the kinds of problems that don't just slow down your crew—they get you noticed by the health inspector for all the wrong reasons.

More Than Just Plumbing—It's a Food Safety Mandate

That three-step wash-rinse-sanitize process isn't just a suggestion; it's a cornerstone of food safety regulations. There's a reason health codes are so specific. The U.S. Food and Drug Administration’s Food Code, for example, requires three-compartment sinks or an equivalent system in most commercial kitchens. It’s all about preventing cross-contamination and making sure your tools are truly clean.

For a pizzeria owner, this means your sink setup is non-negotiable. A clogged drain isn't just a plumbing problem—it's a compliance failure that can result in fines, forced closures, and damage to your restaurant's reputation.

To help you get a handle on this critical system, let's break down each compartment's role and the specific challenges you'll face in a pizza kitchen.

For a quick reference you can post by the sink, here's a simple guide that frames everything in the context of a busy pizzeria.

A Pizzeria's Quick Guide to the 3 Compartment Sink

This table breaks down each compartment's role and highlights common pizza-related drain challenges and their immediate solutions.

| Compartment | Drain's Purpose | Common Pizzeria Issue | Fast Fix |

|---|---|---|---|

| 1. Wash | Removes heavy food solids, grease, and sauce from pans, cutters, and prep tools. | Solidified cheese and dough bits from pizza pans and prep creating an initial clog in the strainer. | Always pre-scrape pans thoroughly. Use a high-quality sink strainer and clean it out multiple times per shift. |

| 2. Rinse | Clears away soap residue and any lingering food particles after the wash stage. | Soap scum and small debris build up, slowing down the water flow. | Ensure rinse water is clear and hot. Regularly flush the drain with hot water to dissolve any forming soap buildup. |

| 3. Sanitize | The final step where sanitized items are immersed; the drain ensures proper water level. | Sanitizer chemicals can be corrosive to cheap drain components over time. | Invest in stainless steel drain components that resist corrosion. Ensure proper chemical dilution to protect both staff and equipment. |

By understanding what's happening in each sink bay, you can stop clogs before they start and keep your kitchen's most important sanitation tool working flawlessly.

Designing a Pizzeria-Proof Drain Layout

For any pizzeria owner, the layout of your 3 compartment sink drain system is just as crucial as your dough recipe. Think of it as the wastewater highway running beneath your kitchen. A single bottleneck can cause a traffic jam that grinds your entire operation to a halt.

A well-designed system makes sure all that grease, cheese, and dough residue flows away without a fight. This planning starts long before you connect a single pipe. It’s about understanding the natural workflow of your kitchen, from the pizza prep table to the dish pit. For a deeper dive into laying out your entire space, our guide on commercial kitchen layout design is the perfect place to start.

Anatomy of a Pizzeria Drain System

To build a plumbing system that can handle the chaos of a dinner rush, you need to know the key players. Each part has a specific job in keeping wastewater moving and preventing clogs that can ruin a busy night.

- Sink Strainers: This is your first line of defense. Quality basket strainers catch the big stuff—cheese curds, stray bits of pepperoni, and dough scraps from pizza prep—before they have a chance to enter your pipes.

- Drain Flanges: This is the simple but critical fitting that connects the strainer to the drainpipe, creating a watertight seal at the bottom of each sink basin.

- Continuous Waste Pipe: This horizontal pipe is the collector, tying the drains from all three compartments into a single, unified line.

- P-Trap: You can’t operate without this U-shaped pipe. It holds a small amount of water that acts as a seal, blocking foul sewer gases from creeping up the drain and into your kitchen.

If any one of these components fails, the entire system is compromised. You're left dealing with leaks, clogs, or smells that no one wants in their restaurant.

Choosing the Right Drain Size and Materials

Not all plumbing parts are created equal, especially when they're up against the constant assault of a pizzeria's wastewater. The grease and food solids demand heavy-duty solutions, and your first big decision is the diameter of your drainpipes.

While a 1.5-inch drain is pretty standard, upgrading to a 2-inch drain is one of the smartest investments a pizzeria can make. That extra half-inch provides a much wider pathway for wastewater, making it significantly harder for solidified cheese and grease to build up and cause a complete blockage. It's like upgrading a two-lane country road to a four-lane highway—it just handles more traffic with fewer jams.

Choosing 2-inch drains over the standard 1.5-inch size can reduce the frequency of serious clogs by over 50% in high-grease environments like pizzerias. This small upgrade in size provides a massive upgrade in reliability.

The materials you choose are just as important. Your drains will face a daily barrage of hot water, grease, and harsh sanitizing chemicals.

| Component | Recommended Material | Why It's Better for Pizzerias |

|---|---|---|

| Strainers & Flanges | Stainless Steel | Resists corrosion from sanitizers and can withstand the daily abuse of heavy pots and pans without cracking. |

| Piping & Fittings | Schedule 40 PVC | Strong, affordable, and highly resistant to the acidic nature of tomato sauce and the buildup of grease. |

Steer clear of those lightweight, chrome-plated brass or flimsy plastic drain kits you see in hardware stores. They're built for homes, not for the brutal environment of a commercial kitchen. They will fail, leading to frustrating downtime and expensive emergency calls to a plumber. Investing in the right stuff from day one is how you build a drain system that's truly pizzeria-proof.

Navigating Pizzeria Plumbing and Health Codes

For a new pizzeria owner, plumbing and health codes can feel like a foreign language. But once you understand the logic behind them, it all starts to make sense. These rules aren't just bureaucratic red tape; they exist to protect the public from foodborne illness. Think of your plumbing as the first line of defense in your food safety plan, and the health inspector is just making sure it's built to win.

Getting this stuff wrong isn't a small mistake. It can lead to some seriously painful consequences, like steep fines, renovation orders, or even getting shut down right before a busy weekend. The 3 compartment sink drain is almost always one of the first things an inspector checks, so let's break down exactly what they're looking for.

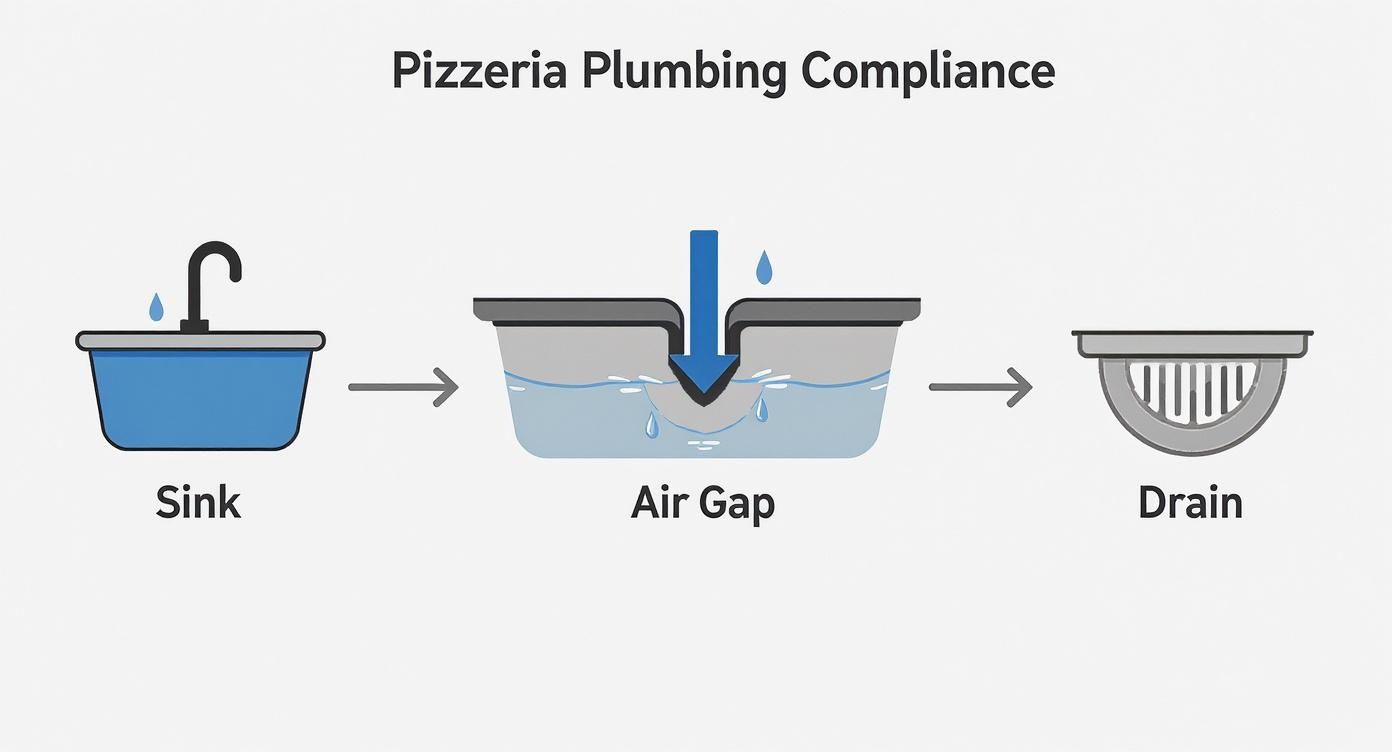

The Unmistakable Rule of the Air Gap

One of the most critical—and often botched—requirements is the air gap. It's nothing complicated, just a physical space between the bottom of your sink's drainpipe and the top of the floor drain. This gap needs to be at least one inch, but local codes might require more.

So, why is this tiny space so important? Imagine the main sewer line in your building gets a nasty clog and starts backing up. Without an air gap, that contaminated wastewater has a direct path right back up your pipes and into the sink basin where you sanitize your pizza peels and dough trays. It's a disgusting and dangerous scenario.

An air gap is like a one-way street for your wastewater. It makes it physically impossible for sewer backflow to contaminate your clean sinks, protecting your equipment and, more importantly, your customers.

This isn't just a suggestion; it's a non-negotiable standard in food service. An inspector will spot a missing air gap from a mile away, and it's an immediate red flag that you don't have a proper indirect drainage system. Your sink must drain indirectly into the floor drain, not be hard-plumbed straight into the sewer line.

The Grease Trap: A Pizzeria's Best Friend

If you're making pizza, you're producing grease. Every slice of pepperoni, every handful of sausage, and every bit of cheese contributes to the fats, oils, and grease (FOG) that wash down your drain. When that FOG hits the cold pipes, it solidifies into a thick, waxy mess that can cause catastrophic blockages.

That’s where a grease trap (or grease interceptor) comes in. It's not optional; it’s required by law for a reason. This simple tank works to catch the FOG before it ever reaches the city sewer system. Here’s the play-by-play:

- Wastewater Enters: All the greasy water from your sink flows into the trap.

- FOG Separates: Being lighter than water, the fats, oils, and grease float to the top.

- Solids Sink: Heavy food scraps and dough from pizza prep sink to the bottom, forming a layer of sludge.

- Cleaner Water Exits: The much clearer water from the middle layer flows out to the sewer.

Getting the size right is crucial. A grease trap that's too small will get overwhelmed in a hurry, letting grease escape and causing the very clogs you're trying to prevent. To make sure you're compliant and your pipes stay clear, you'll need to dig into grease trap sizing for your specific needs.

Building a Compliant System from the Start

Getting your plumbing right from day one saves you a world of headaches later. It's all about designing a system that's both safe and functional. If you want to get a better sense of how your kitchen's plumbing fits into the bigger picture, it's worth spending some time understanding Mechanical, Electrical, and Plumbing (MEP) systems. This helps you appreciate how every pipe and drain connects to the building’s core infrastructure. By making code compliance a priority from the start, you're building a solid foundation for a successful pizzeria, free from the stress of plumbing disasters and health code violations.

A Step-by-Step Guide to Drain Installation

Plumbing your pizzeria's 3 compartment sink drain can feel like a daunting task, but honestly, with a bit of guidance, it's something you can definitely handle. This guide will walk you through the process step-by-step, giving you the confidence to tackle minor repairs or even a full installation without having to call a plumber for every little drip.

Think of it like folding a pizza box for the first time. You start with a flat, confusing piece of cardboard, but once you learn how the pieces connect, it snaps into a solid, functional box. Your drain assembly works the same way.

Assembling the Core Components

First things first, lay out all your parts and make sure you have everything you need. A standard commercial sink kit should include basket strainers, flanges, a mix of rubber and paper gaskets, PVC pipes, slip nuts, and a P-trap. For a pizzeria, you’ll want to stick with a heavy-duty stainless steel and Schedule 40 PVC kit.

Your first move is to install the individual drain baskets into each sink basin. This is where most leaks happen, so getting this connection right from the start is absolutely critical.

- Apply Plumber's Putty: Grab a small ball of plumber's putty and roll it between your hands to create a thin rope, like a tiny breadstick. Press this rope firmly around the underside of the drain flange.

- Set the Strainer: From inside the sink, place the flange into the drain opening and press down firmly. The putty should squish out a bit, creating a nice, watertight seal.

- Secure from Below: Now, get underneath the sink. Slide the rubber gasket onto the strainer's threads, followed by the paper or cardboard friction gasket. Finally, screw on the big locknut and hand-tighten it until it’s snug.

Pro Tip: Give that locknut a final quarter-turn with channel-lock pliers, but that's it. If you crank down on it too hard, you risk cracking the fitting or squeezing out all the putty, which ironically creates the very leak you're trying to prevent.

Connecting the Continuous Waste Pipe

With the baskets secured in each basin, it's time to connect them all into one system using the continuous waste pipe. This is the main horizontal pipe that collects water from all three sinks and sends it down the drain.

This simple infographic shows you exactly how the water needs to flow to stay compliant: from the sink, through your drain system, to an air gap, and finally into the floor drain.

Think of this visual as the golden rule from the health department. It shows the non-negotiable sequence required to prevent nasty backflow contamination in your kitchen.

The job involves cutting and fitting short pieces of PVC pipe with tee fittings to link each sink bay. Just make sure every connection has a plastic washer and is hand-tightened. And remember, the pipe needs a slight downward slope—about ¼ inch per foot—to let gravity do the heavy lifting.

You're not alone in focusing on good plumbing hardware; it's a huge market. The global sink drain segment hit an estimated $4.41 billion in 2023 and is expected to grow to $5.8 billion by 2032. That growth just shows how critical quality plumbing is in commercial kitchens everywhere. You can explore more data about the sink drain market to see these trends for yourself.

Installing the P-Trap and Final Connections

The last piece of this puzzle is the P-trap. That's the U-shaped pipe that holds a little bit of water, creating a seal that stops sewer gases from stinking up your kitchen. It connects right at the end of your continuous waste pipe.

- Attach the P-Trap: Connect the P-trap to the end of the horizontal waste arm.

- Align with Floor Drain: Make sure the final outlet pipe hangs directly over the floor drain, leaving at least a one-inch air gap. This is a critical health code requirement.

- Final Tightening: Go back and give every connection one last check. All the slip nuts should be snug—hand-tight plus a gentle turn with pliers is usually all you need.

Once everything is connected, it's time for the moment of truth. Fill each sink compartment with water, then pull the plugs one by one. Keep a close eye on every joint and connection, looking for even the smallest drip. This simple test will confirm your new 3 compartment sink drain is ready for the nightly rush.

Keeping the Drains Clear in a High-Volume Pizzeria

In the controlled chaos of a busy pizzeria, a backed-up 3 compartment sink drain isn't just a nuisance—it’s a full-stop crisis. The only way to win the war against grease, cheese, and dough scraps is with a proactive game plan. Think of it this way: 15 minutes of smart maintenance every day can save you from hours of downtime, lost sales, and the headache of a plumbing emergency.

This isn’t about reacting when the water stops draining. It's about building simple, daily habits that prevent clogs from ever getting a foothold in your pipes. That consistency is what separates a smooth-running kitchen from one that’s always one bad shift away from a major backup.

Your Daily Drain Defense Plan

The best defense is a good offense, and that starts with simple tasks your crew can turn into muscle memory. These daily non-negotiables are your first line of defense against the specific kind of gunk only a pizzeria can produce.

- Scrape Every Pan, Every Time: Before a single pan or utensil from the pizza prep table touches the water, it needs a thorough scraping into the trash. Hardened cheese and stubborn dough bits are the number one villains behind serious clogs.

- Finish with a Hot Water Flush: At the end of every shift, fill each sink basin with the hottest water you can get from the tap and pull the drains. This quick flush helps melt and push through any grease that's started to cling to the inside of your pipes.

- Empty Strainers Constantly: Your basket strainers are the last line of defense. They need to be emptied multiple times throughout a shift, not just when you’re closing up for the night.

This routine isn't just a suggestion; it’s essential for keeping the circulatory system of your kitchen—its plumbing—healthy. The commercial world is catching on, too. The global market for these sinks is expected to jump from around $500 million in 2025 to nearly $2.087 billion by 2035. You can get more insights on this growing market over at Datainsightsmarket.com.

Weekly and Monthly Maintenance Routines

While daily habits handle the immediate threats, a structured weekly and monthly routine is what stops the slow, creeping buildup that leads to those really nasty blockages.

Once a week, give your drains a treatment with an enzyme-based cleaner. Forget the harsh chemical drain openers you see at the hardware store. Those are terrible for a food environment and can eat away at your pipes. Enzymes are different; they introduce good bacteria that literally digest the organic gunk—fats, grease, and food particles—keeping your lines clear without the risk.

Never, ever use caustic chemical drain openers. They create toxic fumes, can cause serious chemical burns, and will corrode older metal pipes, creating leaks and setting you up for even more expensive repairs.

Your grease trap is the final gatekeeper in this system. It needs to be cleaned on a strict schedule, usually every one to three months, depending on your sales volume and what your local health department requires. A full grease trap is a useless grease trap. Once it’s full, all that grease sails right past it and into your main lines, causing deep, stubborn clogs that are a nightmare to clear.

How to Clean a Grease Trap the Right Way

Cleaning the grease trap is a messy job, but it’s absolutely critical. First, you’ll skim the solid layer of grease off the top. After that, you bail out the water in the middle. Finally, you scoop out all the solid sludge that has settled at the bottom.

This process not only keeps foul odors from taking over your kitchen but ensures the trap can actually do its job. For those really stubborn blockages that even the best maintenance routine can't prevent, calling in professional drain cleaning services will give your pipes the deep clean they need to keep your pizzeria humming. By layering these daily, weekly, and monthly tasks, you turn your drain system from a potential liability into a reliable part of your operation.

Common Questions About Pizzeria Sink Drains

Even with a perfectly installed 3 compartment sink drain, questions and the occasional problem are just part of running a high-volume pizzeria. Knowing the common issues that crop up can help you troubleshoot on the fly, keeping your kitchen compliant and your service flowing smoothly.

Think of this section as your quick-reference guide for the real-world headaches of managing your sink and drain system. These are the answers you need when things go wrong in the middle of a busy shift.

Why Does My Sink Constantly Clog with Cheese and Dough?

This is, without a doubt, the number one problem in any pizza kitchen. Clogs from cheese and dough are relentless, usually because staff aren't scraping pans and pizza prep tools thoroughly before they hit the water. The moment hot, melted cheese meets cold drain water, it solidifies into a waxy, greasy blockage. At the same time, leftover bits of dough swell up and create a stubborn, cement-like obstruction.

Your first line of defense is a mandatory pre-scraping and pre-rinsing routine for every single item that goes into the sink. Your second is a non-negotiable weekly treatment with an enzyme-based drain cleaner; it actively digests all that organic gunk before it can build up into a full-blown crisis.

A common mistake is letting the wash water temperature drop. Keep your wash water consistently hot—at least 110°F—to help emulsify fats and keep them moving down the pipes. A full grease trap is another top suspect, so sticking to a strict cleaning schedule is critical.

What Is an Air Gap and Why Is It So Important?

An air gap is just what it sounds like: an open space, usually at least one inch, between the end of your drainpipe and the top of the floor drain. Think of it as a one-way street for your wastewater. It lets dirty water from your sink flow out freely but makes it physically impossible for nasty water from a floor drain backup to flow back into your clean sink.

Health inspectors are incredibly strict about this because it's a critical food safety measure. Without an air gap, a building-wide sewer clog could force raw sewage right back into the sink you use to sanitize pizza cutters and pans. It's a major health hazard that could get your restaurant shut down on the spot. Nailing this is a key part of any successful restaurant health inspection checklist.

Can I Connect My Pizza Prep Sink to This Drain?

It might seem like a clever way to simplify your plumbing, but tying a pizza prep table sink directly into your 3 compartment sink drain line is almost always a terrible idea—and often a direct violation of local plumbing codes. Sinks used for food prep and handwashing have their own strict drainage requirements.

They almost always need their own separate, indirect drain line that also ends with an air gap. Tying them all together creates an overloaded, complex system that's a nightmare to service and far more likely to clog.

- Code Violations: Combining drains is an easy way to get an immediate citation from a health inspector.

- Clog Risk: You're just creating more opportunities for food solids from multiple sources to team up and cause one massive blockage.

- Maintenance Headaches: Trying to figure out where a problem is coming from becomes much harder when several fixtures share a single drain.

The best practice is always to keep each sink's drainage system independent. It guarantees you're up to code and makes any future maintenance a whole lot simpler.

What Are the Best Drain Materials for a Pizzeria?

In a commercial kitchen, durability is everything. Your drain components have to stand up to constant abuse from high heat, harsh chemicals, and heavy-duty use. For all your sink strainers and flanges, always choose stainless steel. It won't corrode from sanitizers and can handle the daily impact of heavy pots and pans getting dropped in.

For the actual piping under the sink, Schedule 40 PVC is the undisputed industry standard. It's tough, affordable, and highly resistant to damage from grease, acids in tomato sauce, and other food waste.

Steer clear of the flimsy, chrome-plated brass or thin plastic kits you might see in a home improvement store. They will fail fast under the demanding conditions of a busy pizzeria, leading to leaks, cracks, and frustrating repairs that always seem to happen at the worst possible time.

At Pizza Prep Table, we understand that every component of your kitchen, down to the drains, plays a role in your success. Equip your pizzeria with reliable, high-performance gear that stands up to the demands of a busy service. Explore our full range of commercial kitchen solutions at https://pizzapreptable.com.