Your Guide to Refrigerated Pizza Prep Tables

Share

Refrigerated pizza prep tables are specialized commercial units that bring together a refrigerated base, a top rail for holding cold ingredients, and a cutting board work surface all in one place. For a pizzeria, these tables are nothing short of the central hub for building pizzas, keeping toppings like cheese, pepperoni, and vegetables perfectly chilled and always within arm's reach. They're built to make your workflow smoother and keep your food safe, especially during those crazy busy hours.

The Unsung Hero of Your Pizza Assembly Line

Picture your busiest Friday night. The tickets are printing nonstop, and your kitchen is a blur of motion. What’s the one piece of equipment holding the entire operation together? Your refrigerated pizza prep table. It's so much more than a cooler with a cutting board on top; it's the command center for your whole pizza-making process.

This guide is written specifically for pizzeria owners, because you face challenges other restaurants don't. We'll dive into everything from keeping that pepperoni and mozzarella at the perfect, food-safe temperature to setting up a workflow that lets your team sling pies with serious speed and precision.

Why Your Pizza Prep Table Is a Strategic Investment

The right prep table is the heart of your kitchen. It has a direct impact on how fast you can serve customers, the quality of your ingredients, and, when it comes down to it, your bottom line. Think of it less as an expense and more as a strategic investment in making your kitchen run like a well-oiled machine. A solid unit guarantees that every pizza begins with fresh, properly chilled ingredients—the foundation of a great final product.

The importance of this equipment is felt across the entire food service industry. In fact, the global market for these tables is a huge and growing sector. As of 2024, the refrigerated prep table market was valued at around USD 2.1 billion. The sandwich and salad prep table segment alone made up the biggest piece of that pie, holding nearly 42% of the total market revenue. That number really shows just how critical these tables are for keeping food fresh and safe, and for pizzerias, they are the cornerstone of the operation.

More Than Just a Cooler

A pizza prep table is engineered for a very specific, high-pressure job. It's not like a standard work table or a simple undercounter fridge. It cleverly combines three critical functions into one seamless station:

- Refrigerated Storage: The cabinet underneath is perfect for keeping bulk ingredients like dough boxes, extra blocks of cheese, and backup sauces chilled and ready to go.

- Accessible Topping Rail: The top section holds all your pans of prepped toppings. It uses a blanket of cold air to keep them at a consistent, safe temperature, even when the lids are open during a rush.

- Dedicated Workspace: A deep, tough cutting board gives you the real estate you need to stretch dough and build large pizzas without making a mess everywhere.

Ultimately, a good prep table is the key to an organized, efficient kitchen. We actually have a whole guide on the secret sauce behind efficient pizza prep stations if you want to learn more about setting one up. When every part of this station works together, your team can assemble pizzas faster, cut down on ingredient waste, and serve customers more effectively—turning a chaotic rush into a smooth, profitable service.

Anatomy Of A High-Performance Pizza Prep Table

To really get what separates a basic cooler from a high-performance pizza station, you have to look under the hood. A top-tier refrigerated pizza prep table, especially one built for pizza, is a whole ecosystem of carefully engineered parts all working together. Every single feature translates directly into real-world benefits for your pizzeria, hitting everything from food safety to how fast you can sling pies out the door.

Think of it like the difference between a standard family car and a Formula 1 race car. Sure, both have an engine and wheels, but one is purpose-built for extreme performance under pressure. Your pizza prep table is the race car of your kitchen; let's break down its most important parts.

The Unwavering Cold: The Topping Rail

The topping rail is where all the magic happens, but it’s also a critical food safety zone. This component is designed to hold a whole array of pans filled with your essential pizza toppings—pepperoni, mushrooms, onions, and heaps of mozzarella. Its number one job is to keep a consistent temperature, holding everything within the non-negotiable food-safe range of 33°F to 41°F.

A prep table that can’t hold this temperature range, especially during a dinner rush with the lids constantly open, isn't just inefficient—it's a liability. Consistent cold is your first line of defense against foodborne illness and ensures every topping tastes as fresh as it should.

The capacity of this rail is a huge factor, too. A small table might only hold eight 1/6-size pans, which is fine if you have a simple menu. But if you're offering a dozen or more specialty pizzas, you'll need a larger unit with room for 12, 16, or even more pans. This directly impacts how complex your menu can be and how often your staff has to stop making pizzas to run to the walk-in for refills.

The Workspace: The Cutting Board

While the topping rail keeps things cool, the cutting board is where your team actually builds the pizza. For pizzerias, this isn't just any old cutting surface. A standard sandwich prep table often comes with a narrow cutting board, sometimes only 8 to 10 inches deep. That's completely useless for assembling a 16-inch pizza.

High-performance pizza prep tables feature an extra-deep cutting board, typically 16 to 20 inches deep. This added real estate is critical for a few reasons:

- Ample Room: It gives you enough space to stretch dough, apply sauce, and pile on toppings without half of it ending up on the floor.

- Material Matters: Most commercial boards are made from high-density polyethylene (HDPE), a non-porous material that’s easy to clean and won't dull your pizza cutters. It absolutely must be NSF-certified to meet health codes.

- Durability: The board has to be tough enough to withstand the constant scraping of metal spatulas and pizza cutters, day in and day out.

The right cutting board just makes the whole assembly process smoother, reduces mess, and creates a much more ergonomic workspace for your team.

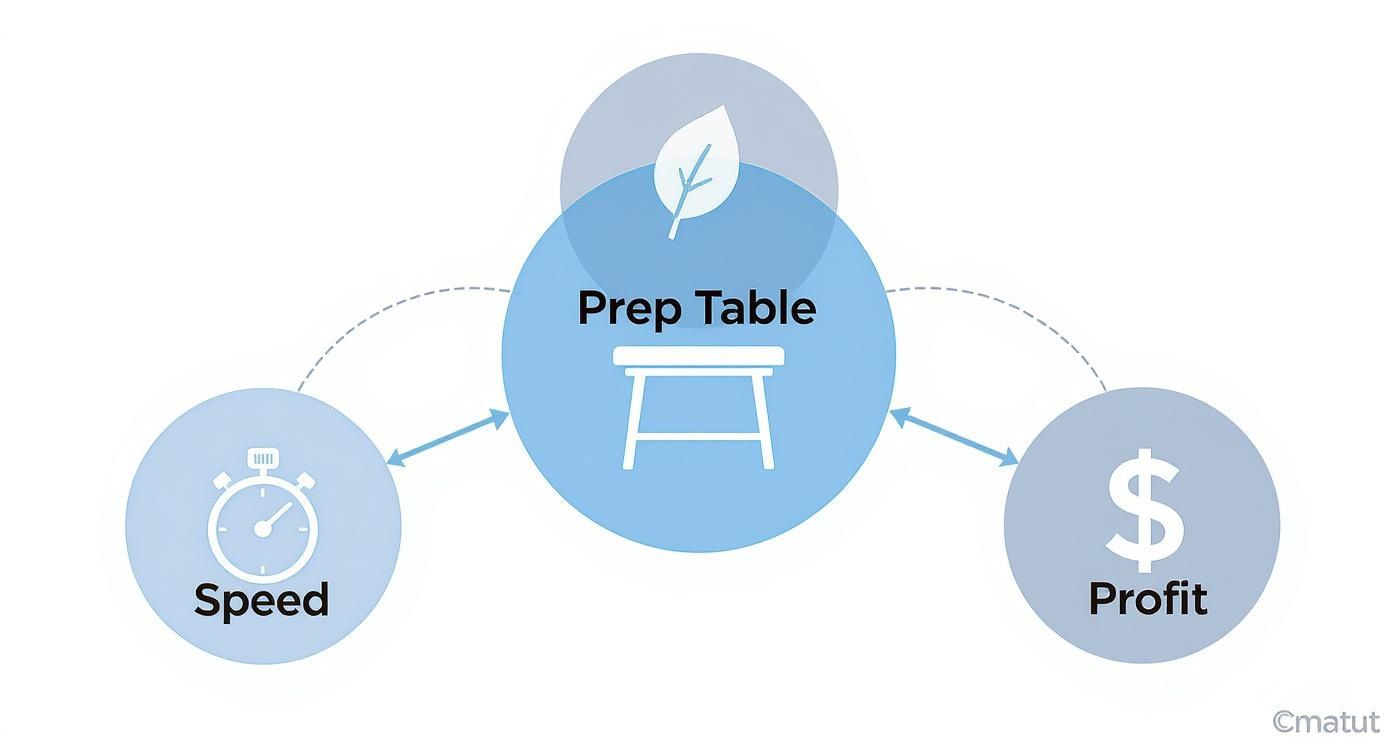

This diagram breaks down how the core components of a refrigerated prep table directly influence a pizzeria's speed, quality, and profit.

The visualization makes it crystal clear: investing in a high-performance table isn't just an equipment expense. It's a strategic move to boost your entire operation's health.

For pizzeria owners, understanding these features is the first step toward choosing a table that truly supports their workflow. Here's a quick comparison of what to look for.

Key Feature Comparison for Pizza Prep Tables

This table compares critical features pizza restaurant owners should evaluate when selecting a refrigerated prep table, highlighting the pros and cons of each option for a pizzeria environment.

| Feature | Standard Option | Premium Option | Why It Matters for Pizza |

|---|---|---|---|

| Cutting Board Depth | 8-10 inches | 16-20 inches | A deep board is essential for stretching and topping large pizzas without making a mess. |

| Pan Capacity (Rail) | 6-8 pans | 12+ pans | Higher capacity supports complex menus and reduces trips to the walk-in for refills. |

| Compressor Location | Rear-mounted | Side-mounted | Side-mounted units save space by sitting flush against a wall and are easier to access for cleaning. |

| Material Quality | Galvanized steel back | Full stainless steel interior/exterior | Full stainless steel resists corrosion from acidic sauces and is far easier to sanitize. |

| Refrigeration Type | Standard forced-air | Advanced forced-air, cold-wall | Advanced systems offer better temperature consistency, especially during a rush, and can be more energy-efficient. |

Choosing premium options isn't just about spending more money; it's about investing in efficiency and reliability that pays off every single shift.

The Engine: The Compressor

The compressor is the heart of any prep table, circulating refrigerant to keep both the storage cabinet and the topping rail ice-cold. Where it's located significantly impacts your kitchen's layout, airflow, and maintenance routine. There are two main setups: rear-mounted and side-mounted.

A rear-mounted compressor is what you'll find in many standard units. While it gets the job done, it needs several inches of clearance between the back of the unit and the wall for proper ventilation. If you push it flush against a wall, it’s going to overheat, work harder, and eventually burn out.

A side-mounted compressor, on the other hand, is usually found in higher-end models. This design lets you place the unit right against a wall, saving precious floor space. It also tends to be much easier to access for cleaning and maintenance, since the coils aren't hidden in the back. These ongoing improvements are driven by a competitive market where leading brands like True Manufacturing and Turbo Air are constantly pushing innovations to meet the needs of demanding kitchens. By understanding these core components, you can choose a pizza prep table that truly works for your kitchen, not against it.

How to Choose the Right Size for Your Kitchen

Picking the right size for your refrigerated pizza prep table is probably one of the most important calls you'll make for your kitchen's workflow. This is about so much more than just finding a unit that slots into an empty space; it's about matching your equipment's capacity to your restaurant's busiest moments.

Think of your prep table like a highway. Sure, a two-lane road gets the job done in a small town, but it turns into a parking lot during big-city rush hour. A prep table that's too small will do the exact same thing to your assembly line on a slammed Friday night. The mission is to build a workflow superhighway that can handle your absolute peak order volume without causing a single bottleneck.

Matching Table Size to Pizza Production

When you see sizes like 48, 60, and 93 inches, don't just think about the dimensions. Think about production capacity. Each size directly translates to how many pizzas your crew can build at once and how smoothly they can operate.

A small, walk-up slice shop, for example, might be perfectly happy with a compact 48-inch, two-door unit. It gives one person plenty of elbow room to assemble pies without hogging precious floor space.

But for a high-volume pizzeria crushing it with delivery and carry-out orders, a 93-inch, three-door beast becomes a necessity. This larger setup allows two, maybe even three, team members to work shoulder-to-shoulder, each in their own zone. That's how you prevent chaos and keep ticket times down when you're in the weeds.

Here's the golden rule: Size your prep table for your busiest hour, not your slowest. Choosing a unit that’s too small is a rookie mistake that forces you to sacrifice speed and quality right when it counts the most.

A Practical Checklist for Measuring Your Space

Before you even start browsing models, grab a measuring tape. Getting precise with your space assessment now will save you from massive headaches on delivery day. It's the small details that get you.

Here’s a quick checklist to run through:

- Measure the Footprint: Get the exact width, depth, and height of the spot where the table will live. Write it down. Don't eyeball it.

- Account for Breathing Room: Most refrigeration units need at least 3-4 inches of clearance at the back and sides for proper ventilation. A compressor that can't breathe will overheat and die an early death. Add this clearance to your initial numbers.

- Check Your Delivery Path: Measure the width of every single doorway, hallway, and tight corner from your back door to the table's final home. A brand-new prep table is just an expensive paperweight if you can't get it inside the building.

- Factor in the Door Swing: Don't forget the refrigerated cabinet doors underneath. Measure how far they swing out to make sure they won't block a walkway or slam into other equipment every time someone grabs more cheese.

Thinking through these points ensures you pick a unit that not only fits your workflow but also slides into your kitchen's layout without a fight. For a deeper look at specific sizes, our guide on choosing a 60-inch pizza prep table is a fantastic starting point for many pizzerias. When you connect your peak volume to the physical reality of your space, you'll land on the perfect size to boost efficiency and help your restaurant grow.

Comparing the Top Prep Table Brands for Pizzerias

Picking a refrigerated pizza prep table can feel like you’re lost at sea, with a dozen brands all claiming to have the best gear. For a pizzeria, this decision is a big deal. The constant heat, the flour dust that gets everywhere, and the non-stop pace of a pizza kitchen demand equipment that’s more than just good—it needs to be a rock-solid, dependable workhorse.

This isn't about picking a fancy brand name. It's about matching a manufacturer's real-world strengths to your pizzeria's daily grind and your budget. Let's break down some of the heavy hitters so you can see what truly sets them apart.

True Manufacturing: The Indestructible Workhorse

When old-school restaurant pros talk about equipment that’s built like a tank, True Manufacturing is almost always the first name that comes up. Think of True as the heavy-duty pickup truck of the commercial refrigeration world. Their prep tables are legendary for their brute strength and ability to just keep running, even in the hottest, most punishing kitchens.

For a pizzeria where ambient temperatures can skyrocket, this is a huge win. True often uses oversized refrigeration systems, which means they don’t have to struggle to hold food-safe temperatures between 33°F and 41°F. That beefy engineering means a longer lifespan and way fewer calls to the repair guy, making a True table a smart long-term investment for an established, high-volume spot that absolutely cannot afford downtime. They do come with a premium price tag, but their reputation for never quitting on you often makes it worth every penny.

Atosa: A Smart Balance of Performance and Price

For new pizzeria owners or anyone keeping a close eye on the budget, Atosa has become a seriously compelling option. Atosa hits that sweet spot between reliable performance and a price that doesn't make you wince, making them a go-to for independent restaurants and startups. They give you all the core features you need without the sticker shock of the legacy brands.

Atosa proves that you don't have to break the bank to get a dependable and NSF-certified prep table. For a new venture where managing cash flow is paramount, choosing Atosa means you can allocate capital to other critical areas like marketing or ingredients without sacrificing core functionality in the kitchen.

Their units are built with quality stainless steel and efficient compressors, so you know they can handle the daily grind of a busy pizzeria. They might not have the same decades-long, battlefield-tested reputation as True, but they back their gear with a solid warranty and offer a ton of value for any owner who needs dependable equipment without paying for the top-shelf name.

Dukers and Kelvinator: Niche Strengths for Modern Kitchens

Beyond the big two, brands like Dukers and Kelvinator bring their own unique strengths to the table that can be the perfect solution for certain kitchens. These guys often zero in on specific areas like energy efficiency or clever design features that can make your pizza-making process a little smoother.

For example, you might find a Dukers model with a super-efficient compressor that uses eco-friendly R290 refrigerant, which translates to lower monthly utility bills. Kelvinator, with its long history in the refrigeration game, might offer an innovative rail cooling system that keeps your toppings perfectly and consistently chilled.

Choosing one of these brands is about solving a specific problem. If your pizzeria is in a city with crazy high electricity costs, making an ENERGY STAR certified model from one of these brands a priority could save you a significant amount of money over the life of the unit. The trick is to look past the brand name and focus on the features that will make your life easier—whether that’s saving on energy, fitting into a tight space, or just making the workflow better.

Keeping Your Investment Cool: Installation and Maintenance That Pays Off

Your new pizza prep table is a serious investment in your kitchen's future. Protecting that investment starts the moment it rolls off the delivery truck. Getting the installation right and sticking to a consistent maintenance schedule are non-negotiable habits that will keep your unit humming, extend its life, and prevent those dreaded emergency repair calls.

Think of it this way: you wouldn't buy a brand-new car and then just decide to skip the oil changes. Your refrigerated pizza prep table is the engine of your assembly line, and it needs the same kind of care to perform at its best for years to come. This is your practical roadmap for both setup and upkeep.

The Day One Setup Checklist

Nailing the installation right from the start prevents a whole mess of future problems. Before you even think about plugging it in, run through this quick checklist. A few minutes of diligence now will pay for itself over and over again.

- Check Your Power Source: These tables are powerful machines. First, confirm the unit's electrical needs (it’s usually 115v/60/1) and make sure you have a dedicated outlet that fits the NEMA plug type (like a 5-15P). Overloading a circuit is just asking for trouble.

- Give It Room to Breathe: The compressor has to pull in cool air to do its job. You absolutely must leave at least 3-4 inches of open space around the back and sides for ventilation. Shoving it up against a wall will make it overheat, jack up your energy bills, and kill the compressor's lifespan.

- Level It for a Perfect Seal: Grab a level and make sure the table is perfectly flat on the floor. If it's crooked, the self-closing doors won't hang right, leaving gaps in the seal. This forces the compressor to work overtime just to keep things cold.

A Simple Maintenance Schedule That Works

Ongoing maintenance doesn't have to be a huge chore. By turning a few key tasks into routine habits, you can keep your prep table running like it's brand new. This simple schedule is built for the real-world demands of a busy pizza kitchen.

Monthly Tasks

- Clean the Condenser Coils: Flour, dust, and grease are the mortal enemies of a refrigeration system. Once a month, unplug the unit and use a stiff brush or a vacuum to gently clean off the condenser coils. Clogged coils are the #1 cause of compressor failure, period.

- Inspect the Door Gaskets: Take a close look at the rubber seals around the doors. Are there any cracks, tears, or spots where they've gone brittle? A bad gasket lets cold air pour out. The old dollar bill trick still works: close the door on a bill. If you can pull it out easily, it's time for a new gasket.

Weekly Tasks

- Deep Clean the Topping Rail: Pull out all the ingredient pans and give the entire topping rail area a thorough wipe-down with a food-safe sanitizer. This is critical for preventing flavor transfer and bacterial growth.

- Sanitize the Cutting Board: Give that polyethylene cutting board a good scrub with hot, soapy water and a sanitizer. Pay extra attention to any deep knife grooves—that's where bacteria love to hide.

When you dedicate just a few minutes each week and month to these tasks, you're not just cleaning. You're performing preventative care that directly protects your bottom line. A well-maintained unit uses less energy, holds its temperature like a rock, and is far less likely to die on you during a Friday night rush.

Smart Ways to Purchase Your Next Prep Table

Dropping a chunk of change on a major piece of equipment like a refrigerated pizza prep table isn't a decision you make on a whim. It requires a smart financial game plan. Let's break down your buying options so you can make the best call for your pizzeria's bottom line and long-term success. The right choice protects your cash flow while making sure your kitchen has the reliable gear it needs to churn out perfect pizzas.

New vs Used Pizza Prep Tables

The first big fork in the road is choosing between a shiny new unit and a seasoned, pre-owned one. A new table is a fantastic investment. It comes with a full manufacturer's warranty, the latest energy-saving tech, and the simple peace of mind of being its first and only owner. Think of it as a pristine, reliable foundation for your pizza assembly line.

On the flip side, a used table has a much friendlier price tag upfront, which can be a lifesaver for a startup or a pizzeria running on a tight budget. But this path isn't without its risks. Used equipment usually comes without a warranty, might be hiding some mechanical gremlins, and could be an energy hog that drives up your utility bills. Digging into the pros and cons is a must, and you can get the full scoop in our guide on finding used pizza prep tables for sale.

When you're kicking the tires on a used unit, be meticulous. Check the door gaskets for a solid seal—any gaps mean it's leaking cold air and money. Listen for any weird rattling or grinding from the compressor, and bring a thermometer to verify it holds a consistent temperature below 41°F. Any signs of rust or serious damage should be major red flags.

Financing and Leasing Your Equipment

You don't always have to pay the full sticker price right out of the gate. Financing and leasing are powerful tools that let you get the high-quality equipment you need now without torpedoing your bank account. These options are especially smart for keeping cash on hand for other must-haves like inventory, marketing, or payroll.

- Equipment Financing: This is basically a loan to buy the prep table. You'll make monthly payments over a set period, and once it's all paid off, you own that workhorse free and clear.

- Leasing: With a lease, you're essentially renting the equipment for a specific amount of time. When the lease is up, you often have the option to buy it, sign a new lease, or even upgrade to a newer model.

When you're mapping out your next big purchase, like a refrigerated prep table, it's a smart move to look into various equipment financing options to manage the cost without a massive upfront hit. This strategy lets you bring in a top-tier asset that'll boost your kitchen's productivity while you keep your financial footing secure.

Questions We Hear All the Time

When you're about to drop some serious cash on a cornerstone piece of equipment like a refrigerated pizza prep table, you’re going to have questions. It's smart to ask. Getting straight, real-world answers is what separates a good purchase from a great one. Here are the questions we hear most often from pizzeria owners just like you.

What Is the Ideal Temperature for a Pizza Prep Table?

Your topping rail—where all the cheese, pepperoni, and veggies live—needs to stay between 33°F and 41°F (that’s 0.5°C to 5°C). This isn't just a friendly suggestion; it's the law. The FDA mandates this temperature zone to stop nasty bacteria from throwing a party in your ingredients. A solid prep table will lock in that temperature and hold it steady, even when your crew is opening and closing the lids a hundred times during a Friday night rush.

Can I Use a Standard Sandwich Table for Making Pizza?

Look, you technically can, but you really, really shouldn't. A real pizza prep table is built with an extra-deep cutting board, usually 19 inches or more. Why? Because you need that space to stretch out a large pie without half of it hanging off the edge. Standard sandwich tables have skinny little boards that turn pizza making into a messy, frustrating battle. Investing in the right tool for the job will pay you back in less wasted dough and faster ticket times.

Using the wrong table is like trying to paint a mural with a tiny brush—it’s frustrating, slow, and the final product just isn't what it could be. The right tool makes all the difference when you're under pressure.

How Often Should I Clean the Condenser Coils?

In a typical restaurant, cleaning condenser coils every 90 days is the standard advice. But a pizzeria isn't a typical restaurant. It's a battlefield of airborne flour, grease, and all sorts of dust. For that reason, you need to be checking and cleaning your coils every single month. When those coils get clogged, the compressor has to work overtime, which means higher energy bills and a much greater risk of it dying on you in the middle of a dinner service.

Is an ENERGY STAR Certified Prep Table Worth the Extra Cost?

One hundred percent, yes. An ENERGY STAR model might have a higher sticker price, but it can be up to 40% more energy-efficient than a standard unit. Think about it: your prep table runs 24/7, making it one of the biggest power hogs in your entire kitchen. The savings on your electric bill add up fast, often covering the initial price difference in just a couple of years. It’s not just an expense; it’s a smart financial move for the long haul.

Ready to find the perfect pizza prep table that can handle your kitchen's demand for speed, safety, and efficiency? Check out our hand-picked selection at Pizza Prep Table and find top-tier models from brands you can count on. https://pizzapreptable.com