Finding the Best Commercial Refrigeration for Your Pizzeria

Share

For any pizzeria owner, the best commercial refrigeration isn't just a single appliance—it’s an entire system. And the heart of that system, the real high-performance engine, is the pizza prep table. Getting this equipment choice right is a strategic investment that hits everything: your food quality, your kitchen's speed, and your bottom line.

Your Pizzeria's Refrigeration Blueprint

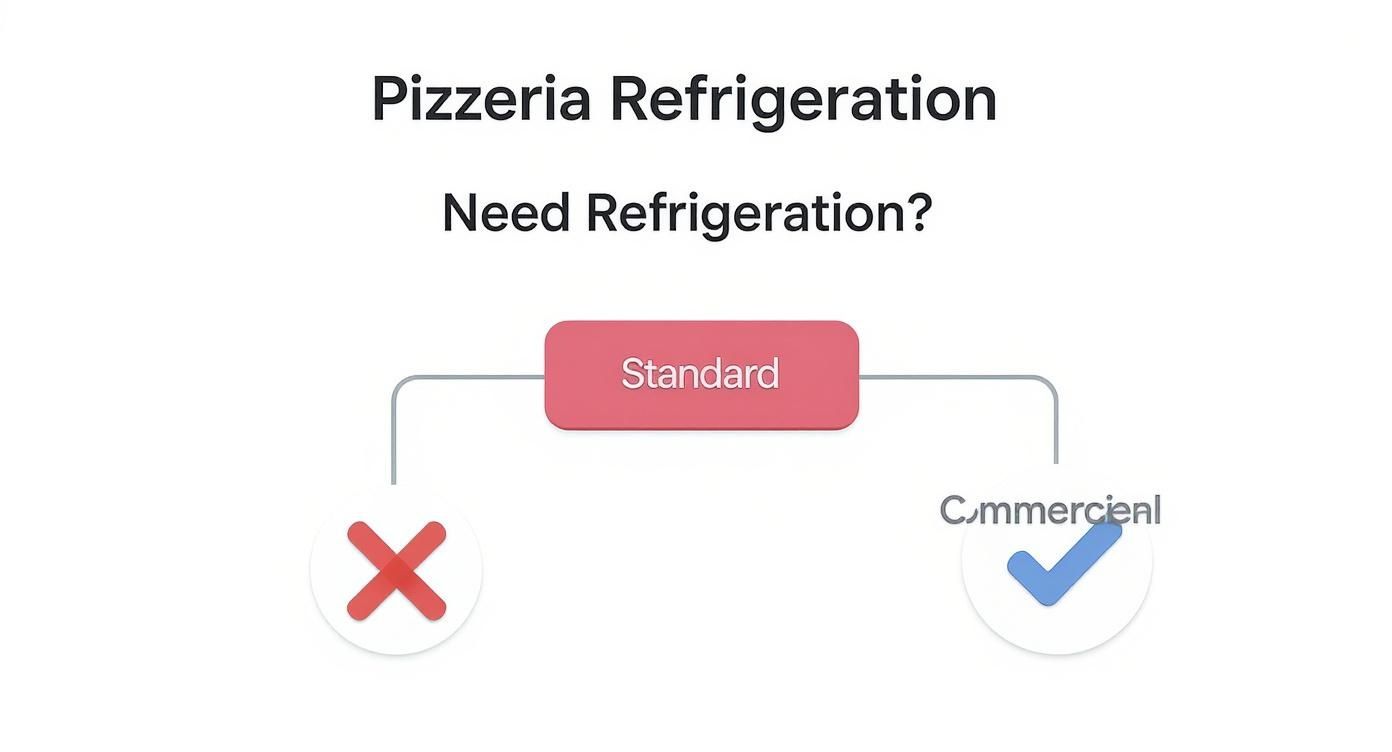

A perfect pizza doesn't start in the oven. It starts long before that, with crisp vegetables, fresh meats, and perfectly chilled cheese, all held at precise, food-safe temperatures. This is where choosing the right commercial refrigeration becomes a critical business decision, not just an item on a checklist. Your pizzeria's success literally depends on keeping ingredients fresh, and the fridge you have at home just can’t handle the pressure.

Think about a busy pizzeria kitchen—it’s a battleground of hot ovens, fluctuating ambient temperatures, and fridge doors swinging open every few seconds. Commercial-grade units are engineered for exactly this chaos. They’re built with powerful compressors and heavy-duty insulation to hold a consistent cold temperature, even when you're slammed during the dinner rush. This guide is your blueprint for building a reliable cold-chain, from your bulk storage to the final topping on the pizza prep line.

Why Specialized Equipment Matters

Think of your refrigeration setup as a key member of your staff. A pizza prep table, for instance, isn't just a cold box. It’s an organized, high-speed workstation designed for consistency. It brings together a refrigerated rail for toppings, a cutting board, and undercounter storage, creating a seamless assembly line. This specialized design means every single pizza gets made with ingredients held at the perfect, safe temperature.

A well-planned refrigeration system is the unsung hero of a great pizzeria. It protects thousands of dollars in inventory, ensures you fly through health inspections, and gives your team the tools to work faster and more efficiently.

This strategic approach is mirrored across the industry. The global commercial refrigeration equipment market was recently valued at around $44.44 billion and is expected to grow, all driven by the non-stop demand for fresh and frozen foods.

Building a Cohesive System

Choosing the right units is really about creating a seamless workflow in your kitchen. As you map out your pizzeria's refrigeration, it helps to understand the bigger picture of various types of commercial HVAC systems, because your refrigeration is a huge part of your kitchen's overall climate control. From walk-in coolers holding bulk dough and cheese to the pizza prep table on the line, every piece has a vital role to play.

Understanding the Pizza Prep Table

If you've ever worked a busy dinner rush in a pizzeria, you know the pizza prep table is the absolute command center. Think of it as the heart of your entire operation—a specialized piece of equipment that's part high-performance refrigerator, part hyper-efficient workstation. It’s where the magic happens, and having the right one is non-negotiable for speed, quality, and your sanity.

This single unit is engineered to solve the biggest challenge in making pizza: keeping a dozen different toppings perfectly chilled but still within arm's reach. No more turning around to grab pepperoni from a separate fridge. No more shouting for someone to restock the cheese. Every second saved on an order adds up, and that’s how you crush a Friday night rush without sacrificing consistency or food safety.

Making the jump to a proper pizza prep table is a foundational decision for any serious pizzeria. It’s the first real step toward a professional, compliant, and profitable operation.

As you can see, choosing specialized commercial equipment isn't just a suggestion; it’s the only path forward for a business that values efficiency, compliance, and the safety of its customers.

The Anatomy of a Pizza Prep Table

To truly get why these tables are so critical, you need to know how they’re put together. Every component is designed with one goal in mind: to create a seamless workflow from a naked dough ball to a perfectly topped pie ready for the oven.

- Refrigerated Rail: This is the star of the show. It’s the open-top section lined with ingredient pans (often called hotel pans) holding your pepperoni, mushrooms, olives, and onions. A steady stream of cold air circulates around these pans, keeping everything at a food-safe temperature below 40°F, even with the lid open during the chaos of service.

- Integrated Cutting Board: Running the entire length of the unit, this durable surface is your primary workspace. It’s where dough gets stretched and pizzas get assembled. Most are made from high-density polyethylene, a material that’s tough, easy to sanitize, and won’t destroy your pizza cutters.

- Undercounter Storage: Beneath the workspace lies a standard refrigerated cabinet. This isn’t just extra space; it’s your immediate backup supply. It holds extra pans of toppings, bulk bags of cheese, and jugs of sauce, allowing your team to restock on the fly without ever leaving the station.

These three parts work in perfect harmony to create a self-contained pizza production line. It's the engine of your kitchen's output.

Standard Top vs. Mega Top Tables

When you start shopping for a pizza prep table, one of the first decisions you'll face is whether to go with a "standard top" or a "mega top." The names sound simple, but the difference has a huge impact on your menu and workflow.

A standard top table typically gives you two rows for ingredient pans. This is a fantastic, streamlined setup for pizzerias with a classic, focused menu. It keeps all the essentials right where you need them without cluttering the workspace.

A mega top table, on the other hand, adds a third row of pans. This simple change boosts your topping capacity by up to 50%. If your menu is loaded with customizable options—think a dozen veggies, multiple cheeses, and every meat under the sun—the mega top is your best friend. It prevents ingredient pans from being stacked on top of each other and keeps your pizza assembly line organized and efficient.

To help you decide which model is the right fit for your pizzeria's menu and operational needs, here’s a quick comparison.

Comparing Pizza Prep Table Features

| Feature | Standard Top Table | Mega Top Table | Best For |

|---|---|---|---|

| Pan Capacity | Two rows of ingredient pans | Three rows of ingredient pans | Standard: Focused, classic menus. Mega: Extensive, customizable menus. |

| Workspace | More open workspace near the cutting board | Less open space, more pan area | Standard: Speed on a core menu. Mega: Variety and organization. |

| Footprint | Slightly smaller overall depth | Slightly deeper to accommodate the third row | Both fit standard kitchen lines, but check specs for tight spaces. |

| Ideal Menu | Pizzerias mastering the classics (pepperoni, sausage, etc.) | Shops offering "build-your-own" with dozens of options | Choose based on your topping count and future menu growth. |

Ultimately, picking between a standard and mega top comes down to one question: how complex is your menu? A mega top provides the flexibility to grow and add new ingredients, while a standard top is perfect for mastering a high-volume, classic pizza operation.

For a deeper dive into making the right choice, you can explore detailed guides on how to select the perfect commercial pizza prep table. Understanding these details ensures your money is well spent.

The pizza prep table is so much more than just a refrigerator. It's an investment in efficiency, safety, and the consistency of your final product. When you choose a model that aligns with your menu and volume, you’re giving your kitchen crew the tool they need to build amazing pizzas fast, which is what keeps customers coming back. It is, without a doubt, the single most important piece of cold storage in any pizzeria.

Essential Refrigeration Beyond the Prep Table

While the pizza prep table is the undisputed star of the show, a successful pizzeria relies on a strong supporting cast. Think of your kitchen's workflow like a well-rehearsed play; every piece of equipment has a specific role. For every pizza that slides into the oven, its ingredients—from the bulk block of mozzarella to the perfectly proofed dough—have made a journey through other critical refrigeration units. Finding the best commercial refrigeration means building this entire ecosystem, not just focusing on one appliance.

This journey starts the moment a delivery truck arrives. Boxes of cheese, tubs of sauce, and stacks of dough trays all need a temporary home that is both spacious and reliably cold. This is where reach-in refrigerators and freezers become indispensable, acting as the primary receiving and storage hubs for your valuable inventory.

The Workhorse Reach-In Refrigerator and Freezer

A reach-in unit is exactly what it sounds like: a standard upright cabinet with doors that your staff can easily "reach into" to grab what they need. These are the workhorses of back-of-house storage, designed for the constant open-and-close traffic of a busy pizzeria. They are essential for holding items that will soon be moved to the prep table.

When choosing a reach-in, one of your first decisions will be the door configuration. Each style serves a distinct purpose in a pizzeria's workflow.

- Solid Doors: These are the champions of energy efficiency. With better insulation than glass, solid doors excel at trapping cold air, which is a huge advantage in a hot kitchen. They're perfect for storing bulk ingredients that don't need to be seen, like large bags of cheese or boxes of frozen toppings.

- Glass Doors: What you lose in insulation, you gain in visibility. Glass doors let your team see inventory at a glance without opening the door and letting precious cold air escape. This is ideal for quickly locating specific sauces, prepped vegetables, or drinks, which reduces search time and keeps the kitchen moving.

Many pizzerias end up using a combination of both. A solid-door freezer might hold bulk meats, while a glass-door refrigerator keeps prepped items organized and visible.

Planning Your Cold Storage Capacity

Beyond door types, shelving and overall capacity are critical. A well-organized reach-in prevents inventory chaos and food waste. Adjustable shelving lets you customize the interior to fit everything from short sauce containers to tall, stacked dough boxes. This flexibility is key to maximizing every square inch of cold storage.

For operations that need both cold and frozen storage but are tight on floor space, it's worth exploring different configurations. You can find more information about balancing these needs in our detailed guide on the undercounter refrigerator freezer combo, which applies similar principles of space efficiency.

A well-planned reach-in system acts as the kitchen's library. It keeps every ingredient cataloged, accessible, and perfectly preserved, ensuring the pizza prep table is always stocked and ready for service.

When to Invest in a Walk-In Cooler

For a small pizzeria, one or two reach-in units might be all you need. But as your business grows, so does your inventory. When you find yourself playing Tetris with boxes of cheese and struggling to fit another delivery, it’s time to consider a walk-in cooler.

A walk-in cooler isn't just a bigger refrigerator; it’s a game-changer for bulk purchasing and operational scale. It allows you to buy ingredients in larger quantities—often at a lower cost per unit—which directly impacts your bottom line. It provides ample space for rolling racks of proofing dough, cases of tomatoes, and anything else you need to support a high-volume pizza operation.

Making the leap to a walk-in is a significant investment, but it’s a clear sign that your pizzeria is scaling successfully. It frees up valuable kitchen floor space by consolidating storage and fundamentally changes how you manage inventory, moving from daily deliveries to less frequent, larger orders. This strategic upgrade is a cornerstone of an efficient and profitable pizzeria.

Key Features That Drive Profitability

Picking the right type of unit is just step one. To find the best commercial refrigeration for your pizzeria, you have to look closer at the features that hit your daily workflow, food safety, and—most importantly—your operating costs. These are the details that separate a good pizza prep table from a great one, turning a necessary expense into an asset that actually drives profit.

Think of it like choosing an engine for a delivery car. Sure, any engine will make the car move, but the right one gives you better fuel economy, needs less maintenance, and performs reliably under pressure. The same is true for your refrigeration's features; they determine its real-world value and efficiency for years to come.

Energy Efficiency A Smart Financial Choice

One of the most significant, yet most overlooked, features is energy efficiency. Commercial refrigeration runs 24/7, making it one of the biggest electricity hogs in your pizzeria. A unit that wastes energy is like having a leaky faucet, constantly dripping money right out of your profits.

This is where certifications like ENERGY STAR become your best friend. An ENERGY STAR-certified pizza prep table or reach-in can use up to 40% less energy than a standard model. This isn't magic; it's just better insulation, more efficient compressors, and higher-quality components. While the sticker price might be a bit higher, the monthly savings on your utility bill add up fast, often paying back the difference in no time.

Choosing an energy-efficient model isn't just an environmental decision; it's a strategic financial one. Over the lifespan of the equipment, these savings can amount to thousands of dollars that go directly back into your business.

For a deeper look into how these savings compound, our guide on energy-efficient commercial refrigeration breaks down the long-term benefits for pizzeria owners.

Compressor Location Matters in a Hot Kitchen

The compressor is the heart of your refrigeration system, and where it's located makes a huge difference in its performance—especially in a hot pizzeria kitchen. You'll typically find two main types for pizza prep tables: top-mount and bottom-mount.

- Top-Mount Compressors: These are the champs for most pizzeria environments. Since heat rises, a top-mounted compressor pushes hot air up and away from the cool air it's trying to maintain. It’s also less likely to suck in flour, dust, and other gunk from the floor, which helps prevent clogs and keeps air flowing smoothly.

- Bottom-Mount Compressors: These are easier for technicians to access for maintenance, and they raise the bottom shelf to a more comfortable, ergonomic height. However, in a hot, flour-dusted pizzeria, they can pull in floor debris and may have to work harder since they sit in the warmer air near the floor.

For most pizzerias, a top-mount compressor is the superior choice. It's built to last and run more efficiently in a demanding setting.

Essential Features for Safety and Durability

Beyond energy use and compressor placement, a few other features are simply non-negotiable for a professional kitchen. These elements make sure your pizza prep table is safe, durable, and ready for any health inspection.

Digital Temperature Controls

Forget those old analog dials. Modern pizza prep tables come with precise digital thermostats that let you set and monitor temperatures with dead-on accuracy. This is absolutely critical for food safety, ensuring your toppings are always held below the 40°F danger zone. Many models even have external displays so you can check temps at a glance without ever opening the door.

Durable Construction

A pizzeria kitchen is a tough place to live. Look for units built with high-grade stainless steel (like 304 or 430 grade) on both the inside and out. Stainless steel resists rust, is a breeze to sanitize, and is tough enough to handle the daily bumps and scrapes of a busy kitchen.

NSF Certification

The NSF (National Sanitation Foundation) certification is your seal of quality and safety. It guarantees that the equipment is designed and built in a way that promotes food safety, with smooth, easily cleanable surfaces. An NSF-certified pizza prep table is essential for passing health inspections and showing everyone you're serious about public safety.

The growing demand for high-quality refrigeration reflects what's happening in the real world. U.S. frozen food sales recently shot past $72 billion, an increase of 8.6% in just one year, driven by busy lifestyles and the need for convenient meal options. This just highlights how important reliable, high-capacity cold storage is for any pizzeria trying to keep up. You can discover more insights about commercial refrigeration trends at GMI and see how the industry is adapting. By picking equipment with these key features, you ensure your pizzeria is ready to run efficiently and safely for years to come.

Choosing the Right Refrigeration Brand

Stepping into the world of commercial refrigeration can feel like trying to pick just one topping for a pizza when you’ve got dozens spread out in front of you. Every brand promises the moon when it comes to reliability, but certain brands really shine in the pizzeria environment. Finding the best commercial refrigeration for your pizzeria means matching a brand’s real-world strengths to your kitchen's unique chaos, from a tight budget to the relentless pace of a Friday night rush.

Instead of just throwing a list of names at you, let’s walk through the showroom together. We'll look at the reputations, the tech, and the on-the-ground performance that makes a few of these brands the go-to choices for pizzeria owners. This will give you a solid starting point for finding the right pizza prep table.

True Manufacturing: The Benchmark for Durability

Ask any seasoned pizzeria owner about refrigeration that just refuses to quit, and one name will almost always come up: True Manufacturing. For decades, True has built its reputation on making equipment that is, for lack of a better word, a tank. Their units are famous for their heavy-duty construction and powerful compressors that hold temperature like a bulldog, even in the sweatiest kitchens.

This obsession with raw durability makes True a fantastic choice for high-volume pizzerias where the equipment gets pushed to its limits, day in and day out. Their pizza prep tables, like the TPP series, are absolute workhorses built for constant abuse.

- Key Feature: True's oversized refrigeration systems are legendary. They’re engineered to pull down temperatures fast and keep them steady, even when the lids are open during a non-stop dinner service.

- Ideal User: The pizzeria owner who puts long-term reliability above everything. If your philosophy is "buy it once, buy it right," and you need a prep table that will shrug off years of intense service, True should be at the top of your list.

Turbo Air: Innovation and Energy Efficiency

While True is famous for its rugged build, Turbo Air has carved out a space by focusing on smart, energy-efficient tech. They're a brilliant option for pizzeria owners who keep a close eye on their monthly utility bills and want modern features that actually make life easier. Many of their pizza prep tables are ENERGY STAR certified, which translates directly to lower operating costs.

Their self-cleaning condenser is a standout feature. This system uses a little rotating brush to automatically clear dust and debris off the condenser coils—a critical maintenance job that often gets forgotten in a busy pizzeria. A clean condenser means the unit runs more efficiently and is way less likely to break down.

For a pizzeria, where flour dust is a constant reality, a self-cleaning condenser isn't just a cool gadget—it's a preventative shield that protects your investment and keeps your pizza prep table running at its best, day after day.

Turbo Air's pizza prep tables, like their Super Deluxe series, pack in these advanced features without cutting corners on the fundamentals of great refrigeration.

- Key Feature: That patented self-cleaning condenser is a game-changer. It seriously cuts down on maintenance and keeps your energy bills in check in a flour-heavy kitchen.

- Ideal User: The tech-savvy, cost-conscious pizzeria operator. If you're looking for modern features that give you a clear return on investment through energy savings and less maintenance, Turbo Air offers incredible value.

Avantco: Balancing Quality and Value

For new pizzerias or anyone working with a tighter budget, finding an affordable pizza prep table that won't fall apart in a year is a huge challenge. This is exactly where Avantco shines. The brand has made its name by offering reliable, NSF-certified commercial refrigeration at a price that’s hard to beat, making it one of the best ways to get into professional-grade equipment.

Avantco has a whole lineup of pizza prep tables and reach-ins that cover all the essentials. You get durable stainless steel construction, simple digital temperature controls, and efficient compressors. They might not have all the premium bells and whistles of the high-end brands, but they deliver solid, dependable performance that gets the job done.

This smart balance makes Avantco a go-to for startups, food trucks, or any pizzeria that needs to make its capital go further without compromising on food safety or basic function.

- Key Feature: Avantco’s strength is its incredible price-to-performance ratio. You get a fully capable, commercially-rated pizza prep table for a fraction of what you’d pay for a premium brand.

- Ideal User: The startup pizzeria, the budget-conscious restaurateur, or anyone who needs a solid secondary unit. If you need a dependable prep table that meets health codes without a massive upfront cost, Avantco is an unbeatable choice.

Maintenance Tips to Protect Your Investment

Buying a top-notch pizza prep table is a major investment in your pizzeria. Think of proper maintenance as the insurance policy that protects it. A solid care routine is your best defense against those nightmare scenarios: catastrophic failures, eye-watering emergency service calls, and a rail full of spoiled toppings.

These simple habits will stretch the lifespan and boost the performance of your equipment, especially those all-important pizza prep tables. A few minutes of prevention each day are worth way more than hours of painful repairs down the line.

Your staff can easily tack these tasks onto their opening or closing duties. It's a small lift with a big payoff.

- Daily Wipe-Down: Clean every interior and exterior surface with a food-safe sanitizer. This stops grime from building up and makes the bigger cleaning jobs much less of a headache.

- Check Door Gaskets: Just run a finger along the rubber door seals. If you feel a wisp of cool air escaping, that gasket might need a good cleaning or even a replacement. A leaky seal forces your compressor to work overtime.

- Monitor Temperatures: Keep a log of the temperatures for each unit. A slow, steady creep upward is one of the earliest warning signs that a problem is brewing. Catching it early can save you a fortune.

Deeper Cleaning and Inspections

Don't skip the weekly and monthly stuff. These tasks are critical for keeping the heart of your prep table—the condenser—running efficiently. A dirty condenser coil is a recipe for disaster, forcing the whole system to work harder, suck down more electricity, and eventually burn out way too soon.

Think of your condenser coils as the lungs of your pizza prep table. If they get clogged with all the flour and dust floating around a pizzeria kitchen, the unit can't breathe properly. It starts to overheat and struggle, just trying to keep up.

Once a month, make sure to unplug the unit and use a stiff brush to gently clean those condenser coils. While this kind of hands-on maintenance is a must, you should also look into specialized policies like equipment breakdown insurance to protect your valuable gear from unexpected mechanical failures.

And if you ever hear strange noises or notice the cooling just isn't what it used to be, don't try to be a hero. Call a professional technician right away.

Frequently Asked Questions

Buying a pizza prep table can feel a little overwhelming, so let's clear up a few of the most common questions pizzeria owners ask. Think of this as the quick-start guide to making a smart decision for your kitchen.

How Do I Choose the Right Size Pizza Prep Table?

The perfect size really boils down to two things: how complex your menu is and how many pizzas you're slinging during your busiest hours. A great rule of thumb is to make sure you have enough pan space for all your core toppings so your crew isn't constantly running to the walk-in during a dinner rush.

For most small to medium shops, a 48 to 60-inch wide table hits the sweet spot, giving you a good balance of prep area and topping capacity. If you're running a high-volume operation, though, you'll probably want to look at a 72-inch or larger model to keep up with the demand. And here's a pro tip: always, always measure your kitchen doorways and the final spot for the unit before you click "buy."

Is an ENERGY STAR Certified Pizza Prep Table Worth the Extra Cost?

One hundred percent, yes. While you might pay a little more upfront for an ENERGY STAR certified unit, the long-term savings are huge. These models are built with better compressors and insulation, which can slash your energy use by up to 40%.

Over the life of the unit, the money you save on your monthly electric bill will easily cover that initial price difference, and then some. It’s a smart financial move that starts paying you back from day one.

Think of it this way: the extra upfront cost isn't an expense, it's a down payment on years of lower utility bills. It's one of the easiest ways to boost your pizzeria's profitability.

What Is the Difference Between a Top-Mount and Bottom-Mount Compressor?

A top-mount compressor, as the name suggests, sits on top of the unit. This is perfect for a hot, flour-dusted pizzeria kitchen because it vents hot air up and away from the cold cabinet. It also stays much cleaner since it’s elevated away from all the dust and debris on the floor.

A bottom-mount compressor, on the other hand, is usually easier for a technician to get to for service. It also raises the lowest shelf, making it a bit easier to reach things without bending over. The downside? It can suck in more floor gunk and may have to work a bit harder in a hot kitchen. For the vast majority of pizzerias, a top-mount unit is the better choice.

Ready to equip your pizzeria with the best commercial refrigeration for the job? The team at Pizza Prep Table is here to help you select the perfect pizza prep table to streamline your kitchen, protect your ingredients, and serve up amazing pies. Check out our full selection at pizzapreptable.com.