Choosing the Right Back bar Refrigerator for Your Pizzeria

Share

At its core, a back bar refrigerator is simply a compact, commercial-grade fridge designed for quick access to ingredients. But for a smart pizzeria, it’s a strategic weapon. When you place one right in the prep line, it becomes the holding station for perfectly chilled toppings, sauces, and dough—exactly where your team needs them. This one simple move can completely transform your pizza prep table's speed and efficiency.

The Secret Ingredient to a Faster Pizza Prep Table

Picture your craziest Friday night. The ticket machine is spitting out orders, and your pizza makers are a blur of flying flour and cheese. The secret to keeping that line moving isn't just a hotter oven; it's a flawlessly organized pizza prep table. This is where a back bar refrigerator becomes the unsung hero of your pizzeria, the real secret ingredient for speed and consistency.

Think of it as the pit crew station for your pizza chef. Instead of taking those extra steps back and forth to a massive walk-in cooler, every single essential pizza ingredient is stored just inches away from the action. Integrating cold storage directly into your pizza prep workflow isn't just a minor tweak—it's a fundamental shift in how you design an efficient pizzeria.

Minimizing Steps, Maximizing Output

In any high-volume pizzeria, wasted motion is wasted money. Every single step a cook takes away from the pizza prep table to grab cheese, pepperoni, or sauce adds precious seconds to each order. Over a busy dinner rush, those seconds pile up into minutes, slowing down your entire operation.

A well-placed back bar refrigerator completely eliminates this problem. By keeping high-use ingredients within arm's reach of the pizza prep table, you create a streamlined, ergonomic workstation where your team can build pizzas faster and with fewer mistakes. Not only does this crank up your kitchen's output, but it also reduces the physical strain on your staff.

The core benefit is simple: a more efficient workflow directly translates to higher profitability. When you can produce more pizzas per hour without sacrificing quality, you serve more customers and increase revenue.

The Power of Proximity

When you pair a back bar refrigerator with a pizza prep table, you create a powerful, self-contained "pizza zone." This setup guarantees that all your temperature-sensitive ingredients are held at optimal, food-safe temperatures right up until the moment they hit the dough. That proximity is critical for both speed and quality.

Just look at the key benefits of this integrated approach:

- Improved Food Safety: Toppings like meats and cheeses are kept at consistent, cold temperatures, slashing the risk of spoilage and keeping you in line with health codes.

- Enhanced Ingredient Freshness: Storing ingredients in a dedicated, nearby unit prevents them from sitting out at room temperature for too long, which preserves their flavor and texture.

- Reduced Order Errors: With everything organized and in plain sight, chefs can quickly grab the right toppings, leading to fewer mistakes and less food waste.

At the end of the day, this piece of equipment is so much more than just a cold box. It's a core strategic asset that directly fuels your pizzeria's speed, efficiency, and success. By rethinking its role, you can turn a simple appliance into a powerful tool for growth.

Finding the Perfect Fit for Your Pizzeria's Layout

Choosing the right back bar refrigerator isn't just about picking a size; it's a strategic decision that shapes your entire kitchen's rhythm. When every square foot counts, especially around your pizza prep table, the cooler you choose can either become a seamless part of your workflow or a constant, frustrating obstacle.

Let's walk through the two biggest decisions you'll make—door style and overall size. Think of this as creating a mental blueprint for your pizzeria, because each choice solves a specific real-world problem you face every day at the pizza prep table.

Door Styles: The Gateway to Your Ingredients

The doors on your back bar cooler are more than just an entry point. They dictate how your team interacts with the unit during the middle of a chaotic dinner rush, and picking the right style can dramatically improve your kitchen's flow.

-

Glass Doors for Quick Inventory: In a high-volume pizzeria, glass doors are a game-changer. Your chef can see in a split second if the pepperoni, mozzarella, or mushroom bins are getting low without ever opening the door. This saves precious seconds, keeps the cold air in, and is absolutely perfect for the fast-paced pizza line.

-

Solid Doors for Superior Insulation: If your back bar cooler is going to live right next to a heat source like a pizza oven, solid doors are a must. They offer much better insulation, fighting off the ambient heat to keep the inside consistently cold. This reduces the strain on the compressor, saves energy, and protects your ingredients from dangerous temperature swings.

-

Sliding Doors for Tight Spaces: Think of these as the pocket doors of commercial refrigeration. In a narrow aisle or a cramped pizza prep area where a swinging door would just get in everyone's way, sliding doors are the ultimate space-saver. Staff can zip past the unit even when the doors are open—a critical advantage in a tight kitchen.

Sizing Your Unit for Maximum Impact

Once you’ve nailed down the door style, the next big piece of the puzzle is size. This decision hinges on your sales volume, the variety of toppings you carry, and the physical footprint you have to work with. You're looking for that sweet spot between having enough cold storage for your pizza prep table and not tripping over a massive piece of equipment.

A proper fit is crucial for a smooth workflow. You can get a much deeper understanding of how equipment placement impacts your team's productivity by checking out our complete guide to commercial kitchen layout and design.

It's no surprise that these units are becoming more common. The global back bar cooler market is projected to be valued at around $1.5 billion in 2025 and is expected to hit $2.3 billion by 2033. That's steady growth, proving just how essential they've become in modern kitchens.

A well-sized back bar refrigerator should feel like a natural extension of your pizza prep table, not a bulky afterthought. The goal is to maximize cold storage without disrupting the ergonomic flow of your workspace.

Let’s look at a couple of common pizzeria scenarios:

-

The Compact Workstation: For smaller shops or as a secondary cooler for specialty toppings, a single-door or two-door under-counter model (24 to 48 inches wide) is perfect. It slides right under a standard pizza prep table, creating a clean, unified station for one or two pizza makers.

-

The High-Volume Hub: Got a constant stream of orders? A three-door back bar refrigerator, often 60 to 90 inches wide, acts as your prep line's command center. This workhorse holds bulk quantities of your most popular pizza ingredients, cutting down on those time-wasting trips to the walk-in cooler during peak hours.

By carefully thinking through both the door type and the unit's size, you can land on a back bar refrigerator that doesn't just fit your space—it actually improves the entire rhythm of your pizzeria.

Essential Features for a High-Volume Pizza Workflow

Once you've nailed down the right size and door style, it's time to dig into the details that separate a basic cooler from a true workhorse. In a pizzeria, your back bar refrigerator isn't just for show; it’s a critical part of your production line, especially when parked next to a busy pizza prep table. These are the features that make all the difference during a chaotic dinner rush.

Think of this as your buyer's checklist. We’re looking past the shiny stainless steel exterior to see how the guts of the machine will hold up under pressure. Features that look minor on a spec sheet can be absolute game-changers in a high-volume pizza kitchen.

Absolute Precision in Temperature Control

Let’s be clear: consistent temperature is non-negotiable in a pizzeria. You're storing high-risk, high-cost ingredients like cheese, pepperoni, and sausage. Even a small temperature swing can put you in the food safety "danger zone," risking quality, customer health, and your reputation.

This is why you should always look for models with digital thermostats and displays. They give you an instant, at-a-glance confirmation that your ingredients are safely below 40°F (or 4°C). This isn’t just a nice-to-have; it's a must-have for passing health inspections and avoiding thousands of dollars in spoiled product.

An advanced cooling system is your best friend on a busy night. It ensures that even when the doors are opened dozens of times an hour, the unit quickly recovers its internal temperature. That rapid recovery is what preserves the integrity of your meats and cheeses throughout the entire shift.

To help you zero in on what truly matters for your operation, here’s a quick-glance table breaking down the essential features and their direct impact on your pizza-making process.

Essential Back Bar Refrigerator Features for Pizzerias

| Feature | Benefit for Pizza Prep | Why It's Important |

|---|---|---|

| Digital Thermostat | Precise, at-a-glance temperature monitoring. | Ensures pizza ingredients like cheese and meats stay below the 40°F food safety threshold, preventing spoilage and passing health inspections. |

| Adjustable Shelving | Accommodates bulky dough boxes and shallow topping pans. | Maximizes every inch of storage, preventing wasted space and keeping the pizza prep table organized during a rush. |

| LED Lighting | Brightly illuminates the entire cabinet interior. | Allows staff to find the right pizza ingredient instantly, shaving precious seconds off every single order. |

| Front Ventilation | Allows for built-in installation under a pizza prep table. | Prevents the compressor from overheating and failing, which is a common issue with rear-vented units placed in tight spaces. |

Looking at this table, you can see how each feature directly solves a real-world problem you face every day in the kitchen. It’s not just about buying a cold box; it’s about investing in a tool that boosts your efficiency and protects your bottom line.

The Game-Changer of Adjustable Shelving

A pizzeria’s cold storage needs are all over the place. One minute you're trying to slide in a full hotel pan of shredded mozzarella, and the next you need space for short, wide sauce containers and tall, bulky dough boxes. This is where fixed, non-movable shelves become a huge headache.

Adjustable shelving is one of those seemingly small features that has a massive impact on your daily workflow. It gives you the power to customize the refrigerator's interior on the fly.

- Maximize Vertical Space: Drop a shelf down to make room for tall stacks of dough trays or third-pans piled high with toppings.

- Create Efficient Zones: Raise a shelf to create the perfect slot for shallow containers of olives and mushrooms, eliminating wasted air space above them.

- Adapt to Menu Changes: When you add a new special pizza or switch suppliers, you can reconfigure the layout in seconds to fit new container sizes. No stress, no hassle.

This flexibility ensures every last cubic inch of your refrigerated space gets used, which helps keep your main pizza prep table clear and your ingredients perfectly organized.

Bright Lighting and Smart Ventilation

Finally, let's talk about two often-overlooked features that make a world of difference. First up is interior lighting. The best modern units use bright, energy-efficient LED lighting that completely illuminates the cabinet. Your chefs can instantly spot and grab the right pizza topping without rummaging around, saving critical seconds on every order.

Even more important, though, is the ventilation system. Most back bar coolers are designed to be built right into a counter or squeezed tightly between other pieces of equipment. For that kind of setup, a front-breathing ventilation system is absolutely non-negotiable. This design pulls air in and pushes it out through the front grille, which stops the compressor from overheating when there’s zero clearance on the back and sides. Shoving a rear-ventilated unit under a pizza prep table is just asking for equipment failure and a cooler full of spoiled food.

Creating the Ultimate Pizza Prep Workstation

Your entire pizza-making strategy comes to life on the prep line. A back bar refrigerator and a pizza prep table shouldn't just share floor space; they need to work together like a single, well-oiled machine. This seamless integration is what separates a decent setup from the ultimate pizza-making workstation, unlocking a new level of speed and efficiency.

The real goal here is to create a self-contained "pizza zone" where every single cold ingredient is just an arm's reach away. This isn't just about making life easier; it's smart ergonomics that cuts out wasted movement. Think about the seconds you save on every single pizza when your chef doesn't have to walk to another cooler for cheese, pepperoni, or peppers. Over a busy night, those seconds turn into faster ticket times and happier customers.

The Blueprint for an Ergonomic 'Pizza Zone'

Building a truly efficient workstation is all about thoughtful planning. The most critical decision you'll make is where to place your back bar refrigerator in relation to your pizza prep table. The right setup minimizes steps, reduces physical strain on your crew, and streamlines the entire pizza-building process from start to finish.

The most effective layout, hands down, is placing the back bar cooler directly underneath the pizza prep table. This under-counter setup is the gold standard for pizzerias because it creates a perfect, uninterrupted flow. Your pizza maker can turn, open a door, grab ingredients, and get back to the pizza without taking a single step. That fluid motion is the foundation of a high-output kitchen.

For this dream setup to become a reality, a few technical details are non-negotiable.

- Height Compatibility: The back bar refrigerator has to be the right height to slide perfectly under your pizza prep table. Most standard units are designed to be between 34 and 36 inches tall for exactly this reason.

- Ventilation Clearance: As we've covered, a front-breathing ventilation system is a must-have for any under-counter placement. This allows the unit to push hot air out the front, keeping the compressor from overheating and failing prematurely.

- Depth Considerations: The cooler's depth is also a big deal. Market data shows that operators are leaning towards space-saving units, with models in the 20-25 inch depth range making up almost 40% of the market because they fit so well with standard counters. You can explore more about these market trends by reading the full research on back bar cooler demand.

From Theory to Reality: Practical Examples

Let's see how this integrated pizza zone plays out in a real pizzeria. Picture a two-person team slammed during a dinner rush. One person is stretching and saucing dough, while the second is adding toppings and loading the oven. With an under-counter back bar refrigerator, the topping station never runs dry.

The chef can open one door to access a full pan of mozzarella and another for high-volume meats like pepperoni. This is far more efficient than relying on the small refrigerated wells of a traditional pizza prep table, which can empty out fast and force time-wasting trips to the walk-in. The cooler acts as a bulk backup, right where the action is. For a deeper look at different refrigerated tables, our guide on refrigerated sandwich prep tables is a great resource, as many of the core principles overlap.

By designing your workstation around the principle of "a place for everything, and everything in its place," you dramatically reduce the mental and physical load on your kitchen staff. This allows them to focus solely on crafting high-quality pizzas at speed.

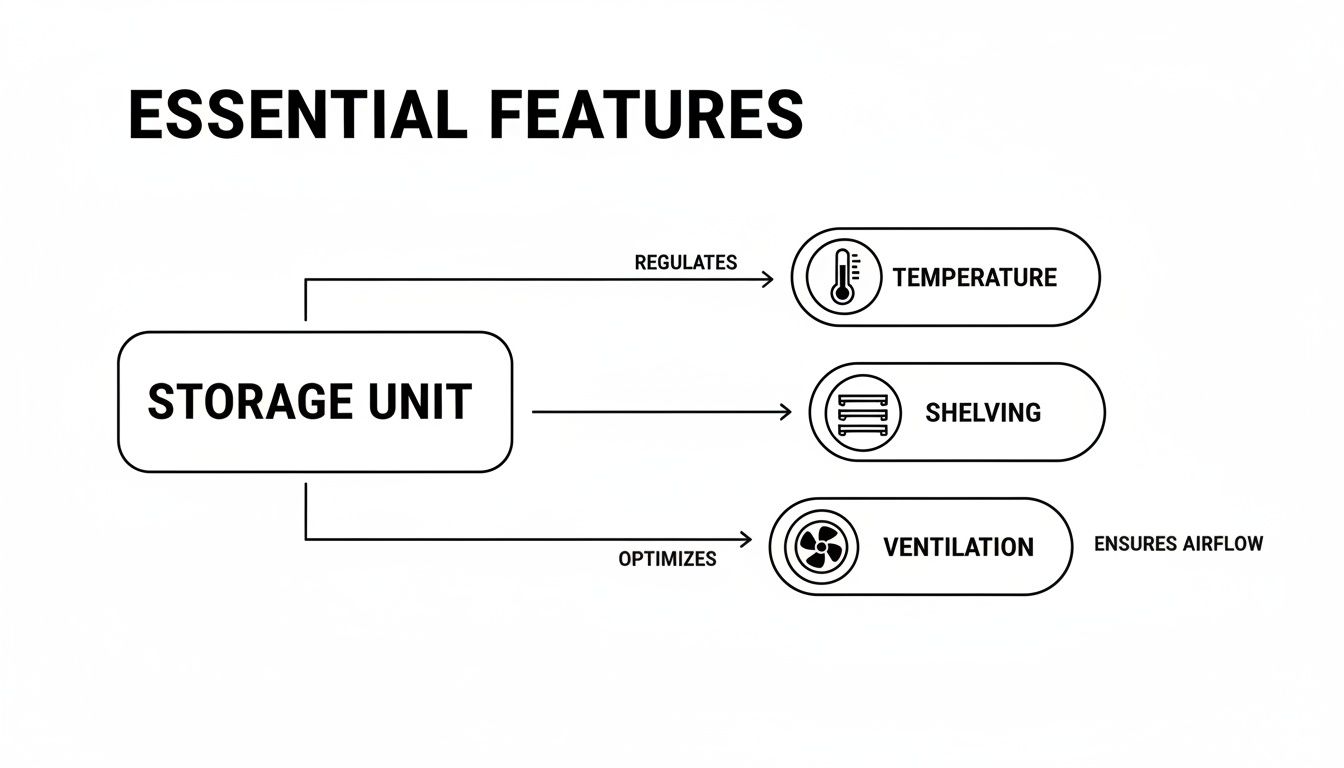

This concept map breaks down the features—temperature, shelving, and ventilation—that are absolutely critical to making this integration work.

The visual makes it clear: a successful workstation depends on more than just placement. The unit's core functions have to be tough enough to handle the demanding environment of a pizza prep line.

Ultimately, integrating a back bar refrigerator into your pizza prep station is a strategic investment in your workflow. It directly impacts your hourly output, the consistency of your product, and the overall stress level in your kitchen. By following this blueprint, you can build a workstation that doesn't just keep ingredients fresh, but actually fuels your pizzeria’s growth.

Smart Maintenance to Protect Your Investment

Think of your back bar refrigerator as more than just a piece of equipment; it's a daily workhorse and a serious financial investment. Especially in a demanding pizzeria kitchen—a battlefield of flour, heat, and grease—protecting that investment means more than just being careful. It requires a smart, proactive maintenance plan to keep your unit running efficiently for years. This isn't just about preventing costly breakdowns; it's about protecting the valuable pizza ingredients inside.

A great first move for long-term value is choosing an ENERGY STAR certified model right from the start. These units are specifically engineered to be up to 20% more energy-efficient than standard models, which translates directly into lower monthly utility bills. It's like getting a small, recurring discount on your operating costs for the entire life of the cooler.

Your Pizzeria Maintenance Checklist

In a pizza shop, the air is thick with fine flour dust and grease particles—the natural enemies of refrigeration components. A simple, repeatable maintenance routine is your best defense against your equipment giving up on you prematurely.

Here's a straightforward plan to keep your back bar refrigerator in top shape:

- Clean Condenser Coils Monthly: The condenser coil is like the radiator in your car; its job is to get rid of heat. In a pizzeria, it gets clogged fast with a sticky mix of grease and flour, forcing the compressor to work overtime. A monthly cleaning with a stiff brush and a vacuum is the single most important task you can do.

- Inspect Door Gaskets Weekly: A leaky door seal is like leaving a window open with the AC blasting. Cold air escapes, and the unit constantly runs to try and keep up. Run your hand along the seals to feel for drafts and look for any cracks or brittleness. A tight seal is crucial for both energy savings and food safety.

- Wipe Down Interior Surfaces Daily: This simple habit prevents the buildup of food residue and stops potential cross-contamination in its tracks. It keeps your pizza ingredients in a hygienic environment and helps extend the life of the interior components.

Calibrating for Consistency and Safety

Beyond the physical cleaning, making sure your thermostat is accurate is absolutely critical for food safety. An incorrectly calibrated thermostat can lead to your pizza ingredients being stored at unsafe temperatures, which is a huge risk for spoilage and customer health.

Grab an independent appliance thermometer and stick it in a glass of water inside the unit. After a few hours, compare its reading to your refrigerator's digital display. If you see a significant difference, you’ll know it’s time to recalibrate according to the manufacturer’s instructions to keep everything below that crucial 40°F (4°C) threshold.

This proactive approach doesn't just maximize the lifespan of your back bar cooler; it also aligns with the growing demand for efficient commercial equipment. The global market for these units hit $1.49 billion and is projected to grow significantly, driven by demands from the hospitality industry and ongoing tech upgrades. You can dig into the data behind this growth and find more details about the back bar refrigerator market here.

Of course, maintaining the refrigerator is just one piece of the puzzle. You also need to focus on proper food handling to ensure ingredient quality. You can learn more about how to properly store food to extend its shelf life. This combination of equipment care and smart food practices will protect your investment from every angle.

Investing in Efficiency for Your Pizzeria

Picking out the right back bar refrigerator isn't just about buying a cold box. It’s a strategic move that touches every part of your pizzeria—your daily workflow, the quality of your ingredients, and even your long-term profits. A good unit doesn't just sit there; it becomes a genuine partner to your pizza prep table, reinforcing the efficient system you've worked so hard to build.

Think of this investment as a balance between the upfront price tag and the long-term payoff. A solid, well-built cooler is a reliable workhorse you can count on during a chaotic Friday night rush. Go for an energy-efficient model, and you’ll see the savings show up on your utility bills, month after month.

Finalizing Your Decision

Before you pull the trigger, take one last look at what your pizzeria truly needs. Be honest about your space and workflow. Does a compact single-door unit fit perfectly, or does your volume demand a high-capacity three-door model? The goal is to prioritize features that solve actual problems you face on the pizza prep table every day.

- Must-Have Features: You absolutely need things like a digital thermostat for precise temperature control, adjustable shelving that can fit both dough boxes and topping pans, and front ventilation if it's going under a pizza prep table. These are the non-negotiables.

- Nice-to-Have Features: Things like glass doors or specific handle styles are secondary. They’re great, but they don't matter if the unit can’t handle the heat and hustle of a real commercial kitchen.

At the end of the day, you're looking for a model that will show up and work reliably, shift after shift. It needs to make grabbing ingredients effortless, maintain rock-solid food safety, and help your team build fantastic pizzas faster and more efficiently.

When you invest in the right gear, you're not just buying stainless steel; you're building a stronger, more resilient business. This back bar refrigerator is a key piece in the larger puzzle of improving restaurant operations for greater efficiency. To really understand the financial upside of modern equipment, check out our guide on selecting energy-efficient commercial refrigeration—it shows how smart choices can seriously cut down your operating costs.

Common Questions from Pizzeria Owners

When you're close to pulling the trigger on a new back bar refrigerator, a few final questions always pop up. Getting these details sorted out is the difference between buying a piece of equipment and making a smart investment that will serve your pizzeria for years. Here are the things we hear most often from owners just like you.

Can a Back Bar Refrigerator Really Handle the Heat of a Pizza Kitchen?

Absolutely, but you have to pick the right one. This isn't the place for a residential mini-fridge. Commercial-grade back bar coolers are built for the battlefield of a hot kitchen, designed to operate efficiently even when the pizza ovens are blazing.

The single most important feature to look for is a front-breathing ventilation system. If you're sliding this unit under a pizza prep table or placing it next to hot equipment—which is almost always the case in a pizza shop—this design is non-negotiable. It pulls cool air in and pushes hot air out through the front grille, so the compressor won't suffocate and burn itself out.

Can I Use It for More Than Just Pizza Toppings?

You bet. Its versatility is one of its biggest strengths. While it's perfect for holding overflow cheese and pepperoni right on the line, a back bar fridge is a true utility player in a pizzeria. We see them used all the time for:

- Storing dough boxes: The adjustable shelves let you create enough vertical space to stack dough trays, keeping them perfectly chilled and ready for service.

- Chilling sauces: It’s the perfect spot for pre-portioned pizza sauce, garlic butter, or specialty sauces, keeping them right where your pizza makers need them.

- Holding other prepped ingredients: Use it for anything that needs to stay cold, like sliced veggies for salads or cooked chicken wings for appetizers.

What's the Right Temperature for My Pizza Ingredients?

Food safety is everything. All your perishable pizza ingredients—cheese, meats, pre-cut vegetables—have to be stored at or below 40°F (4°C). This is exactly why a reliable digital thermostat is a must-have feature, not a nice-to-have.

A clear digital display gives you and your team at-a-glance confidence that your valuable ingredients are held at a safe temperature. It's your best defense against spoilage and potential health code dings.

It's also a smart move to keep a separate, calibrated thermometer inside the unit. Check it daily to make sure the unit's display is accurate. A simple habit like this is crucial for protecting the quality of your pizza ingredients.

How Much Ventilation Space Does It Need?

This is a great question, and the answer depends entirely on the design. For a front-breathing unit made for under-counter use, you typically don't need any clearance on the back or sides. They are engineered to be fully enclosed. Still, always give the manufacturer's spec sheet a quick look to confirm their exact requirements.

On the other hand, if you opt for a unit with rear or side ventilation, you have to give it room to breathe. These models need several inches of open space around the vents for proper airflow. Blocking them is the fastest way to overheat the compressor and cause a breakdown, especially in a sweltering pizzeria kitchen.

Ready to build the ultimate pizza-making station? Pizza Prep Table has a handpicked selection of commercial back bar refrigerators designed to slide right in with your pizza prep table, making your kitchen faster and more efficient. Check out our collection and find the perfect fit for your pizzeria.