The Pizzeria Owner’s Guide to the Best Commercial Fridges

Share

For a pizzeria, the best commercial fridges aren't just appliances; they're the heart of your entire operation. Getting this choice right directly impacts your speed, quality, and bottom line. The undisputed champion is the pizza prep table, which blends refrigerated topping storage with a dedicated workspace, making it the central hub for your assembly line. This core unit, backed up by reliable reach-in and under-counter fridges, creates a powerful ecosystem that keeps ingredients fresh and your kitchen humming.

Choosing Your Pizzeria's Most Valuable Player

The success of your pizzeria hinges on a lot more than just the perfect dough recipe. It depends on the unsung hero of your kitchen: the commercial refrigerator, especially the pizza prep table.

This isn't just about keeping cheese cold. We're talking about a strategic investment in food quality, service speed, and ultimately, your profitability. Think of your refrigeration setup not as a simple appliance, but as the cornerstone of your entire pizza-making workflow.

A poorly chosen fridge, particularly a prep table, can quickly become a bottleneck, slowing down your pizza makers during the Friday night rush. In contrast, the right setup supercharges your workflow, ensuring every single ingredient is perfectly chilled and always within arm's reach.

The Strategic Role of Refrigeration in a Pizzeria

The core challenge every pizzeria owner faces is picking refrigeration that perfectly matches their unique way of working. Your choice will dictate how efficiently your team can sling pizzas, how fresh your toppings stay under pressure, and how well you use every square inch of your kitchen. The goal is to create a seamless path from bulk storage to the final, perfectly topped pie assembled on your pizza prep table.

This guide moves beyond dry technical specs to give you a clear roadmap for making the smartest choice from day one. We’ll break down the essential units that form a high-functioning pizza kitchen:

- The Pizza Prep Table: The command center of your assembly line.

- Reach-In Refrigerators: The workhorses for bulk ingredient and dough storage.

- Under-Counter Models: The flexible players that add cold storage exactly where it’s needed most.

Your pizza prep table is more than a cold box; it's a strategic asset that directly influences your kitchen's rhythm and your final product's quality. A smart selection pays dividends in efficiency and customer satisfaction every single day.

Why Your Pizza Prep Table Choice Matters

Imagine your pizza prep table as the quarterback of your kitchen team. It needs to be reliable, accessible, and built to handle the fast-paced demands of service.

If your toppings aren't held at a consistent, food-safe temperature, you're risking both quality and a visit from the health inspector. If the layout is awkward, you lose precious seconds on every single order. Those seconds add up to significant delays and lost revenue during your busiest hours.

When it comes down to it, choosing the best commercial fridges for your pizzeria, starting with the prep table, is about building a foundation for success. By understanding the specific roles of each type of unit and how they work together, you can design a kitchen that is not only productive but also poised for growth.

Breaking Down Your Pizzeria's Fridge Team

Step into any pizzeria that’s firing on all cylinders, and you’ll see it’s more than just a kitchen—it's a carefully choreographed dance. At the center of that dance is a specialized lineup of commercial refrigerators. Each piece has a specific job, and they all work together to make sure every pizza gets built fast with ingredients that are perfectly fresh.

Think of your refrigeration as a strategic team. You’ve got your star player, the pizza prep table, on the front line, a solid supporting cast for drinks and sides, and a deep bench for holding all your bulk supplies. When you get the right players in the right positions, your workflow becomes seamless.

The Command Center: Pizza Prep Tables

The heart and soul of any pizzeria is the pizza prep table. This isn't just another fridge; it's the command center for your entire assembly line. It’s a brilliant piece of engineering that combines a refrigerated base for dough and backup ingredients with a refrigerated top rail, all sitting neatly under a wide cutting board workspace.

This all-in-one design puts every essential ingredient—from mozzarella and pepperoni to mushrooms and onions—chilled and right at your pizza maker's fingertips. They can crank out pizza after pizza without taking a single unnecessary step, which is how you crush a dinner rush instead of letting it crush you.

The Supporting Cast: Under-Counter and Worktop Fridges

Next up are the versatile supporting players: under-counter and worktop refrigerators. These compact units are the secret to smart, decentralized cooling. Instead of your staff constantly walking back to a main cooler, these fridges bring the cold storage right to where the action is.

Picture an under-counter unit tucked under the drink station, packed with sodas and water. Maybe another one sits at the salad station, holding prepped veggies and dressings. A worktop model, with its tough stainless steel top, can even double as extra workspace, making every square inch of your pizzeria count.

These units are fantastic for:

- Cutting Down Kitchen Traffic: By putting ingredients at their point of use, you stop employees from crisscrossing the kitchen and creating bottlenecks.

- Boosting Organization: Every station has its own supply, keeping your main coolers from becoming a chaotic mess.

- Speeding Up Service: When staff can grab what they need instantly, every order across your menu gets out the door faster.

The Bulk Storage Workhorses: Reach-In and Walk-In Coolers

Finally, every pizzeria needs a heavy-duty solution for bulk storage. This is where your reach-in refrigerators and, for bigger operations, walk-in coolers come into play. They’re the deep bench of your refrigeration team, tasked with holding the big stuff—cases of sauce, giant blocks of cheese, bulk meats, and proofed dough trays.

A reach-in is your classic upright commercial fridge. It gives you a ton of storage capacity without eating up too much floor space, making it perfect for holding the ingredients you'll use to restock the prep table throughout the day.

For any high-volume pizzeria, a walk-in cooler is non-negotiable. It’s your central warehouse, letting you buy ingredients in bulk, cut down on delivery frequency, and guarantee you never run out of mozzarella on a slammed Saturday night.

This tiered approach to refrigeration—from the frontline prep table to the backup reach-in—is what keeps your internal supply chain running smoothly. The need for this kind of reliable, efficient equipment is driving huge growth in the industry. The global commercial refrigeration market was valued at around USD 85.6 billion in 2024 and is expected to nearly double by 2034, all fueled by kitchens looking for systems that save them money. You can learn more about the expanding commercial refrigeration equipment market and its trends. Each fridge has a role to play in turning raw ingredients into delicious, profitable pizzas.

How to Calculate Your Pizzeria’s Refrigeration Needs

Buying a commercial refrigerator isn't just a purchase; it's a major investment in your pizzeria's workflow. Getting the size wrong is a classic, costly mistake. Go too small, and you’ll cripple your kitchen during a Friday night rush, forcing constant restocks from the walk-in and creating painful bottlenecks at the prep table. But if you buy a fridge that’s too big, you’re just burning money—wasting precious floor space and cranking up your utility bills.

To find that sweet spot, you have to move beyond guesswork. The key is to use your own operational data. We'll look at three core factors: your daily pizza output, how fast you turn over ingredients, and the complexity of your menu. This data-first approach makes sure you get a system that supports you now and has room to grow later.

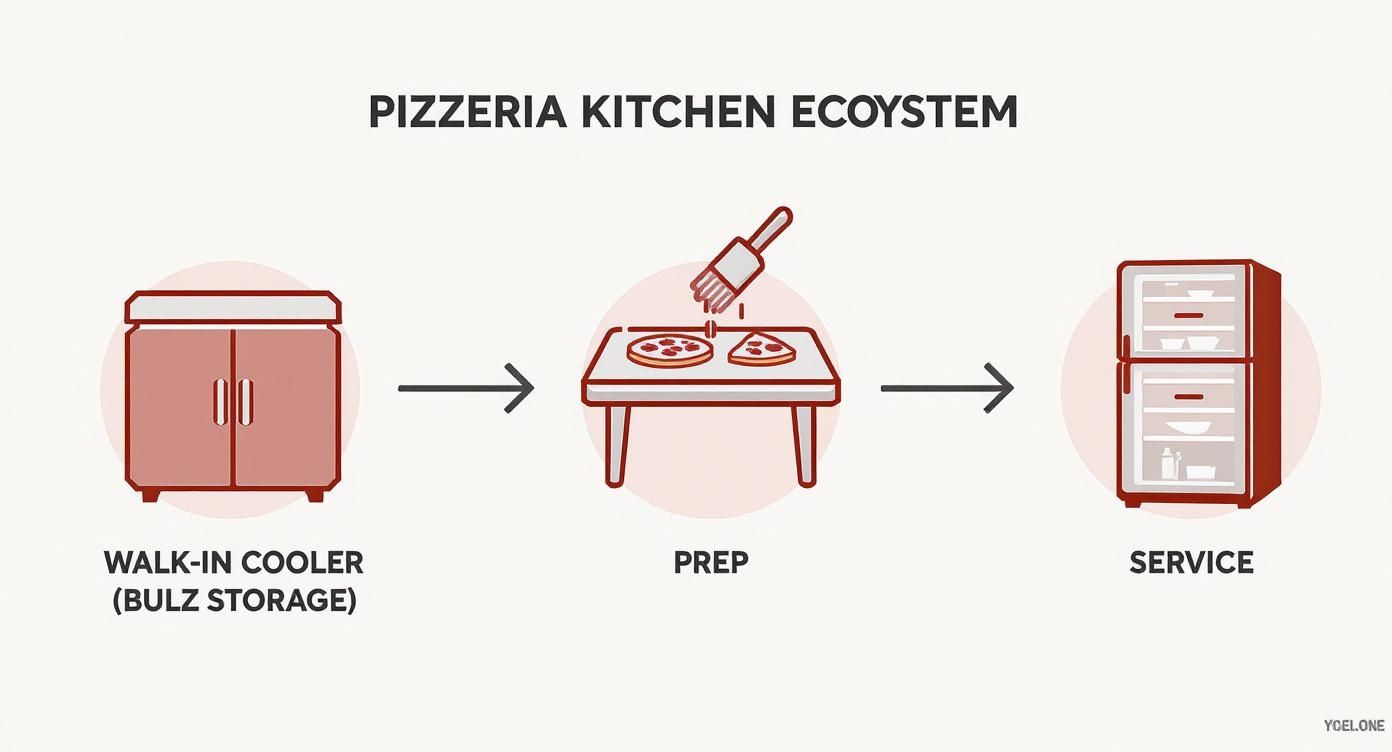

This visual below breaks down the typical journey of ingredients in a pizzeria, from bulk storage in the walk-in, to the prep line, and finally to the oven.

This flow is exactly why sizing your pizza prep table correctly is so vital. It keeps the kitchen moving smoothly, without delays or cross-contamination headaches.

Sizing Based on Your Busiest Night

Here's the most common mistake I see: sizing refrigeration for an average day. The best commercial fridges for your shop are the ones that can handle your absolute busiest night of the week—usually a Friday or Saturday. Let's walk through it with a real-world pizzeria example.

Meet Maria, owner of 'Maria's 150-Pizzas-a-Night Bistro.' During her peak service, her team is cranking out 150 pizzas. We can use that number to figure out exactly what she needs.

1. Calculate Your Dough Storage Needs:

First up, Maria has to figure out her dough tray capacity for the prep line. If her standard trays hold 12 dough balls each, the math is simple:

- 150 pizzas / 12 dough balls per tray = 12.5 trays

To be safe, Maria needs enough refrigerated space for at least 13 dough trays just to get through her busiest service. This calculation tells her precisely the under-counter or reach-in capacity she needs right at the pizza prep station.

2. Determine Pizza Prep Table Topping Capacity:

Next is the pizza prep table—the command center. Running out of toppings mid-rush is a nightmare. Maria needs to know how many refrigerated topping pans (usually sixth-size pans) she'll need on the line.

- Core Toppings: Cheese, pepperoni, mushrooms, onions, peppers, sausage (6 pans)

- Specialty Toppings: Olives, pineapple, bacon, anchovies, fresh basil, jalapeños (6 pans)

For her menu, Maria needs a pizza prep table with a rail that holds a minimum of 12 sixth-size pans. This ensures every ingredient is within arm's reach, eliminating those frantic dashes to the walk-in.

By basing your calculations on your peak output, you are essentially stress-testing your kitchen on paper. This proactive planning prevents real-world failures when the pressure is on and ticket times matter most.

Planning for Bulk Storage and Growth

With the frontline prep station sorted, the last piece of the puzzle is bulk storage. This is where your big reach-in or walk-in cooler comes in. Maria needs enough space to restock her prep table and cover several days of service without a hitch.

A good rule of thumb is to hold enough cheese, sauce, and key meats for at least 2-3 times her peak night's volume. For her 150-pizza night, that means having enough bulk ingredients on hand for 300-450 pizzas. This buffer prevents a disaster if a supplier is late and also allows for cost savings through bulk purchasing.

Finally, always build in a buffer for growth. If Maria plans to expand her menu or expects business to grow by 20% in the next year, she should add that percentage to her final capacity calculations. A little foresight ensures her investment in one of the best commercial fridges today will continue to pay dividends as her business grows tomorrow.

Nail Your Food Safety and Pizzeria Workflow

Picking the right commercial fridge is about so much more than just size or features. It's a direct investment in the safety of your food and the sanity of your staff. The best pizza prep tables aren't just cold boxes; they're precision tools designed to protect your ingredients, your customers, and your hard-earned reputation. It all starts with the non-negotiables that every professional kitchen lives by.

Right at the top of that list is NSF certification. When you see that NSF mark on a pizza prep table, it’s your guarantee that the unit has been put through the wringer. It's been tested and certified to meet strict public health standards, meaning it's built with food-safe materials, is a breeze to clean thoroughly, and can handle the daily abuse of a pizzeria. For any serious pizzeria, NSF isn't a bonus—it's the bare minimum.

The Critical Role of Precise Temperature Zones

Once you've got certification covered, the next deal-breaker is the unit's ability to hold precise temperatures. Different pizza toppings have different needs. Meats like pepperoni and sausage need to stay at the colder end of the safe zone—always below 40°F—to keep bacteria from growing. Fresh veggies, on the other hand, can get frostbite if things get too chilly.

This is where you can really see the difference between a cheap unit and a quality pizza prep table. They’re engineered with powerful, balanced refrigeration systems to make sure every corner of the unit stays within the food-safe sweet spot of 33°F to 41°F. That consistency is everything for preserving ingredient quality and sailing through health inspections. To really get into the weeds on this, check out our guide on how temperature control is essential for food safety.

Think of your pizza prep table as the guardian of your inventory. A unit with fluctuating temperatures is like leaving the back door unlocked—it’s an open invitation for spoilage, waste, and serious health risks.

Nailing these specific temperature zones prevents cross-contamination and ensures every single pizza starts with the freshest possible ingredients. That's a difference your customers can absolutely taste.

Designing Your Pizzeria's Traffic Grid

Looking beyond a single unit, it’s the strategic placement of your refrigeration that turns a basic kitchen into a high-speed production line. Think of your kitchen like a city's traffic grid. The goal is to create the most direct routes for your team, eliminating traffic jams and wasted steps. Your pizza prep table's placement is the blueprint for that grid.

A logical flow starts the second a delivery truck pulls up:

- Bulk Storage (Walk-In Cooler): This is your main warehouse. It should be located as close as possible to the delivery entrance to minimize how far heavy boxes have to be lugged across the kitchen.

- Prep Stations (Pizza Prep Table): Your prep table is the central intersection of your kitchen. Position it strategically between the walk-in and the ovens to create a straight-line path for assembling pizzas.

- Final Touches (Under-Counter Fridges): Keep smaller under-counter units for drinks, salads, or desserts near the final packing or service area. This keeps that separate traffic flow away from the hot line entirely.

This kind of thoughtful layout does way more than just save a few steps. It drastically cuts down on the time a pizza maker has to spend walking away from the prep line, which translates directly to faster ticket times. During a dinner rush, shaving just 15-20 seconds off each order by eliminating a trip to a poorly placed cooler can mean serving dozens of extra customers.

Looking Beyond the Price Tag at Total Cost of Ownership

When you're outfitting your pizzeria, it's easy to get tunnel vision and focus only on the initial price of a new pizza prep table. But that sticker price is just the first chapter of a much longer story. A cheaper unit might feel like a win today, but it could end up costing you thousands more over its lifespan in sky-high utility bills and surprise repair costs.

The real number you should be looking at is the Total Cost of Ownership (TCO). Think of it like buying a car. You wouldn't just look at the purchase price, right? You’d factor in its gas mileage, insurance costs, and how often it’s likely to break down. TCO applies that same common-sense logic to your pizza equipment, giving you the complete financial picture of your investment.

Breaking Down the True Cost

Total Cost of Ownership isn't some complicated formula cooked up by accountants. It’s a straightforward way to see the real cost of a piece of equipment over its entire life. For a pizza prep table or reach-in, the TCO is basically the sum of these four things:

- Initial Purchase Price: This is the upfront amount you pay for the unit.

- Energy Consumption: This is often the biggest hidden expense—the cost of electricity to run the fridge day in and day out for years.

- Routine Maintenance: The budget for scheduled service, like cleaning condenser coils and checking refrigerant levels.

- Potential Repair Costs: The money you'll inevitably spend fixing unexpected breakdowns.

When you add it all up, you’ll often find that a slightly more expensive, energy-efficient model is by far the smarter financial move for your pizzeria in the long run.

Why Energy Star Ratings Matter More Than You Think

That little blue Energy Star label is your best friend when it comes to predicting future energy costs. It’s not just a fancy sticker; it’s a government-backed guarantee that a refrigerator meets strict efficiency standards. A certified unit can be up to 40% more efficient than a standard model, which translates directly into serious annual savings on your utility bills.

Choosing an Energy Star pizza prep table is one of the easiest financial wins for a new pizzeria. The monthly savings on your electricity bill can effectively pay back the higher initial investment in just a few years.

So what's the magic behind these savings? It comes down to modern engineering. High-efficiency compressors use less juice to keep things cold, better insulation stops that precious cold air from escaping, and bright LED lighting throws off less heat than old-school bulbs. Each part works together to lower your operating costs every single day. For a deeper dive, check out our guide on the benefits of energy-efficient commercial refrigeration.

This push for efficiency isn't just a niche trend; it's taking over the industry. Energy-efficient models now make up about 40% of refrigerator sales worldwide, and that number is expected to climb to 50% by 2025. This growth is driven by smarter tech that helps restaurant owners keep more money in their pockets. You can discover more insights about the refrigerator market and see how these advancements are shaping the future.

Ultimately, looking past the initial price and focusing on TCO ensures your investment in one of the best commercial fridges helps build a healthier bottom line for years to come.

Must-Have Features for Your Pizza Prep Table

The pizza prep table is the undisputed command center of any pizzeria. It’s where your team builds every single pie, and its performance directly impacts your speed, consistency, and food safety. Choosing the right one means looking past the basic specs and focusing on the features that will withstand the heat and chaos of a busy pizzeria.

Think of it as the difference between a family sedan and a purpose-built delivery truck. Sure, both can get you from point A to point B, but only one is designed for the heavy-duty, non-stop demands of commercial use. The best pizza prep tables are engineered with specific, robust features that make them true workhorses.

Topping Rails: Cold-Wall Versus Forced-Air

One of the most critical decisions you'll make is how the topping rail stays cold. This choice directly affects how well your cheese, pepperoni, and veggies stay fresh and food-safe right up until they hit the oven.

- Cold-Wall Refrigeration: This system works by embedding refrigerant lines right into the walls surrounding the food pans. It’s a gentle, consistent way to cool that’s fantastic for preventing delicate ingredients like basil or shredded lettuce from drying out. The trade-off? The recovery time can be a bit slower after the lid has been open for a while.

- Forced-Air Refrigeration: This system blows cold air over the top of the food pans, much like the main cabinet of a standard fridge. It offers lightning-fast temperature recovery, which is a lifesaver for high-volume pizzerias where the lid is constantly being opened and closed. The constant airflow, however, can sometimes dry out more sensitive toppings.

For most pizzerias, a well-designed forced-air system is the way to go. It offers the best balance of performance, ensuring your toppings stay safely chilled even during the most intense dinner rush.

Built to Last: Material Quality and Smart Design

The daily grind of a pizzeria kitchen is tough on equipment. That’s exactly why material quality is non-negotiable. Look for units built from high-grade 300-series stainless steel, which offers superior resistance to rust and corrosion—especially important with acidic ingredients like tomato sauce.

The cutting board is another component you'll interact with all day long. A thick, durable, and easily removable polyethylene cutting board is the industry standard for a reason. It gives you an ideal surface for dough work and is simple to pull out for cleaning and sanitizing. Smart design also extends to how easy the unit is to clean.

A prep table with coved corners—those rounded, seamless interior edges—is dramatically easier to clean than one with sharp 90-degree angles. This small detail eliminates those hard-to-reach spots where bacteria can hide, making your daily sanitation routine that much simpler.

Power and Efficiency Under the Hood

Let's face it, a pizzeria kitchen is a hot environment. Your prep table’s compressor needs to be powerful enough to keep its cool when things heat up. An oversized compressor isn’t just a luxury; it’s an essential feature that ensures your unit doesn't struggle to hold temperature when the ovens are blazing.

An insulated lid for the topping rail is another must-have. It traps cold air, reducing the strain on the compressor and saving a significant amount of energy overnight and during slower periods. Efficiency is only getting more important. The U.S. Department of Energy's 2025 conservation standards are set to drive major improvements, with consumers expected to see lifetime savings of around $4.6 billion.

You can read more about these evolving commercial refrigeration standards and how they'll impact new equipment. At the end of the day, selecting the right features is a huge part of finding the perfect commercial pizza prep table for your specific needs.

Got Questions? We’ve Got Answers.

Even after you've done your homework, a few specific questions always come up right before you pull the trigger on a big purchase. We get it. Below, we've tackled some of the most common things we hear from pizzeria owners about choosing the right refrigeration, especially pizza prep tables. Think of this as the final checklist to help you buy with total confidence.

What's the "Magic Number" for a Pizza Prep Table Rail Temperature?

For both food safety and keeping your ingredients tasting great, that topping rail needs to hold steady between 33°F and 41°F (that’s 0.5°C to 5°C). This isn't just a suggestion; it's the critical food-safe zone required by pretty much every health department out there.

This temperature range is the sweet spot. It keeps sensitive stuff like cheese, pepperoni, and fresh veggies perfectly chilled and ready to go, but without any risk of freezing. Holding this precise temperature consistently is what separates the best commercial fridges from the ones that will let you down.

A prep table that can't keep its rail cool is a huge red flag. It’s not just a food safety nightmare waiting to happen; it’s a sign of an underpowered system that will almost certainly fail you during a Friday night rush, costing you a fortune in wasted product.

How Often Should I Really Clean My Fridge’s Condenser Coils?

The standard advice is to clean the condenser coils on your commercial refrigerators at least every 90 days. But let's be honest, a pizzeria isn't a standard environment. With all that airborne flour and grease, it's one of the toughest kitchens on equipment.

Because of this, you really should be giving them a look every month and cleaning them whenever they look fuzzy. Clogged coils make your compressor work way harder than it should, which sends your energy bills through the roof and can lead to a premature—and very expensive—compressor failure. A few minutes of cleaning is the cheapest insurance policy you can buy for your fridge.

Should I Get a Front-Breathing or Rear-Breathing Pizza Prep Table?

This one is all about your pizzeria layout. A front-breathing unit is the hero of tight spaces. It pulls air in and pushes it out from the front grille, which means you can slide it right up against a wall or snug between other pieces of equipment without choking its airflow.

Rear-breathing units, on the other hand, need a few inches of breathing room at the back to work right. They cool just as well, but they're not nearly as flexible for those compact pizzeria kitchens where every single inch of floor space is prime real estate.

Is a Marble Top Actually Better Than a Cutting Board for Prep?

Marble looks fantastic and stays naturally cool, which is great when you're working with dough. But it has a big Achilles' heel: it's porous. That means it can soak up stains from things like tomato sauce and is tougher to sanitize properly.

Stainless steel with a polyethylene board is, without a doubt, the king in commercial kitchens for a reason. The steel is non-porous, ridiculously durable, and a breeze to clean and sanitize. You can beat on it all day, and it just keeps working.

The perfect setup for a pizza prep station? A heavy-duty polyethylene cutting board placed right over a stainless steel top. You get the ideal surface for building pizzas while keeping the unmatched durability and hygiene of stainless steel underneath.

At Pizza Prep Table, we live and breathe this stuff. We focus on sourcing the durable, high-performance refrigeration that real pizzerias need to thrive. Take a look at our hand-picked selection of top-tier pizza prep tables and find the unit that will become the backbone of your kitchen. Let's build a foundation for quality and efficiency together.