Bottle Cooler Breakdown: Finding Your Bar's Perfect Fridge

Share

Choosing the Right Bottle Cooler for Your Bar or Restaurant

A bottle cooler is a vital piece of commercial refrigeration designed to store and display beverages at optimal serving temperatures. Choosing the right one—whether it's a high-volume horizontal model, a glass-door upright display, or a space-saving undercounter unit—directly impacts customer satisfaction and sales.

The market's steady growth reflects a simple truth: perfectly chilled drinks sell. When customers see their favorite beverages displayed attractively and served at the ideal temperature (typically 32-38°F), they are more likely to order more. This makes quality bottle cooling equipment essential for any successful foodservice operation, especially with the rise of outdoor dining.

Unlike standard refrigerators, commercial bottle coolers are built to maintain consistent temperatures during the busiest service hours, ensuring every drink you serve is perfect.

The Science of Chill: How Bottle Coolers Work

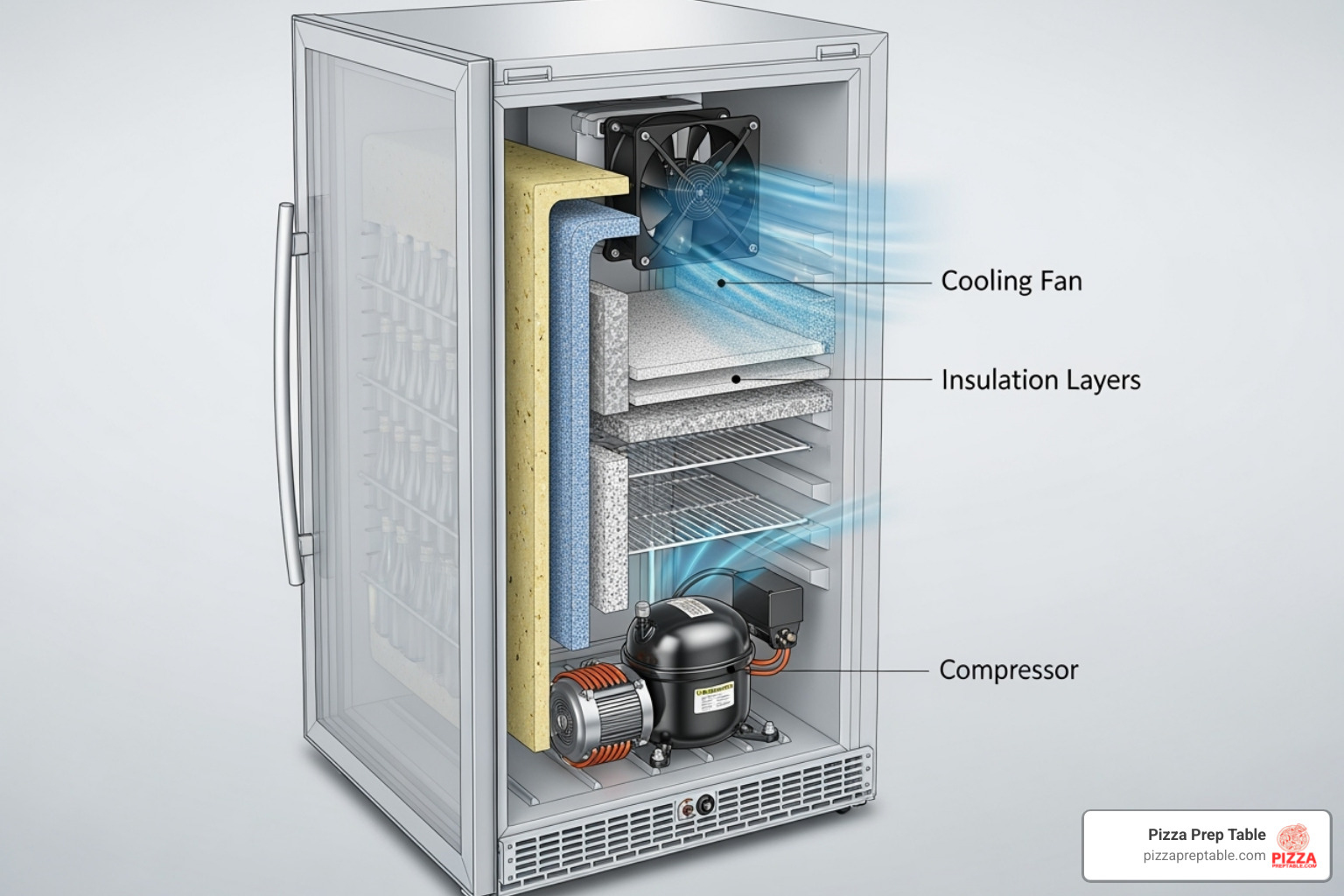

A bottle cooler doesn't create cold; it removes heat. This process, known as the refrigeration cycle, is the same science behind our commercial fridge freezer combos. It's an application of vapor-compression refrigeration.

In short, a refrigerant fluid cycles through the system to transfer heat from inside the cooler to the outside air. The compressor pressurizes the refrigerant, which then cools and liquefies in the condenser coils. After passing through an expansion valve, the now super-cold liquid flows through evaporator coils inside the cooler. Air from your beverages passes over these coils, the refrigerant absorbs the heat, and your drinks get chilled. This cycle repeats to maintain the set temperature.

However, this process is only effective with proper insulation. Without it, the compressor would run constantly to fight heat leaking in, wasting energy and causing premature wear.

Compressor vs. Thermoelectric Cooling

When shopping for a bottle cooler, you'll find two main cooling technologies. For commercial use, the choice is clear.

Compressor coolers are the industry standard. Using the mechanical refrigeration cycle, they achieve very cold temperatures (32 B0F or lower) with precise temperature control. They perform reliably even in hot kitchens, making them essential for commercial applications. The trade-off is more noise and higher energy use, but their power is non-negotiable for business environments.

Thermoelectric coolers are quiet and energy-efficient but lack power. They can only cool about 20-30 B0F below the ambient air temperature. In a hot 85 B0F kitchen, your drinks would only reach a lukewarm 55-65 B0F. Their performance degrades as the room gets hotter, making them unsuitable for the demands of a commercial setting.

For any serious foodservice business, compressor-based systems are the only viable option for a bottle cooler.

| Feature | Compressor Coolers | Thermoelectric Coolers |

|---|---|---|

| Cooling Power | Powerful, reaches 32 B0F or below | Limited, only 20-30 B0F below ambient |

| Temperature Control | Precise, wide range (29 B0F - 61 B0F) | Limited range, ambient dependent |

| Ambient Sensitivity | Performs well in hot environments | Poor performance when ambient temp rises |

| Energy Efficiency | More efficient for larger capacities | Better for small personal units |

| Noise Level | Louder due to compressor | Very quiet operation |

| Commercial Suitability | Excellent for high-demand use | Poor for commercial applications |

Insulation and Construction

Great insulation is what keeps the cold in and the heat out. Double-wall insulation with high-density foam is a common and effective method. The denser the foam, the better the unit retains its temperature and the less the compressor has to work.

Stainless steel construction is ideal for its resistance to corrosion, dents, and scratches, plus it's easy to sanitize. While some units use black painted steel for aesthetics, the interior should be durable. Galvanized steel interiors provide a tough, hygienic surface that withstands the constant loading and unloading of bottles.

Commercial-grade construction also includes features like electronic temperature controls, easy-glide lids, and adjustable shelving. These are not luxuries but necessities for a unit that needs to perform reliably day after day.

Types of Commercial Bottle Coolers

Choosing the right bottle cooler isn't a one-size-fits-all decision. Commercial units are specialized for different operational needs, and the right choice can transform your workflow. Just as we cover in our Commercial Fridge Shopping Made Easy and Cool guide, understanding your specific use case is key.

Horizontal (Chest-Style) Coolers

Horizontal bottle coolers are the workhorses for high-volume beverage service. These top-loading chests are built for storing hundreds of bottles or cans and enabling fast service during peak hours. Their durability is a key feature, with robust stainless steel exteriors and galvanized steel interiors. Many include easy-glide lids and bin dividers for better organization, allowing bartenders to quickly find what they need.

Upright & Back Bar Coolers

Upright and back bar bottle coolers turn storage into a sales tool. With glass door displays and LED lighting, they create an attractive visual showcase of your beverage selection. This merchandising tactic encourages impulse buys and increases sales. These units also provide excellent brand visibility for premium products and often integrate seamlessly into bar cabinetry, much like an Undercounter Refrigerator with Glass Door, for a professional, built-in look.

Undercounter & Built-in Bottle Cooler Models

In tight spaces, undercounter bottle coolers are essential. They fit neatly beneath countertops, saving floor space while keeping beverages accessible. The most important feature is a front-venting system, which allows for seamless integration into cabinetry without overheating. This design improves kitchen workflow by placing chilled drinks exactly where staff needs them, eliminating unnecessary movement during busy service.

For more on compact refrigeration, see our guide on Small Undercounter Refrigerator options.

Glass Frosters

Glass frosters are a secret weapon for enhancing drink presentation. These specialized units chill beer mugs and cocktail glasses to extremely low temperatures, creating a frosty effect that signals premium quality to customers. Serving a drink in a perfectly frosted glass lifts the customer experience, justifies premium pricing, and sets your establishment apart. It's a detail that shows you care about quality service, encouraging repeat business.

Key Features to Consider When Choosing Your Bottle Cooler

Selecting the right bottle cooler is an investment in your business's efficiency and customer satisfaction. Focusing on the features that truly matter will help you choose a unit that can handle the demands of your operation.

Capacity and Size

First, determine how much storage you need. Bottle and can capacity can range from a few dozen to several hundred. Common widths for commercial coolers include 34", 50", 64", 79", and 94". Always measure your available space before buying. Also, consider the interior layout. Units with adjustable shelves and bin dividers offer the flexibility to store various bottle and can sizes, which is crucial as your menu changes. Planning capacity is similar to Walk-In Cooler Sizing; it's about matching storage to demand.

Material and Durability

A commercial bottle cooler must be durable. Stainless steel exteriors are the top choice for their resistance to rust, dents, and how easy they are to clean. Black painted steel is a budget-friendly alternative that still offers good durability. Look for commercial-grade construction throughout, including galvanized steel interiors and heavy-duty lids, which are designed to withstand the daily grind of a busy bar or restaurant.

Temperature Control and Range

Precise temperature control is non-negotiable. Digital thermostats are standard on quality units, allowing you to set and monitor exact temperatures for consistency. Most bottle coolers operate in the 32-38°F range. Some specialized "Frosty Brew" models can go even colder, down to 29°F, for an extra-crisp serve. Look for units with forced-air refrigeration systems that ensure temperature consistency throughout the entire cabinet, eliminating warm spots.

For more on commercial cooling, see our guide on Mini Fridges That Mean Business: Top Commercial Picks.

Energy Efficiency and Sustainability

An energy-efficient bottle cooler saves you money on utility bills. Look for units with R290 refrigerant, a natural hydrocarbon that can provide up to 40% energy savings. ETL certification is another mark of quality, indicating the unit meets safety and performance standards. Eco-friendly features like high-quality insulation and LED lighting also contribute to lower operating costs, making them a wise long-term investment.

Top Bottle Cooler Brands and Models

When choosing a bottle cooler, brand reputation is a key indicator of reliability. Some manufacturers have a proven track record of building equipment that stands up to the rigors of commercial use. Investing in a trusted brand ensures your cooler won't fail during a busy service.

For High-Volume: Beverage-Air & Migali

For busy bars and restaurants that move a high volume of drinks, you need a bottle cooler built for endurance.

Beverage-Air is a top choice for operators who prioritize reliability. Their horizontal models feature heavy-duty construction and forced-air refrigeration to ensure even cooling. With multiple size options (from 34" to 94" widths), you can find a model to fit your space. Their "Frosty Brew" models can reach temperatures as low as 29°F, managed by full electronic control systems.

Migali focuses on energy efficiency with its use of R290 refrigerant, which can significantly cut energy costs. They combine this efficiency with performance, offering forced air refrigeration systems and adjustable digital thermostats to deliver consistent cooling.

For Premium Display: Gamko & True

A bottle cooler can be a powerful sales tool. When customers see your selection displayed attractively, they are more likely to make a purchase.

Gamko offers a wide range of coolers, including their Maxiglass series, designed with glass door options and LED lighting to turn your beverage inventory into a compelling visual display. Their focus on aesthetic design means these coolers improve your bar's overall look.

True Manufacturing is known for its long-term value. While their units may have a higher upfront cost, their durable construction and energy-efficient designs make them a smart investment. They offer precision temperature control and attractive glass doors that boost product visibility.

For more on product displays, check out our guide on Chill Out with These Top Cake Display Refrigerators.

For Compact Spaces: Icyglee & SPT

For smaller footprints, several brands offer compact bottle coolers that deliver performance without taking up valuable space.

An excellent example is a cooler with a front-venting design, which allows it to be installed under a counter without overheating. These units can often hold over 100 cans while maintaining quiet operation. Features like hidden door locks add security, and ETL certification ensures safety standards are met.

SPT also provides various compact solutions. Their undercounter models can reach temperatures as low as 29-32°F in a small footprint, integrating seamlessly into existing layouts. These compact units allow you to add dedicated beverage cooling exactly where it's needed most.

For more space-saving ideas, explore our guide on Undercounter Freezers: Top Picks for Every Kitchen and Need.

Frequently Asked Questions about Bottle Coolers

Here are answers to the most common questions we hear from business owners about choosing and maintaining a bottle cooler.

How do I clean and maintain my bottle cooler?

Proper maintenance protects your investment and ensures food safety. Follow this simple schedule:

- Daily/Weekly: Wipe down the interior with a mild soap solution and a soft cloth. Clean the exterior, using a specialized stainless steel cleaner if applicable.

- Monthly: Unplug the unit and clean the condenser coils with a brush or vacuum. Clogged coils are a leading cause of inefficiency and failure.

- Regularly: Inspect the door and lid gaskets for cracks or tears. A damaged seal wastes energy and forces your compressor to work harder.

Always unplug the unit before any cleaning or maintenance.

What is the typical price range for a commercial bottle cooler?

Pricing for a commercial bottle cooler depends on size, brand, and features.

- Entry-level ($1,000 - $2,000): Smaller undercounter or compact horizontal models suitable for low-volume needs.

- Mid-range ($2,000 - $5,000): Larger units with better construction (like stainless steel), digital controls, and forced-air cooling.

- High-end ($5,000+): Premium brands offering maximum capacity, superior durability, advanced features, and the highest reliability for high-volume operations.

Think of the price as an investment. A more expensive, reliable unit often has a lower total cost of ownership due to fewer repairs and better energy efficiency.

What are the latest trends in the bottle cooler market?

The bottle cooler market is constantly evolving. Key trends include:

- Energy Efficiency: The shift to R290 refrigerant is the biggest trend, offering significant energy savings. Improved insulation and efficient compressors are also becoming standard.

- Smart Technology: Some high-end models now feature remote temperature monitoring and maintenance alerts via smartphone apps.

- Customization: Manufacturers are offering more options for custom finishes and flexible interior layouts to match a business's brand and aesthetic.

- Improved Display: Back bar coolers feature improved LED lighting and anti-fog glass doors to make beverage selections more appealing and drive sales.

Conclusion: Lift Your Beverage Service

From the science of refrigeration to the importance of durable construction, it's clear that the right bottle cooler is more than just a fridge—it's a cornerstone of your beverage service. Choosing the correct model, whether it's a high-capacity horizontal unit or a sleek glass-door display, directly impacts workflow, sales, and customer satisfaction.

A quality commercial bottle cooler ensures every drink is served at the perfect 32-38°F, improves your bar's appearance, and stands up to the demands of a busy environment. Modern energy-efficient models with R290 refrigerant also lower your operating costs, making it a smart investment that pays for itself.

At PizzaPrepTable.com, we specialize in helping businesses find the ideal refrigeration solutions. We understand that the right equipment is key to your success.

Ready to improve your beverage service? Explore our selection of beverage refrigerators and find the perfect bottle cooler to keep your drinks chilled and your customers happy.