A Pizza Restaurant's Guide to the Undercounter Refrigerator Freezer Combo

Share

An undercounter refrigerator freezer combo is a compact, dual-temperature unit designed to fit seamlessly under a standard pizza prep table. It provides both chilled and frozen storage in a single, space-saving footprint. For a busy pizza restaurant, this is a game-changer—it means having instant access to fresh pizza toppings and frozen dough right at the prep station, which drastically cuts down on wasted steps and speeds up your entire pizza line.

The Secret Ingredient to a Faster Pizza Line

Picture your busiest Friday night. The order printer is hammering away, and your pizza makers are a blur of motion, stretching dough and slinging toppings. The real secret to keeping that line moving isn't just about skilled hands—it's about an optimized workspace where every ingredient is exactly where it needs to be. This is where the right undercounter unit, placed directly under the pizza prep table, becomes your most valuable player.

An undercounter refrigerator freezer combo is the heart of a high-speed pizza station. Think of it as a personal, dedicated pantry for your pizza maker, built right into the prep table. No more running to the walk-in cooler for another block of mozzarella or trekking to a distant chest freezer for that backup box of sausage. Everything is right there, within arm's reach.

Optimizing Every Movement in Pizza Prep

This kind of strategic placement completely transforms the pizza-making process. By keeping those essential ingredients directly below the prep surface of the pizza table, you create a seamless, ergonomic flow that has some serious benefits:

- Reduced Ticket Times: When every topping and backup ingredient is just inches away, each pizza gets made faster. That directly improves your throughput during those critical peak hours.

- Enhanced Ingredient Integrity: Less time spent out of controlled temperatures means your cheese stays perfectly chilled and your veggies remain crisp. Quality control becomes automatic at the prep table.

- Improved Kitchen Flow: Minimizing staff movement around the pizza prep table reduces the traffic jams and potential accidents that are all too common in a crowded kitchen.

An efficient kitchen isn't just about speed; it's about minimizing wasted energy. Placing critical ingredients directly at the point of use turns a standard pizza prep table into a high-performance workstation, reducing physical strain on your team and boosting overall productivity.

The demand for these smart, space-saving solutions is exploding across the foodservice industry. In fact, the global market for undercounter units, including these combo models, was valued at around USD 2.9 billion in 2023. Projections show it climbing to about USD 4.5 billion by 2032, which tells you just how valuable they are in modern commercial kitchens. You can find more insights on this market trend over at Dataintelo.com.

Take a look at how these units immediately pay off at your pizza prep table:

Immediate Benefits for Your Pizza Prep Station

This table shows how an undercounter refrigerator freezer combo directly improves key aspects of your pizzeria's daily operations.

| Benefit | Impact on Pizzeria Operations | Example Application at the Pizza Prep Table |

|---|---|---|

| Workflow Efficiency | Eliminates trips to walk-in coolers and freezers. | A pizza maker grabs fresh mozzarella from the fridge side and frozen sausage from the freezer side without taking a single step away from the prep table. |

| Space Optimization | Frees up valuable floor space by combining two appliances into one. | A small kitchen can now fit an extra prep table or piece of cooking equipment where a separate freezer used to be. |

| Ingredient Quality | Reduces the time ingredients spend at room temperature. | Freshly sliced mushrooms and peppers stay crisp and cold right up until they go on the pizza, improving final product quality. |

| Reduced Labor Strain | Minimizes bending, reaching, and walking, which reduces physical fatigue on staff. | A less tired pizza-making team is more focused and productive throughout a long, busy shift, leading to fewer errors and better morale. |

Ultimately, this piece of equipment is far more than a simple appliance. It’s a core investment in your pizzeria's operational excellence. By consolidating storage and optimizing access at the pizza prep table, the undercounter refrigerator freezer combo ensures your team can build perfect pizzas consistently, even when the pressure is on. It’s the secret ingredient that supports speed, quality, and a smoother service every single shift.

Choosing the Right Combo Unit for Your Pizzeria

Not all refrigeration is created equal, especially when it has to survive in a hot, flour-dusted pizzeria kitchen. Picking the perfect undercounter refrigerator freezer combo is about more than just reading a spec sheet; it's about matching the equipment to the unique chaos of a pizza prep line. Get it right, and you'll boost your kitchen's flow, lock down food safety, and protect your profits.

A pizzeria kitchen is a high-heat battleground, and that puts a ton of stress on refrigeration compressors. This is why the unit’s condenser location and type are such a big deal. For most tight pizza lines, front-breathing units are the way to go. They pull in and push out air from the front, which means you can install them flush under the pizza prep table with zero clearance on the sides and back, saving precious space.

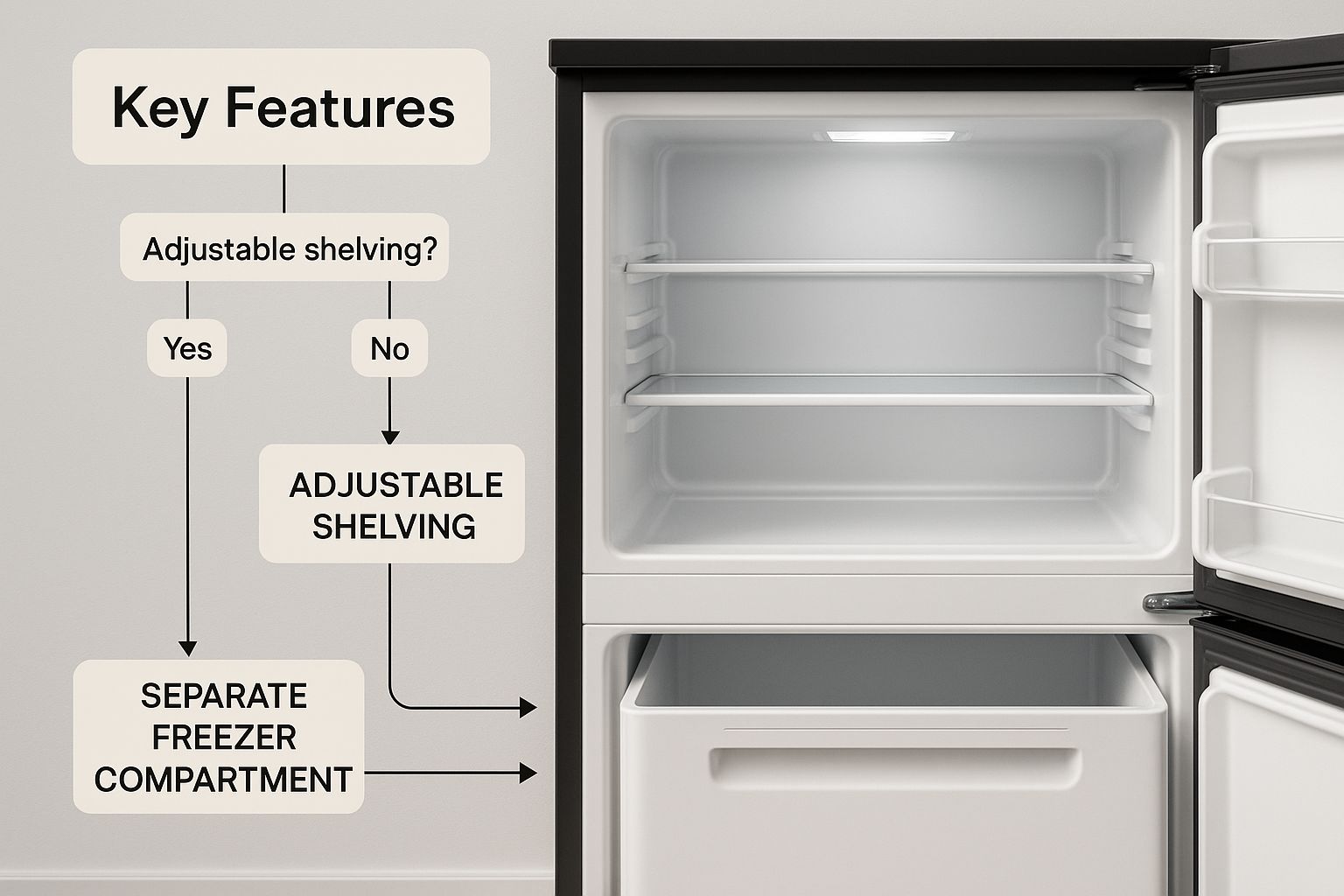

This infographic breaks down the key features you should be looking for.

As you can see, a smart interior design with adjustable shelving and a clear divider between the fridge and freezer zones is a must-have for keeping all your different pizza ingredients organized right under the prep table.

Matching Capacity to Your Pizza Volume

First things first, figure out how much storage you actually need at your pizza prep station. Think about it in terms of your weekly pizza volume. A small spot slinging 100-200 pizzas a week might get by with a compact unit, but a high-volume shop will need something bigger to avoid running out of ingredients mid-rush.

Your choice of a https://pizzapreptable.com/blogs/pizza/small-undercounter-refrigerator needs to line up with how you operate, making sure you have enough room for toppings without creating a logjam at the prep table. The goal is simple: hold enough chilled cheese, sauce, and veggies—plus frozen specialty meats or backup dough—to power through your busiest shifts.

Durability and Sanitation Standards

In a world of constant sauce spills, cheese crumbles, and aggressive wipe-downs at the pizza prep table, the material your unit is made of is non-negotiable. Always go for stainless steel. It’s tough, a breeze to sanitize, and fights off the corrosion that can eat lesser materials alive in a commercial kitchen.

Just as important is the NSF (National Sanitation Foundation) rating. This certification is your guarantee that the unit is built for easy cleaning and meets strict public health rules. An NSF-rated undercounter combo isn't just a nice-to-have; it's often a must-have to pass your health inspections.

An NSF certification is your assurance that the equipment's design, materials, and construction have been verified to promote food safety. For a pizzeria, where cross-contamination is a constant concern around the prep table, this is a critical mark of quality and compliance.

Making the Smart Investment

Finally, you have to think about the money side of this purchase. Before you drop serious cash on a new appliance, it's smart to look at all your options. Exploring the long-term benefits of renting versus owning business equipment can help you make a financially sound decision that fits your pizzeria's budget and growth plans.

By carefully weighing these practical factors—capacity, construction, and cost—you can pick a combo unit that will be a reliable workhorse for your pizza line for years to come.

Features That Supercharge Your Pizza Prep Workflow

Beyond just keeping things cold, the right undercounter refrigerator freezer combo is loaded with features built for the brutal pace of a pizzeria. These are the details that really matter during a chaotic dinner rush, turning a simple appliance into a powerhouse workstation that sharpens your pizza prep table's rhythm.

Imagine a unit that actually adapts to your pizza toppings inventory. One week, you’re storing deep pans of pre-portioned dough. The next, it’s all shallow trays of sliced pepperoni and mushrooms. This is where adjustable shelving becomes your best friend.

This kind of flexibility lets you customize the interior on the fly. No space gets wasted, and every ingredient—from bulky blocks of cheese to small containers of olives—has its designated spot right under the prep table.

Precision Control and Consistency

In a pizzeria, temperature isn't a suggestion—it's the law. Precise digital temperature controls are non-negotiable for both food safety and the quality of your pizza. They let you lock in and monitor exact temperatures, making sure your mozzarella stays perfectly chilled without freezing over and your frozen dough balls stay rock solid.

This level of control eliminates the temperature swings that spoil ingredients and put your entire operation at risk.

Another must-have is an auto-defrost cycle. Picture one of your cooks wrestling to pry a frozen block of sausage from a freezer caked in ice. That icy buildup murders efficiency, blocks airflow, and forces the compressor to work overtime.

An auto-defrost function takes care of this problem before it even starts. It periodically melts away any frost, maintaining consistent temperatures and saving your team from the miserable, time-sucking job of manual defrosting. The result? A unit that just works, keeping your pizza ingredients perfectly preserved.

A pizzeria’s workflow is a delicate balance of speed and quality. An auto-defrost feature is like a silent, tireless assistant, ensuring your freezer is always ready for service without any unexpected downtime or wasted labor at the pizza prep station.

The Financial Benefits of Smart Design

Modern units are also built with your bottom line in mind. An ENERGY STAR certified model might cost a little more upfront, but it pays for itself with lower utility bills. These units use smarter compressors and better insulation, sipping electricity instead of guzzling it.

This push for efficiency is a huge trend in the commercial refrigeration industry, which is projected to grow from USD 57.01 billion in 2024 to USD 69.13 billion by 2029. This growth is fueled by businesses like yours demanding energy-efficient equipment to slash operating costs. You can get a better sense of this trend by checking out the latest commercial refrigeration market insights.

Choosing an efficient model isn't just a "green" decision; it's a smart financial move that directly pads your profit margin every single month.

Integrating Your Combo Unit for Maximum Flow

Having the right equipment is only half the battle. Knowing exactly where to put it is what turns a good kitchen into a great one. The placement of your undercounter refrigerator freezer combo isn't just about finding an empty space—it's a strategic move that can make or break your pizza team's speed and efficiency.

Think of your pizza prep table as the command center. Everything needs to be within immediate reach, with no wasted steps. The sweet spot for your combo unit is directly beneath your main prep surface. This simple move transforms the station into a self-contained powerhouse, stopping your pizza makers from constantly turning, walking, or even pivoting to grab what they need.

The Ergonomics of Pizza Making

A smart kitchen layout reduces physical strain on your team and directly translates to faster service. When your refrigerated toppings and frozen backups are right below the action at the prep table, your pizza makers can find a rhythm, an economy of motion that pays off big time during a chaotic Friday night rush.

Here’s a simple way to organize your unit for maximum speed:

- Top Drawers/Easiest to Reach (Refrigerator): This is prime real estate. Reserve it for your heavy hitters—shredded mozzarella, pepperoni, and fresh veggies that go on almost every pizza.

- Lower Area (Refrigerator): This spot is perfect for ingredients that are used a little less often. Think specialty cheeses, different sauces, or prepped items that don't need to be restocked every five minutes.

- Freezer Section: This is your backup squad. Store extra dough balls, frozen meats like sausage or meatballs, and backup blocks of cheese here.

Following this simple hierarchy means 90% of the ingredients your team needs are just a hand's reach away from the prep table surface. The workflow stays smooth, fast, and uninterrupted.

The goal is to create a "golden triangle" right at the pizza prep table—dough, sauce, and primary toppings all accessible without taking a single step. Sliding your undercounter combo unit into this zone is how you make that perfect flow a reality.

Give Your Unit Room to Breathe

Finally, let's talk about one of the most critical—and most often ignored—parts of installation: ventilation. That compressor is working hard to keep things cool, especially in a hot pizzeria kitchen. If it can't breathe, it's going to overheat, run inefficiently, and eventually burn out.

Most commercial units need at least 1-3 inches of clearance on the sides and back to get proper airflow. But in the tight quarters of a pizza line, front-breathing models are the clear winner, as they can be installed with zero side clearance right under the prep table. Always, always check the manufacturer's spec sheet to avoid a costly mistake. A well-ventilated unit is a happy, long-lasting unit. For a deeper look at optimizing your entire workspace, check out our guide on commercial kitchen layout design.

Keeping Your Unit Running Like New

In the non-stop chaos of a busy pizzeria, equipment maintenance can easily slide to the bottom of the to-do list. I get it. But ignoring your undercounter refrigerator freezer combo is a recipe for disaster. A few minutes of consistent care can save you from expensive repairs, protect your precious inventory, and seriously extend the life of your investment.

Think of it as a small insurance policy for your pizza prep station. Simple, consistent actions are what prevent a catastrophic failure during a Saturday night rush. When a unit is neglected, it doesn't just work harder and burn more electricity—it becomes a genuine food safety risk.

A Practical Maintenance Checklist for Your Pizza Prep Station

To keep your unit in prime condition, you need to break down the maintenance into small, manageable chunks. A little bit of attention daily, weekly, and monthly makes all the difference, especially in a kitchen where flour dust and high heat are a constant battle for refrigeration.

Here’s a simple schedule you can actually stick to for your pizza prep station:

-

Daily Tasks (Just 2 Minutes):

- Wipe Down Gaskets: Give the door gaskets a quick wipe with a damp cloth. This keeps the seal tight, locking in the cold air so your compressor isn't constantly running on overdrive.

- Clean Spills Immediately: Any sauce or topping spills on or around the prep table unit need to be cleaned up right away. It prevents stains, keeps things sanitary, and avoids sticky situations later.

-

Weekly Tasks (5-10 Minutes):

- Clear Condenser Coils: Airborne flour is the mortal enemy of refrigeration. Use a stiff brush or a vacuum to gently clear the dust and gunk from the condenser coils so they can breathe and exchange heat efficiently.

- Check for Obstructions: Make sure boxes or topping containers aren't blocking the interior air vents. Blocked vents lead to uneven cooling and nasty frost buildup.

-

Monthly Tasks (15 Minutes):

- Verify Temperature Accuracy: Grab an external thermometer and double-check that both the fridge and freezer sections are holding the right temperatures. Don't just trust the built-in display.

- Deep Clean the Interior: Empty the unit completely. Wash all the interior surfaces and shelving with a food-safe sanitizer. This is also the perfect time to spot any hidden cracks or issues.

Following a routine like this helps you get ahead of trouble. Being proactive and understanding what can go wrong is key; you can find some great insights on preventing common fridge freezer faults to stay prepared.

Consistent maintenance isn't just about cleaning; it’s about preserving the heart of your equipment. A clean condenser coil can improve a unit's efficiency by up to 30%, which directly saves you money on your electricity bill every single month.

At the end of the day, these simple checks are just good business. They make sure your equipment runs reliably and stays in line with the strict food safety guidelines for restaurants that protect both your customers and your reputation. That small time commitment is what keeps your pizza line running without a hitch and protects your valuable gear.

Got Questions About Undercounter Combos? We've Got Answers.

When you're outfitting your pizzeria, the right questions lead to the right investments. Smart pizza restaurant owners dig into the details before they buy. Here are the straight-up answers to the most common questions we hear about adding an undercounter refrigerator freezer combo to a pizza prep table.

Getting these things cleared up now helps you pick the right model and use it perfectly from day one. A good unit should make your pizza prep line easier, not create new problems.

How Much Breathing Room Does My Combo Unit Need Under the Prep Table?

Proper airflow is everything for a refrigeration unit, especially when it’s working next to a hot pizza oven. Most commercial models need at least 1-3 inches of space on the sides and back to keep the compressor from burning out.

But for a packed pizza line, front-breathing models are the only way to go. These units are engineered to pull in cool air and push out hot air through a grille on the front. This means you can slide them right into a tight spot under the prep table with zero clearance on the sides and back. Always double-check the spec sheet from the manufacturer, though.

Glass Door or Solid Door for a Pizza Prep Station?

For the chaos of a high-volume pizza prep station, a solid door wins, hands down. Solid stainless steel doors provide way better insulation, which is absolutely critical when your pizza ovens are blasting heat just a few feet away.

They're also built to take a beating—and they will. A solid door can handle the bumps and slams of a busy kitchen. While a glass door lets you peek at your inventory, the energy loss and the constant risk of it shattering just aren't worth it in this specific, high-pressure spot on the pizza line.

In the heat of a dinner rush, durability and thermal efficiency are what matter, not visibility. A solid door is a workhorse built to keep the cold air locked in and handle the pressure of a busy pizza prep table.

Can I Store Raw Meats and Pizza Toppings Together?

Yes, but you have to be militant about food safety to prevent cross-contamination. The golden rule is to always store ready-to-eat foods like cheese and veggies on shelves above any raw meats.

Everything needs to be in its own sealed, food-safe container—no exceptions. To keep things simple and safe, most pizzerias dedicate their under-prep-table combo to toppings and give bulk raw meats their own separate refrigerator.

Ready to streamline your pizza line and boost efficiency? Explore the perfect Pizza Prep Table and undercounter solutions for your kitchen. Visit us at https://pizzapreptable.com to find the equipment that will power your pizzeria's success.