Blast Chiller Commercial Guide for Your Pizzeria

Share

A blast chiller commercial unit is, in simple terms, a specialized refrigerator built for one thing: getting hot food cold, fast. For a pizzeria, this means you can take a huge batch of simmering sauce, freshly cooked toppings, or even par-baked crusts and drop their temperature in minutes, not hours. This rapid cooling slams the brakes on bacterial growth and locks in that just-made freshness.

The Secret Ingredient to Pizzeria Efficiency

Imagine having perfectly chilled pizza sauce, crisp toppings, and proofed dough ready to go at a moment's notice, all without ever compromising on quality or safety. That's the real power a commercial blast chiller brings to the controlled chaos of a modern pizzeria. It’s the unsung hero working behind the scenes, making sure every ingredient is at its absolute best.

This piece of equipment is so much more than just a powerful fridge. Its main job is to rocket hot foods through the food safety 'danger zone'—that critical window between 40°F and 140°F where bacteria throw a party and multiply like crazy.

A Time Machine for Freshness

The best way to think of a blast chiller is as a 'time machine for freshness.' It essentially hits the pause button, preserving the exact quality of your signature marinara or perfectly rendered sausage right after it's cooked. This is a world away from traditional cooling methods, which can take an eternity to bring hot foods down to a safe temperature.

Your standard walk-in cooler is designed to keep cold food cold, not to make hot food cold. Shoving a big, steaming pot of sauce in there jacks up the temperature of the whole unit, putting your other ingredients at risk and forcing the compressor to work itself to death. Understanding the complete workflow of making delicious pizzas is key when you're looking for these kinds of efficiency boosts.

A blast chiller isn’t just about speed; it's about control. It gives you precise control over food safety, ingredient quality, and kitchen workflow, turning chaotic prep schedules into a streamlined, predictable process.

That slow cooling process in a regular fridge isn't just inefficient; it's a huge food safety gamble. In a busy pizza kitchen, this inefficiency means lost time, wasted product, and the constant threat of a health code violation.

Solving Pizzeria-Specific Problems

A blast chiller commercial unit is tailor-made to solve the unique headaches you find at a pizza prep table. It offers real, tangible solutions that make daily operations smoother and elevate the final product you hand over the counter.

Here are the specific problems it solves:

- Prevents Bacterial Growth: By chilling sauces, meats, and cooked veggies in minutes, it completely halts microbial growth, guaranteeing your ingredients are always safe to serve.

- Maintains Ingredient Texture: It locks in the delicate texture of your cheese blends, stops vegetables from turning to mush, and keeps cooked meats juicy and tender.

- Preserves Par-Baked Crusts: Shock freezing par-baked crusts locks in moisture and prevents the formation of large, destructive ice crystals that ruin the dough's structure.

- Reduces Food Waste: You can safely preserve leftover ingredients and prep in large batches, which drastically cuts down on spoilage and slashes your food costs.

In the end, this workhorse proves its worth by turning your pizza prep table into a model of efficiency, safety, and consistency.

To really get why a blast chiller is such a game-changer for a pizzeria, you have to look past the speed and see the science. It’s not just about making food cold, fast. It’s about protecting the very texture, flavor, and structure of your pizza ingredients.

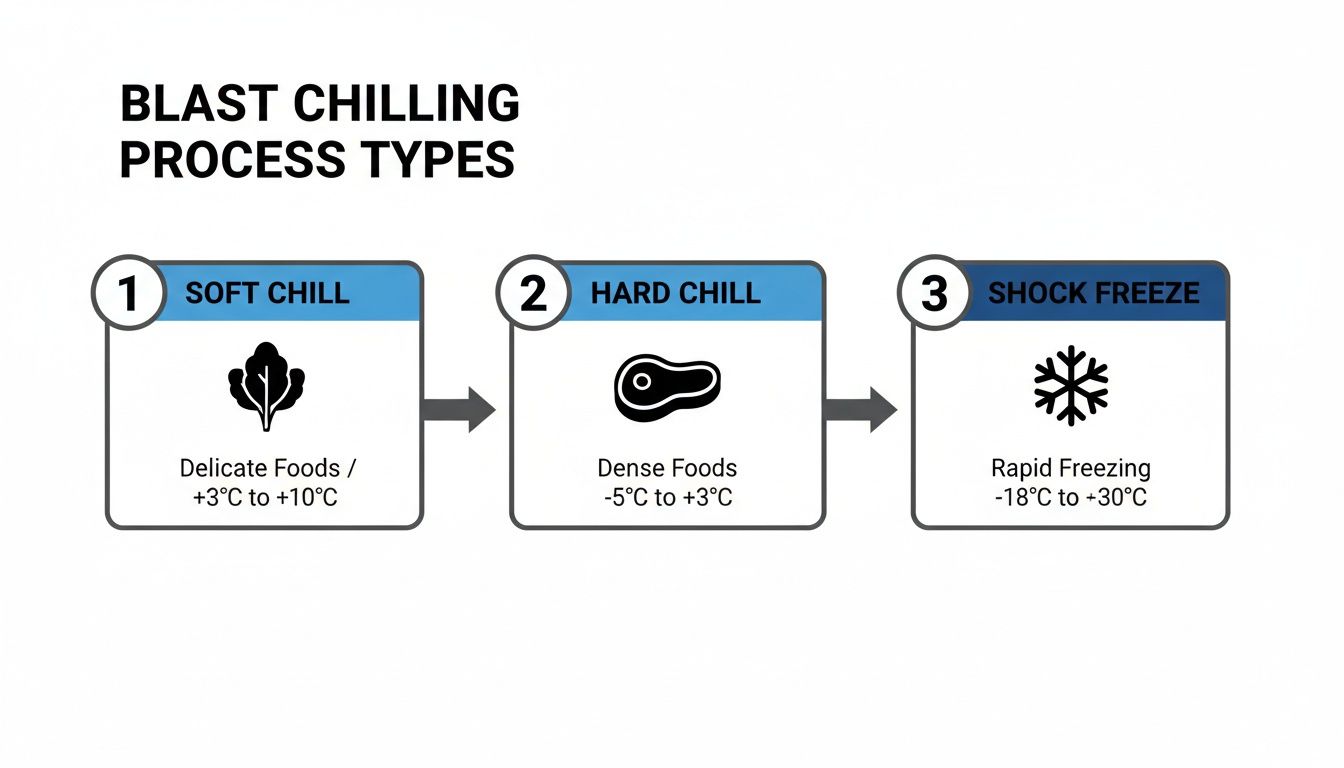

A blast chiller pulls this off with three different functions, each one perfectly dialed in for a specific job on your prep line. Think of them like specialized tools in a mechanic's shop. You wouldn't use a sledgehammer to tighten a small bolt, right? The same idea applies here. Each mode—soft chilling, hard chilling, and shock freezing—is designed to preserve specific ingredients so everything from your fresh mozzarella to your precious dough balls stays in peak condition.

Soft Chilling for Delicate Toppings

Soft chilling is the gentle giant of the blast chiller world. It uses slightly warmer, less intense air to cool things down without causing any damage. This mode is your go-to for anything delicate that would get bruised or ruined by a harsh temperature drop.

Think about these common pizza toppings:

- Fresh Mozzarella: Soft chilling keeps it from getting rubbery or weeping out all its moisture. You preserve that perfect, creamy texture.

- Sliced Veggies: Things like bell peppers, mushrooms, and onions keep their crispness and bright color instead of turning into a limp, soggy mess.

- Cured Meats: Thinly sliced prosciutto or pepperoni get cooled down safely without messing up their delicate fat structure, which is where all the flavor lives.

This gentle touch ensures the ingredients you spent time prepping so carefully actually make it to the oven in one piece.

Hard Chilling for Dense Sauces and Meats

Next up is hard chilling, which is the real workhorse for most pizzerias. This function cranks up powerful fans to blast frigid air around, rapidly dropping the temperature of dense, heavy foods. It’s built for items that hold a ton of heat and would otherwise take hours to cool in a regular walk-in.

Hard chilling is the perfect match for your big-batch staples like thick tomato sauces, hearty meat toppings like sausage or ground beef, and even dense soups. By getting these items through the temperature danger zone in a flash, you’re not just guaranteeing food safety—you’re locking in all those rich, complex flavors you worked so hard to develop. This is a core part of maintaining consistent quality, a topic we dive deep into in our guide on temperature control for food safety.

The whole point of hard chilling is maximum speed with maximum safety. It's the setting that lets your crew cook a 20-gallon batch of your signature marinara in the morning and have it safely stored and ready for the dinner rush just a couple of hours later.

It's no surprise this tech is catching on. The global market for blast chillers was valued at USD 1.63 billion in 2021 and is expected to hit USD 2.62 billion by 2029. That growth is coming from kitchens that rely on soft chilling (to 37°F), hard chilling (to 32°F), and shock freezing (to -22°F) to keep their food quality leagues ahead of older methods.

Shock Freezing to Preserve Perfect Dough

Finally, we get to shock freezing, the feature that truly separates a blast chiller from any regular freezer. This mode plunges temperatures to deep-freeze levels in an incredibly short time, which is the secret to preserving the cellular structure of your pizza dough.

Here’s a simple way to think about it. When you freeze dough in a standard freezer, the slow process forms large, jagged ice crystals. These crystals are like tiny daggers, puncturing the dough’s delicate gluten network. When you thaw it out, that damaged dough leaks moisture, giving you a dry, dense, and seriously disappointing crust.

Shock freezing, on the other hand, creates tiny microcrystals that are more like fine sand. These little crystals freeze the water inside the dough’s cells without bursting them. So when you thaw and bake a shock-frozen dough ball, the gluten structure is still intact, holding onto its moisture and its ability to rise. The result? A lighter, airier crust with a killer chew—the kind of quality that turns first-time visitors into loyal regulars.

Streamlining Your Pizza Prep Table Workflow

This is where the rubber meets the road. Knowing what a blast chiller does is one thing, but seeing how it completely transforms the flow of your kitchen is another. It's not just another piece of stainless steel; it's a new way of thinking that makes your entire operation smarter and faster.

The whole game changes with one simple shift: moving from a frantic 'just-in-time' prep model to a calm, collected 'prep-ahead' strategy. Forget scrambling to cook toppings during the lunch rush. Now you can knock out huge, economical batches whenever it makes sense for you.

The Prep-Ahead Revolution

Imagine this: first thing in the morning, you cook a massive stockpot of your signature marinara. In the old days, that pot would sit on a counter for hours, slowly cooling down while lingering in the food safety "danger zone." It's slow, it's risky, and it ties up valuable space.

With a blast chiller, that steaming hot sauce goes straight from the stove into the chiller. In about 90 minutes, it's brought down to a perfectly safe 37°F. This 'cook-chill' method completely sidesteps that long, hazardous cooling period, freeing up your counters and your staff's attention for more important things.

This is the foundation of a truly organized pizzeria. You can prep core ingredients days in advance, totally confident they’ll keep their peak flavor and texture. Your team is no longer a slave to the daily prep cycle for every single item on the line.

This infographic shows you the different tools a blast chiller uses to get the job done right for various ingredients.

As you can see, each mode—Soft Chill, Hard Chill, and Shock Freeze—is dialed in for specific foods, from delicate veggies to dense meats and even dough balls.

Conquering the Dinner Rush

The real payoff hits when the ticket printer starts screaming between 5 PM and 9 PM. That's when every tiny inefficiency in your kitchen gets exposed. This is where the blast chiller earns its keep and then some.

With perfectly chilled, portioned ingredients lined up and ready at the commercial pizza prep table, your team moves with a speed and precision that's just not possible otherwise.

- Sauce: Tubs of perfectly cooled marinara are ready to go. Every pizza gets a consistent, safe, and flavorful base.

- Toppings: Pre-cooked sausage, grilled chicken, and sautéed onions are already portioned and at your cook's fingertips. No more waiting for hot items to cool before they can hit the dough.

- Cheese: Delicate cheeses that were soft-chilled hold their texture. They don't clump, making them easier to sprinkle for that perfect melt.

This setup turns the frantic scramble of pizza making into a smooth, assembly-line operation. The result? Ticket times drop dramatically. When your crew can build pizzas faster, you get them in the oven and out to happy customers more quickly. For more tips on setting up your line, take a look at our guide on the commercial pizza prep table.

“Before the blast chiller, our prep was a constant race against the clock. Now, we batch-cook our toppings and sauces two days in advance. We’ve cut our daily prep time by 40%, and the stress level during service has plummeted. Our ticket times are down, and our consistency is way up.”

This isn't just about saving time; it's about creating a less stressful, more controlled environment where your team can actually perform at their best under pressure. Every pizza that leaves your kitchen is built with the same high-quality, perfectly prepped ingredients, guaranteeing the kind of consistency that turns first-time visitors into loyal regulars.

Choosing the Right Commercial Blast Chiller

Picking the right blast chiller commercial unit isn’t like buying a standard fridge. It’s a serious investment in your pizzeria’s speed, safety, and the quality of every single pie that goes out the door. We’re going to skip the generic advice and get right into what matters for a real-world pizza kitchen.

First thing's first: you have to get a real handle on capacity. Don't just guess or grab the biggest unit on sale. Think about your actual prep. How many gallons of sauce are in your typical batch? How many trays of proofed dough do you need to chill at once? Answering these questions will point you to a machine that fits your workflow without wasting energy or precious kitchen real estate.

Under-Counter vs. Reach-In Models

For most pizzeria owners I talk to, kitchen space is the final frontier. This is where the physical form of your blast chiller becomes a make-or-break decision. You’re mainly looking at two options: under-counter and reach-in models.

-

Under-Counter Blast Chillers: These are the space-saving champs of the kitchen. They’re designed to slide right under a counter or tuck in next to your main pizza prep table, which is a massive workflow advantage. Your crew can move a hot pot of sauce or a tray of par-baked crusts into the chiller in just a few steps.

-

Reach-In Blast Chillers: These are the bigger, freestanding beasts. They offer a ton more capacity, which is essential if you're a high-volume spot prepping enormous batches of meatballs, gallons of sauce, or dozens of dough trays at once.

For independent pizzerias and smaller chains, the under-counter model is almost always the perfect fit. Being able to tuck it away keeps your kitchen pathways clear and puts that rapid-chilling power right where you need it most. This is especially true as urban kitchens get smaller; with over 70% of new city restaurant openings being under 1,000 sq ft, compact and efficient equipment is king. You can discover more insights about countertop blast chillers and see why their market is growing.

Deciding between an under-counter and reach-in model comes down to balancing your kitchen's physical footprint with your daily production volume. Let's break down the key differences specifically for a pizza workflow.

Blast Chiller Commercial Feature Comparison for Pizzerias

| Feature | Under-Counter Model | Reach-In Model | Why It Matters for Pizza Prep |

|---|---|---|---|

| Footprint | Compact, fits under standard counters. Saves valuable floor space. | Larger, freestanding unit. Requires dedicated floor space. | In a tight kitchen, an under-counter unit keeps your prep line flowing smoothly without creating traffic jams. |

| Capacity | Smaller batches. Ideal for chilling 1-2 hotel pans of sauce or a few dough trays at a time. | High volume. Can handle large stock pots, multiple sheet pan racks, or dozens of dough trays simultaneously. | If you prep sauce daily, under-counter is fine. If you make a week's worth on Monday, you'll need the capacity of a reach-in. |

| Workflow | Excellent. Can be placed directly next to the prep station for immediate access. | Good, but often placed away from the main line, requiring more steps to load and unload. | Proximity is speed. Placing the chiller at the point of use saves dozens of wasted steps per shift, which really adds up. |

| Best For | Independent pizzerias, small chains, kitchens with limited space. | High-volume restaurants, commissaries, large-scale dough or sauce production. | Match the machine to your business model. The corner shop and the regional chain have very different equipment needs. |

Ultimately, the goal is to integrate the blast chiller so seamlessly that it feels like a natural extension of your prep line, not an obstacle your team has to work around.

Decoding the Spec Sheet

Once you’ve settled on a type, it’s time to look at the numbers. Spec sheets can feel a little intimidating, but for a pizzeria owner, there are only a few metrics that truly matter.

A blast chiller's real power is measured by its chilling capacity—a simple metric telling you exactly how much food it can cool in a specific time. Look for a rating like "chills 50 lbs from 160°F to 38°F in 90 minutes." This number cuts through the marketing fluff and tells you what the machine can actually do.

Beyond that core number, here are the other must-haves on your checklist:

- NSF Certification: This is absolutely non-negotiable. An NSF mark means the unit has been independently tested to meet strict public health and safety standards. Without it, you’re gambling with your next health inspection.

- Energy Efficiency: Keep an eye out for ENERGY STAR ratings. A more efficient unit might have a higher price tag, but it can save you hundreds, if not thousands, in utility costs over its lifespan. Think of it as a long-term investment in lower overhead.

- Programmable Cycles: A good blast chiller commercial unit will let you customize cycles. You need the control to set a gentle "soft chill" for delicate fresh mozzarella and an aggressive "hard chill" for a dense, five-gallon pot of marinara. The ability to save these programs means you get consistent results every time, no matter who’s running the machine.

Thinking through these factors ensures you get a unit that doesn't just fit your space, but has the power, safety credentials, and smarts to become a true workhorse. The right choice will streamline your prep, protect your expensive ingredients, and help you serve a better, safer, and more consistent pizza every single time.

Calculating the ROI for Your Pizzeria

When you're thinking about dropping serious cash on new equipment, the numbers have to add up. An investment in a blast chiller commercial unit isn't just about getting a shiny new toy for the kitchen; it's a cold, hard financial decision that should directly boost your bottom line. A clear return on investment (ROI) isn't some vague hope—it's something you can actually measure through real savings on food, labor, and even customer loyalty.

The financial case for this equipment is getting stronger every day. The global market for commercial countertop blast chillers is on track to hit $470 million by 2033, and it's not because they look cool. It's because smart operators are chasing efficiency. These machines crash temperatures from 160°F down to 40°F in less than 90 minutes, which can slash bacterial growth by up to 90%. The result? Pizzerias are reporting savings of 15-20% in labor costs alone. You can read the full research about these market trends to see how the whole industry is shifting.

Slashing Food Waste Costs

For any pizzeria owner, food waste feels like a constant punch to the gut. It's that tray of prepped mushrooms that got a little too warm on the line, the leftover sauce from a slow Tuesday that has to get tossed, or the par-baked crusts that went stale. A blast chiller goes straight for the heart of this problem.

By rapidly cooling your ingredients, you dramatically extend their shelf life—safely. That extra marinara can be perfectly preserved for days, and prepped veggies stay crisp and ready to go. This power to 'rescue' and reuse ingredients that would normally end up in the bin translates directly into smaller weekly food orders and more cash in your pocket.

Optimizing Your Labor Spend

Let's be honest, labor is one of your biggest headaches. A blast chiller can fundamentally change how you manage your team's time. Instead of paying cooks to stand around during slow periods or scramble like mad right before the dinner rush, you can switch to a large-batch prep system.

This lets your team cook huge batches of sauce, toppings, and other items during the quiet morning hours. Everything then gets blast-chilled and stored, perfectly fresh and ready for service.

This shift from grinding out the same prep tasks every single day to smart, strategic batch cooking means you're spending fewer payroll dollars on low-value work. You can tighten up schedules, cut down on overtime, and have your team focused on what actually makes you money: slinging perfect pizzas during peak hours.

Boosting Product Consistency and Loyalty

The last piece of the ROI puzzle is a little harder to pin to a spreadsheet, but it's just as real: product consistency. When every single pizza that goes out the door has the same great sauce and perfectly textured toppings, your customers notice. Consistency builds trust, and trust is what creates loyal regulars.

A loyal customer base means more repeat business and the kind of positive word-of-mouth that marketing dollars can't buy. When you're weighing the financial impact, it's a lot like evaluating other major equipment purchases. You can find some great perspectives in general guides on commercial equipment ROI that dig into these same principles.

A Sample ROI Calculation

Let's run some real-world numbers. Imagine a pizzeria saves a conservative $200 a month by cutting down on food waste and another $400 a month by optimizing labor.

- Total Monthly Savings: $200 (Food) + $400 (Labor) = $600

- Total Annual Savings: $600 x 12 = $7,200

Now, let's say that pizzeria invests in a solid under-counter blast chiller for $12,000. Figuring out the payback period is simple.

- Payback Period: $12,000 (Cost) / $7,200 (Annual Savings) = 1.67 years, or just about 20 months.

In a completely realistic scenario like this one, the machine pays for itself in well under two years. After that, it's just pure savings hitting your bottom line for years to come. To get a better grip on your own pizzeria's numbers, play around with our restaurant profit margin calculator and see where savings like these would make the biggest difference.

Your Top Questions About Blast Chillers, Answered

New equipment is a big decision. When it's something as powerful as a blast chiller commercial unit, you want to know exactly how it will fit into your kitchen, your workflow, and your budget. We hear the same questions from pizzeria owners all the time, so let's get right to them with some straight talk.

This isn't about reciting specs from a manual; it’s about answering the real-world questions you have when you're trying to run a smarter, better pizzeria.

How Much Kitchen Space Do I Actually Need?

This is usually the first question, and for good reason—every square inch in a pizzeria is prime real estate. The good news is, you don't need to knock down a wall. Blast chiller manufacturers know you're tight on space, so they’ve designed units specifically for kitchens like yours.

The smartest move is to think about integrating it with your pizza prep table. Compact under-counter models are the perfect fit for most independent pizzerias. These units are typically 27 to 48 inches wide, which means they can slide right under your existing counter, replacing an old, less useful fridge.

Before you do anything else, grab a tape measure. Figure out exactly what you've got to work with, and always, always leave a few inches on the sides and back for ventilation. An under-counter blast chiller puts incredible cooling power right where you need it, without turning your kitchen into an obstacle course.

Can a Blast Chiller Really Make My Pizza Dough Better?

Yes, absolutely. This isn't just a small improvement; the difference is night and day, and it all comes down to the science of what happens when dough freezes. Your customers will notice it in the final bake.

A standard freezer is slow. As it gradually lowers the temperature, large, sharp ice crystals form inside your dough balls. These crystals act like tiny razor blades, literally shredding the delicate gluten network you spent so much time developing. When you thaw that dough, the damaged structure can’t hold water properly, resulting in a crust that bakes up dense and disappointingly flat.

A blast chiller's shock freeze function prevents this completely. By crashing the temperature at an incredible speed, it forms tiny microcrystals that leave the gluten structure untouched. It perfectly preserves the dough's cellular integrity.

What does this mean for you? When you thaw that shock-frozen dough, it performs just like a fresh ball. It holds its moisture and structure, giving you a lighter, airier crust with a fantastic oven spring and that perfect chew. It’s a massive advantage for any pizzeria that wants to prep dough days—or even weeks—ahead without sacrificing quality.

Are These Things a Pain to Clean and Maintain?

Not at all. Any blast chiller commercial unit worth its salt is built for the chaos of a real kitchen, and that includes cleanup. Designers know that if a machine is a hassle to clean, it won't get cleaned right, and that’s a food safety nightmare.

Modern blast chillers are designed with easy maintenance in mind. Here’s what makes them simple to handle:

- Stainless Steel Construction: The inside and outside are almost always made from durable stainless steel. It’s tough, and you can wipe it down and sanitize it in seconds.

- Coved Corners: The interior corners are rounded, which is a brilliant little detail. There are no sharp 90-degree angles for gunk and bacteria to hide in.

- Removable Pan Supports: The racks that hold your pans slide right out. You can run them through your commercial dishwasher for a deep clean without any scrubbing.

The daily routine is simple: wipe down the inside after you use it. Once a week, clean the door gaskets and air filters. Then, just have a pro check the condenser coils periodically. It’s no more work than what you already do for your other refrigerators.

What’s the Difference Between a Blast Chiller and a Regular Freezer?

This is a common point of confusion, but the distinction is critical. They are two completely different tools designed for two completely different jobs. You can't substitute one for the other.

Think of it like this: your commercial freezer is a storage unit. Its only job is to hold food that is already frozen and keep it at a stable, safe temperature. It's a parking garage for your frozen inventory.

A blast chiller commercial unit, on the other hand, is a processing machine. Its one and only purpose is to take hot food and crash its temperature down through the food safety danger zone (140°F to 40°F) as fast as humanly possible. It’s the high-speed on-ramp that gets your food safely to its chilled or frozen destination.

This matters for two huge reasons. First, for HACCP compliance and basic food safety, you need a tool built for rapid cooling. A standard freezer just isn't powerful enough to do this safely with hot food. Second, a freezer's slow process ruins the texture and flavor of fresh food. The blast chiller is engineered to do the exact opposite—it locks in freshness at its absolute peak.

Ready to see how the right equipment can change your pizzeria's workflow? At Pizza Prep Table, we specialize in helping independent pizzerias find the perfect tools to boost efficiency and quality. Explore our selection of commercial refrigeration solutions, including under-counter models that fit seamlessly with any pizza prep table.

Discover the right equipment for your kitchen at https://pizzapreptable.com