Choosing Your 60 Inch Pizza Prep Table

Share

A 60-inch pizza prep table is the engine room for a busy pizzeria. It perfectly balances a generous work surface with plenty of refrigerated storage, all without eating up your entire kitchen floor plan. This "sweet spot" size turns a chaotic scramble into a smooth assembly line, making it a critical asset for boosting speed, consistency, and ultimately, your pizzeria's profits.

Why a 60-Inch Prep Table Is Your Pizzeria's Hero

Picture your busiest Friday night. The tickets are flying in, and your pizza crew is a blur of motion. Right in the middle of this controlled chaos sits the 60-inch pizza prep table—your kitchen's command center. This specific size has become the go-to for countless pizzerias for one simple reason: it hits the perfect balance. It’s big enough to handle the rush but still compact enough to fit into most kitchen layouts.

This table isn't just another piece of equipment; it's a strategic tool built for peak pizza-making efficiency. Think of it like a pilot's cockpit. Everything a pizza maker needs—from chilled pepperoni and mozzarella to perfectly proofed dough—is organized and within arm's reach. Centralizing all your ingredients and tools is the secret to churning out a consistent, high-quality pizza every single time.

The Sweet Spot for Size and Function

The 60-inch width gives one or two pizza chefs enough elbow room to work side-by-side without bumping into each other. This is absolutely vital during peak hours when you're firing out multiple orders at once. The deep cutting board allows for seamless dough stretching, saucing, and topping, all in one fluid motion.

Underneath this workspace, the refrigerated base keeps all your backup ingredients at food-safe temperatures. By integrating cold storage right into the prep surface, you eliminate those constant, time-wasting trips to a separate walk-in cooler. Those saved seconds add up fast on a busy night. To see just how much this setup can improve your pizzeria's rhythm, check out our guide on the secret sauce behind efficient pizza prep stations.

A well-organized prep station is the heart of a profitable pizzeria. By minimizing movement and keeping ingredients fresh, a 60-inch table directly contributes to lower ticket times and reduced food waste, boosting your bottom line.

An Investment in Profitability

Investing in the right equipment is about more than just making pizzas; it's about building a solid foundation for your pizzeria's success. The size and versatility of these tables are major reasons they're a staple in so many pizzerias. In fact, the pizza prep tables market is projected to grow significantly, reaching a market size of USD 4.92 billion by 2033. This isn't just a trend; it's a shift toward smarter, more efficient kitchen design in the pizza industry.

To give you a quick snapshot, here’s what a 60-inch table brings to your pizza operation.

Key Benefits of a 60-Inch Pizza Prep Table at a Glance

| Feature | Impact on Your Pizzeria |

|---|---|

| Optimized Workflow | Ingredients are within arm's reach, drastically cutting down prep time per pizza. |

| Spacious Work Surface | Allows 1-2 chefs to work comfortably side-by-side, increasing output during rushes. |

| Integrated Refrigeration | Keeps backup ingredients fresh and food-safe, reducing trips to the walk-in cooler. |

| Improved Consistency | Centralized ingredients ensure every pizza gets the same toppings, every time. |

| Reduced Food Waste | Proper cold storage and easy access mean less spoilage and more profit. |

This table empowers your team to work smarter, not harder, which directly translates to a healthier business.

Ultimately, a 60-inch pizza prep table establishes a rhythm in your kitchen that leads to tangible benefits:

- Faster Ticket Times: With an organized workflow, pizzas get made and sent to the oven in record time.

- Improved Pizza Consistency: Centralized ingredients ensure every pizza is made to your exact standards.

- Reduced Food Waste: Proper refrigeration and easy access mean fewer spoiled ingredients hitting the bin.

- Higher Staff Morale: An efficient workspace reduces stress and frustration for your pizza team, which is priceless.

This unit is far more than a simple table; it's a core asset that directly impacts your pizzeria's speed, quality, and overall success.

Understanding the Anatomy of a Pizza Prep Table

To really get why a 60 inch pizza prep table is such a workhorse, you have to stop seeing it as just a big, cold box. Think of it more like three specialized zones, all working in perfect harmony. Each part has a very specific job that makes your entire pizza-making process faster, safer, and way more organized.

When you break it down, you see how every single component was designed to solve a problem that every busy pizzeria faces. From keeping pepperoni perfectly chilled to giving your crew a durable workspace, the whole design is about boosting efficiency and locking down quality control. Let's pull apart these three core zones and see how they directly impact what happens in your pizzeria every day.

The Refrigerated Topping Rail

Right at the top, you’ve got the refrigerated topping rail. This is basically your pizzeria’s command center—an immediate-access pantry for all your pizza essentials. This is where your pepperoni, mushrooms, onions, and mozzarella live, perfectly chilled and always within arm's reach. A powerful, forced-air refrigeration system keeps cold air moving around every single food pan, making sure ingredients stay in that food-safe sweet spot, usually between 33°F and 41°F.

This constant chill isn't just about passing health inspections; it's about the quality of your pizza. Nobody wants a pizza made with lukewarm cheese or sad, wilting veggies.

A lot of 60 inch pizza prep table models come with a "mega-top" design. This just means the rail is deeper, giving you room for an extra row of food pans. It sounds like a small thing, but during a chaotic dinner rush, it's a massive advantage.

- Standard Top: Usually holds two rows of 1/6-size food pans.

- Mega Top: Can often hold three rows, boosting your on-hand ingredient capacity by up to 50%.

That extra capacity means your team makes fewer trips to the walk-in cooler for refills. Those saved seconds add up on every single pizza, keeping your pizza line flowing smoothly when it matters most.

The Main Cutting Board Workspace

Sitting directly in front of the topping rail is the main stage: the cutting board. This is where the real work happens—stretching dough, saucing the base, and building the final masterpiece. On a 60 inch pizza prep table, you've got enough elbow room for one or even two pizza makers to work side-by-side without bumping into each other.

The material of this cutting board is a bigger deal than you might think. Most commercial-grade tables use a high-density polyethylene.

A high-quality polyethylene cutting board is non-porous, which is just a fancy way of saying it won't soak up juices, bacteria, or odors. This makes it incredibly easy to clean and sanitize—a critical factor for preventing cross-contamination between a meat lover's pizza and a veggie supreme.

This material is also kinder to your pizza cutters and knives, helping them stay sharp longer. And a deep cutting board, often 19 inches or more, gives you plenty of real estate for even the biggest pies. That means less flour and toppings ending up on the floor, which makes for a cleaner, safer kitchen.

The Refrigerated Base Doors and Drawers

Underneath the workspace, you'll find the refrigerated base. This is the bulk storage unit for your entire prep station. It's where you stash backup pans of toppings, bags of cheese, tubs of sauce, and trays of pre-portioned dough. Having this storage built right in is a cornerstone of the table's efficiency, completely eliminating the need for a separate under-counter fridge.

When you're picking out a 60 inch pizza prep table, you'll usually have to choose between two main setups for the base:

- Doors: These are your best bet for storing bulky or odd-shaped items. Think big containers of pizza sauce, boxes of cheese, or stacked dough boxes. The shelves inside are usually adjustable, giving you a ton of flexibility.

- Drawers: Perfect for organizing standard-sized items you need to grab in a hurry. A lot of pizzerias use drawers to hold multiple dough trays, letting staff grab a fresh one without having to unstack a whole pile of them.

The right choice here really comes down to your pizzeria's workflow. If you make dough in huge batches, the bulk storage of doors might be the winner. But if you're a high-volume shop where every second counts, the quick-access organization of drawers might be a better fit. Once you understand how these three zones work together, you'll see the prep table not just as a piece of equipment, but as a thoughtfully designed system for cranking out pizzas at scale.

How to Choose the Right 60 Inch Pizza Prep Table

Picking out a 60 inch pizza prep table isn't just another purchase. Think of it as a long-term investment in your pizzeria's heartbeat—its efficiency and its success. To get it right, you need to think like a seasoned pizzeria operator, looking past the price tag to see the real value in build quality, workflow, and durability.

Let’s walk through how to pick the perfect table for your pizzeria. Your first step should be grabbing a tape measure and getting a feel for your kitchen's daily rhythm. The right table will feel like a natural part of your pizza-making process, not some clunky obstacle your team has to dance around.

Measure Your Kitchen for Optimal Workflow

Before you even glance at a single model, get to know your space. Where is this 60 inch pizza prep table going to live? Think about the classic "kitchen work triangle"—the path between your prep station, the pizza oven, and your main walk-in cooler. You want this new table to shrink that triangle, not stretch it out.

Pay close attention to clearance. You need enough room for your crew to hustle past, even when the refrigerator doors are swung wide open. But even more important is giving the unit room to breathe.

- Front-Breathing Refrigeration: These units are the most flexible. They pull in and push out air right from the front grille, meaning you can snug them up against a wall or right next to other equipment without worrying about them overheating.

- Rear-Breathing Refrigeration: These models need some personal space. They require several inches of clearance at the back and sides to get rid of heat. If you cram them into a tight spot, the compressor will work overtime, jacking up your energy bills and leading to an early breakdown.

Knowing this difference is a huge deal. It will immediately tell you which models are even an option for your pizzeria's layout.

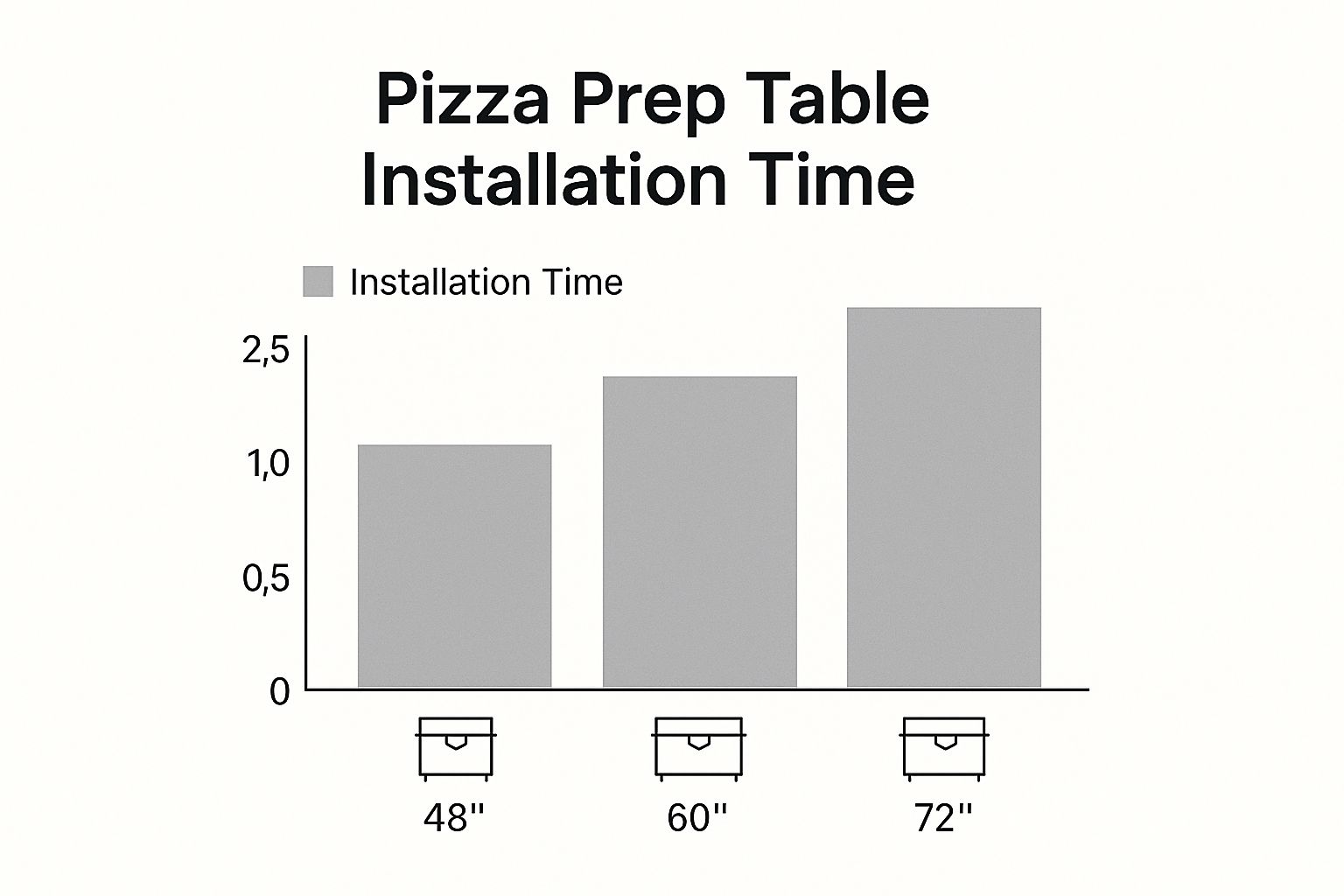

This image shows how much time you should block off for installation based on table size. It's a good way to plan for any downtime.

As you can see, a 60-inch model gives you a massive jump in workspace but only adds a little bit more installation time compared to a smaller unit. It's a great balance for a busy pizzeria.

Doors vs. Drawers: Deciding on Your Base

The refrigerated base of your pizza prep table is your immediate-access pantry, and how you set it up will make or break your team's speed. The choice usually comes down to doors versus drawers.

The decision between doors and drawers for your prep table's refrigerated base really boils down to what you're storing and how fast you need to get to it. One offers pure, unadulterated space, while the other is all about surgical precision and speed.

Comparing Doors vs. Drawers for Your Prep Table Base

| Configuration Type | Best For | Pros | Cons |

|---|---|---|---|

| Doors | Bulk storage, irregularly shaped items (e.g., sauce buckets, large cheese blocks) | Maximum storage flexibility, adjustable shelving, lower initial cost | Can be less organized, requires more bending and reaching |

| Drawers | Standardized, portioned items like pizza dough trays | Superior organization, quick access, better ergonomics | Less flexible for bulky items, higher initial cost |

To nail this choice, just look at your inventory. If you're constantly grabbing big tubs of sauce or giant blocks of cheese, doors are your friend. They give you the open, flexible space you need. But if your workflow is all about grabbing pre-portioned dough balls or specific toppings in a flash, drawers will absolutely streamline your process and shave precious seconds off every single pizza order.

Why Stainless Steel Grade Matters

Listen, not all stainless steel is the same. The grade of steel in your 60 inch pizza prep table is what determines whether it will stand up to the daily grind of a pizzeria or start looking rough after a year. Pizza ingredients, especially good old tomato sauce, are acidic and will eat away at cheaper metals over time.

You want to see 304-grade stainless steel, especially for the top work surface and the interior. This grade has more chromium and nickel, which is just a fancy way of saying it's way better at resisting rust and corrosion from acidic foods and harsh cleaning chemicals.

Sure, a table made with 430-grade steel might be cheaper upfront, but it’s far more likely to get pitted and damaged. For a pizzeria, 304-grade is the only smart long-term play. If you want to dive deeper into this, our complete guide to the commercial pizza prep table has you covered.

And it's not just you looking for this kind of gear. The entire food prep tables market was valued at USD 1.18 billion in 2023 and is projected to climb to USD 1.62 billion by 2029. That growth is being fueled by pizzerias just like yours needing efficient, specialized stations to keep up with demand.

By focusing on these key factors—your pizzeria's layout, the right base configuration, and top-notch materials—you can pick a 60 inch pizza prep table that won't just be a piece of equipment, but a true workhorse for your business for years to come.

Exploring Advanced Features and Innovations

Let's be honest, modern pizza prep tables have come a long way from being just a cold box with a cutting board slapped on top. The best units today are loaded with smart features designed to make your pizzeria run smoother, keep food safer, and actually lower your operating costs. When you start to understand these features, you stop seeing a 60 inch pizza prep table as just another expense and start seeing it as a real investment in your pizzeria’s future.

These aren't just tiny tweaks; they're significant upgrades that solve the real-world headaches of a busy pizza kitchen. From eco-friendly refrigeration that can seriously cut your energy bills to components that clean themselves and prevent surprise breakdowns, these are the details that separate a decent table from a great one.

The Power of Eco-Friendly Refrigerants

One of the biggest leaps forward in refrigeration technology has been the switch to eco-friendly refrigerants. You’ll see many top-tier models now using R290 hydrocarbon refrigerant, and for good reason. It's a natural, non-toxic substance that's a win for both the planet and your wallet.

Unlike the old-school refrigerants that were tough on the ozone layer, R290 has zero Ozone Depletion Potential (ODP) and a tiny Global Warming Potential (GWP). This helps shrink your pizzeria's carbon footprint, which is something more and more customers actually care about. But the benefits you'll feel immediately are financial.

R290 systems are known to be up to 25% more energy-efficient than older models. That means your prep table’s compressor doesn't have to fight as hard to keep things cool, leading to a direct drop in your monthly electric bill. You'll notice it.

Self-Cleaning Condensers: A Smart Investment

The condenser coil is the heart of your refrigeration system, but in a pizza kitchen, it's also a magnet for dust, grease, and flour. Once it gets clogged, the compressor starts working overtime, jacking up your energy costs and heading straight for burnout—one of the most expensive repairs you can face. This is exactly why a self-cleaning condenser is worth its weight in gold.

Think of a self-cleaning condenser as an automated insurance policy for your refrigeration system. By regularly clearing away buildup, it ensures the unit runs at peak efficiency, preventing the gradual strain that leads to sudden, catastrophic failures during your busiest dinner rush.

This feature uses a small rotating brush that automatically sweeps the condenser coils clean several times a day. It's a simple, brilliant action that stops the gunk from building up and suffocating your system. It will save you hundreds on professional maintenance calls and, more importantly, prevent the nightmare of your equipment dying mid-shift.

Forced-Air Systems for Ultimate Temperature Control

Consistency is everything in the pizza business, and that starts with your ingredients. An advanced forced-air refrigeration system is a non-negotiable feature for ensuring every single topping pan on your rail—from front to back—stays at a perfectly consistent, food-safe temperature. It works by actively circulating cold air all around each pan, killing off the dangerous "warm spots" that plague less effective systems.

This technology is critical for a couple of key reasons:

- Quality Control: It guarantees your cheese, meats, and veggies stay fresh and safe, which directly protects the quality and taste of every pizza you sell.

- Health Inspections: It helps you ace your health inspections by making sure all ingredients are held within the required temperature range, typically between 33°F and 41°F.

These kinds of innovations have completely changed the game. Models like the True TPP-AT-60-HC now feature these environmentally friendly systems, along with self-cleaning condensers and powerful forced-air circulation. The result is better performance and way less maintenance. You can check out more details about these high-performance prep tables online. These features aren't just nice extras; they are essential tools for running a modern, efficient, and profitable pizzeria.

Mastering Installation and Maintenance

You’ve invested in a powerful 60 inch pizza prep table; now it’s time to protect that investment. Getting the setup right from day one and sticking to a simple upkeep routine isn't just a good idea—it's what separates a high-performing asset from a constant source of headaches and repair bills in your pizzeria.

Think of it this way: overlooking a few key steps during installation is like building a house on a shaky foundation. It puts unnecessary stress on the whole unit, leading to premature wear and tear. A few minutes of careful setup can save you from major problems down the road.

The Critical First Steps of Installation

Proper installation is about more than just finding a spot for your new table. Where you put it and how you set it up directly impacts the health of its most vital component: the refrigeration system.

First, ensure proper ventilation clearance. This is easily the most overlooked—and most critical—step. Your prep table's compressor creates heat as it works to keep ingredients cold. If that heat gets trapped, the compressor has to work overtime, driving up your energy bill and eventually burning itself out. Always follow the manufacturer’s guidelines, which usually call for a few inches of open space at the back and sides.

Next, level the unit perfectly. An unbalanced table puts constant, uneven stress on the frame and door hinges. Over time, this will cause the doors to sag, breaking the seal. A bad seal means cold air is constantly leaking out, forcing the compressor to run nonstop and putting your food safety at risk. Grab a level and adjust the table’s feet until it’s rock-solid on all sides.

A correctly leveled and ventilated pizza prep table can operate up to 15% more efficiently than one that's improperly installed. That simple setup process translates directly into lower energy bills and a longer life for your compressor.

Your Roadmap to Long-Term Reliability

Once your 60 inch pizza prep table is humming along, a simple maintenance routine is your best defense against unexpected breakdowns. This isn't about complicated technical work; it’s about consistent, easy checks that anyone on your team can handle. To ensure your 60-inch pizza prep table remains a kitchen hero for years, understanding the broader principles of preventive maintenance is essential.

Think of it as a quick health check-up for your most important piece of pizza equipment.

Weekly Maintenance Checklist:

- Wipe Down Door Gaskets: Food gunk and grime build up here, preventing a tight seal. A quick wipe with a damp cloth and mild soap keeps them flexible and effective.

- Inspect and Clean the Cutting Board: Sanitize it daily, of course, but give it a deep clean once a week. If you can, remove it from the table and give it a good scrub to eliminate any deep-set bacteria.

- Check for Obstructions: Make sure nothing is blocking the interior air vents. These are crucial for circulating cold air evenly through the cabinet.

Monthly Maintenance Checklist:

- Clean the Condenser Coils: In a pizza kitchen, the condenser coil is a magnet for flour, dust, and grease. A clogged coil is like trying to breathe with a bag over your head—it suffocates the compressor. Unplug the unit once a month and use a stiff brush or a vacuum to gently clean the coils.

- Test the Door Seals: The dollar bill test is a classic for a reason. Close the refrigerator door on a bill. If you can pull it out with no resistance, the gasket is worn and needs replacing. A weak seal is a massive energy waster.

- Calibrate Thermometers: Check the built-in thermometer against a reliable, calibrated food thermometer. This is non-negotiable for food safety and will keep the health inspector happy.

This straightforward routine is your roadmap to avoiding costly repairs. By dedicating just a few minutes each week and month, you’ll ensure your 60 inch pizza prep table remains the reliable command center your pizzeria depends on.

Optimizing Your Pizzeria’s Workflow

The best equipment in the world won't make a difference if your process is a mess. A 60 inch pizza prep table isn't just a fancy refrigerator; it's the command center of your entire pizza production line. When you treat it with the same focus as a factory assembly line, you start to see real gains in speed, consistency, and—most importantly—profit.

It all starts with a simple French culinary concept: mise en place, which just means "everything in its place." For a pizzeria, this idea comes to life at your topping rail. A smart, well-organized rail is the secret to shaving precious seconds off every single pizza order.

Designing Your Topping Rail for Speed

Think of your topping rail like a musician's piano—every key needs to be exactly where you expect it. The most efficient layout isn't organized by food group; it's organized by popularity. This simple shift cuts down on wasted movement and hesitation, especially during a chaotic dinner rush.

Put your heavy hitters, like mozzarella and pepperoni, in the prime real estate directly in front of the pizza maker. Less-common toppings, like anchovies or pineapple, can live on the ends. This setup ensures that for 80% of your orders, your team's movements are short, direct, and practically automatic.

When you arrange your topping rail based on sales data, you build muscle memory for your staff. This small tweak can trim several seconds off the time it takes to top a pizza. That adds up to minutes saved per hour and faster ticket times all night long.

Ergonomics and Tool Placement

Beyond the toppings, think about the ergonomics of the whole station. Every tool needs a home, and that home should be based on the natural flow of making a pizza. Spatulas, ladles, and cutters should be within an easy, comfortable reach—no twisting, no overextending.

- Sauce Ladle: Keep it right next to the sauce container. No more messy drips across the cutting board.

- Pizza Cutter: Have it waiting near the end of the prep line, right where the pizza moves to the oven.

- Extra Dough Trays: Store them in the refrigerated base directly below the workspace for instant access.

This kind of intentional placement creates a smooth, repeatable rhythm for every single pizza. That’s the real secret to building both speed and consistency.

Restocking and Staff Training

A perfectly organized station can fall apart mid-service if your restocking game isn't on point. Set up a system where backup ingredients are pre-portioned and ready to roll. When a topping pan gets low, another team member should be able to swap it out in under 10 seconds flat, without ever breaking the pizza maker's flow. For more ideas on efficient setups, check out our guide on the best pizza tables for sale to slice your prep time.

Finally, solid training is what makes all these efficiencies stick. Every single person on your pizza team needs to know the exact layout and workflow of that 60 inch pizza prep table. When everyone builds a pizza the same way, you slash errors, improve ticket times, and make sure every customer gets the same great pizza, every single time.

Got Questions? We've Got Answers

Stepping up to a new piece of equipment always brings up a few questions. It's smart to get all the details before you commit. Here are some of the most common things pizzeria owners ask when considering a 60 inch pizza prep table for their kitchen.

Can One Person Really Handle a 60 Inch Table?

Absolutely. In fact, a 60-inch model is pretty much the perfect sweet spot for a single pizza maker. It gives you plenty of elbow room to stretch dough, sauce, and top pies without feeling boxed in.

But the real magic happens during a rush. You have enough space for a second person to jump in and help out, making it a super versatile size that adapts to your staffing needs on the fly.

How Many Topping Pans Can I Fit on a 60 Inch Table?

This can vary a bit between models, but you can count on most standard 60 inch pizza prep tables holding eight 1/3-size food pans in the rail.

If you’re serious about toppings and want to minimize trips to the walk-in, look for a "mega-top" version. Those can often pack in up to twelve 1/3-size pans, which is a game-changer for keeping service moving.

Food safety is non-negotiable. A quality prep table isn't just a workspace—it's a refrigerator. It needs to hold a rock-solid temperature between 33°F and 41°F across every single pan to keep your ingredients fresh and your customers safe.

What Kind of Electrical Hookup Do I Need?

Good news here. Most 60-inch pizza prep tables are designed to be plug-and-play. They run on a standard 115V connection and will work with a regular commercial outlet.

They usually pull somewhere between 5 and 9 amps. But—and this is important—always, always double-check the spec sheet for the exact model you're buying. You need to be sure your kitchen's circuits can handle the load without any drama.

Ready to see how a new table can transform your pizzeria's workflow? At Pizza Prep Table, we live and breathe this stuff. We have a huge selection of top-tier prep tables built to make your kitchen faster and more consistent.

Explore our collection of 60-inch pizza prep tables today!