Prep Tables That Work as Hard as You Do

Share

Why Prep Tables Are Essential for Any Commercial Kitchen

Prep tables are the backbone of any successful commercial kitchen. These specialized workstations combine storage, refrigeration, and a dedicated work surface into one efficient unit, dramatically improving productivity. By keeping ingredients organized, accessible, and at safe temperatures, they increase speed, improve food safety, and create a more logical workflow.

Whether you run a pizza shop, sandwich deli, or full-service restaurant, the right prep table transforms your kitchen's operations. A pizzeria benefits from deep cutting boards and raised ingredient rails, while a sandwich shop needs shallow prep rails for easy pan access. Understanding these differences is key to choosing the right unit.

With years of experience in the foodservice industry, I'm Sean Kearney, and I've seen how the right prep table can make or break a kitchen's efficiency. These workhorses are essential for any operation, adapting to your specific needs to keep your kitchen running smoothly.

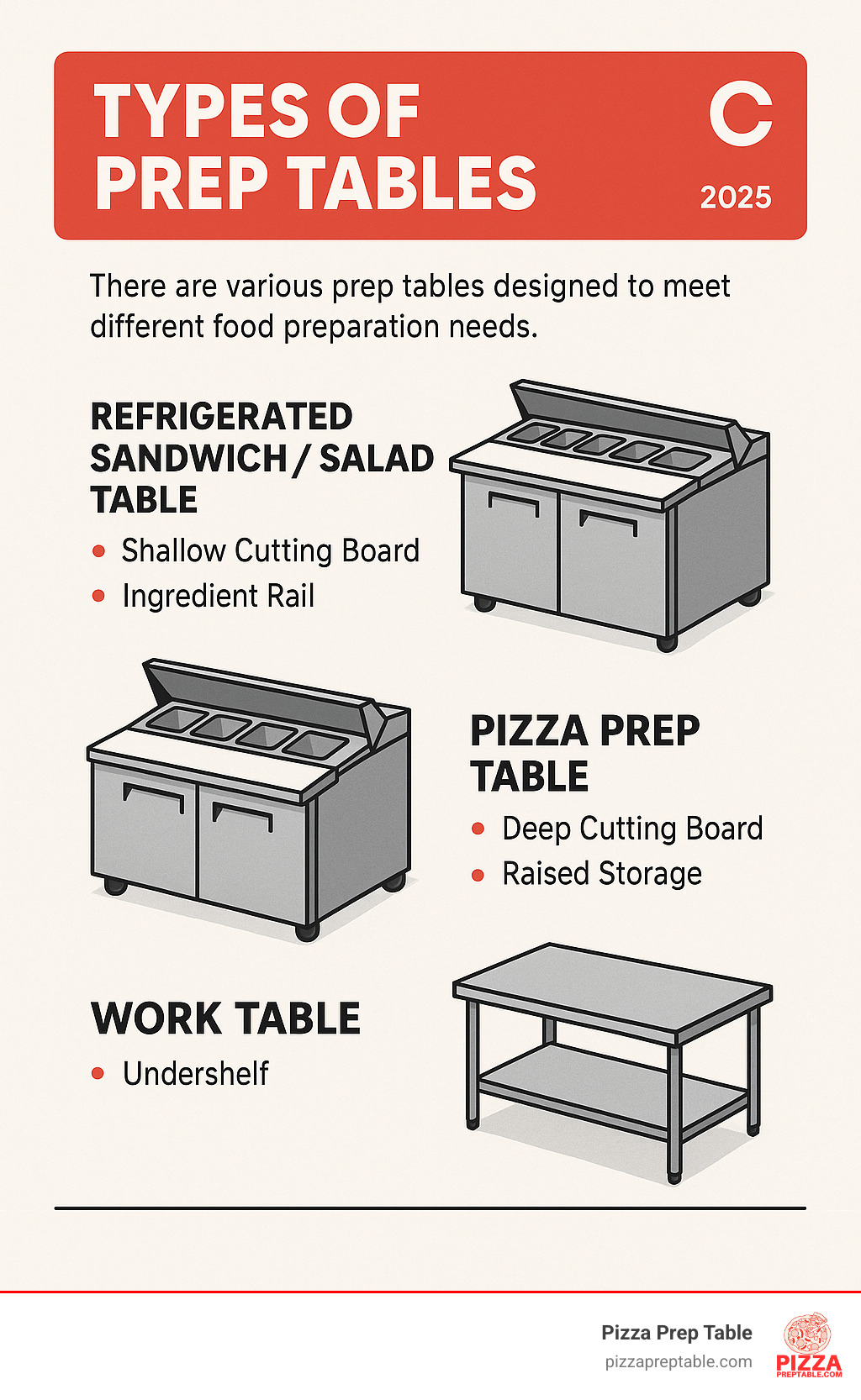

A Closer Look at Different Types of Prep Tables

Not all prep tables are created equal. Different kitchen operations need different types of prep stations to work at their best. Whether you're building subs at lightning speed or crafting artisan pizzas, the right table can make your team more efficient and your food safer.

Each type is designed with specific tasks in mind, and understanding these differences will help you make the smartest choice for your kitchen.

Refrigerated Sandwich & Salad Tables

Ideal for delis and cafes, these prep tables are designed to keep fresh ingredients for sandwiches and salads cold and accessible. Their key feature is a refrigerated prep rail with smart airflow systems that direct cold air onto food pans, ensuring ingredients like lettuce and cheese stay fresh and food waste is minimized. Standard features include a durable poly cutting board, precise digital controls, and an insulated roll cover to maintain freshness. These units keep everything organized and within reach, speeding up service in busy shops. For more details, see our guides on Sandwich Prep Table Refrigerator and Food Tables 101: Digesting the Facts and Figures.

Specialized Pizza Prep Tables

Pizza prep tables are engineered for the specific demands of pizzerias. They feature a deep cutting board (16-20 inches) that provides ample room for stretching dough and adding toppings. A raised rail positions ingredient pans for quick access, while the refrigerated base offers bulk storage for cheese, toppings, and dough storage. With lengths up to 119 inches, these tables allow for simultaneous order preparation, making them essential for speed and consistency. Learn more in our guides to Commercial Pizza Prep Table, The Secret Sauce Behind Efficient Pizza Prep Stations, and the Atosa Pizza Prep Table.

General Work Tables & Equipment Stands

General work tables are versatile, non-refrigerated surfaces perfect for a variety of tasks. Use them as sturdy equipment stands for mixers and slicers or for prep work like meat tenderizing and vegetable chopping. Most include undershelves for convenient storage of pots and pans, maximizing floor space. Their flexibility allows you to create dedicated stations for different tasks, which improves workflow and reduces cross-contamination. For maximum organization, many kitchens rely on Using prep sheets for kitchen organization to streamline their processes. Learn more in our guide, Table Talk: Restaurant Kitchen Prep Tables Explained.

Refrigerated Chef Bases

Chef bases are low-profile, space-saving prep tables with refrigerated drawers, designed to fit under countertop cooking equipment like griddles or ranges. This provides easy ingredient access right at the cooking station, keeping items like burger patties or chopped vegetables at hand. By eliminating trips to the walk-in cooler, chef bases streamline the cooking process, speed up service times, and are invaluable in high-volume kitchens. Find more about these efficient units in our Refrigerated Chef Base guide.

Choosing the Right Material and Features

Investing in commercial prep tables is a significant decision that impacts your kitchen's durability, food safety, and overall functionality. It's a long-term investment, so choosing the right materials and features is paramount to ensuring your table works as hard as you do for years to come.

Decoding Prep Table Materials

The material of your prep table is crucial for durability and cleaning. Each type offers unique benefits for kitchen operations.

| Material | Benefits |

|---|---|

| Stainless Steel | T-304 18 Ga offers superior corrosion resistance, is easy to clean, and its non-porous surface prevents bacteria growth. |

| Wood | Ideal for dough kneading and baking prep, providing a natural, non-stick texture. |

| Polyethylene | Durable, stain-resistant cutting surfaces that are easy to sanitize and replace. |

Stainless steel (specifically T-304 18 gauge) is the industry standard for its resilience and hygienic properties. For bakeries, wood tops are excellent for kneading dough. Poly cutting boards are common for general prep, as they are gentle on knives and simple to sanitize or replace.

Key Features to Look for in Commercial Prep Tables

Smart features can significantly boost a prep table's functionality.

- Backsplashes and marine edges contain spills and splashes, protecting walls and floors and simplifying cleanup.

- Undershelves or storage cabinets provide essential storage for pots, pans, and supplies without using more floor space.

- Casters for mobility offer flexibility, allowing you to easily move the table for cleaning or reconfiguring your kitchen layout. Ensure they have locking wheels for stability.

- Integrated sinks and faucets create all-in-one workstations, streamlining tasks like washing and prepping produce.

Certifications and Energy Efficiency

For refrigerated prep tables, certifications guarantee safety and performance. Look for ETL Certification and NSF Listed status, which confirm the unit meets strict food safety standards for materials and cleanability. An ENERGY STAR rating is also crucial, as it signifies lower energy consumption. Modern units with R290 refrigerant can offer up to 40% energy savings, significantly reducing utility costs over time. For efficient options, explore our guide to Top Dukers Pizza Prep Tables to Keep Your Dough Cool and Your Customers Happy.

Choosing the right materials and features isn't about finding the most expensive option - it's about finding the perfect match for your kitchen's specific needs and workflow. The right prep table will serve you faithfully for years, making every service smoother and more efficient.

A Closer Look at Different Types of Prep Tables

When we talk about prep tables, we're not just referring to a single, monolithic piece of equipment. The world of commercial kitchen prep is as diverse as the dishes we create. Different kitchen tasks and workflows call for specialized tables designed to optimize efficiency and maintain food safety. Understanding these distinctions is key to outfitting your kitchen for success.

Refrigerated Sandwich & Salad Tables

For delis and cafes, refrigerated sandwich and salad prep tables are essential. They keep fresh ingredients at safe, consistent temperatures in an accessible workspace. Key features include a refrigerated prep rail that circulates cold air below food pans for uniform cooling. Models from brands like Migali use exclusive airflow systems to direct the coldest air onto pans, ensuring maximum freshness and reducing food waste. These tables also feature a durable poly cutting board, digital controls for precise temperature management, and an insulated roll cover to minimize condensation. Learn more in our guides on the Sandwich Prep Table Refrigerator and Food Tables 101: Digesting the Facts and Figures.

Specialized Pizza Prep Tables

Pizza prep tables are engineered for the unique demands of pizza making. They feature a deep cutting board (16-20 inches) to accommodate large doughs and a raised rail for quick access to toppings. The refrigerated base provides ample storage for bulk ingredients, cheese, and dough. Some tables are up to 119 inches long, offering enough space for multiple orders at once. A dedicated pizza prep table is a necessity for speed and consistency. Explore our Commercial Pizza Prep Table options, learn about The Secret Sauce Behind Efficient Pizza Prep Stations, and check out specific models like the Atosa Pizza Prep Table.

General Work Tables & Equipment Stands

General work tables provide a versatile, sturdy surface for tasks not requiring refrigeration, like chopping vegetables or tenderizing meat. They can also serve as stable equipment stands for heavy mixers or grills. Many include undershelves for convenient storage, helping to maximize your floorplan. We recommend using these tables to create designated workstations, which improves efficiency and reduces cross-contamination. To further organize your kitchen, consider Using prep sheets for kitchen organization. Learn how these tables can transform your workflow in our guide, Table Talk: Restaurant Kitchen Prep Tables Explained.

Refrigerated Chef Bases

Refrigerated chef bases are an ingenious solution for kitchens with limited space. These low-profile prep tables fit directly under countertop cooking equipment and feature integrated refrigerated drawers. This design keeps ingredients like burger patties or chopped vegetables at the cook's fingertips, eliminating trips to a walk-in cooler. This immediate access streamlines cooking, speeds up service, and is ideal for high-volume cook lines. Find out more in our guide on the Refrigerated Chef Base.

Choosing the Right Material and Features

Alright, let's talk about making smart choices! Investing in commercial prep tables isn't just buying another piece of equipment; it's a big decision that really shapes your kitchen's everyday life. We're talking about its durability, how well it supports food safety, its overall functionality, and ultimately, its value as a long-term investment. So, picking the right materials and features is super important to make sure your table works as hard as you do, for many years to come.

Decoding Prep Table Materials

Choosing the right material for your prep table impacts its durability, ease of cleaning, and suitability for specific tasks. Stainless Steel is the top choice for commercial kitchens. When you see T-304 18 Ga stainless steel, you know you're getting top quality with excellent corrosion resistance and an easy cleaning surface. Wood tops are champions for baking, providing an ideal surface for dough kneading. Polyethylene surfaces, often seen as removable poly cutting boards, are fantastic for food safety as they are gentle on knives, easy to sanitize, and simple to replace.

Key Features to Look for in Commercial Prep Tables

Beyond the main material, clever add-ons can make a world of difference in your kitchen. Think of these as the little extras that boost efficiency and safety!

- A backsplash protects walls from splashes, while marine edges contain spills on the tabletop, keeping floors clean and safe.

- Undershelves and enclosed storage cabinets offer invaluable storage for tools and ingredients, keeping your workspace organized.

- Casters for mobility provide flexibility, allowing you to move the table for cleaning or to reconfigure your layout. Look for locking casters for stability.

- Integrated sinks and faucets create a complete wash-and-prep station, saving time and steps in a busy kitchen.

Certifications and Energy Efficiency

When you're investing in a prep table, especially one with refrigeration, you want to make sure it meets high standards for safety and performance. Look for ETL Certification and NSF Listed marks. NSF Listed is especially important; it means the equipment has been tested to meet strict food safety standards, ensuring it's built for easy cleaning and prevents bacterial growth. Beyond safety, consider energy efficiency. An ENERGY STAR rating means the unit meets strict energy-saving guidelines. Many modern refrigerated prep tables now use R290 refrigerant, an eco-friendly coolant that can lead to up to 40% energy savings compared to older models! It’s a win for your wallet and the planet. Want to see some great examples? Check out our guide on the Top Dukers Pizza Prep Tables to Keep Your Dough Cool and Your Customers Happy.

A Closer Look at Different Types of Prep Tables

When we talk about prep tables, we're not just referring to a single, monolithic piece of equipment. The world of commercial kitchen prep is as diverse as the dishes we create. Different kitchen tasks and workflows call for specialized tables designed to optimize efficiency and maintain food safety. Understanding these distinctions is key to outfitting your kitchen for success.

Refrigerated Sandwich & Salad Tables

For delis and cafes, refrigerated sandwich and salad prep tables are essential. They keep fresh ingredients at safe, consistent temperatures in an accessible workspace. Key features include a refrigerated prep rail that circulates cold air below food pans for uniform cooling. Models from brands like Migali use exclusive airflow systems to direct the coldest air onto pans, ensuring maximum freshness and reducing food waste. These tables also feature a durable poly cutting board, digital controls for precise temperature management, and an insulated roll cover to minimize condensation. Learn more in our guides on the Sandwich Prep Table Refrigerator and Food Tables 101: Digesting the Facts and Figures.

Specialized Pizza Prep Tables

Pizza prep tables are engineered for the unique demands of pizza making. They feature a deep cutting board (16-20 inches) to accommodate large doughs and a raised rail for quick access to toppings. The refrigerated base provides ample storage for bulk ingredients, cheese, and dough. Some tables are up to 119 inches long, offering enough space for multiple orders at once. A dedicated pizza prep table is a necessity for speed and consistency. Explore our Commercial Pizza Prep Table options, learn about The Secret Sauce Behind Efficient Pizza Prep Stations, and check out specific models like the Atosa Pizza Prep Table.

General Work Tables & Equipment Stands

General work tables provide a versatile, sturdy surface for tasks not requiring refrigeration, like chopping vegetables or tenderizing meat. They can also serve as stable equipment stands for heavy mixers or grills. Many include undershelves for convenient storage, helping to maximize your floorplan. We recommend using these tables to create designated workstations, which improves efficiency and reduces cross-contamination. To further organize your kitchen, consider Using prep sheets for kitchen organization. Learn how these tables can transform your workflow in our guide, Table Talk: Restaurant Kitchen Prep Tables Explained.

Refrigerated Chef Bases

Refrigerated chef bases are an ingenious solution for kitchens with limited space. These low-profile prep tables fit directly under countertop cooking equipment and feature integrated refrigerated drawers. This design keeps ingredients like burger patties or chopped vegetables at the cook's fingertips, eliminating trips to a walk-in cooler. This immediate access streamlines cooking, speeds up service, and is ideal for high-volume cook lines. Find out more in our guide on the Refrigerated Chef Base.

Choosing the Right Material and Features

Alright, let's talk about building blocks! Investing in commercial prep tables isn't just about picking a surface; it's a big decision that truly shapes your kitchen's future. This is a long-term investment, so choosing the right materials and those clever extra features is absolutely vital.

Decoding Prep Table Materials

The foundation of your prep table – its material – is super important. It dictates how long it lasts and how easy it is to keep spotless. The undisputed champion is Stainless Steel. It's incredibly durable, super hygienic, and resists rust. When you see specs like T-304 18 Ga, that's telling you about its premium quality. Wood tops, while less common for general prep, shine for specific tasks like dough kneading. Finally, poly cutting boards, often integrated into tables, are non-porous, easy to clean, and gentle on knife blades, making them perfect for food safety.

Key Features to Look for in Commercial Prep Tables

Beyond the basic material, certain features can truly lift your prep table's performance and make your kitchen life much easier.

- Backsplashes: These built-in guards protect your walls from splashes and spills, making cleanup much simpler.

- Marine Edges: A marine edge is a raised lip around the tabletop designed to contain liquids, a lifesaver for safety and sanitation!

- Undershelves: Most prep tables come with these handy shelves for storage of pots, pans, or ingredients. Some tables even offer storage cabinets for enclosed storage.

- Casters for Mobility: Wheels make your table mobile, allowing for flexible layouts and easy cleaning under and around the unit.

- Integrated Sinks and Faucets: For ultimate convenience, some prep tables come with a built-in sink, saving precious steps and time.

Certifications and Energy Efficiency

When choosing a prep table, especially a refrigerated one, looking for specific certifications is a smart move. NSF Listed is a big one, meaning the table has been rigorously tested to meet strict standards for public health and safety. For refrigerated models, an ENERGY STAR rating means the unit is designed to be more energy-efficient, which translates directly into lower utility bills. Many modern units use eco-friendly refrigerants like R290, which can offer up to 40% energy savings compared to older units. That's a lot of dough saved over time! To see some great examples, check out our guide on the Top Dukers Pizza Prep Tables to Keep Your Dough Cool and Your Customers Happy.