Finding the Best Commercial Fridge for Your Pizzeria

Share

When you're outfitting a pizzeria, the best commercial fridge isn't just one appliance. It’s a whole system, a team of specialized coolers working together to keep things fast, fresh, and flowing. The star player in this lineup is always the pizza prep table, which cleverly combines refrigerated storage for toppings right under your main workspace. This is the heart of any efficient pizza line.

What Is the Best Commercial Fridge for a Pizzeria

Forget searching for a single, perfect commercial fridge for your pizzeria. What you’re really building is a cooling ecosystem designed for making pizza. Each piece of equipment has a specific job to do, whether it's keeping mozzarella and pepperoni at safe temperatures, speeding up service during a dinner rush, or making sure every pie that goes out the door tastes consistently amazing.

This integrated approach is the secret sauce for a high-volume pizza kitchen. A well-designed refrigeration workflow eliminates bottlenecks, cuts down on food waste, and keeps your pizzaiolos moving like a well-oiled machine, even when the orders are piling up.

The Pizzeria Refrigeration Ecosystem

The ideal setup is a combination of specialized units that work in harmony. While the pizza prep table gets all the attention, it relies on a strong supporting cast to keep your kitchen humming. The right mix will depend on your pizza volume and space, but the core roles of each unit don't change.

- Pizza Prep Table: This is the command center where all the action happens. It gives your crew instant access to chilled toppings in their pans while providing a wide cutting board for stretching dough and building pies. Its main job is to keep ingredients within a safe temperature zone during active prep.

- Reach-In Refrigerator: Parked close by, a reach-in unit holds all your immediate backup items. Think extra pans of pepperoni and mushrooms, blocks of cheese, gallons of sauce, and trays of proofed dough balls ready to go.

- Walk-In Cooler: For any serious pizzeria, a walk-in cooler is a must-have for bulk inventory. This is where you store entire cases of cheese, big tubs of sauce, and crates of produce, which lets you buy smart and reduce how often you need deliveries.

The core principle for a pizzeria is simple: design a flow where ingredients move seamlessly from bulk storage (the walk-in) to accessible backup storage (the reach-in), and finally to the active prep line (the pizza prep table). This workflow minimizes steps and maximizes pizza output.

To figure out which pieces are right for your kitchen, let’s break down their primary functions. Of course, choosing the best commercial refrigerator brands is a critical part of building a system that won't let you down.

| Refrigerator Type | Primary Role in a Pizzeria | Best Use Case |

|---|---|---|

| Pizza Prep Table | Active ingredient storage and prep | The main assembly line where every pizza gets made. |

| Reach-In Refrigerator | Accessible backup storage | Storing items needed to restock the pizza prep line quickly during a shift. |

| Walk-In Cooler | Bulk inventory storage | Holding large quantities of dough, cheese, and toppings bought in bulk. |

Once you understand these distinct roles, you can stop looking for a single magic appliance. Instead, you can focus on designing a powerful, efficient refrigeration system that's built specifically for your pizzeria’s needs. That strategic thinking is the real key to finding the best commercial fridge for making pizza.

Assessing Your Pizzeria's Refrigeration Needs

Picking out the right commercial fridge for your pizzeria isn't about scrolling through catalogs. It all starts with a hard look at your own operation—how your kitchen breathes and moves from the quiet morning prep to the absolute chaos of a Friday night dinner rush. Getting this self-assessment right is the single most important step. It’s what stops you from overspending on a beast of a unit you don’t need, or worse, under-equipping your kitchen and creating bottlenecks that kill your pizza-making speed and risk food safety.

The perfect refrigeration setup is completely contextual. A tiny slice shop's needs are a world away from a sprawling, full-service pizzeria with a huge menu. To figure out what you need, you have to start by asking the right questions about your pizza business.

Mapping Your Pizzeria's Workflow

To nail down your needs, you have to get specific with numbers. I’m not just talking about how many pizzas you sell, but the nitty-gritty of your topping variety and ingredient flow. A clear picture here will point you directly to the right size and type of pizza prep table and supporting refrigeration.

Start by digging into these key operational questions:

- Daily Pizza Volume: Seriously, how many pizzas fly out the door during your busiest lunch and dinner service? This number is the biggest clue for sizing your pizza prep table.

- Menu Complexity: How many different toppings do you offer? The more ingredients you juggle, the more refrigerated pan slots you’ll need right on the prep line.

- Dough and Cheese Volume: What’s your weekly burn rate for bulk items like dough balls and blocks of mozzarella? This will tell you whether a standard reach-in will cut it or if you absolutely need a walk-in cooler.

- Kitchen Layout: What are the actual, physical dimensions of your kitchen? Your available square footage will dictate the footprint of your units and might push you toward models with specific features, like front-breathing compressors for tight spots against the wall.

A classic rookie mistake is planning for the pizzeria you have today, not the one you're building. Your refrigeration setup shouldn't just handle this week's rush; it needs to support your growth over the next few years.

Answering these questions maps your operational reality to specific equipment. A high volume of toppings points directly to a larger pizza prep table, while massive weekly cheese orders make a powerful argument for investing in a walk-in cooler. If you need a hand with that piece of the puzzle, you can learn more about correctly sizing a walk-in cooler in our guide.

The Role of Each Unit in Your Pizzeria

Think of your refrigeration system as a team where each player has a distinct job. The pizza prep table is your frontline warrior, keeping toppings perfectly chilled and within arm's reach during the heat of service. Your reach-in refrigerator is the immediate backup, holding restock items close by so the line never stops. And the walk-in cooler? That's your central warehouse, the backbone holding all your bulk pizza ingredients.

Understanding this dynamic is crucial for making a smart investment. It's especially true when you see how the market for this gear is growing. The global food prep tables market was valued at USD 1.18 billion in 2023 and is on track to hit USD 1.62 billion by 2029. That growth, fueled by a booming foodservice industry, means more innovation and better pricing for pizzeria owners like you. You can dive into more insights about food prep table market trends on Arizton.com. Investing in the right prep table isn't just buying a piece of metal; it's positioning your pizzeria within a professionally equipped, thriving part of the industry.

By taking the time to carefully evaluate your pizzeria's unique volume, menu, and space, you can build a refrigeration system that works as a single, efficient unit. This is how you make sure every dollar you spend on equipment pays you back in smooth service and happy customers.

Comparing Pizza Prep Table Features and Sizes

Your pizza prep table isn't just a piece of equipment; it's the heart of your entire pizza-making operation. Picking the right one goes way beyond just measuring the empty space in your kitchen. The best commercial fridge for your prep line has to sync up with your pizzeria's volume, menu, and workflow, because it directly impacts your speed and quality during that chaotic dinner rush.

Getting the size right is the first make-or-break decision. A unit that’s too small will instantly create a bottleneck, leaving your crew frustrated and customers waiting. Go too big, and you’re just wasting precious kitchen real estate and burning money on energy costs. The right choice is all about your pizzeria's scale.

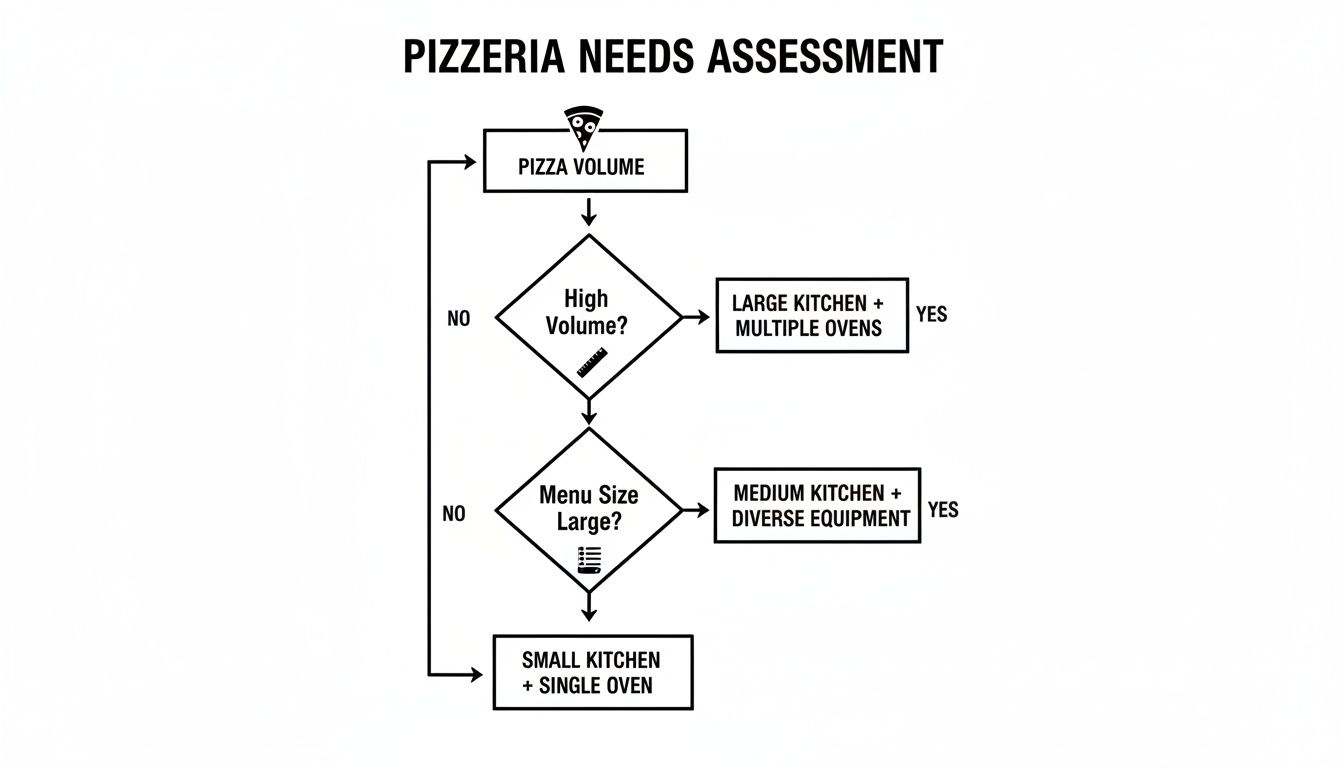

This flowchart can help you map out the decision process based on what your pizza shop actually needs.

As you can see, it really boils down to three things: how many pizzas you're slinging, the size of your topping menu, and the physical space you have to work with. A smart assessment of these factors helps you land on a prep table that helps you grow instead of holding you back.

Matching Table Size to Pizzeria Volume

The most common pizza prep table sizes you'll see are 44", 67", and 93". Each size is really a shorthand for a specific type of pizza operation, mostly defined by its pan capacity—that’s the number of topping containers the refrigerated rail can hold.

- 44-Inch Models: These compact units are the perfect fit for small slice shops, cafes that have a single pizza on the menu, or food trucks. They usually hold about six 1/3-size pans, which is plenty for a simple, focused pizza menu.

- 67-Inch Models: This is the go-to workhorse for most small and medium independent pizzerias. With room for around nine 1/3-size pans, it strikes a great balance between topping variety and footprint. It gets the job done without taking over your whole kitchen.

- 93-Inch Models: Built for the big leagues. These large-format tables are for high-volume pizzerias and can hold twelve or more 1/3-size pans. They're designed for kitchens with huge menus and multiple cooks working the line at the same time.

I see this all the time: pizzeria owners pick a size based on their current kitchen layout, not their actual peak service volume. If your crew is constantly bumping elbows and waiting for a spot on the line, your table is too small. Period.

To help you visualize the right fit, here’s a quick breakdown of how table size lines up with real-world pizzeria operations.

Choosing the Right Pizza Prep Table Size

Use this table to match your pizzeria's daily output and menu needs with the ideal prep table size for maximum efficiency.

| Table Size | Pan Capacity (1/3 Pans) | Ideal Pizzeria Type | Operational Scenario |

|---|---|---|---|

| 44" | 6 Pans | Small slice shops, food trucks, cafes with a limited pizza menu. | Perfect for a focused menu with core toppings. One person can comfortably manage the entire station. |

| 67" | 9 Pans | Independent pizzerias, mid-volume restaurants. | The sweet spot for most pizza operations. Offers enough variety for a solid menu without a massive footprint. |

| 93" | 12+ Pans | High-volume pizzerias, chains, kitchens with extensive menus. | Designed for multiple cooks working side-by-side. Essential for places with a huge list of toppings. |

Choosing the right size is the foundation, but a few key features will make or break your daily pizza-making workflow.

Standard Rail vs. Mega Top Configuration

Beyond the length of the table, the design of the ingredient rail itself is a huge factor in your pizzeria's efficiency. This is where you have to decide between a standard top and a "mega top," and for pizzerias with a diverse menu, it’s a critical choice.

A standard rail holds a single row of pans, keeping them flush with the work surface. It’s a simple and effective design that works for most pizza operations. A mega top, on the other hand, is built with a deeper, often angled rail that can hold two or even three rows of pans. This can boost your on-hand topping capacity by over 30% without making the unit any wider. For a pizza shop offering dozens of toppings, this is an absolute game-changer—it drastically cuts down on restocking the line mid-service.

While mega tops give you way more capacity, standard rails offer a flatter, more open workspace. The decision really comes down to your menu's complexity versus how much prep area you want. For a deeper look at how different styles affect workflow, check out our guide on refrigerated sandwich and pizza prep tables.

Critical Features for Pizzeria Operations

A few technical features are what separate a reliable, compliant pizza prep table from just a basic cooler. Getting these details right ensures your investment meets health codes and can handle the abuse of a commercial pizza kitchen.

NSF Certification: This is completely non-negotiable. An NSF (National Sanitation Foundation) sticker guarantees the unit is designed for easy cleaning and meets strict public health standards. You simply will not pass a health inspection for your pizzeria without it.

Cutting Board Material: The built-in cutting board needs to be deep enough—usually 19 inches or more—to handle large pizza skins. Most are made from high-density polyethylene, a tough, non-porous material that won’t get torn up by pizza cutters and is easy to sanitize.

Refrigeration System: Where the compressor is and how it works matters a lot in a pizzeria.

- Front-Breathing Compressors: These units pull in and push out air from the front, so you can install them right up against a wall or next to other equipment. This is a lifesaver in tight pizza kitchens.

- Air-Cooled vs. Cold-Wall: Most modern pizza prep tables use forced-air refrigeration to blow cold air evenly around the pans. Some older or cheaper models might use cold-wall tech, which can sometimes create hot and cold spots in your toppings.

Demand for this kind of specialized gear is growing fast. The global pizza prep table market hit USD 1.27 billion in 2024 and is expected to climb to USD 2.1 billion by 2033. This just shows how vital these units are for any professional pizza business.

And don't forget, your workflow doesn't stop once the pizza is made. While you're optimizing the prep area, remember that efficiency extends to packaging, like having high-quality pizza boxes ready for delivery. By carefully comparing all these features, you can lock in the best commercial fridge to be the foundation of your pizzeria’s success.

Choosing Between Reach-In and Walk-In Coolers

While the pizza prep table is the star of your production line, it’s the backup storage that keeps the whole operation from grinding to a halt. Deciding between a reach-in refrigerator and a full-blown walk-in cooler isn’t just about how much space you have; it’s a strategic choice that dictates your ingredient inventory, shapes your pizzeria’s rhythm, and ultimately impacts your bottom line.

For a new pizzeria, this decision is usually pretty straightforward. When your footprint is tight and your startup capital is even tighter, a one or two-door reach-in refrigerator is the logical first step. Think of it as the immediate backup for your pizza prep line, holding just enough extra dough, cheese, and sauce to get you through a busy Friday night without taking over your whole kitchen.

The Case for the Reach-In Refrigerator

A reach-in cooler is the perfect partner for pizzerias with a manageable, steady volume. It’s designed for quick grabs—think extra dough boxes, blocks of mozzarella, and backup containers of toppings. By placing it just a few steps from the prep line, you create an efficient little loop for restocking that minimizes downtime when the pizza orders are flying in.

The advantages of starting with a reach-in are crystal clear:

- Smaller Footprint: These units slide neatly into existing kitchen layouts, saving that precious floor space for more essential cooking and prep stations.

- Lower Initial Cost: For any startup or small pizzeria, the lower upfront investment makes a reach-in a much more financially sound and accessible choice.

- Flexibility: You can opt for solid doors to get better insulation or glass doors for a quick inventory check at a glance, tailoring the unit to your specific workflow.

A reach-in is the workhorse that supports the daily grind. It ensures your cooks can quickly grab what they need to replenish the pizza prep table without ever having to leave the main kitchen area. That kind of efficiency is what keeps ticket times down when you’re in the weeds.

When to Make the Leap to a Walk-In Cooler

As your pizzeria grows, you’ll start to feel the squeeze. The signs are always the same: you’re getting more frequent deliveries, your reach-in shelves are overflowing, and you can’t take advantage of bulk pricing on cheese and pepperoni. This is the moment a walk-in cooler stops being a luxury and becomes an absolute necessity for scaling your pizza business.

A walk-in completely transforms your inventory game. It gives you the space to store ingredients by the pallet, from giant wheels of parmesan to entire cases of pepperoni. This is how you unlock better pricing from suppliers, which can seriously lower your food costs over time.

A walk-in cooler is more than just a big refrigerator; it's a central inventory hub for your pizzeria. It allows for superior organization with dedicated shelving for produce, dairy, and proteins, which dramatically improves food safety and reduces waste from cross-contamination.

The benefits for a high-volume pizzeria are massive:

- Bulk Purchasing Power: Storing ingredients by the pallet can slash your cost of goods by 5-15% or more. That’s a saving that goes straight to your bottom line.

- Superior Organization: With designated zones for different food categories, you can implement a strict "first-in, first-out" (FIFO) system, making sure older dough and sauce always get used first.

- Operational Efficiency: A well-organized walk-in makes it much faster for staff to pull full cases of ingredients for the day's prep, streamlining the entire pizzeria's morning routine.

Choosing the best commercial fridge system means planning for where you want your pizzeria to be, not just where you are. While a reach-in serves a vital role, a walk-in cooler is what unlocks serious operational scale and purchasing power.

Comparing the Impact on Pizzeria Logistics

Your choice here directly affects the daily rhythm of your pizzeria. With a reach-in system, restocking the prep line is a constant, small-batch process that happens throughout a shift. In a walk-in system, prep cooks can pull entire cases of ingredients once or twice a day—a much more efficient use of their time.

| Feature | Reach-In Refrigerator | Walk-In Cooler |

|---|---|---|

| Ideal For | Startups, small pizzerias, low-to-medium volume | High-volume pizzerias, restaurants focused on growth |

| Inventory Strategy | Frequent, smaller deliveries; just-in-time restocking | Bulk purchasing, pallet storage, long-term inventory |

| Kitchen Workflow | Quick access for restocking the pizza line mid-shift | Central hub for daily prep; less frequent line restocking |

| Primary Benefit | Low initial cost and small footprint | Long-term savings and superior inventory control |

In the end, it’s all about balancing your current needs against your future ambitions. A reach-in is the perfect partner for a lean pizza operation, but a walk-in provides the powerful infrastructure you need to build a high-volume pizza empire.

Getting Under the Hood: Technical Specs and Long-Term Value

When you're shopping for a commercial fridge for your pizzeria, it's easy to get fixated on the price tag. But experienced operators know the real story is in the spec sheet. The engineering details—the guts of the machine—are what determine how reliable it will be, how much it will cost you to run every month, and ultimately, how long it will last in a demanding pizza kitchen.

Think of it this way: a cheap fridge that constantly needs repairs or sends your electricity bill through the roof is no bargain. It's a long-term headache. Taking a few minutes to understand the core components helps you calculate the unit's total cost of ownership, which is a far more useful number than the initial price.

Compressor Placement and the Battle Against Pizza Oven Heat

The compressor is the heart of your refrigerator, and where it's located—top or bottom—has a huge impact on performance, especially in a hot pizza kitchen.

- Top-Mount Compressors: These are the champs for hot, busy pizza kitchens. Heat rises, right? A top-mounted compressor pulls in cooler, cleaner air from above the unit, avoiding all the flour, dust, and grease that inevitably coats the floor of a pizzeria. This simple design choice often means better efficiency and a longer life in a demanding spot like a pizza line.

- Bottom-Mount Compressors: The main advantage here is ergonomics. A bottom-mount design lifts the lowest shelf off the floor, making it easier for your staff to access without straining their backs. The downside? These units are notorious for sucking in floor debris, which means you’ll be cleaning the coils more often to prevent it from overheating and failing. They’re best suited for cooler, cleaner parts of the kitchen.

Here's a pro tip: Always choose a top-mount compressor for your main pizza prep table. It's a strategic move to fight the ambient heat from your ovens and can save you from major performance headaches later on.

The decision really boils down to your kitchen's layout. Put the top-mount units in the hot zones near the ovens and save the bottom-mounts for less chaotic prep areas.

Decoding Energy Efficiency and Defrost Systems

Your pizza prep table and coolers are going to run 24/7, making them major players on your monthly utility bill. The easiest first step is to look for the ENERGY STAR certification. These models are proven to be more efficient and can easily save you hundreds of dollars a year in electricity. A more efficient unit also pumps out less ambient heat, making your kitchen a little more bearable for your crew.

Next up is the defrost system. An automatic defrost cycle is non-negotiable. It prevents ice from building up on the evaporator coils, which would otherwise make the compressor work overtime and burn more energy. While it's a standard feature on most modern units, their efficiency can differ, so it's a smart thing to compare between models.

The market for this equipment reflects a wide range of needs. The refrigerated pizza prep table is a critical investment, and market data shows that premium models can achieve exceptional customer satisfaction ratings despite a higher retail price. Simultaneously, more accessible stainless steel tables see high sales volumes, indicating that pizzeria owners operate at various financial scales. For operators selecting commercial refrigeration, this data shows that while budget-friendly options exist, commercial-grade refrigerated models deliver superior food safety and temperature control, making them a wise long-term investment. Learn more about best-selling pizza prep tables at Accio.com.

Build Quality and What the Warranty Really Tells You

A commercial refrigerator's toughness comes down to its materials and the warranty that backs it up. Stainless steel is the industry standard for both the outside and inside for good reason: it fights off rust, stands up to harsh cleaning chemicals, and is a breeze to sanitize. Look closely at the shelving, too—epoxy-coated or stainless steel shelves will easily outlast the cheaper stuff.

Finally, read the warranty. A solid warranty that covers parts, labor, and especially the compressor for an extended period (often five years or more) is a huge vote of confidence from the manufacturer. It tells you they believe in their product. To really protect your investment, it pays to implement comprehensive facility management best practices. This big-picture approach to maintenance ensures your equipment stays a reliable asset, not a liability, for years.

Of course. Here is the rewritten section, crafted to sound like it was written by an experienced human expert.

Final Questions Before You Buy

Choosing the right refrigeration system for your pizzeria always brings up a few last-minute questions. I get these all the time from operators who are about to make a big investment and want to be absolutely sure they're getting it right. Let's tackle the most common ones.

Getting these details sorted out isn't just about ticking boxes; it's about making sure your new equipment fits perfectly into your kitchen's flow from the moment it's installed.

How Much Clearance Does a Commercial Fridge Need?

This is a classic "it depends" question, but the general rule of thumb is to leave at least 3-4 inches of breathing room around the sides and back. This space is critical for proper airflow, allowing the condenser coils to push out hot air and keep the unit from overheating and working itself to death.

But what if you're working in a tight pizza kitchen where every inch is precious? Look for a front-breathing unit. These are engineered to pull air in and vent it out through a grille on the front, meaning you can slide them right up against a wall or another piece of equipment with almost no side clearance. Just make sure you always, always double-check the manufacturer's spec sheet before you finalize your layout.

What Is the Difference Between a Pizza Prep and Sandwich Prep Table?

At first glance, they look almost identical, but the real difference is in the cutting board. It's all about the depth. A true pizza prep table is built with a seriously deep cutting board, usually 19 inches or more. That extra real estate is essential for stretching out a large pie without toppings falling all over the floor.

A sandwich prep table, on the other hand, has a much narrower board—typically around 10-12 inches deep. It’s perfectly fine for lining up subs or building salads, but it’s a nightmare for making pizza. The workflow is just too cramped.

I’ve seen operators try to save a few inches of floor space by buying a sandwich prep table. It's a mistake they almost always regret. You can't make pizza efficiently when your dough is hanging off the edge of the board. Always get the table that’s actually designed for your main product.

Ready to build the perfect refrigeration system for your pizzeria? Explore top-tier pizza prep tables and get expert advice at Pizza Prep Table. Find the ideal equipment to boost your efficiency and quality today at https://pizzapreptable.com.