Your Guide to the 44 Inch Pizza Prep Table

Share

When the dinner rush hits, the line between chaos and control is razor-thin. For many of the best pizzerias, the 44 inch pizza prep table is what makes all the difference. It’s the secret weapon that turns a frantic prep line into a smooth, high-speed pizza assembly station.

This isn't just about adding more counter space; it's about finding the perfect balance of a compact footprint and an efficient, organized workspace. It becomes the command center where speed and consistency are born, right at the heart of your pizza-making operation.

Your Pizzeria's Secret Weapon

Think about how a master pizzaiolo organizes their station. Every tool and every topping is perfectly placed to shave seconds off the process. A 44 inch pizza prep table brings that same level of purpose-built organization right into your pizzeria's kitchen. It’s more than just a piece of stainless steel; it’s the heart of your pizza production line.

This specific size hits a sweet spot that many other units miss. You get enough refrigerated rail space for all your core pizza toppings—pepperoni, mushrooms, onions, cheese—while still having plenty of room on the cutting board. Your team can stretch dough and build pies without feeling like they're working in a closet.

The Foundation of an Efficient Pizzeria

For any pizzeria, workflow is king. The journey from a simple dough ball to a perfectly cooked pizza needs to be a smooth, uninterrupted path. A well-designed prep station is the most critical link in that chain, and the 44-inch model is engineered to optimize every single step of pizza making.

The impact on your day-to-day operations is immediate and obvious.

Here’s a breakdown of why this specific size is such an effective choice for so many pizzerias.

Why a 44 Inch Prep Table is the Ideal Choice for Pizzerias

| Key Benefit | Impact on Your Pizzeria |

|---|---|

| Optimized Pizza Workflow | By keeping chilled toppings within arm's reach, your staff wastes less time walking to and from a separate refrigerator, shaving precious seconds off every single pizza order. |

| Enhanced Pizza Consistency | With an organized mise en place, every pizza maker has access to the same fresh ingredients, ensuring every pizza that leaves your kitchen meets the same high standard. |

| Improved Food Safety | The integrated refrigeration keeps temperature-sensitive toppings like cheese and meats in the safe zone (typically 34°F to 40°F), cutting down on spoilage and ensuring you nail your health inspections. |

This obsession with efficiency isn't just a "nice to have"—it's a requirement in a crowded market. The U.S. pizza industry is projected to hit around $50.1 billion in 2024, spread across more than 74,000 pizzerias. With that much competition, operational excellence is how your pizzeria stands out.

More Than Just a Table—It's a Pizza-Making Strategy

Investing in the right equipment is a strategic move that pays you back long after the initial purchase. A 44 inch pizza prep table empowers your team to work smarter, not just harder.

It's a tool that eliminates bottlenecks, reduces staff stress during peak hours, and directly contributes to a better final pizza. The balanced design means one person can run the station at full capacity, or two can work side-by-side during an intense rush without bumping elbows.

By creating a dedicated, self-contained pizza workstation, you build the foundation for a more productive and profitable pizzeria. Of course, having the right gear is only half the battle. To truly get the most out of your setup, check out our guide on how to prep pizza like a pro for tips that will help you maximize your new equipment.

Breaking Down Your Pizza Prep Table’s Anatomy

To pick the right 44 inch pizza prep table, you have to look past the spec sheet and really get to know its guts. Think of it as building the perfect cockpit for your pizza-making operation; every single part has a job to do, all aimed at boosting your speed, safety, and the quality of your final pizza. When you understand this anatomy, you make sure your investment actually makes your pizzeria more efficient and profitable.

It's no surprise the global market for these tables is booming—it hit around USD 1.2 billion in 2023 and is expected to nearly double by 2032. That explosion shows just how vital this purpose-built gear is for any serious pizzeria. For a deeper dive into the numbers and market trends, you can check out the full report on the pizza prep tables market from Verified Market Reports.

The Heart of Freshness: The Refrigerated Rail

First up is the refrigerated rail. It's the most visible and, frankly, the most critical part of your pizza prep table. This is where your toppings live, held at a food-safe temperature, usually between 34°F and 40°F, fresh and ready for action. But here’s the catch: not all refrigeration systems are created equal.

You'll run into two main types:

- Forced-Air Refrigeration: This system uses fans to blow cold air all around the food pans. It’s like a convection oven, but for cooling. It delivers consistent temperatures and recovers its cool quickly after the lid is opened, making it a must-have for high-volume pizzerias where that rail is getting accessed constantly.

- Cold-Wall Refrigeration: This simpler method has refrigerant lines built right into the walls of the rail. It’s often more energy-efficient, but it can sometimes struggle with even cooling and takes longer to get back to temperature.

For any pizzeria that gets busy, a forced-air system is almost always the way to go. It guarantees every pan, from the pepperoni in the front to the olives in the back, stays in the food safety zone, even during a crazy dinner rush.

The Foundation of Durability: Stainless Steel Grades

The metal your pizza prep table is made from is a huge deal. It directly affects how long the unit will last and how easy it is to clean. Most commercial tables are stainless steel, but the specific grade of that steel is what really matters.

Key Insight: Getting the difference between stainless steel grades is crucial. The right choice can add years to your equipment's life and save you endless maintenance headaches, protecting your investment from the harsh reality of a commercial pizzeria.

The two grades you’ll see most often are 304 and 430. Here’s what that means for your pizzeria:

- Type 304 Stainless Steel: This is the good stuff. It has more chromium and nickel, giving it way better resistance to rust and corrosion. Considering acidic ingredients like tomato sauce and brined olives are a daily reality in a pizzeria, this grade is your best defense against long-term damage.

- Type 430 Stainless Steel: This is the more budget-friendly option. It's still durable, but with less nickel, it's more likely to corrode over time from acidic spills and harsh cleaning chemicals. You’ll often find it used on the exterior sides and back of a unit, where food isn't touching it directly.

For any part of a 44 inch pizza prep table that touches food, especially the work surface, insist on Type 304 stainless steel. It’s a non-negotiable feature for any serious pizzeria.

The Mark of Safety: NSF Certification

Finally, when you're looking at any piece of commercial kitchen equipment for your pizzeria, keep an eye out for the NSF certification mark. This isn't just some fancy sticker; it’s your guarantee that the prep table has been put through the wringer and approved by NSF International, a top public health and safety organization.

An NSF-certified table meets super strict standards for:

- Material Safety: It ensures the metals and plastics used won't leach nasty chemicals into your pizza toppings.

- Design & Construction: This confirms the unit is designed to be cleaned easily and thoroughly, with no little cracks or crevices for bacteria to hide.

- Product Performance: It verifies that the equipment actually does what it claims, especially when it comes to holding a safe temperature for your ingredients.

In most places, using NSF-certified equipment is required by law for any commercial pizzeria. It’s a critical stamp of approval that protects your customers, your crew, and your business.

Choosing The Right Brand For Your Pizzeria

Picking the right brand for your 44-inch pizza prep table can feel a little like navigating a maze of stainless steel. It’s easy to get lost in spec sheets and price tags, with every manufacturer claiming to be the best. But here’s the secret: the "best" table isn't about a brand name, it's about finding the perfect table for your pizzeria.

Your brand choice should be a direct reflection of your business model. Are you a high-volume slice shop, cranking out hundreds of pies an hour? Or are you a cozy, gourmet spot where every pizza is a carefully crafted work of art? Each style has completely different demands, and the right brand will meet those needs without making you pay for features you’ll never touch.

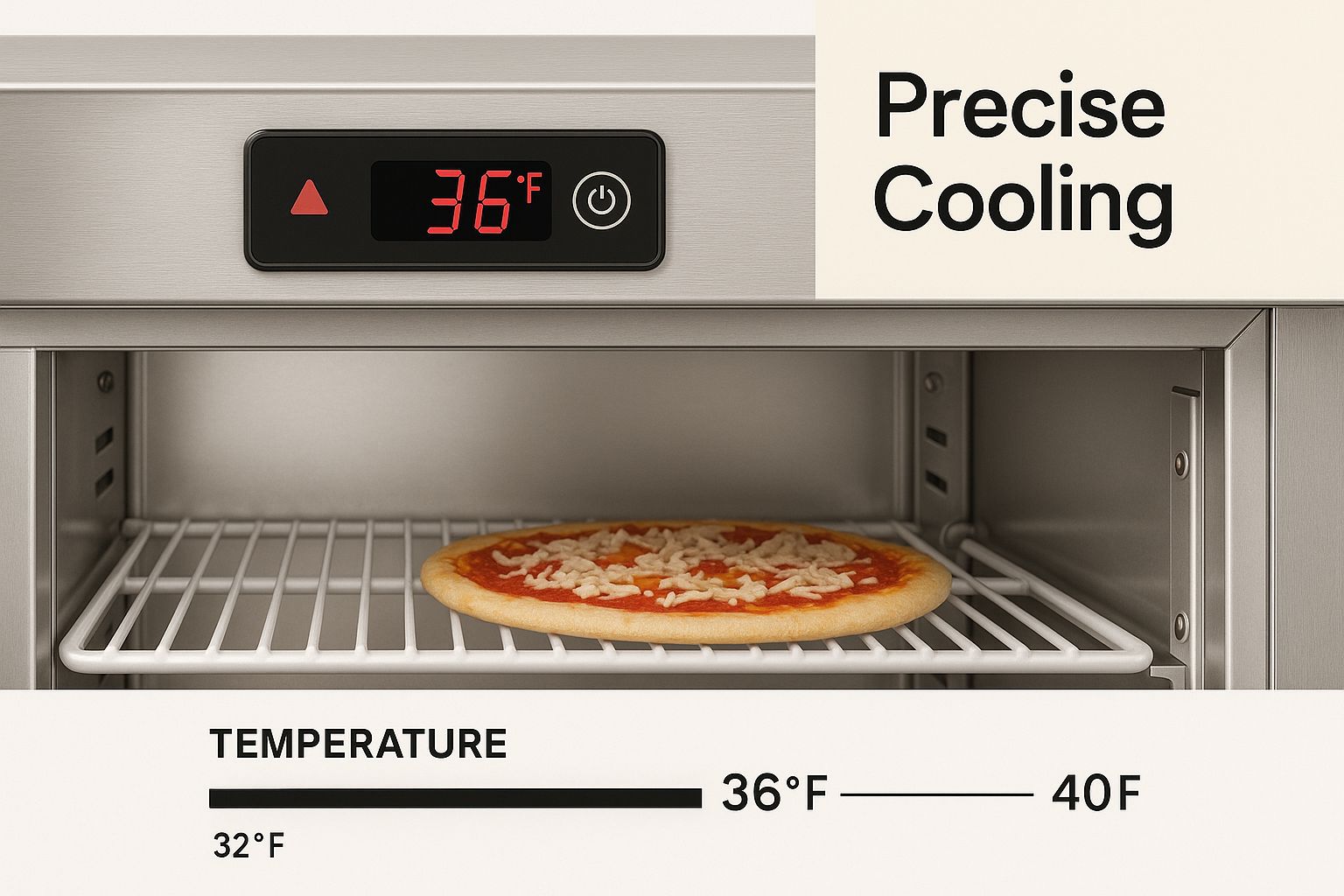

This image really drives home the importance of precise cooling, a feature that top-tier brands obsess over to keep your pizza ingredients fresh and, most importantly, food-safe.

As you can see, the digital controls and chilled interior are working in harmony. This constant temperature is what protects the quality and safety of your toppings during the chaos of a busy service.

Matching Brands To Pizzeria Profiles

Let's cut through the noise and connect some of the leading brands to real-world pizzeria needs. This isn't just about comparing features on a list; it's about matching the right machine to your daily reality.

-

For the High-Volume Urban Slice Shop: Here, speed and reliability are king. You need a tank that can take a beating day in and day out. This is where brands like True Manufacturing shine. They're legendary for their bulletproof construction and powerful refrigeration systems that snap back to temperature in seconds. They also have a massive service network, which means less downtime. They cost more upfront, but for a pizzeria where every minute of downtime costs you money, that investment pays for itself.

-

For the Family-Owned Pizzeria: You're looking for that perfect blend of quality, dependability, and value. Turbo Air is a fantastic contender in this space. They deliver excellent features like efficient cooling and solid construction, but often at a more approachable price point than the premium brands. Their focus on energy efficiency can also lead to real savings on your utility bills over the long haul—a huge plus for any pizzeria owner watching the bottom line.

-

For the Startup or Budget-Conscious Pizzeria: When you're just starting out, every dollar counts. Brands like Avantco or Atosa offer reliable, entry-level options that get the job done without wrecking your budget. These units give you all the essentials—like NSF-compliant construction and solid refrigeration—at a price that's hard to beat. They're a smart way to get your pizzeria up and running with new, dependable equipment while keeping your capital free for other startup costs.

A Deeper Dive Into The Brands

To make things even clearer, let's lay out how these brands stack up against each other. Think of this as a quick-glance guide to help you narrow down your choices based on what truly matters for your pizzeria.

44-Inch Pizza Prep Table Brand Comparison

A comparative look at leading pizza prep table brands, highlighting their main strengths and the type of pizzeria they best serve.

| Brand | Best For | Key Feature Highlight | Price Range |

|---|---|---|---|

| True Manufacturing | High-volume pizzerias & busy slice shops | Unmatched durability & rapid temperature recovery | $$$$ (Premium) |

| Turbo Air | Family-owned pizzerias & mid-volume operations | Strong balance of features, reliability, and value | $$$ (Mid-Range) |

| Avantco / Atosa | Startup pizzerias & food trucks | Solid, no-frills performance at an entry-level price | $$ (Value) |

Ultimately, the right brand is the one that solves your pizzeria's specific problems. Don't get swayed by a fancy logo; focus on the features that will make your kitchen run smoother and more profitably.

Key Factors That Impact Your Pizzeria's Bottom Line

Beyond the brand stamped on the front, a few key details will have a direct impact on your pizzeria's profitability and day-to-day operations. When you're comparing models, make these your priority.

Energy Efficiency and ENERGY STAR Ratings

A pizza prep table runs 24/7, making it one of the biggest energy vampires in your kitchen. An ENERGY STAR certified model can be 30-40% more efficient than a standard unit. That translates into hundreds, sometimes even thousands, of dollars in savings over its lifespan. Don't just look at the purchase price; think about the total cost of ownership for your pizzeria.

An ENERGY STAR rating isn't just a sticker; it's a promise of lower operating costs. The slightly higher initial investment is often paid back within the first couple of years through reduced utility bills, making it one of the smartest financial decisions you can make for your pizzeria.

Warranty and Service Reliability

When your prep table dies during a Friday night rush, you need help—and you need it fast. A strong warranty and a reliable, accessible service network are absolutely non-negotiable for a pizzeria. Top-tier brands often provide comprehensive warranties (2-3 years parts and labor, 5+ years on the compressor) and have technicians ready to go. Before you buy, do a little digging on the brand's service reputation in your local area.

Choosing the right equipment is a cornerstone of building a successful pizzeria. To dig deeper into how different models can work in your kitchen, take a look at our detailed guide on various prep tables for restaurant settings. It will give you a broader perspective on picking a unit that truly supports your business's growth.

Optimizing Your Pizzeria Workflow

Owning the right equipment is a fantastic start, but true profitability comes from how you use it. Your 44 inch pizza prep table is more than just a stainless steel surface; it's the central hub of your pizzeria's productivity. Optimizing its setup is the difference between a chaotic, stressful shift and a smooth, high-output operation.

Think of your prep station as a finely tuned instrument. Every topping, tool, and ingredient has to be placed with a purpose. This isn't just about being tidy—it's about engineering a workflow that shaves precious seconds off every single pizza you make.

The Art of Mise en Place for Pizza

The French culinary term mise en place, meaning "everything in its place," is the golden rule for your pizza prep table. A well-organized setup cuts down on wasted movement, minimizes errors, and keeps your team locked in, especially during the dinner rush. The goal is to create a seamless flow from dough to oven.

This boils down to a few key strategies for your pizzeria:

- Ergonomic Topping Placement: Put your most frequently used toppings—like cheese, pepperoni, and sauce—in the most accessible spots on the refrigerated rail. Ingredients for specialty pizzas that get ordered less often can be placed further away. This simple change can eliminate hundreds of wasted motions per shift.

- Logical Pizza-Building Flow: Arrange your ingredients in the same order you apply them. Sauce and cheese should be closest to where the dough is stretched, followed by meats, and then vegetables. This creates a natural assembly line that becomes second nature for your pizza makers.

By locking in a consistent and logical layout, you build muscle memory for your team, which directly translates into faster ticket times and less mental fatigue.

Mastering Ingredient Rotation and Waste Reduction

An optimized workflow isn't just about speed; it's also about plugging the leaks in your pizzeria's budget. Your refrigerated rail is a prime area for potential spoilage if you don't manage it like a hawk. This is where the FIFO (First-In, First-Out) method becomes non-negotiable for a profitable pizzeria.

Putting FIFO into practice is straightforward:

- Label Everything: The moment a new container of toppings is opened, slap a label on it with the date.

- Rotate Stock: Always place newer containers behind the older ones, both in the refrigerated rail and in the storage cabinet below.

- Use Oldest First: Train your staff to always grab ingredients from the container at the front. This ensures food gets used long before it has a chance to spoil.

A study on restaurant food waste found that spoilage accounts for a huge portion of losses, with poor stock rotation being a primary culprit. By strictly sticking to FIFO, a pizzeria can reduce its ingredient waste by as much as 10-15%—a saving that goes straight to your bottom line.

Beyond the physical setup, maintaining a pristine and pest-free environment is crucial for any optimized workflow. Learn more about effective fly control strategies for restaurants to ensure your prep area stays hygienic and professional.

Creating a Seamless Pizzeria Triangle

Your 44 inch pizza prep table doesn't operate in a vacuum. Its true power is unlocked when it's perfectly integrated with the other key stations in your pizzeria: the dough station and the oven. This creates an efficient "pizzeria triangle" that minimizes footsteps and maximizes output.

Ideally, the flow should be linear and uninterrupted. The dough station should be right next to the prep table, allowing your pizza maker to stretch a base and immediately slide it onto the cutting board. From there, the table should be positioned for a quick, direct path to the oven.

This strategic placement means a pizza can go from a dough ball to a fully topped pie ready for baking in just a few steps. When you multiply that over hundreds of orders a night, this streamlined path significantly boosts your pizzeria's overall capacity and reduces the physical strain on your employees. A well-organized station transforms a good pizzeria into a great one.

Installation and Maintenance That Pays Off

Your 44 inch pizza prep table is a long-term investment. It's the workhorse that powers your pizzeria's daily grind, and you've got to protect it. Getting the installation right from day one and sticking to a consistent maintenance schedule are the two best things you can do to keep it running smoothly, extend its life, and dodge those dreaded emergency repair bills.

Think of it this way: you wouldn't buy a high-performance pizza oven and then never clean it. The same logic applies here. A few simple routines can save you thousands in repair bills and lost business from unexpected downtime. Plus, you’ll keep your energy costs down and your pizza toppings perfectly chilled.

Setting Up Your Prep Table for Success

A proper setup is the foundation for a long and trouble-free life for your equipment. If you rush this part, you're just asking for performance issues and long-term damage. Before you even think about plugging it in, let's walk through a few key steps to get it right from the very start.

First and most importantly, the compressor needs to breathe. Most pizza prep tables are front-breathing, meaning they pull air in and push it out through the front grille. This design is great because it lets you place the unit flush against a wall, but you absolutely cannot block that front grille. I recommend leaving at least 3-4 inches of clearance.

Crucial Takeaway: Blocking the compressor's airflow is like forcing a runner to breathe through a straw. The unit will overheat, work way harder than it should, and eventually burn out. This is one of the top reasons I see compressors fail prematurely in busy pizzerias.

Next up, grab a level. Make sure the unit is perfectly flat by placing the level on the cutting board and adjusting the casters or legs until it’s stable. If your table is even slightly off-kilter, the doors might not seal properly. That lets cold air escape and warm air creep in, wasting energy and putting your ingredients in the temperature danger zone.

A Practical Maintenance Checklist for Your Pizzeria

Once your 44 inch pizza prep table is set up and humming along, a simple, consistent maintenance routine is your best defense against breakdowns. Don't think of it as a chore; see it as a small investment of time that pays off big time. For a deeper dive, reviewing some professional preventive maintenance tips for commercial refrigeration is a great way to build good habits.

Here’s a practical checklist, broken down by how often you should do it:

Daily Tasks (5 Minutes)

- Wipe Down All Surfaces: Use a mild detergent and a soft cloth to clean the stainless steel exterior, interior, cutting board, and door gaskets. This keeps acidic stuff like tomato sauce from building up and causing damage.

- Check Temperatures: Just a quick glance at the digital thermostat is all it takes. Make sure the unit is holding its set temperature, which should be between 34°F and 40°F.

Weekly Tasks (15 Minutes)

- Deep Clean the Interior: Pull out all the food pans and shelving. Give them a good wash and sanitize the inside of the cabinet to stop bacteria and mold from taking hold.

- Inspect Door Gaskets: Run your fingers along the rubber door seals. Are there any cracks, tears, or stiff spots? A bad gasket is a massive energy leak.

Monthly Tasks (20-30 Minutes)

- Clean the Condenser Coils: This is the single most important task you can do. Unplug the unit, take off the front grille, and use a stiff brush or a vacuum to gently clear away all the flour, dust, and grime from the coils. Clean coils help the system cool efficiently, lowering energy use and reducing stress on the compressor.

- Check and Tighten Hardware: Make sure all the casters, hinges, and handles are nice and tight.

Following these simple routines will keep your pizza prep table in prime condition, making sure it stays a reliable partner in your kitchen for years. While this guide is all about pizza-specific tables, a lot of these same principles apply to other refrigerated units. You can see how these ideas adapt to different equipment in our article on the versatile prep table sandwich station.

Answering Your Top Questions

When you're about to invest in a cornerstone piece of equipment like a 44 inch pizza prep table, the real-world questions always start to pop up. These are the practical concerns that go way beyond a spec sheet, touching on how you'll actually use it during a busy service, its long-term value, and the little details that make a huge difference in a pizzeria.

We’ve talked to pizzeria owners and equipment experts to get you direct, actionable answers. This is the stuff you need to know, whether you're picking out a new unit or just trying to get the most out of the one you already have.

What Is the True Pizza Capacity of a 44 Inch Prep Table During a Dinner Rush?

Forget what the spec sheet says about pan capacity for a minute. The real capacity is all about workflow and how many pizzas you can get out the door.

Think of a 44 inch pizza prep table as the perfect command center for one pizzaiolo working at top speed. It’s also a comfortable space for two to work side-by-side without bumping elbows. It’s designed to hold every core ingredient you need, easily supporting 40 to 60 pizzas per hour, depending on how skilled your staff is and how complex your pizzas are.

The magic of this size is its balance. It’s big enough for serious volume but compact enough that your staff isn’t wasting steps—a major slowdown in any pizzeria. The base cabinet usually gives you about 12 cubic feet of refrigerated storage, which is perfect for holding backup dough, sauce, and cheese to keep the line moving without a single interruption.

Should I Choose a Unit with Drawers or Doors for My Pizzeria?

This is a great question, and the answer really comes down to your pizzeria's flow and what you prioritize day-to-day. Both have their strengths, so it’s all about how your team works.

- Doors: These are all about flexibility. They’re perfect for storing bulky items like big tubs of sauce, boxes of cheese, or odd-shaped containers. Units with doors also tend to be a bit easier on the wallet, which can be a huge plus for a new pizzeria.

- Drawers: This is where organization and ergonomics shine. They give you easy, pull-out access to things like dough boxes or pre-portioned toppings. This design saves your staff from constantly bending down and digging around in a dark cabinet, which really reduces physical strain over a long shift.

For a high-volume pizzeria where speed, precise ingredient rotation, and keeping your team comfortable are top priorities, drawers are often worth every penny. The boost in efficiency and better ergonomics can lead to faster service and a happier, more productive crew.

How Important Is an ENERGY STAR Certification for a Pizzeria?

It's a huge deal and should be right at the top of your list. A pizza prep table is one of the few things in your kitchen that runs 24/7, making it a major player on your energy bill.

An ENERGY STAR certified model is built smarter—it has a more efficient compressor, better insulation, and tighter door gaskets. That combination can slash its energy use by 30-40% compared to a standard unit.

Yes, the initial price might be slightly higher, but the savings on your monthly utility bill give you a quick return on that investment. Over the life of the unit, those savings can easily add up to thousands of dollars. Better yet, many local utility companies offer rebates for buying ENERGY STAR commercial gear, which can bring down your upfront cost and make it a no-brainer for your pizzeria.

Can I Use the Cutting Board for Tasks Other Than Pizza Prep?

For the sake of food safety and preventing cross-contamination, you absolutely need to dedicate that cutting board exclusively to making pizza. Using it to slice raw meat, chop salad veggies, or prep anything with common allergens is a recipe for introducing harmful bacteria to your ready-to-eat pizza ingredients.

Most tables come with a removable, NSF-approved polyethylene cutting board for a reason—it's non-porous and super easy to clean and sanitize. If you are ever in a pinch and absolutely must do another task there, follow these steps without fail:

- Use Separate Boards: Place a completely separate, color-coded cutting board on top of the main one for that specific task.

- Clean Immediately: As soon as you’re done, remove that temporary board.

- Sanitize Thoroughly: Give the integrated cutting board and the entire surrounding area a deep clean and sanitization before a single pizza ingredient touches it again.

This kind of discipline isn't optional; it's what separates a professional pizzeria from the rest. It protects your customers, your reputation, and keeps you on the right side of the health department. By treating your 44 inch pizza prep table as a dedicated station, you reinforce the high standards that create a consistently excellent—and safe—product.

Ready to build the efficient, high-output pizza station your restaurant deserves? At Pizza Prep Table, we specialize in connecting pizzeria owners with the perfect equipment to match their vision and budget. Explore our curated selection of top-tier 44-inch pizza prep tables and find the ideal solution to elevate your kitchen's workflow.