The Complete Guide to Choosing the Best Pizza Peel

Share

Why Every Pizza Kitchen Needs the Right Pizza Peel

A pizza peel is a flat, shovel-like tool used to transfer pizzas into and out of ovens. For background on the tool's history and design, see Peel (tool)). Here's what you need to know:

Primary Functions:

- Launching - Sliding raw pizza dough into the oven

- Turning - Rotating pizzas during cooking for even baking

- Retrieving - Removing finished pizzas from hot ovens

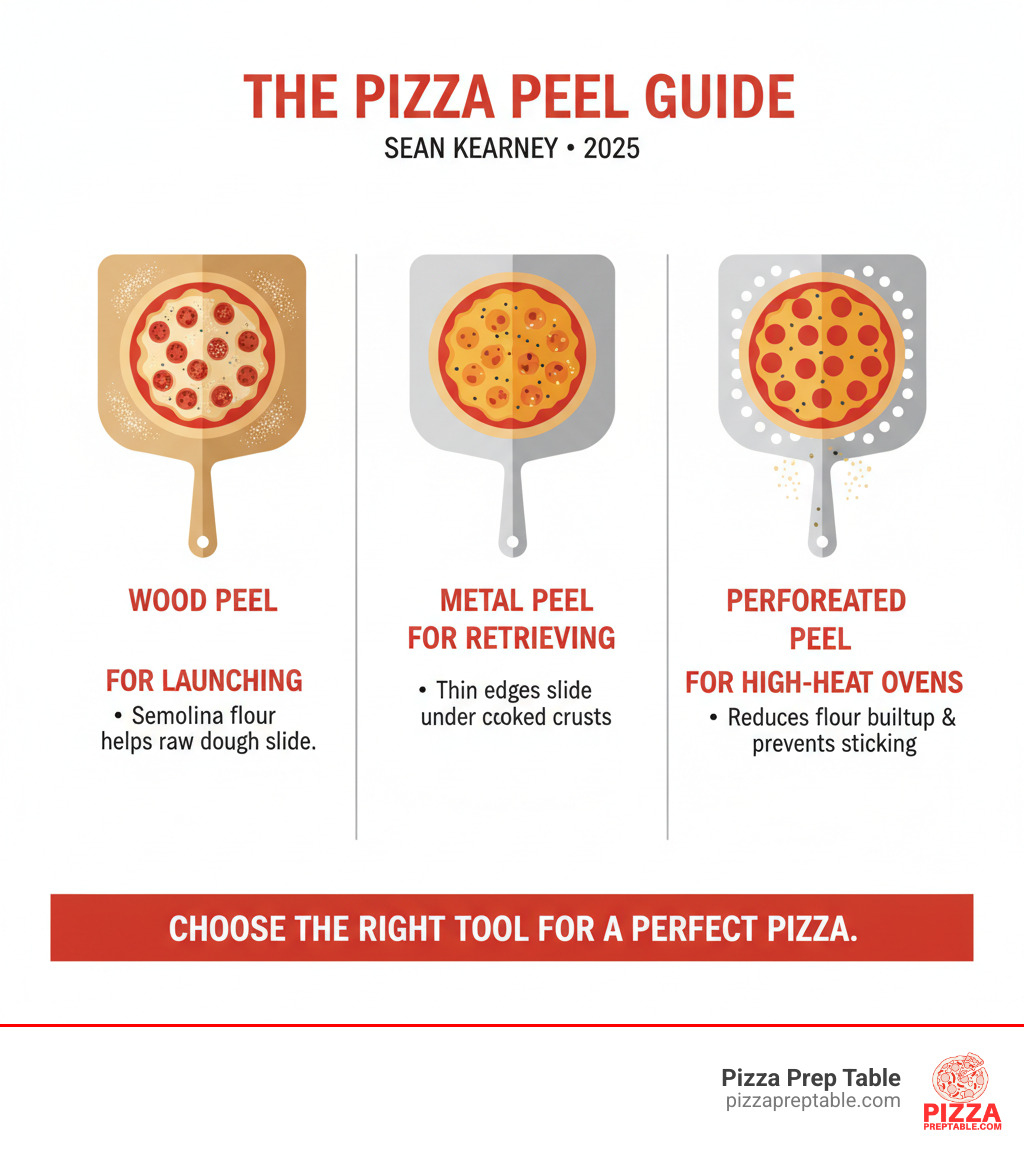

Main Types:

- Wood peels - Best for building and launching pizzas (dough sticks less)

- Metal peels - Ideal for turning and retrieving (thinner edges slide under crusts easily)

- Perforated peels - Reduce flour buildup and prevent sticking

As one pizza equipment expert puts it: "It's nearly impossible to move fresh pizza dough into a pizza oven—or even a home oven—without a pizza peel."

For pizzeria owners, choosing the right peel affects your kitchen's efficiency, food safety, and pizza quality. The wrong peel can lead to stuck dough, damaged pizzas, and burned hands. The right one makes launching perfect pies look effortless.

Different materials serve different purposes. Wooden peels work great for prep work because raw dough sticks less to their dry surface when dusted with flour. Metal peels excel at retrieval since their thin edges (around 1.5mm thick) slide under cooked crusts without pushing the pizza around.

I'm Sean Kearney, and my experience in restaurant equipment sales has shown me how the right pizza peel can transform a kitchen's workflow and pizza quality. After helping countless pizzeria owners choose equipment that maximizes their productivity, I'll guide you through everything you need to know about selecting the perfect peel for your operation.

Understanding the Different Types of Pizza Peels

Choosing the right pizza peel is like picking the perfect tool for any job – it makes all the difference in your results. After years of helping pizzeria owners select equipment, I've seen how the wrong peel can turn pizza making into a frustrating battle, while the right one makes it look effortless.

Let me walk you through the main types of pizza peels and what makes each one special.

Wood Pizza Peels

There's something magical about a wooden pizza peel. Maybe it's the way it connects you to centuries of pizza-making tradition, or how it feels perfectly balanced in your hands. But beyond the romance, wood peels have some serious practical advantages.

Wood peels excel at building and launching pizzas. Raw dough naturally sticks less to wood than metal, especially when you dust the surface with flour or semolina. The porous wood surface absorbs moisture from the dough, creating a natural non-stick barrier that makes launching smooth and confident.

The Baker's Board Pizza Peel perfectly demonstrates these qualities. Made from lightweight basswood, it gives you a stable workspace for stretching dough and adding toppings, then launches your creation with minimal fuss.

Different wood types offer unique benefits. Basswood stays light and easy to maneuver. Acacia brings durability and stunning grain patterns that look great if you're using the peel for serving. Pine offers an affordable entry point for home pizza makers, though it won't last as long as harder woods.

But wood peels aren't perfect. They're thicker than metal peels – usually around 10 millimeters – which means you need a more confident scooping motion when retrieving pizzas. They also require more care to prevent warping and can be trickier to keep spotlessly clean in commercial settings.

Metal Pizza Peels

If wood peels are the gentle giants of pizza making, metal peels are the precision instruments. Aluminum and stainless steel peels dominate professional kitchens for good reason.

The thin profile is their superpower. At just 1.5 millimeters thick, metal peels slide under cooked pizzas like a hot knife through butter. The American Metalcraft Aluminum Pizza Peel showcases this perfectly – its razor-thin edge retrieves pizzas without disturbing toppings or pushing the pie around your oven.

Aluminum peels are incredibly lightweight, reducing friction and making quick movements effortless. They're also nearly indestructible and easy to sanitize – crucial advantages in busy commercial kitchens.

The trade-off? Raw dough sticks more to metal surfaces. You'll need to be generous with your semolina dusting and work quickly to prevent sticking. Metal also conducts heat, so these peels can get uncomfortably hot during extended oven work.

Perforated Pizza Peels

Here's where modern engineering meets traditional pizza making. Perforated pizza peels solve one of the biggest problems in pizza kitchens: excess flour burning in your oven.

Those little holes are game-changers. As you move your pizza, excess flour and semolina fall through the perforations instead of sliding into your oven. This keeps your oven cleaner, prevents bitter smoke from burnt flour, and gives you better-tasting crusts.

The reduced surface contact also creates less friction, making launches and retrievals smoother. Plus, removing material makes the peel lighter – a blessing when you're working with larger pizzas or during busy dinner rushes.

The Ooni 14-inch Perforated Pizza Peel demonstrates these benefits beautifully, with slightly raised sides that add stability while the perforations do their magic.

Perforated peels shine in high-heat ovens where flour burns quickly. If you're running wood-fired or high-temperature deck ovens, the flour-shedding ability becomes essential for consistent results.

Composite & Other Materials

Innovation never stops in the pizza world, and that includes pizza peel materials. Composite materials like Richlite offer interesting alternatives to traditional wood and metal.

Epicurean peels made from paper composite promise durability and easy cleaning – some are even dishwasher safe. That's a huge advantage for busy commercial operations where every minute counts.

But here's the reality check: performance varies significantly with composite materials. Some have heavily textured surfaces that grip dough too aggressively, making launches challenging. While they're durable and low-maintenance, they don't always deliver the smooth pizza-handling experience you get with quality wood or metal peels.

The key is understanding that each material serves different needs. Your choice depends on your kitchen's volume, your oven type, and whether you prioritize ease of use or ease of cleaning.

For more insights on selecting the right equipment for your pizza operation, check out our comprehensive guide on commercial kitchen equipment.

Key Features to Consider When Choosing Your Pizza Peel

Picking the perfect pizza peel goes way beyond just choosing wood or metal. The devil's in the details, and getting these key features right can mean the difference between pizza perfection and a frustrating kitchen disaster.

Peel Size and Shape

Getting the size right is absolutely crucial for your pizza peel. Too small, and you'll be wrestling with dough hanging over the edges. Too big, and you'll be playing bumper cars with your oven walls.

Blade size is where most people start, and for good reason. The most common sizes are 12-inch, 14-inch, and 16-inch peels. Your choice should match both your pizza ambitions and your oven's reality.

Think about the pizza size you typically make. Your peel needs to be slightly larger than your biggest pie to give you a comfortable margin for error. Nothing's worse than having your perfectly crafted pizza hanging off the edges when you're trying to slide it into a blazing hot oven.

Oven size matters just as much, if not more. For outdoor pizza ovens, we always recommend a peel that's slightly smaller than the oven opening itself. Picture this: if your oven opening is 12 inches, go with a 10- or 11-inch peel. Trust me, you'll thank yourself when you're not scraping the sides trying to maneuver your masterpiece. Even with regular home ovens, measure that interior space first. I've seen too many beautiful pies get stuck because someone got overly ambitious with peel size.

For more guidance on matching equipment dimensions to your space, check out our guide on how to choose the right pizza prep table dimensions for your kitchen.

Shape might seem like a small detail, but it can make a real difference in your workflow. Square peels tend to be fan favorites because they give you more surface area for prep work. Those extra corners make it easier to stretch your dough into that perfect circle and provide more room for arranging toppings. The Ooni 14-inch Perforated Pizza Peel is a great example of this square design philosophy.

Round or semi-circle peels certainly have their place, but many pizza makers find them a bit limiting when it comes to the initial prep work. They're perfectly functional, just not quite as accommodating for the creative process.

Handle Length and Comfort

The handle of your pizza peel isn't just something to hold onto – it's your lifeline to safety and control. Get this wrong, and you'll know it immediately.

Short handles under 12 inches work beautifully for home ovens and compact kitchens. They give you precise control and won't take up half your storage space. But if you're working with anything hotter than a standard home oven, you'll want more distance between your hands and that heat.

Long handles are where things get serious. For professional electric ovens, you're looking at around 24 inches. But when you step into outdoor pizza ovens that can hit 900°F, those handles stretch out to 4-6.5 feet. At those temperatures, a long handle isn't just convenient – it's the difference between perfect pizza and a trip to the emergency room.

Handle material affects both comfort and durability. Wood handles feel natural and comfortable in your hands, while metal handles last longer and clean up easier. There's no wrong choice here, just different priorities.

Here's something that doesn't get talked about enough: handle shape matters more than you'd think. Rounded handles are generally much more comfortable than flat, blocky ones. I've seen lightweight peels feel heavy and awkward simply because the handle wasn't designed with human hands in mind. Your grip and control suffer when you're fighting an uncomfortable handle, especially when you're carrying a fully loaded pizza.

Launching Peel vs. Turning Peel

Once you start getting serious about pizza making, especially with high-temperature ovens, you'll find that one pizza peel might not be enough. Professional pizzaiolos often work with what I like to call a "peel arsenal."

Your large launching peel is the star of the show. This is your main pizza peel with that broad, flat surface perfect for building your pizza and sliding it smoothly into the oven. Most of what we've discussed so far applies to launching peels.

But then there's the small turning peel – a game-changer for serious pizza makers. This compact tool, often circular or semi-circular, comes with a much longer handle and serves one primary purpose: rotating pizza quickly and precisely inside a scorching hot oven.

When your oven cooks pizzas in 60-90 seconds, you need to move fast and accurately. The smaller head of a turning peel lets you access tight spaces and rotate your pizza without disturbing the entire pie. A tool like the Ooni Pizza Turning Peel shows just how compact and maneuverable these tools can be.

For home pizza makers, a quality all-purpose peel might cover all your needs. But if you're running a pizzeria or you're passionate about authentic high-heat pizza making, having both a launching and turning peel will lift your pizza game significantly.

How to Use and Maintain Your Pizza Peel

Your pizza peel is like a trusty sidekick in your pizza-making journey. But even the best sidekick needs to be used properly and cared for to perform at its peak. Let's explore the essential techniques and maintenance tips that will keep your peel working smoothly for years to come.

How to Prevent Pizza from Sticking to the Peel

Nothing ruins a perfect pizza quite like having it stick stubbornly to your pizza peel when you're trying to launch it into the oven. Trust me, we've all been there – watching helplessly as our beautiful creation refuses to budge, or worse, slides off in a sad, crumpled heap.

The secret weapon in your anti-stick arsenal is semolina flour. This coarse, granular flour acts like tiny ball bearings under your dough, creating a smooth runway for launch. Sprinkle it generously across your peel's surface using a fine mesh strainer for even coverage. If you don't have semolina on hand, cornmeal works as a decent backup, though it will add a slightly different texture to your crust bottom.

Once your pizza is assembled, give it the "shake test" – a gentle wiggle to make sure it slides freely on the peel. If it doesn't move easily, lift the edges of the dough and dust a bit more semolina underneath. The key here is working quickly. Dough is a living thing that absorbs moisture from both the flour and your toppings, so the longer it sits, the more likely it is to stick.

Pay attention to moisture levels too. Overly wet dough or soggy toppings are your enemy. If you're using fresh mozzarella or juicy vegetables, consider draining them slightly or adding them at the last minute before launching.

You might wonder about using parchment paper as a foolproof solution. While it seems logical, we strongly advise against it for pizza making. Most parchment paper has a temperature threshold of around 450°F, but pizzas are typically cooked at 500°F to 550°F, and outdoor ovens can reach much higher. At these temperatures, parchment paper becomes a combustion risk, potentially catching fire or burning under your crust and creating unpleasant flavors.

Cleaning and Maintaining Your Pizza Peel

Taking care of your pizza peel isn't complicated, but doing it right will extend its life dramatically and keep it performing like new.

Hand washing is the golden rule for almost all pizza peels, especially wooden ones. Use warm, soapy water with a soft cloth or sponge – nothing abrasive that could scratch the surface. After washing, rinse thoroughly and dry immediately with a towel. For commercial kitchens, metal peels should get a final dip in sanitizing solution to meet food safety guidelines for restaurants.

Wooden peels need special attention. Never let them soak in water – this is the fastest way to cause warping and cracking. If your peel does warp despite your best efforts, try leaving it overnight with the convex side facing up, which sometimes helps it flatten back out.

Oiling wood peels periodically works wonders, just like seasoning a cast iron pan or caring for a cutting board. Use food-safe mineral oil or board cream to prevent drying, cracking, and splitting. This seasoning process also improves the peel's natural non-stick properties over time.

Metal peels are generally easier to maintain. While some might be dishwasher safe, always check the manufacturer's instructions first. Hand washing is usually safer and helps preserve the peel's lifespan, especially if it has a wooden handle.

Common Mistakes to Avoid

Even experienced pizza makers can fall into these traps, so let's help you avoid the most common pitfalls.

Cutting pizza directly on your launching peel might seem convenient, but it's a mistake that will haunt you later. Each cut creates grooves and scratches that make the surface grippier over time, leading to more sticking problems. If you want to serve pizza on a peel, use a separate serving board or transfer your finished pizza to a cutting board first.

Letting dough sit too long on the peel is another common error. Dough absorbs moisture continuously, so have your oven preheated and your launch strategy ready before you start building your pizza.

While flour and semolina are essential, using too much can backfire. Excessive flour burns in high-heat ovens, creating smoke and bitter flavors that can ruin your carefully crafted pizza. Aim for an even, light dusting rather than a thick coating.

The launching technique itself trips up many people. Don't push the pizza into the oven like you're shoving it through a door. Instead, use a confident, swift shimmy motion – forward and back – to slide the pizza smoothly off the peel onto your baking surface. It takes practice, but once you get the rhythm, it becomes second nature.

Finally, avoid the temptation to use parchment paper in high-heat ovens. As we discussed earlier, this creates safety hazards and can negatively impact your crust quality. Stick with the tried-and-true flour dusting method for the best results.

Frequently Asked Questions about Pizza Peels

After years of helping pizzeria owners choose the right equipment, I've noticed the same questions about pizza peels come up again and again. Whether you're opening your first restaurant or upgrading your current setup, these are the answers that matter most.

Is a wood or metal pizza peel better?

Here's the truth: asking whether wood or metal is better is like asking whether a screwdriver or hammer is better. They're both tools, but they excel at different jobs.

Wood shines for prep and launching. When you're building a pizza and getting ready to slide it into the oven, wood is your friend. The dry, slightly porous surface grabs less onto raw dough, especially when you dust it with semolina flour. This means fewer disasters where your beautiful pizza gets stuck halfway off the peel.

Metal wins for retrieval and turning. Once your pizza is cooked, you want something thin that can slip under that crispy crust without pushing the whole pie around. Metal peels are typically around 1.5mm thick - much thinner than wood - making them perfect for this job. They're also more durable when repeatedly exposed to high oven temperatures.

Walk into any busy pizzeria in New York or San Francisco, and you'll likely see both types in action. The pros use wooden peels for launching and metal ones for everything else. It's not about preference - it's about using the right tool for each task.

For home cooks working with just one peel, think about what matters most to you. If you struggle with dough sticking during launch, go wood. If retrieving cooked pizzas feels clumsy, choose metal.

What size pizza peel do you need?

Getting the size wrong is one of the fastest ways to turn pizza night into a frustrating experience. I've seen too many people try to wrestle oversized peels into small ovens or attempt to launch large pizzas with tiny peels.

Start with your oven opening. Your pizza peel needs to fit comfortably through your oven door with room to maneuver. For most home ovens, a 12-inch or 14-inch peel works perfectly. If you're using an outdoor pizza oven with a smaller opening, measure first. A peel that's 1-2 inches smaller than your oven opening gives you the control you need.

Match your pizza size. Your peel should be at least as wide as your largest pizza, preferably a bit bigger. Making 10-inch pizzas? A 12-inch peel gives you breathing room. Planning 14-inch pies? You'll want at least a 14-inch peel, though 16-inch provides more security.

Don't forget the handle length. This is where safety meets practicality. Standard home ovens work fine with shorter handles, but if you're working with a 900°F outdoor oven, you want that extra distance between your hands and the heat. Just remember that a 4-foot handle in a small kitchen becomes a weapon waiting to knock something over.

For guidance on sizing kitchen equipment properly, check out our detailed guide on how to choose the right pizza prep table dimensions for your kitchen.

Can a pizza peel be used for serving?

Absolutely! In fact, some of the most beautiful pizza peels are designed specifically for this dual purpose. Acacia wood peels, in particular, make stunning serving boards that add rustic charm to any table presentation.

The key is understanding which peels work best for serving. Wood peels with attractive grain patterns make natural serving boards, while metal peels, though functional, don't have quite the same visual appeal for tableside presentation.

Here's the important part: if you plan to serve on your launching peel, resist the urge to cut the pizza directly on it. Those knife marks and scratches might look rustic, but they create grooves where dough will stick during your next launch. You'll end up with a beautiful serving board that's frustrating to use for its primary job.

The smart approach? If serving presentation matters to you, consider having a dedicated serving peel separate from your launching peel. This way, you can cut freely on your serving board without compromising the smooth surface you need for launching pizzas successfully.

Many restaurants use this dual-purpose approach effectively, presenting pizzas on attractive wooden peels that double as serving boards, then transferring slices to plates. It's a simple touch that lifts the dining experience without requiring additional equipment investment.

Conclusion: Finding the Perfect Peel for Your Kitchen

After working with countless pizzeria owners from busy New York kitchens to cozy California family restaurants, I've seen how the right pizza peel can transform both the cooking process and the final product. It's not just about having a tool to move pizza around—it's about finding the perfect partner for your specific kitchen needs.

The journey through different pizza peel materials shows us that there's no single "best" option. Wood peels shine when you're building and launching pizzas, thanks to their natural non-stick properties with raw dough. Metal peels become your best friend for retrieval and turning, with their thin edges sliding effortlessly under crispy crusts. Perforated peels offer that modern touch, keeping your oven cleaner by shedding excess flour before it can burn.

Size considerations matter more than many realize. I've watched too many beautiful pizzas get mangled because someone tried to force an oversized peel into a compact oven opening. Your peel should be slightly smaller than your oven's mouth but large enough to handle your biggest pizza comfortably. Handle length isn't just about convenience—it's about safety, especially when you're working with those scorching outdoor ovens that can hit 900°F.

For home use, a quality wooden or metal peel can handle most tasks admirably. But commercial operations often benefit from having both a launching peel and a smaller turning peel. This dual approach lets you optimize each step of the pizza-making process.

The maintenance side can't be overlooked either. A well-cared-for pizza peel will serve you faithfully for years, while a neglected one becomes a source of frustration with stuck dough and warped surfaces. Remember to dust with semolina, work quickly, and never cut directly on your launching peel.

At Pizza Prep Table, we've built our reputation on understanding that every piece of equipment in your kitchen plays a role in your success. Whether you're just starting out with a small neighborhood spot or expanding an established pizzeria, having the right tools makes all the difference. From our specialized commercial pizza prep tables to the finishing touches that make perfect pies possible, we're here to support your culinary vision.

Ready to complete your pizza-making setup? Explore essential commercial pizza oven supplies for perfect pies and find how Pizza Prep Table can help you create the kitchen of your dreams.