Used Pizza Prep Tables for Sale: A Pizzeria's Ultimate Buyer's Guide

Share

For any pizzeria owner, keeping a lid on startup costs is everything. That’s why hunting for used pizza prep tables for sale isn't just a good idea—it's one of the smartest financial moves you can make. This is about being strategic, directly slashing your initial investment so you can pour that cash into things that matter on day one, like top-shelf pepperoni or a killer local marketing campaign. You’re not just buying a table; you’re getting a professional-grade workhorse at a fraction of the cost, purpose-built for the high-volume world of pizza making.

Why Smart Pizzerias Buy Used Pizza Prep Tables

When you're opening a new pizzeria or giving your kitchen an upgrade, the equipment list feels endless, and those costs add up fast. A brand-new pizza prep table can put a serious dent in your budget, often running into thousands of dollars. Going with a used model gives you an immediate and substantial financial leg up, letting you put your money where it can make a bigger impact on your grand opening's success.

This isn't about settling for second-best. It's a calculated business decision for a pizza shop. A high-quality, pre-owned unit from a trusted brand can deliver the exact same durability and performance as a new one, but at a price point that’s way more manageable for a new or growing pizzeria.

The Financial Upside of Buying Used

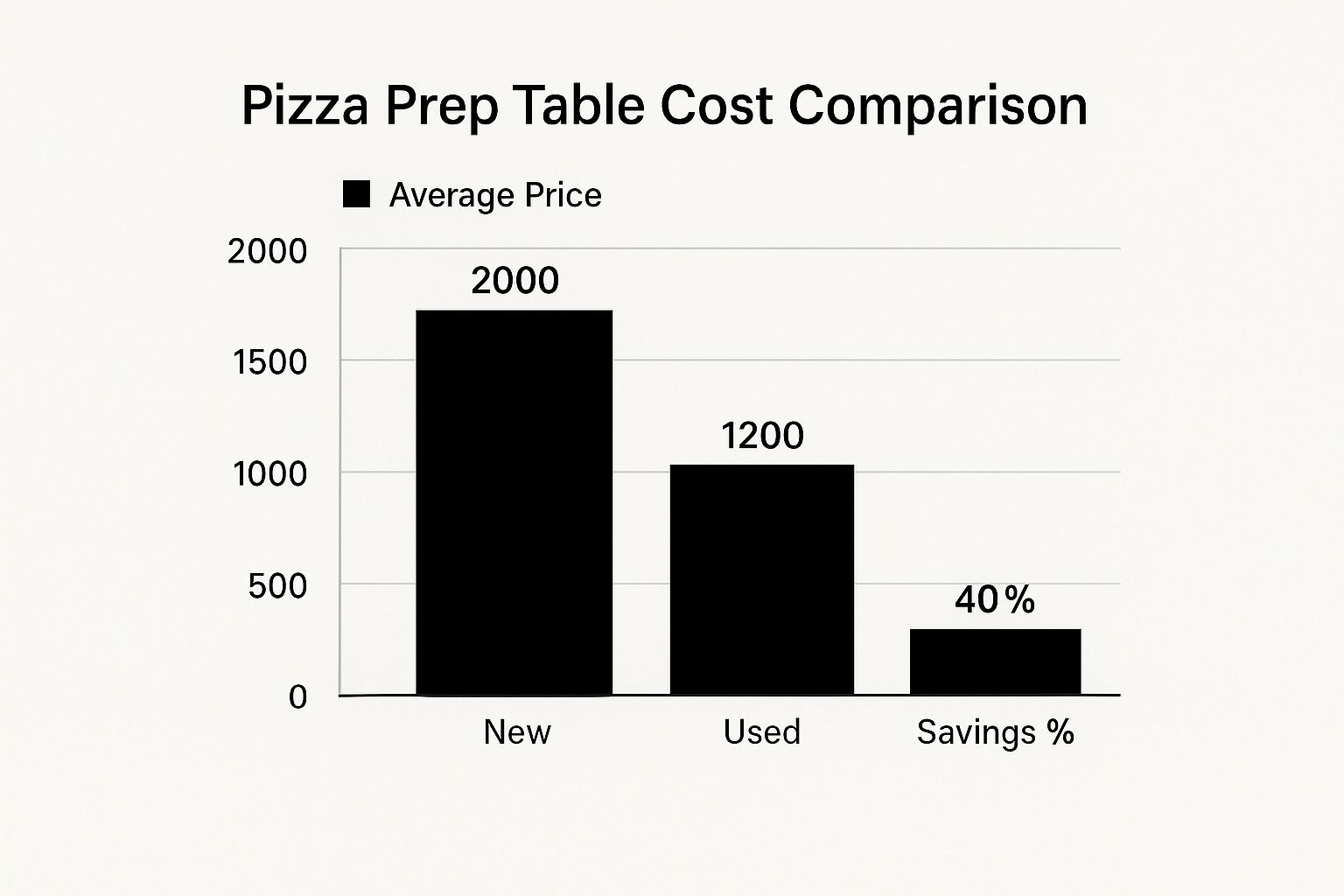

The number one reason for a pizzeria to look for used pizza prep tables is, without a doubt, the cost savings. You can often land a high-performance unit for 40% to 70% less than its brand-new sticker price. This isn't just a small discount; it's a massive reduction in what you need to spend upfront.

Let's look at a real-world pizzeria scenario. A new, mid-range 72-inch pizza prep table might set you back $4,500. You could find a comparable used model—maybe just a few years old and in great shape—for around $2,000. That’s an instant $2,500 in your pocket that you can reinvest directly into your pizza business.

What could your pizzeria do with that extra cash?

- Premium Ingredients: Spring for that higher-quality Grande cheese or specialty sausage to make your pizzas stand out.

- Marketing Budget: Fund a grand opening blitz or run some targeted social media ads showing off your signature pies.

- Staffing: Hire an extra pizza maker to make sure service is smooth from the moment you open.

- Contingency Fund: Build a cash cushion for those inevitable surprise expenses, like a broken mixer on a Friday night.

A well-maintained used table isn't a liability; it's an asset with a proven track record. It has already demonstrated its ability to perform in a commercial pizza kitchen, shifting your perspective from "used" to "proven."

To put the financial benefits into perspective, let's break down the numbers side-by-side.

New vs Used Pizza Prep Table Cost Breakdown

| Factor | New Pizza Prep Table | Used Pizza Prep Table |

|---|---|---|

| Upfront Cost | $4,500 - $8,000+ | $1,500 - $3,500 |

| Immediate Savings | $0 | $2,500 - $4,500+ |

| Depreciation | High in the first year | Minimal, already depreciated |

| Return on Investment | Longer payback period | Faster, due to lower initial cost |

The table makes it crystal clear: choosing a used unit dramatically lowers your barrier to entry and frees up capital that is critical for a new pizzeria's survival and growth.

More Than Just Savings

While the money is a huge factor, there are other practical benefits. The market for pizzeria equipment is always churning. In fact, the global pizza prep tables market is on track to hit USD 4.92 billion by 2033, thanks to a constant cycle of new pizzerias opening and others upgrading. This creates a steady flow of quality used units hitting the market, which is great news for buyers.

Of course, the initial cost is only part of the equation. Smart pizzeria owners are always thinking about long-term operational expenses. For some general guidance, you can explore various energy efficiency tips to help keep your utility bills in check. A pizza prep table is just one piece of the puzzle, and seeing how it fits with all your other commercial food prep equipment is the key to building an efficient pizza kitchen from day one.

Where to Find High-Quality Used Pizza Prep Tables

Finding a great deal on a used pizza prep table isn't just about saving a few bucks—it's about knowing where the real gems are hiding. Your treasure map for uncovering these deals starts right here. Instead of just jumping on the first Facebook listing you see, a bit of strategic searching across different channels can land you a much better machine at a much better price for your pizzeria.

The hunt requires a little detective work, but the payoff is huge. From online marketplaces to your local restaurant network, every source has its own quirks, advantages, and potential pitfalls for a pizza restaurant owner.

Digital Marketplaces and Classifieds

Let’s be honest, platforms like Facebook Marketplace and Craigslist are probably the first places you’ll look. They offer a direct line to local sellers, which means you can often see the unit in person before handing over any cash and, more importantly, avoid those killer shipping fees.

But you have to be careful here. You're almost always buying "as-is," with zero warranty or backup if the compressor gives out a week later. It's on you to really vet the seller and the equipment. Ask direct questions: How old is it? What’s the service history? Why are you selling it? A seller who is open and detailed is a much better bet than one who gives you one-word answers.

Pro Tip: Don't just search for "used pizza prep tables for sale." Get creative. Try searching for terms like "pizzeria closing sale," "pizza kitchen equipment," or even "commercial refrigeration" to find listings that might be miscategorized.

Restaurant Supply Liquidators and Auction Houses

For a more professional—and often safer—transaction, turn to restaurant supply liquidators and auction houses. These businesses are pros who specialize in handling equipment from restaurants that have closed their doors or upgraded their kitchens.

Liquidators are a fantastic resource for a few key reasons:

- Refurbished Options: Many have in-house techs who inspect, clean, and repair equipment before it ever hits the sales floor. This often includes replacing worn-out parts like gaskets or fan motors.

- Potential Warranties: While not guaranteed, some dealers will offer a short-term warranty, maybe 30-90 days. That bit of coverage provides some serious peace of mind for a pizzeria owner.

- Bundled Deals: If you need more than just a prep table, you can usually negotiate a package deal for a pizza oven, dough mixer, or other essentials.

Auction houses, both online and in-person, can be a goldmine for incredible bargains. The trick is to do your homework before you start bidding. Know the market value of the models you’re eyeing and set a firm budget. It's way too easy to get caught in the excitement of a bidding war and overpay.

This approach taps into a huge market. The general food prep table market was valued at USD 1.18 billion and is only getting bigger. The availability of used equipment from trusted brands like True Manufacturing and Turbo Air gives pizzerias a vital, budget-friendly way to get professional-grade gear and compete effectively.

Networking With Other Pizzeria Owners

One of the most powerful, yet often overlooked, methods is simply talking to people in your local pizzeria community. Get connected with other pizzeria owners, whether it's through local business groups or just by stopping by their shops during a slow afternoon.

Fellow owners can be your absolute best source for a well-maintained machine. Someone who is upgrading their kitchen might be thrilled to sell their old, reliable prep table to another local pizzeria they trust. The biggest advantage here is transparency; you’re often getting a unit with a known service history from a peer who gets how crucial reliable equipment is for making pizzas day in and day out. This direct connection often leads to the best-quality used pizza prep tables for sale.

Once you've found your prep table, don't forget the final step: getting it to your pizzeria safely. A prep table is incredibly heavy, and its refrigeration components are delicate. Taking a few minutes to learn about safely moving heavy commercial kitchen equipment will protect your new investment. A little planning here can save you from a lot of costly damage and heartache.

Your Essential Pre-Purchase Inspection Checklist

Alright, you've tracked down a promising used pizza prep table. Now for the most important part of the whole deal: the in-person inspection. This is where you put on your detective hat. A careful once-over can be the difference between scoring a pizza kitchen workhorse and buying someone else's expensive headache.

Think of it this way: every dent, strange noise, and temperature swing tells a story about the unit's past life in another pizza shop. Your job is to read that story and decide if it's a machine you can trust. Don't be timid—get up close and personal with it.

Assessing the Refrigeration System

The heart and soul of any pizza prep table is its refrigeration. If this fails, it's not just a hassle; it's a food safety nightmare and a major hit to your wallet. This is where you need to spend most of your time.

First things first, call the seller ahead of time. Ask them to plug the unit in at least an hour before you get there. This gives it enough time to pull down to its proper operating temperature. And bring your own trusted thermometer. Never, ever rely on the unit's built-in display—they can be notoriously inaccurate.

Once you arrive, start taking temperatures:

- The Refrigerated Base: Stick your thermometer in the main cabinet, shut the door, and give it a few minutes. You're looking for a steady temperature at or below 40°F (4°C).

- The Topping Rail: The ingredient wells need to be holding that same food-safe temp. Check a few different spots along the rail to make sure the cooling is even, from the pepperoni to the mushrooms.

Next, just listen. A healthy compressor should cycle on and off. If it runs constantly without ever shutting off, that's a huge red flag.

A compressor that runs nonstop is screaming for help. It could point to a slow coolant leak, a dying motor, or bad insulation—all of which are costly repairs. That constant hum is the sound of your savings vanishing into a future service call right before a weekend pizza rush.

Finally, check the gaskets—the rubber seals around the doors and lids. Run your hand along the seams when they're closed. Feel a draft of cold air? The gaskets are shot and need replacing. It's a relatively cheap fix, but it's a fantastic bargaining chip.

As you can see from the data, the potential savings are huge when buying used, which is exactly why a thorough inspection is critical to lock in that value.

That nearly 40% average savings is what makes this worthwhile. Your job is to make sure the unit's condition justifies that discount.

To help you spot trouble, I've put together a quick-reference table. Think of this as your cheat sheet for translating what you see into what it'll cost your pizzeria. These are the red flags I've learned to look for over the years.

Inspection Red Flags and What They Mean

| Symptom You Notice | What It Likely Means | Potential Cost to You |

|---|---|---|

| Compressor runs constantly | Low refrigerant, failing motor, or bad insulation | $300 - $1,200+ |

| Uneven cooling in the rail | Clogged evaporator coils or failing fan motor | $150 - $500 |

| Water pooling inside | Clogged drain line or bad door seals | $50 - $250 |

| Loud clanking/grinding noises | Failing compressor or fan motor bearings | $400 - $1,500+ |

| Frayed or damaged power cord | Serious fire and electrical hazard | $75 - $150 for replacement |

Spotting one of these doesn't always mean you should walk away, but it absolutely means you need to adjust your offer to cover the future repair bill.

Inspecting the Structure and Exterior

Once you feel good about the refrigeration, it's time to judge the book by its cover. A prep table in a busy pizzeria is going to have some battle scars, and that’s fine. What you need to do is tell the difference between cosmetic scuffs and serious structural damage.

Give the whole thing a good look-over. Check for rust, especially around the bottom, corners, and any welded joints. On the stainless steel surfaces, light scratches are normal. But deep gouges or big dents can weaken the metal and create nasty spots for bacteria to grow.

Get hands-on with these specific parts:

- Doors and Drawers: Swing them open and closed a few times. Are they smooth? Do they sag or look misaligned? Wobbly doors often mean worn-out hinges, which can put a lot of stress on the unit's frame.

- Legs and Casters: The table needs to be rock-solid. Give it a push. If it wobbles, it's a hazard. If it has wheels (casters), make sure they roll easily and that the brakes lock securely.

- Electrical Cord and Plug: Carefully inspect the power cord for any cracks, fraying, or exposed wires. A damaged cord is a serious fire hazard and must be replaced, no exceptions.

The cutting board is another tell-tale component. It's going to show wear, but look for deep knife grooves from pizza cutters, heavy stains, or any warping. If it's in really rough shape, you'll have to replace it, so be sure to factor that cost into your negotiation.

Verifying Key Information

Before you even think about making an offer, do this one last thing. Every piece of commercial equipment has a data plate—a little metal tag or sticker with all its vital stats. It’s usually on an inside wall or on the back near the compressor.

Find it and take a picture with your phone. The plate will have the model number and serial number. With that info, you can go online and find the unit's real age, its original specs, and whether you can still get parts for it. Discovering a unit is 15 years old when it was advertised as "gently used" is powerful leverage. This simple step protects you from getting ripped off and helps you know exactly what you’re buying.

How to Negotiate the Best Price for Your Pizza Prep Table

Getting a great deal on a used pizza prep table isn't about aggressive lowballing. It’s about walking in prepared and using the information you've gathered to land a fair price that reflects the unit's real-world condition. Your most powerful tool here is that pre-purchase inspection you just did. Every potential flaw you spotted can become a tangible negotiating point.

Remember, every issue you noted—from a worn gasket to a noisy compressor—has a real-world cost tied to it. This knowledge is your leverage. When you approach the negotiation with specific, data-backed points, you shift the conversation from a simple haggle into a straight-up business discussion for your pizzeria.

Use Your Inspection Findings as Leverage

Your goal is to justify your offer with clear, undeniable facts. Instead of just saying, "It seems a little beat up," you need to present a calculated argument. This shows the seller you’ve done your homework and you're serious about making a fair deal, not just kicking tires.

Let's say the cutting board is deeply grooved and stained beyond saving. Before you even make your offer, pull out your phone and do a quick search for a replacement board for that specific model. If a new one costs $250, you can present that figure directly.

Frame your offer professionally: "The table looks solid, but this cutting board will need immediate replacement, which I see costs about $250. I'd be willing to take it off your hands for your asking price minus that replacement cost." It’s an approach that’s professional, hard to argue with, and bases your negotiation on concrete numbers.

The same logic works for almost any issue:

- Worn Gaskets: "The door seals are definitely leaking cold air. I got a quick quote, and new gaskets for this model are $90. I'll need to factor that into my offer."

- Cosmetic Damage: For significant dents or rust, you can argue for a discount based on the potential for future problems or just the difficulty in keeping it sanitary.

- Age of the Unit: If the data plate reveals the table is much older than advertised, you can reference the expected lifespan of commercial pizza equipment as a solid reason for a lower price.

Anchor Your Offer in Market Reality

Knowing the going rate for used pizza prep tables for sale is your second-best tool. Before you ever talk to the seller, you should have already scouted what similar models are selling for on online marketplaces, liquidator sites, and completed auction listings.

This research gives you a realistic price range to work within. If the seller is asking $2,000 for a unit you've seen listed elsewhere for $1,500 in similar condition, you can politely bring this up. You could say, "I've been tracking the market for this model, and they seem to be consistently selling in the $1,400 to $1,600 range. Would you be willing to come down to $1,600?"

The key is to be respectful but firm. You're not trying to insult the seller; you're just demonstrating that your offer is based on the current market value, not just some random number you pulled out of thin air. This positions you as a knowledgeable pizzeria owner who means business.

Negotiate Beyond the Price Tag

Sometimes, a seller just won't budge much on the price. I've been there. When this happens, it's time to shift your focus and negotiate for added value. Getting extra items or services thrown in can be just as valuable as a cash discount.

Think about what else would make the deal better for your pizzeria. Could you get them to throw in some extras?

- Ask for Included Delivery: Commercial freight can be surprisingly expensive. Getting the seller to deliver the table to your restaurant could easily save you several hundred dollars and a major headache.

- Request Extra Pans: It never hurts to ask if they have any spare ingredient pans (like ninth-pans or sixth-pans) they could include. These small additions add up and save you money and hassle later.

- Bundle Other Equipment: If the seller is a pizzeria that's closing down, see if they have other small items you might need. Pizza screens, peels, or other utensils could be included for a small additional cost or even for free just to help them clear the space and close the deal.

By combining direct price negotiation with a smart strategy for added value, you give yourself more ways to win. You walk away not just with a piece of equipment, but with a great deal that genuinely benefits your pizzeria's bottom line.

Post-Purchase Care and Maintenance Tips

You did it. You negotiated a great deal and hauled your used pizza prep table back to its new home in your pizzeria. That's a huge win, but the real work starts now. Your focus has to shift from getting the asset to protecting it.

A solid, consistent maintenance routine is the single most important thing you can do to extend its life and make sure it remains a profitable workhorse for your pizza kitchen. Neglecting the simple stuff is a one-way ticket to expensive emergency repairs and brutal downtime—usually right in the middle of a Friday night pizza rush.

By building some simple daily, weekly, and monthly habits, you can keep your unit humming along efficiently and maintain the highest standards of food safety.

Your Daily Maintenance Routine

The foundation of a long-lasting prep table is built on simple actions that take just a few minutes at the end of a shift. Think of this as your first line of defense against grime, bacteria, and unnecessary strain on the equipment.

- Wipe Down All Surfaces: At the end of the day, grab a food-safe cleaner and hit every surface. That means the cutting board, the exterior doors, and the stainless steel lid. This keeps bacteria from setting up shop and ensures your pizza station always looks professional.

- Clean Ingredient Wells: Pull all the food pans out of the topping rail. Wipe down the inside of the rail to get rid of any spilled cheese, sauce, or moisture. This is absolutely critical for preventing mold and cross-contamination.

- Clear Debris: Sweep or wipe away any flour and cornmeal that have fallen around the base of the unit, paying close attention to the vents. Keeping that area clear is key to good airflow for the condenser.

Essential Weekly Checks

Once a week, it's time to dig a little deeper. These tasks focus on the parts of the table that see the most action and are vital for performance.

- Deep Clean the Gaskets: Gently clean the door and lid gaskets with warm, soapy water. While you're at it, check for any cracks, tears, or brittleness. A good seal is what keeps the cold air in and your energy bills down.

- Check Temperature Logs: Take a look at your temperature logs. Is the unit consistently holding at or below 40°F? Any wild swings could be an early warning sign that something’s not right.

- Inspect and Sanitize Topping Stations: Go beyond the daily wipe-down. This is a good time to properly clean and rethink how you have things organized. For fresh ideas on setting up for maximum speed, you can review our guide to prep like a pizza pro with these topping stations.

Key Monthly Maintenance Tasks

Your monthly tasks are a bit more involved, but they protect the mechanical heart of your prep table. This is how you prevent the most common—and most expensive—failures.

Your number one job here is cleaning the condenser coil. The condenser is what pulls heat out of the unit, but it’s also a magnet for all the dust, flour, and grease floating around your pizza kitchen. When it gets clogged, the compressor has to work way too hard, leading to overheating and, eventually, a total breakdown.

Think of a clogged condenser coil like trying to run a marathon while wearing a winter coat. The system will overheat, strain itself, and eventually break down. This is the #1 preventable cause of refrigeration failure in commercial pizza kitchens.

It's a simple fix. Just unplug the unit, find the coils (usually behind a grille at the bottom), and use a stiff-bristled brush and a vacuum to gently clean away all the buildup. Seriously, this one task can save you thousands in repair bills. For a wider view of keeping all your kitchen gear in top shape, you can reference a comprehensive commercial-grade maintenance checklist.

This kind of proactive care is more important than ever. The market for pizza prep tables is forecasted to grow at an annual rate of 7.1%, a reflection of the global demand for efficient and safe kitchen operations. As more pizzerias open, the supply of quality used pizza prep tables for sale will grow, but their longevity will always come down to diligent maintenance. You can learn more about this market growth and its implications on Dataintelo.com.

Questions We Hear All the Time from Pizzeria Owners

When you're hunting for a used pizza prep table for sale, it's natural for questions to start piling up. It’s a serious investment, even on the second-hand market, and you want to be sure you're making a smart move for your pizzeria.

We get it. We've collected the most common questions we hear directly from pizzeria owners just like you. Here are some straight-shooting answers to help you feel confident in your search.

What’s a Fair Price for a Used Pizza Prep Table?

Figuring out a fair price is a bit of a balancing act. A good rule of thumb is that a used table should run you somewhere between 40% and 70% of what a comparable new model costs today. Where it falls in that range really depends on a few key things.

The brand is a huge driver of value. Big names like True and Turbo Air just hold their value better than the lesser-known brands. Age, physical condition, and of course, size all play a major role, too. Before you even think about an offer, do your homework and find the current retail price of a similar new table.

Use the notes from your inspection as direct negotiating points. A table with worn-out gaskets or a bunch of cosmetic damage shouldn't command the same price as a clean, well-maintained unit. It just makes sense that a newer, well-cared-for table from a top-tier brand will be at the higher end of that price spectrum.

Are Refurbished Prep Tables Worth the Extra Cost?

In most cases, absolutely—especially if you're not a refrigeration expert yourself. Refurbished tables are a fantastic middle ground between buying an "as-is" unit from a private seller and paying the premium for something brand-new. They cost more than a typical used table, but what you’re really buying is peace of mind.

A reputable dealer has had their own technicians inspect, repair, and deep-clean the table. They often go ahead and replace commonly worn parts like fan motors, door seals, or sometimes even the compressor.

The biggest advantage of buying refurbished is the warranty. Even a short 30- to 90-day warranty protects you from an immediate lemon and shows the seller is confident in their work. This is protection you simply won't get in a private sale on Craigslist.

If you aren't completely confident in your own ability to spot potential red flags during an inspection, that slightly higher cost for a refurbished unit is a very smart investment in your pizzeria's stability.

What Are the Most Reliable Brands to Look For?

In the controlled chaos of a commercial pizza kitchen, some brands have built a reputation for being nearly indestructible. When you're looking for a used pizza prep table, it's a wise move to focus your search on these names.

Keep an eye out for these industry workhorses:

- True Manufacturing: Widely considered a top-tier brand, known for its bulletproof construction and rock-solid reliability.

- Turbo Air: Another fantastic choice, often praised for its smart features and energy efficiency.

- Beverage-Air: A company that's been around forever with a solid track record for producing durable and dependable refrigeration.

Sure, these brands might come with a slightly higher price tag on the used market, but their long-term value is undeniable. Replacement parts are generally easy to find, and most service techs are familiar with them, which can save you a ton of time, money, and stress if a repair is ever needed for your pizza station. For a deeper dive on what makes certain tables stand out, you might be interested in our post about prep tables that work as hard as you do.

How Can I Test the Refrigeration System Myself?

You don't need to be a technician to run a few basic—but critical—tests. The most important tool you can bring with you is your own trusted, calibrated thermometer. Don't rely on the unit's display.

First, stick your thermometer inside the refrigerated base cabinet, shut the door, and let the unit run for at least 30 minutes. You need to see if it can consistently hold a food-safe temperature, which is 40°F (4°C) or below.

Next, just listen. The compressor should cycle on for a bit and then cycle off. If it runs constantly without ever taking a break, that’s a major red flag. It could signal anything from a coolant leak to a failing motor. Finally, press your fingers around the edges of the doors and lids. If you feel cold air leaking out, the gaskets are shot and will need to be replaced.