A Pizzeria's Guide to the 48 Inch Pizza Prep Table

Share

A 48-inch pizza prep table is so much more than just a refrigerated counter; for a busy pizzeria, it’s the command center. This specific size is a sweet spot, offering plenty of cold storage for toppings without hogging your entire kitchen footprint. It’s designed to turn a chaotic prep line into a smooth, efficient pizza-building machine.

Why Your Pizzeria Needs a 48-Inch Prep Table

Ever find yourself staring at a cramped, messy prep line during the dinner rush? You're not alone. The secret to a smooth, high-volume service often isn't just your oven, but how organized your prep station is. This is where the 48-inch pizza prep table becomes the unsung hero of countless successful pizzerias.

Think of it as your kitchen's mission control. This size strikes a crucial balance: it's compact enough to slide into most kitchen layouts without creating a traffic jam, yet it’s spacious enough to hold all your essential pizza toppings in one refrigerated, easy-to-reach spot. No more frantic dashes to the walk-in for another container of mozzarella or mushrooms.

Solving Common Pizzeria Pain Points

A well-equipped pizza prep table isn't just a hunk of stainless steel—it's a direct solution to the daily headaches that slow down service and ding your quality. It’s built to tackle the exact issues that plague busy pizza shops.

This single unit directly addresses challenges like:

- Topping Overflow: It gives every ingredient an organized, refrigerated slot, preventing cross-contamination and keeping your workspace from becoming a disaster zone.

- Workflow Bottlenecks: By putting everything in one place, it creates a logical flow from dough to oven, cutting out wasted steps and saving precious seconds on every pizza order.

- Food Safety Scares: Consistent, forced-air refrigeration keeps sensitive toppings like cheese and meats safely below 40°F, even when the lid is open during a crazy rush.

The Perfect Balance of Space and Storage

The 48-inch size is incredibly popular in pizzerias for a reason, as it perfectly balances workspace with cold storage. A typical table of this size holds between 12 to 16 (or even up to 18 in mega-top versions) 1/6-size food pans. This gives your team plenty of room to offer a full range of pizza toppings, all within arm's reach.

It's the ideal setup for kitchens with moderate to high volume, letting you assemble pizzas faster without ever sacrificing ingredient freshness.

A disorganized prep station is a profit killer. Every extra second an employee spends searching for an ingredient is a second they aren't making a pizza, which directly impacts ticket times and customer satisfaction during your busiest hours.

Of course, great equipment is only half the battle. Every successful pizzeria also needs high-quality professional menus to show off their amazing creations. A solid prep table like this one is what empowers your crew to execute that menu with the speed and precision of a pit crew, turning chaotic service into a streamlined, profitable operation.

Mastering the Anatomy of Your Pizza Prep Station

Let's ditch the owner's manual for a minute. A 48-inch pizza prep table isn't just a hunk of stainless steel; in a busy pizzeria, it's a finely tuned pizza-making machine. To really get the most out of it, you need to see each part for what it truly is—a tool to boost your kitchen's workflow.

Think of the whole unit as a self-contained ecosystem built for speed. Every component has a job, from keeping pepperoni perfectly chilled to giving you the perfect stage to build your pies. Once you understand the anatomy, you can turn those brochure features into real-world benefits that shave seconds off ticket times.

The Topping Command Center

The heart of any pizza prep station is the refrigerated pan rail. This is way more than just cold storage; it's your 'topping command center.' This is where smart organization becomes pure speed. A standard 48-inch unit can hold twelve 1/6-size pans, giving you a dedicated spot for every key topping on your menu.

The secret here is all about creating a logical flow. Don't just toss ingredients in wherever they fit. The pros organize by category to build muscle memory for their pizza makers.

- Meat Zone: Group your proteins—pepperoni, sausage, ham, bacon—on one side. This stops your team from scanning the whole rail every time.

- Veggie Zone: Keep the other side for your vegetables like onions, mushrooms, olives, and peppers.

- Cheese Station: Your cheese is likely the most-used ingredient, so it deserves a prime spot, maybe in a larger pan right in the middle for easy access.

This kind of methodical layout shaves precious seconds off every single order. When your crew can reach for toppings without thinking, the assembly process becomes a smooth, repeatable dance.

Your Pizza Assembly Line

That cutting board running the full width of the table? That's your 'assembly line.' It’s not just for chopping. This is the main stage where every pizza gets built, from stretching the dough to the final sprinkle of herbs.

Its location right next to the topping rail is no accident. A pizzaiolo can stretch dough, ladle sauce, and add toppings in a seamless motion without taking a single extra step. This integrated design is what keeps you from hitting a bottleneck during the dinner rush. If you want to dive deeper into picking the right setup, you might like our guide on picking the perfect kitchen prepping table.

The distance between your chilled toppings and your work surface is a key metric for efficiency. A great prep table makes that distance zero, cutting out wasted motion and creating a high-speed, ergonomic workstation.

The Dough and Sauce Reserve

Down below, the refrigerated cabinet is your 'dough and sauce reserve.' This isn't just overflow storage; it’s a strategic depot for your most critical bulk items. That spacious cabinet lets you keep backup sauce, extra cheese, and—most importantly—trays of proofed dough balls perfectly chilled and right where you need them.

Having immediate access is a total game-changer during peak hours. Instead of a mad dash to the walk-in cooler when you're running low, your team can restock the rail in seconds. Keeping your dough at a consistent, cool temperature right at the station also guarantees every pizza starts with the same perfect foundation, leading to a better, more consistent pie for your customers.

Designing a High-Efficiency Kitchen Layout

Owning the right equipment is only half the battle. Where you put it is what truly separates a chaotic kitchen from a profitable one. Your 48 inch pizza prep table is the heart of your pizza production line, but its real value depends entirely on where it lives in your kitchen's ecosystem. A poorly placed table creates traffic jams and stress, while a well-placed one builds a superhighway for speed and efficiency.

The goal is to create a workflow that feels natural and effortless for your staff. Think of it like a perfectly executed relay race: the dough maker hands off to the pizza builder, who then passes the pie to the oven operator. Each station should be just a single, logical step from the next, cutting out wasted movement and the frantic energy that defines a disorganized kitchen.

The Pizza Production Triangle

The most effective pizzeria layouts almost always follow a simple, time-tested principle: the "Pizza Production Triangle." This concept locks three critical stations into a tight, efficient work zone where your staff can operate with minimal wasted motion. Your prep table sits right at the center of this powerhouse trio.

The three points of this essential triangle are:

- The Dough Station: This is where it all begins—dough is pressed, stretched, and prepped for toppings. It should be located immediately before the prep table in your workflow.

- The Pizza Prep Table: Your 48-inch unit is the main assembly area. Here, the stretched dough gets its sauce, cheese, and toppings before the final step.

- The Pizza Oven: This is the final destination. The oven needs to be just a few steps from the prep table, allowing for a quick, safe transfer of the finished pie.

When these three stations are positioned correctly, you create a clear path that dramatically cuts the time it takes to build a pizza. This isn't just about speed; it’s about creating a calm, focused environment where your team can really shine.

Ergonomics and Eliminating Bottlenecks

A well-designed layout also puts a huge emphasis on ergonomics, which is just a fancy way of saying it makes the work physically easier and safer. A pizzaiolo who is constantly twisting, bending, or taking long strides to grab ingredients is going to burn out faster and make more mistakes. Strategic placement of your 48 inch pizza prep table is the key to preventing this.

This is where a 48-inch model really proves its worth. Its physical footprint is large enough for serious production but compact enough to enable ergonomic workflows. It minimizes congestion, allowing staff to pass behind the station or work side-by-side without getting in each other's way. As kitchens increasingly adopt these tables, seamless integration has become a major focus in the industry. Proper placement doesn't just improve speed and reduce errors; it's fundamental to maintaining food safety standards. You can find more insights on optimizing kitchen workflows on arizton.com.

Smart layout design turns your physical space into a competitive advantage. By cutting just five seconds of wasted motion per pizza, a pizzeria making 200 pizzas a night saves over 16 minutes of labor time—every single day.

Below is a simple diagram that shows what an effective linear workflow looks like in a pizzeria.

This visual demonstrates that direct path from the dough station, to the 48-inch prep table, and finally to the oven. It's a clear, efficient assembly line that keeps bottlenecks from ever forming.

Comparing Top 48-Inch Pizza Prep Table Models

Drowning in spec sheets and technical jargon? When you're trying to pick a 48 inch pizza prep table for your pizzeria, the details can feel completely overwhelming. The trick is to cut through all that noise and zero in on the features that actually matter to your pizza-making workflow—from keeping mozzarella perfectly chilled to holding enough pepperoni for the Friday night rush.

Let's skip the generic lists and get into an honest breakdown of the top models from brands you can trust. We'll look at them through the eyes of a pizzeria owner, comparing how their designs and cooling systems stack up to help you find the machine that will become the reliable heart of your production line.

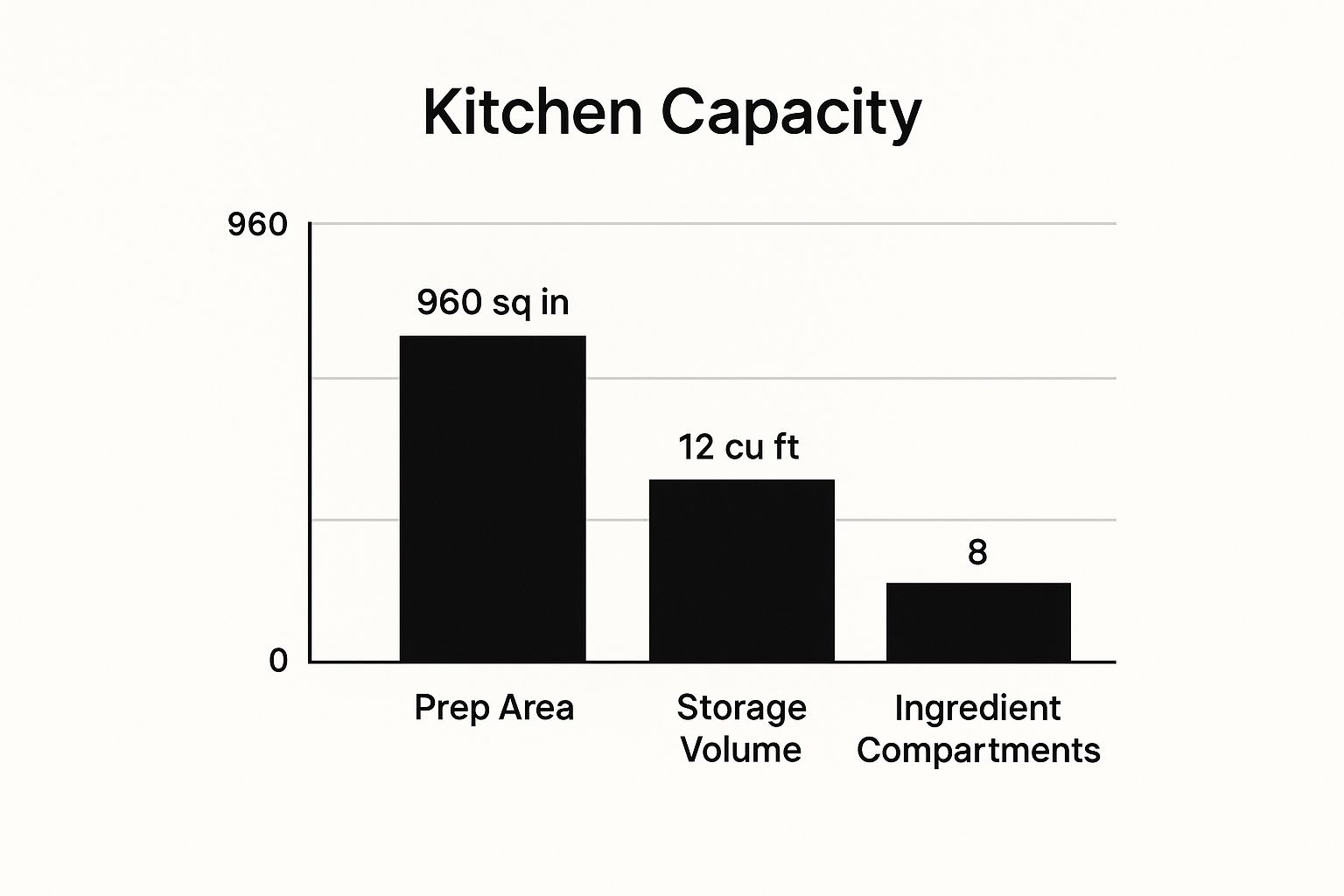

This chart gives you a bird's-eye view of what to expect from a quality 48-inch pizza prep table, highlighting its capacity for prep, storage, and ingredients.

You can see the design is perfectly balanced. It offers plenty of refrigerated storage and a solid workspace without eating up your whole kitchen, making it a great fit for most pizzeria layouts.

Picking the right model is about more than just brand names; it's about matching the machine's strengths to your kitchen's daily grind. To help with that, I've put together a quick comparison of some of the heavy hitters in the 48-inch category.

Comparing Top 48-Inch Pizza Prep Tables

| Model/Brand | Pan Capacity (1/6 size) | Refrigeration Type | Key Pizzeria Feature | Price Range |

|---|---|---|---|---|

| Atosa MSF8302 | 12 | Forced-Air | Balanced airflow for even pan cooling | $$ |

| True TSSU-48-12 | 12 | Factory-Balanced | Oversized system for fast temperature recovery | $$$ |

| Turbo Air TST-48SD | 12 | High-Density Insulated | Self-cleaning condenser for reduced maintenance | $$$ |

This table gives you a quick snapshot, but the real story is in the details of how each unit performs under pressure. Let's dive a little deeper into what makes each of these models tick.

Atosa MSF8302: The Versatile Workhorse

The Atosa MSF8302 is a hugely popular choice for pizzerias that need a dependable, all-around performer without a premium price tag. It’s built with durable stainless steel, inside and out, so it’s tough enough to handle the daily chaos of a busy kitchen while still being simple to sanitize.

What really makes it stand out for pizza prep is its specialized airflow system. This isn't just a fan blowing cold air; it's engineered to circulate that air evenly around all 12 included 1/6-size pans, getting rid of those dangerous warm spots. This is absolutely critical for sensitive toppings like shredded cheese and cured meats, making sure they stay safely chilled below 40°F. Plus, its energy-efficient Embraco compressor helps keep your utility bills in check—a huge win for any restaurant's bottom line.

True TSSU-48-12: The Durability Champion

In the world of commercial refrigeration, True Manufacturing is the benchmark for durability, and the TSSU-48-12 is a perfect example of why. This thing is built like a tank. It's a smart long-term investment for high-volume pizzerias where equipment takes a serious beating day in and day out.

Its killer feature is the oversized, factory-balanced refrigeration system that delivers incredible temperature recovery. What does that mean for you? Even when the lids are open during a relentless dinner rush, the unit gets back down to a safe temperature almost instantly. That feature alone is invaluable for protecting the quality and safety of your ingredients. The high-quality stainless steel and coved interior corners also make deep cleaning way easier, which is crucial for staying on the right side of the health inspector. For a deeper look at what to look for, you can explore our guide on selecting a commercial pizza prep table.

Turbo Air TST-48SD: The Low-Maintenance Innovator

For any pizzeria owner who dreads routine maintenance, the Turbo Air TST-48SD offers a feature that is a genuine game-changer: a self-cleaning condenser. This system uses a rotating brush to automatically clear dust and debris from the condenser coils—a task that is essential for cooling efficiency but often gets forgotten in a busy kitchen.

A clean condenser doesn't just prevent breakdowns; it ensures the unit runs at peak efficiency, using less energy to maintain temperature. This Turbo Air feature directly translates to lower operating costs and greater reliability over the life of the machine.

Beyond this brilliant feature, the TST-48SD also has high-density polyurethane insulation that helps it hold cold temperatures like a fortress. This makes it a fantastic choice for pizzerias looking to cut down on both energy costs and the labor hours spent on equipment upkeep.

Making the Final Call for Your Pizzeria

At the end of the day, choosing the right 48 inch pizza prep table comes down to what your pizzeria needs most.

- For Balanced Performance and Value: The Atosa MSF8302 is an excellent all-around choice. It offers reliable cooling and solid construction at a price that won't break the bank.

- For Unmatched Durability: If your main goal is to buy a machine that will last for years under heavy, constant use, the True TSSU-48-12 is an investment in reliability that will pay for itself.

- For Efficiency and Less Upkeep: For operators who value innovation that saves both time and money, the self-cleaning condenser of the Turbo Air TST-48SD makes it a clear standout.

By weighing these pros and cons against your menu's complexity, daily volume, and budget, you can confidently pick a prep table that will be the cornerstone of your kitchen's efficiency for years to come.

Keeping Your Prep Table Running Like a Champ

Your 48 inch pizza prep table is the heart of your production line, the workhorse that keeps things moving during the dinner rush. But even the toughest equipment needs a little TLC to stay in top shape. Think of preventative care not as a chore, but as an insurance policy for your investment.

A few minutes of attention each day protects you from spoiled ingredients, shocking utility bills, and the dreaded Friday night breakdown that every operator fears. This simple plan breaks down the essential tasks into daily, weekly, and monthly checklists that anyone on your team can handle.

The Daily Habits of a Healthy Machine

Daily maintenance is all about staying clean and aware. These tasks take less than ten minutes at the end of a shift, but they’re your first and best defense against contamination and inefficiency. Get these habits dialed in, and you’ll stop small issues from turning into big headaches.

- Wipe Down Everything: Before you lock up, give the cutting board, interior and exterior surfaces, and door handles a thorough cleaning and sanitizing. This is non-negotiable for preventing bacterial growth.

- Attack Spills Immediately: Don't let acidic stuff like tomato sauce sit around. It can eat away at stainless steel and damage sensitive coils over time. A quick wipe is all it takes.

- Empty and Clean the Pans: Pull out all the topping pans, give them a good wash and sanitize, and wipe down the refrigerated rail underneath. It ensures you’re starting fresh the next day.

Weekly Checks to Stop Wasting Energy

Your weekly tasks are focused on the parts that quietly cost you money when they fail. These quick checks are designed to catch problems before they show up on your energy bill or lead to food sitting in the temperature danger zone.

The number one culprit? The door gaskets—those rubber seals that keep the cold air in. A bad seal makes your compressor work overtime, burning through electricity and putting unnecessary strain on the entire system.

A torn or cracked door gasket can force a refrigerator to use up to 30% more energy. Checking it once a week is one of the easiest ways to keep your utility costs in check and guarantee your prep table holds a safe temperature.

Simply wipe the gaskets down with a damp cloth to get rid of any grime. Then, give them a quick visual inspection for cracks, tears, or brittleness. A tight seal is your best friend for peak performance.

The Monthly Task That Prevents Catastrophe

If you do only one monthly maintenance task, make it this one: clean the condenser coils. The condenser is basically the radiator for your prep table; its job is to push heat out of the refrigeration system. But in a busy pizzeria, it gets caked with grease, dust, and flour.

When the coils are dirty, the unit can't get rid of heat. The compressor is forced to run 24/7, which sends your energy bill through the roof and eventually leads to overheating and total failure. That’s a repair that can set you back hundreds, if not thousands, of dollars.

Here’s the simple, three-step process for this critical job:

- Kill the Power: Safety first. Always unplug the prep table from the wall before you start.

- Find the Coils: The condenser is usually at the back or bottom of the unit. You might need to remove a grille to get to it.

- Gently Clean the Fins: Grab a stiff-bristled brush or a shop vac with a brush attachment and gently clear all the gunk off the coil fins.

Committing a few minutes each month to this one task will dramatically extend the life of your 48 inch pizza prep table. More importantly, it protects your pizzeria from the cost and chaos of an unexpected breakdown.

Viewing Your Prep Table as a Strategic Investment

It's tempting to look at a 48 inch pizza prep table and see just another line item on an expense sheet. I've seen it countless times. But that’s a rookie mistake. This piece of equipment isn't just stainless steel and refrigerant; it's a direct investment in your kitchen's speed, quality, and daily profitability.

Think of this unit as the engine of your entire pizza production line. It’s the tool that lets your team build pizzas with speed and, most importantly, precision. That kind of consistency is what builds trust with your customers—the bedrock of any successful pizzeria.

A Cornerstone for Growth and Excellence

Let's talk about the direct returns on this investment. A streamlined workflow, with every topping chilled and within arm's reach, slashes ticket times. That means you can serve more customers during that chaotic dinner rush, increasing your output and boosting your daily revenue.

It also protects your reputation and your bottom line by upholding critical food safety standards, preventing costly spoilage that eats into your profits. These aren't minor details; they are the absolute core of operational excellence.

An efficient prep station is more than a convenience—it's a profit center. It enables higher output, reduces food waste, and ensures the product quality that turns first-time visitors into loyal regulars.

You don't have to take my word for it. Market trends show a rising demand for fresh, customizable meals. The commercial prep table market, already valued at around USD 1.2 billion, is only expected to grow. This isn't happening by accident. It's driven by smart operators who recognize the need for efficiency and food safety. You can find more insights about these market trends on verifiedmarketreports.com. Your pizza prep table is what positions you to capitalize on this movement.

Of course, the best equipment in the world won't bring people through the door on its own. A crucial part of making this investment pay off is attracting diners through effective local SEO strategies. To see how the right tools can support your pizzeria's goals, check out our guide on prep tables that work as hard as you do. When you pair operational excellence with smart marketing, this purchase transforms from a simple expense into a true cornerstone for your growth.

Got Questions? We've Got Answers

When you're running a pizzeria, investing in a 48 inch pizza prep table is a big move, and it’s smart to have a few questions. It’s a serious piece of equipment, so let's clear up some of the most common things owners ask before they pull the trigger.

Can a "Sandwich Prep Table" Really Handle a Pizza Operation?

You bet it can. The name is a bit of an industry quirk, but don't let it fool you. For a busy pizzeria, these units are purpose-built pizza-making machines.

Think of it as your command center. The refrigerated rail keeps dozens of toppings perfectly organized and chilled, the cutting board is your dedicated space for stretching dough, and the cabinet below is ideal for stashing extra sauce and dough balls right where you need them.

What's the Real Deal with a Mega Top?

A "mega top" is a game-changer, especially if your menu is loaded with specialty pies. It gives you a whole extra row for ingredient pans, which is a massive win for efficiency. On a 48 inch pizza prep table, that can boost your capacity from 12 pans to 16 or even 18.

This isn't just about holding more stuff. It's about raw speed. With more ingredients chilled and ready, your team spends less time restocking and more time slinging pizzas during that Friday night rush.

If you’ve got a long list of toppings, a mega top keeps the line moving without a single hiccup.

How Can I Be Sure My Toppings Stay Consistently Cold?

For food safety, "mostly cold" doesn't cut it, especially with ingredients like cheese and meats. The single most important feature to look for is a high-quality forced-air refrigeration system.

Here's why this matters so much:

- No Warm Spots: Unlike older cold-wall systems that can be unreliable, forced-air actively circulates cold air around every single pan, ensuring even cooling.

- Rock-Solid Temps: This technology holds all your ingredients at a constant, food-safe temperature below 40°F (4°C), even when the lid is open during a rush.

- Maintenance is Your Friend: To keep it working perfectly, you have to do your part. Cleaning the condenser coils once a month is non-negotiable—it prevents overheating and keeps the system running like a champ.

Making sure your unit has this kind of advanced cooling is the best way to protect your inventory and serve a product you can be proud of, every single time.

Ready to get your pizza line running like a well-oiled machine? At Pizza Prep Table, we stock a huge selection of top-tier units built for the grind of a real pizzeria. Check out our collection and find the perfect 48 inch pizza prep table for your kitchen today. Visit us at https://pizzapreptable.com to get started.