The Ultimate Guide to Aluminum Pizza Peels

Share

Why Every Pizzeria Needs an Aluminum Pizza Peel

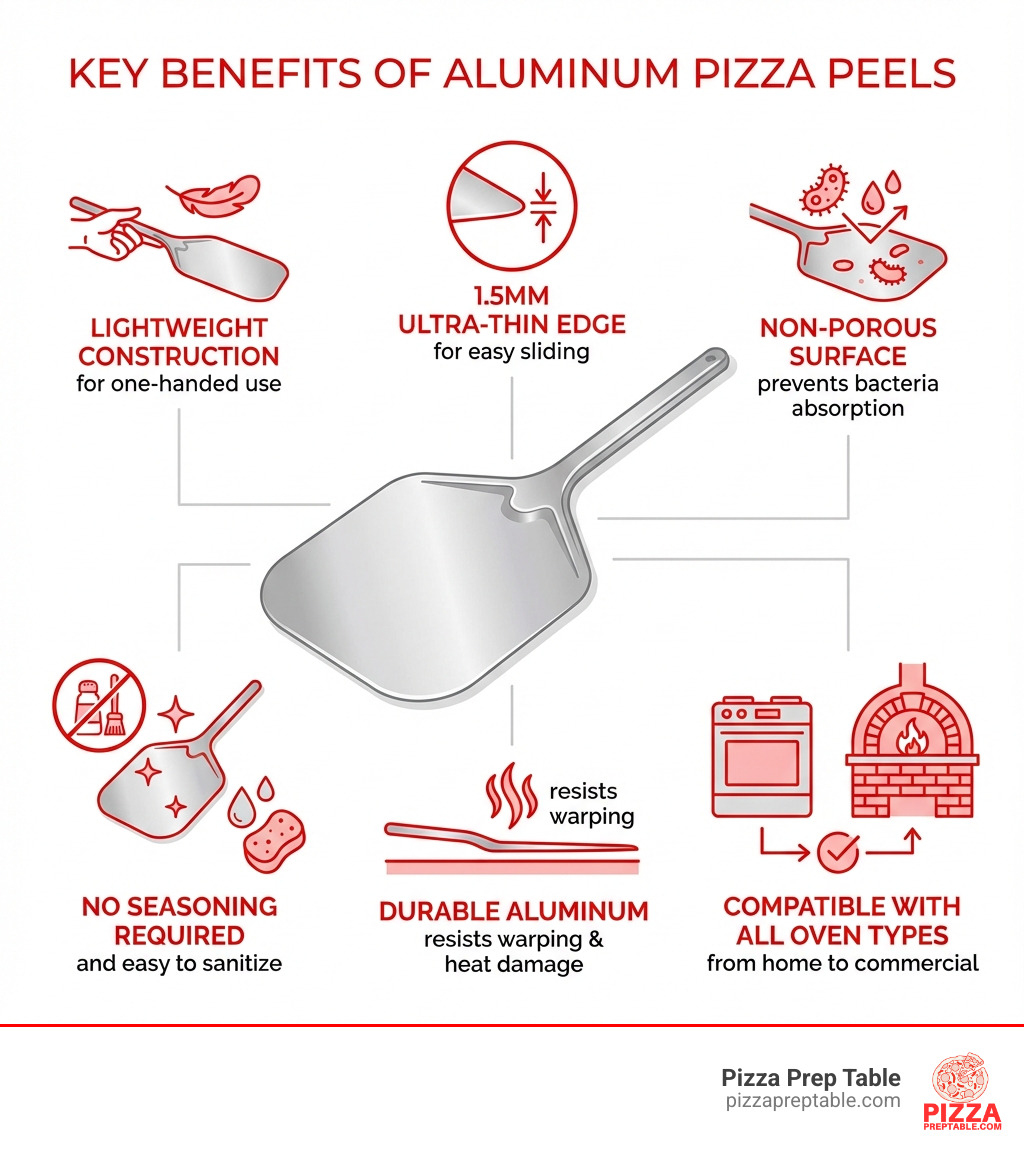

An aluminum pizza peel is the go-to tool for launching, turning, and retrieving pizzas from high-temperature ovens. Here's what you need to know:

Quick Answer: What Makes Aluminum Pizza Peels Stand Out?

- Ultra-thin edge (1.5mm) slides easily under pizza crusts without pushing or tearing dough

- Lightweight design allows one-handed operation and reduces arm fatigue during busy shifts

- Hygienic surface won't absorb bacteria, odors, or food particles like wood can

- No seasoning required and easy to sanitize between uses

- Durable construction resists warping, scratching, and heat damage

- Works in any oven including home ovens, pizza ovens, and grills

If you've ever struggled to get a fresh pizza into a blazing hot oven without it sticking, folding, or sliding off at the wrong angle, you know how critical the right peel is. It's nearly impossible to move fresh pizza dough into a pizza oven without a pizza peel, according to extensive testing by pizza equipment experts.

Wood vs. Aluminum: The Key Difference

Wood peels are traditionally used for launching because dough sticks less to the porous surface. However, aluminum peels excel at turning and retrieving pizzas thanks to their thinner edges that slip under crusts more gracefully. Many professional kitchens use both, but for new pizzeria owners working with limited budgets and space, a quality aluminum peel offers the best versatility for all tasks.

The thin metal construction means aluminum peels don't show signs of wear from stone contact or scratching the way wooden peels do. They're also lighter than wooden peels, making them easier to carry one-handed during long service periods.

I'm Sean Kearney, and I've spent years helping restaurant owners find the right aluminum pizza peels and equipment to maximize their kitchen efficiency. My background in foodservice sales taught me that the right tools make all the difference in profitability and workflow.

Aluminum pizza peel terms at a glance:

Why Choose Aluminum? A Material Showdown

When it comes to outfitting your pizzeria, every tool in your arsenal needs to pull its weight. For pizza peels, the choice of material is paramount, and aluminum consistently rises to the top for many reasons. Let's pit it against other common materials like wood and composite to see why an aluminum pizza peel is often the champion.

Durability: Aluminum is known for its strength. Unlike wood, which can warp, crack, or splinter from heat and moisture, aluminum holds its shape. It resists the singing and scratching that wooden peels suffer from contact with a pizza stone, ensuring a longer lifespan for your investment.

Lightweight: Aluminum peels are significantly lighter than wood, making them easy to carry one-handed. This reduces arm fatigue during busy shifts, allowing pizzaiolos to work more efficiently. Their typical 1.5mm thickness contributes to a feather-light feel, making it effortless to slide them under pies.

Hygiene: Hygiene is critical in a commercial kitchen. Porous wood can absorb moisture and bacteria, requiring careful drying. In contrast, non-porous aluminum is far easier to sanitize, won't absorb odors or food particles, and is often dishwasher safe, making it a more hygienic choice.

Heat Resistance: Aluminum handles the intense heat of a pizza oven like a champ. It won't ignite or char like wood can, providing a reliable tool that withstands the demanding environment of a commercial pizza oven. While it conducts heat, the handle material and length are designed to keep your hands safe, a topic we'll dig into shortly.

Maintenance: Aluminum wins on maintenance. Wooden peels need regular seasoning to prevent splitting and improve non-stick properties. Aluminum peels require no seasoning—just a simple wash with soap and water, saving valuable time and effort in a kitchen.

For a deeper dive into choosing the right tools for your pizza-making journey, check out The Complete Guide to Choosing the Best Pizza Peel.

Here's a quick comparison of the materials:

| Attribute | Aluminum Peel | Wood Peel | Composite Peel |

|---|---|---|---|

| Durability | High, resists warping/charring | Moderate, can warp, crack, splinter | High, but can be grippy |

| Sticking | Low (with flour), can be grippier than wood initially | Very low (with flour), porous surface helps | High (some materials too grippy) |

| Maintenance | Easy to clean, often dishwasher safe, no seasoning | Hand wash, requires seasoning, prone to bacteria | Easy to clean, no seasoning |

| Best Use | Removing, turning, versatile for launching | Launching (traditional choice) | Varies by material, less common for commercial |

| Price | Moderate to High | Moderate to High | High |

Anatomy of the Perfect Aluminum Pizza Peel

Choosing the right aluminum pizza peel isn't just about the material; it's about understanding the nuances of its design. Every feature, from the blade to the handle, plays a critical role in its performance and your team's efficiency.

Blade Size: Blade size must match your pizzas and oven. Pizzerias often need a range of sizes, from 12x14 inches to 20x21 inches for extra-large pies. A versatile 14x16 inch peel, like some from American Metalcraft, is a popular choice. Ensure the peel holds your largest pizza but still fits easily into the oven.

Blade Shape: Most aluminum peels come with either a rectangular (or squared-off) or round blade. Our research indicates that squared-off peels, like the Ooni 14-inch Perforated Pizza Peel, can be easier for stretching and topping pizzas. However, many find round blades perfectly effective, especially smaller turning peels designed for rotating pizzas in tight spaces.

Handle Length: Handle length is crucial for safety with deep commercial ovens, keeping hands away from intense heat. Handles range from 8 inches to over 38 inches, with some peels exceeding 50 inches in total length. Consider your oven's depth when selecting a handle length for your pizzeria in New York City or Los Angeles.

Handle Material: While the blade is aluminum, handles are often wood, plastic, or composite. Wooden handles, particularly rounded ones, tend to be comfortable and provide a sturdy grip. This confidence is essential when moving a heavy pizza from a prep table to a hot oven. Some peels feature detachable wood handles for easy storage.

Weight and Balance: An aluminum pizza peel is inherently lighter than its wooden counterparts. A well-balanced peel feels like an extension of the arm, allowing for fluid, precise movements and reducing strain during a busy shift.

Key Features of an Aluminum Pizza Peel

Beyond the basic anatomy, specific features lift an aluminum pizza peel from good to great.

Blade Thickness (1.5mm): A typical aluminum peel is about 1.5mm thick. This major advantage allows it to slide effortlessly under a pizza without damaging the crust. By contrast, thicker wooden peels (often 10mm+) require more aggressive scooping.

Tapered Edge: A finely tapered or chamfered edge is critical. It allows the peel to glide smoothly beneath the pizza, whether it's raw dough or a cooked pie. Metal peels are ideal for removing pizzas precisely because their thin edges slide under the crust easily.

Handle Comfort: As mentioned, a comfortable handle is key. Rounded wood handles often provide the best grip and feel. We recommend peels with handles that offer a secure, ergonomic grip to ensure better control and less fatigue.

Rivet Construction: For peels with separate handles, the quality of the connection matters. Triple rivets, for example, ensure a strong, durable bond between the handle and blade, preventing wobbling over time.

At Pizza Prep Table, we understand that every detail counts in a busy kitchen. A well-chosen aluminum pizza peel complements an efficient workflow, much like a perfectly designed commercial pizza prep table. For more information on optimizing your kitchen, check out our range of equipment: More info about our pizza prep tables.

Perforated vs. Solid: Which is Right for You?

The debate between perforated and solid aluminum pizza peels is a hot one, and each has its distinct advantages.

Perforated Peels: These peels have holes that reduce friction and allow excess flour to fall away. This prevents flour from burning in the oven, which means less smoke, no bitter taste, and a crispier crust. The holes also improve airflow, helping to prevent a soggy bottom. The Ooni 14-inch Perforated Pizza Peel is a popular example.

Solid Peels: These are the traditional design, offering a continuous, smooth surface. They are generally more robust and can feel more secure when handling very large or heavily topped pizzas. They are also typically easier to clean quickly, as there are no holes for debris to get stuck in.

So, which is right for you? Perforated peels offer an edge in reducing sticking and managing excess flour. However, a solid peel, when properly floured, performs admirably and is often a more budget-friendly option. For an in-depth exploration of this topic, read our article: Holey Grail or Holey Mess? Unpacking the Perforated Pizza Peel.

Mastering Your Peel: Techniques and Maintenance

Having the best aluminum pizza peel is only half the battle; knowing how to use it effectively and maintain it properly is key to perfect pizzas and a long-lasting tool.

Launching Pizza: Launching is easier with an aluminum peel's thin edge. Liberally dust the peel with semolina flour to create a non-stick barrier. After stretching your dough, transfer it to the peel, top it quickly, and use a confident motion to slide it onto your hot pizza stone. Minimize the time raw dough sits on the peel.

Turning Pizza: Once your pizza is in the oven, an aluminum peel's thinness and lightweight nature make it ideal for rotating the pie for an even bake. A smaller, circular turning peel is especially useful for this, allowing you to easily get under the cooking crust and rotate it as needed.

Retrieving Pizza: When your pizza is golden brown and bubbling, the thin edge of the aluminum peel is your best friend. Slide it under the cooked pizza with minimal effort, scoop it up, and transfer it safely to a cutting board.

Oven Compatibility (Home, Pizza Oven, Grill): One of the great advantages of an aluminum pizza peel is its versatility. It can be used in virtually any type of oven.

- Home Ovens: Suitable for launching and retrieving pizzas from a standard home oven with a pizza stone or steel.

- Dedicated Pizza Ovens: Whether it's a wood-fired brick oven in your Dallas pizzeria or a high-temperature outdoor pizza oven, aluminum peels are built to perform in extreme heat.

- Grills: An aluminum peel is indispensable for managing pies over the direct heat of a grill.

Best Practices for Use

To ensure your pizzas launch smoothly every time, follow these best practices:

- Semolina Flour: This is your secret weapon. Dust your aluminum pizza peel generously with semolina flour. Its coarse texture acts like tiny ball bearings, helping the dough slide off.

- Cornmeal: If semolina isn't available, cornmeal is a decent substitute.

- The "Jiggle" Test: Before launching, give the peel a gentle shake. If the pizza slides freely, you're good to go. If it sticks, lift the edge of the dough and sprinkle a little more semolina underneath.

- Work Quickly: Once the dough is on the peel and topped, don't let it sit for too long. The longer it sits, the more likely it is to absorb moisture and stick.

For more detailed strategies to avoid sticky situations, dive into Pizza Peel Perfection: Expert Tips to Prevent Dough from Sticking.

Care and Longevity

Proper care ensures your aluminum pizza peel remains a reliable tool for years to come.

- Hand Washing: We recommend hand washing with warm, soapy water and a soft sponge to protect the finish and any wooden components.

- Avoiding Dishwasher: Peels with wooden handles are not dishwasher safe, as high heat and detergents can cause the wood to warp or crack.

- Proper Storage: Hang your peel in a dry place to prevent warping or damage to the blade. Wall-mounted racks are an efficient storage solution for commercial kitchens.

- Not for Cutting: Never cut pizza directly on the peel. This will scratch the surface, creating grooves where dough can stick. Always transfer the pizza to a cutting board first.

Finding the Right Peel: Features and Price Points

Navigating the market for an aluminum pizza peel can feel overwhelming. Knowing what to look for and understanding how price points are determined will help you make the best choice for your pizzeria.

What to Look for in a Top-Rated Aluminum Pizza Peel

When evaluating aluminum peels, we look for factors that ensure performance and durability:

- Anodized Aluminum: Anodizing is an electrochemical process that creates a harder, more durable, and corrosion-resistant finish. An anodized aluminum pizza peel is less likely to scratch or stain, making it a professional-grade choice.

- Glass-Reinforced Nylon Handles: While wood handles are comfortable, some modern peels feature glass-reinforced nylon handles. These offer excellent heat resistance, durability, and an ergonomic grip.

- Detachable Handles: For pizzerias with limited storage space, peels with detachable handles are a game-changer, offering compact storage without sacrificing reach.

- Blade Shape (Square vs. Round): As discussed, square blades offer more surface area for prep, while round blades are excellent for turning and retrieving, especially in smaller ovens. Many professional kitchens use both.

LIST of Top Features in Premium Peels:

- Thin, tapered blade edge (around 1mm)

- Lightweight yet rigid construction

- Comfortable, heat-resistant handle (wood or reinforced nylon)

- Strong, secure handle-to-blade connection (e.g., triple rivets)

- Appropriate blade size for your pizza dimensions

- Perforated design for reduced sticking and flour management (optional but beneficial)

- Anodized finish for improved durability and hygiene

Some top-rated models that stand out include the American Metalcraft Aluminum Pizza Peel and the Ooni 14-inch Perforated Pizza Peel. These brands are well-regarded for their quality and performance in commercial settings from San Francisco to Atlanta.

Understanding the Cost

The price of an aluminum pizza peel can range from around $8 to over $250. Key cost factors include:

- Material Quality: High-grade and anodized aluminum costs more.

- Size: Larger peels require more material and are more expensive.

- Perforations: The manufacturing process for perforated peels can increase the cost.

- Handle Design: Premium materials, ergonomic shapes, and detachable features add to the price.

- Brand Reputation: Established brands known for quality often have higher prices.

While it might be tempting to opt for the cheapest option, investing in a high-quality aluminum pizza peel can save money in the long run by reducing replacement costs and improving kitchen efficiency.

Frequently Asked Questions about Aluminum Peels

We often hear similar questions from pizzeria owners and home chefs alike. Let's clear up some common curiosities about aluminum pizza peels.

Is wood or aluminum better for a pizza peel?

Each material excels at different tasks.

- Wood for Launching: Traditionalists prefer wood for launching raw dough, as its porous surface is less sticky when floured.

- Aluminum for Turning/Retrieving: Aluminum's thin, lightweight design is superior for turning pizzas in the oven and retrieving cooked pies without damaging the crust.

- The Verdict: It's a matter of preference. Many professional kitchens in cities like Las Vegas or Houston use a two-peel system: a wooden peel for launching and an aluminum one for turning and retrieving.

How do you keep pizza from sticking to an aluminum peel?

Proper preparation and speed are key to preventing sticking on an aluminum pizza peel.

- Use Semolina Flour: Generously dust the peel with coarse semolina flour (or cornmeal) to create a non-stick barrier.

- Work Quickly: Don't let a topped pizza sit on the peel for long. The longer it sits, the more likely it is to stick.

- The Jiggle Test: Before launching, give the peel a gentle shake. If the pizza slides freely, you're ready. If not, lift the dough's edge and add more flour underneath.

Can you cut pizza on an aluminum pizza peel?

No, we strongly advise against it. Cutting on the peel will scratch the aluminum surface. These scratches create grooves where dough can stick in the future. To protect your peel and maintain its smooth surface, always transfer the pizza to a dedicated cutting board before slicing.

The Final Slice: Is an Aluminum Peel Your Perfect Match?

After exploring the many facets of the aluminum pizza peel, it's clear why this tool is a staple in professional kitchens, from the busy pizzerias of New York City to the vibrant food scenes in Austin.

The advantages of an aluminum pizza peel are compelling:

- Durability: Built to withstand high-temperature ovens and the demands of a busy kitchen.

- Performance: Its thin, tapered edge allows for effortless launching, precise turning, and smooth retrieval.

- Versatility: Effective in home ovens, dedicated pizza ovens, and on grills.

- Hygiene and Maintenance: Easy to clean, resistant to bacteria, and requires no seasoning.

- Lightweight Design: Reduces user fatigue, allowing your team to maintain peak performance.

Whether you're opening a new pizzeria in Charlotte or upgrading your equipment in San Antonio, an aluminum pizza peel is an indispensable investment. Its robust construction and ergonomic design lead to a smoother and more successful pizza-making experience.

At Pizza Prep Table, we're dedicated to supplying commercial pizzerias with the high-quality equipment they need to thrive. A great aluminum pizza peel complements our wide selection of commercial pizza prep tables and other restaurant essentials designed to optimize your workflow and deliver perfect pies every time.