Undercounter Refrigerator with Glass Door for Pizza Prep

Share

Think of an undercounter refrigerator with a glass door as the command center for your pizza prep line. It’s not just a cooler; it's a compact, efficient hub that slides right under your pizza prep table, combining refrigerated storage with the immediate visibility of a clear door. This setup is crucial for managing speed and ingredients when the pizza orders start piling up.

Why Your Pizza Prep Station Needs a Glass Door Refrigerator

Picture your pizzeria during the Friday night dinner rush. The tickets are flying, the pressure is on, and every single second counts. Fumbling around for ingredients in a solid-door fridge is simply not an option. This is exactly where an undercounter refrigerator with a glass door becomes more than just cold storage—it’s the cockpit of your entire pizza-making operation.

Imagine a pilot who needs every critical control visible and within arm's reach. A solid-door refrigerator under a pizza prep table is like flying blind. Your pizza makers have to constantly open the door, letting cold air escape and breaking their rhythm just to check on pepperoni or mozzarella levels. All that wasted motion adds up, slowing down the entire pizza line.

Streamline Your Workflow with Visual Access

A glass door completely changes the game at your pizza prep station by providing immediate visual inventory management. With a quick glance, your team knows exactly what they have and what they’re running low on, from dough balls to topping pans.

This instant awareness creates a much smoother, more efficient workflow. The key benefits for a pizzeria are huge:

- Reduced Motion: Staff can spot ingredients before ever opening the door, cutting way down on unnecessary movement during the pizza-making process.

- Fewer Errors: Seeing the toppings clearly helps prevent mistakes, ensuring the right ingredients go on every single pizza.

- Improved Freshness: Limiting how often the door is opened keeps the internal temperature stable. This is vital for preserving the quality of your cheese, vegetables, and cured meats.

By turning your ingredient supply into a visual dashboard, you empower your pizza-making team to work faster and more accurately. This isn't just about seeing what you have; it's about establishing a rhythm that makes your kitchen more productive and profitable.

The Foundation of an Efficient Pizza Prep Line

Ultimately, this piece of equipment is a cornerstone of an effective pizza prep line. It helps you maintain the pace needed to handle high order volumes without ever sacrificing the quality of your pies.

For a deeper dive into creating the perfect pizza workspace, check out our guide to pizza prep chillers, which explores how to set up your entire station for success. Remember, the right refrigerator doesn't just store food—it actively supports the speed and precision required in a top-tier pizzeria.

How a Clear View Boosts Kitchen Efficiency and Profits

Sure, a glass door undercounter refrigerator looks sharp under a pizza prep table, but where it really proves its worth is in the tangible impact it has on your business. That simple act of seeing your ingredients without yanking a door open changes everything in a fast-paced pizza kitchen, from the quality of your food to your bottom line.

Think about what happens every time a solid door opens: cold air rushes out, and warm kitchen air floods in. This constant temperature fluctuation is the enemy of fresh pizza ingredients. With an undercounter refrigerator with a glass door, your staff can do quick visual checks, keeping that door shut far more often.

This stability is a game-changer for pizzerias. It helps preserve the delicate texture of mozzarella, stopping it from getting rubbery. It also keeps veggies like bell peppers and onions crisp, which directly cuts down on food spoilage and ensures every pizza you send out is top-notch.

From Smoother Workflows to Faster Ticket Times

A clear view does more than just protect your ingredients; it completely overhauls the ergonomics of your pizza line. Imagine the physical strain on your crew during a long, busy shift. Less bending and rummaging for toppings under the prep table means a smoother, less tiring pizza assembly process.

This boost in operational speed creates a ripple effect across your entire service:

- Faster Ticket Times: When staff can spot and grab what they need instantly, pizzas get made and hit the oven that much quicker.

- Increased Order Capacity: A more efficient line can handle a higher volume of orders during peak hours, which maximizes your sales potential.

- Lower Energy Bills: The compressor doesn't have to work nearly as hard to maintain temperature when the door stays closed, leading to real savings on your utility bills.

A well-placed glass door unit turns your pizza prep station into a highly productive hub where every movement is efficient and purposeful. It’s a small change that leads to huge improvements in both staff satisfaction and kitchen output.

The growing focus on product visibility and energy efficiency isn't just some passing trend; it's a smart business move for pizzerias. This is backed up by the numbers in the global market for glass door merchandisers, which includes these essential undercounter units. Valued at roughly USD 9.8 billion in 2025, the market is projected to more than double to over USD 20.1 billion by 2035. You can dig into more of this industry growth data from Future Market Insights.

At the end of the day, this piece of equipment isn't an expense—it's an investment in efficiency, quality control, and profitability for your pizzeria. By optimizing your kitchen's workflow, you empower your team, slash waste, and build a stronger, more profitable pizza business.

Choosing the Right Features for Your Pizzeria

Not every commercial refrigerator can handle the heat and intensity of a busy pizza kitchen. When you're picking an undercounter refrigerator with a glass door for your pizza prep table, you have to look past the basic specs and focus on the features that actually perform under pressure. Let's walk through what really matters so you can find a reliable workhorse for your pizzeria.

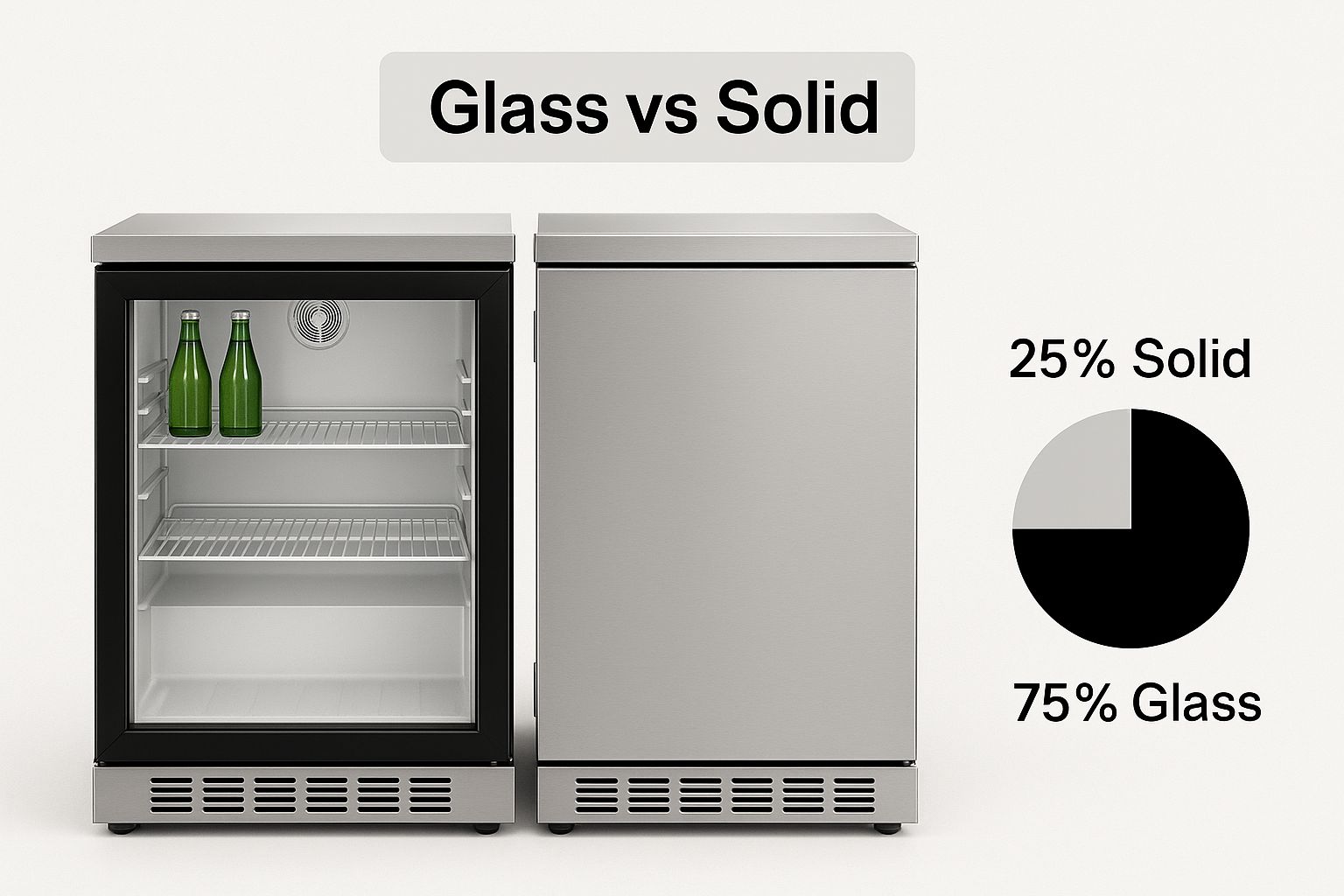

This side-by-side comparison shows you exactly how much your workflow can change just by choosing a glass door over a solid one for your pizza prep station.

Being able to see your pizza toppings at a glance means faster service and less fumbling around, which is a lifesaver during a crazy dinner rush. You're not just buying a window; you're buying speed.

Glass That Beats the Heat

The first thing to look at is the glass itself. A standard, single-pane glass door will quickly become your worst enemy in a hot pizza kitchen. It'll fog up with condensation, completely blocking the view you paid for.

You need a unit with double-pane, low-E coated glass. Think of it as a modern thermal window for your fridge. The gap between the glass panes, often filled with argon gas, acts as insulation. The low-emissivity (low-E) coating is a nearly invisible metallic layer that reflects heat away. This combo is non-negotiable for preventing condensation and keeping the cold air where it belongs—inside.

Feature Comparison for Pizza Prep Refrigerators

When you're outfitting a high-volume pizza kitchen, the small details in your undercounter refrigerator can make a huge difference in your daily grind. This table breaks down the key features to consider, comparing standard options with the high-performance choices that truly stand up to the chaos of a busy pizza service.

| Feature | Standard Option | High-Performance Option | Why It Matters for Pizzerias |

|---|---|---|---|

| Glass Type | Single-Pane Glass | Double-Pane, Low-E Coated Glass | Prevents condensation in hot kitchens, maintaining clear visibility of ingredients and improving energy efficiency. |

| Cooling System | Cold-Wall Cooling | Forced-Air Cooling | Ensures even temperature for all toppings, from cheese to vegetables, preventing hot spots and protecting food quality. |

| Construction | Painted or Galvanized Steel | Durable Stainless Steel (Interior & Exterior) | Resists corrosion from acidic ingredients like tomato sauce, is easy to sanitize, and withstands dents and scratches. |

| Certification | No specific food service certification | NSF Certified | Guarantees the unit meets public health and sanitation standards, which is a must-have to pass health code inspections. |

| Interior Flexibility | Fixed Shelving | Adjustable Shelving | Allows you to customize storage for different-sized containers, maximizing space for bulk sauces, cheese blocks, and dough. |

Choosing the high-performance options isn't about luxury; it's about investing in equipment that won't fail you during your busiest hours. For a pizzeria, these features translate directly to faster prep, better food safety, and a kitchen that runs like a well-oiled machine.

Cooling Systems Built for Consistency

How a refrigerator chills its contents is just as important as how it’s built. For a pizza station loaded with a dozen different toppings, you need even, consistent cooling to prevent some ingredients from freezing while others creep into the temperature danger zone.

-

Forced-Air Cooling: This is what you want for a pizza prep station. This system uses fans to actively circulate cold air all around the cabinet. It’s like central air conditioning for your ingredients, making sure every corner—from the mozzarella in the back to the mushrooms up front—stays perfectly chilled.

-

Cold-Wall Cooling: This older method uses coolant lines embedded in the refrigerator walls. While it's a simpler system, it often creates inconsistent cold spots. That’s a risk you can’t afford with pizza ingredient safety and quality on the line.

A forced-air system is the only way to go for a serious pizza station. It guarantees consistent temperatures from top to bottom, which is crucial for keeping a diverse topping selection fresh and safe.

Construction and Compliance

Finally, take a hard look at the unit's construction and certifications. The interior and exterior should be made of durable stainless steel. This isn't just about looking professional; stainless steel is hygienic, easy to sanitize, and tough enough to resist corrosion from acidic ingredients like tomato sauce.

You also need to confirm the unit is NSF certified. This certification means it has been tested to meet strict standards for public health and sanitation, a key requirement for passing those all-important health code inspections. Another practical feature to look for is adjustable shelving, which lets you customize the space for different-sized topping containers and bulk dough boxes.

This demand for functional, space-saving units is part of a much larger trend. The global market for undercounter refrigerators was valued at USD 1.75 billion in 2024 and is projected to hit USD 2.85 billion by 2033. You can dive deeper into these market trends in this analysis from Verified Market Reports.

Integrating Your Refrigerator for a Seamless Workflow

Getting the perfect undercounter refrigerator with a glass door is a great start, but it's only half the job. To really make that investment pay off, you have to get its integration with your pizza prep table just right. This isn’t about just sliding a box into a hole. It’s about creating a workstation that makes your team faster and feels second nature during the chaos of a dinner rush.

The success of your pizza prep station hangs on one detail that's critical yet so often missed: ventilation. Think of your refrigerator's compressor as its engine—it throws off heat while it's running. If that heat gets trapped under your prep table, the compressor will overheat, chug energy, and eventually burn out. I've seen it happen time and again; it's the single most common and costly mistake pizzeria owners make during installation.

To avoid this, make sure there's enough clearance for the unit to breathe. This is especially true for rear-breathing models. Most manufacturers will tell you to leave at least 2-3 inches of open space on the sides and back. If your kitchen is tight on space, a front-breathing model is a fantastic solution, since it pulls air in and pushes it out through the front grille, eliminating the need for side or rear clearance under the prep table.

Measuring for a Perfect Fit

Before that shiny new refrigerator even shows up on a truck, you need to break out the tape measure. And don't just measure the opening under your pizza prep table once. Measure it three times—at the top, middle, and bottom—to catch any weird inconsistencies in the space. Write down the height, width, and depth, then check those numbers against the unit's spec sheet, always remembering to add in that vital breathing room for ventilation.

A correctly installed refrigerator doesn't just fit—it performs. Giving the compressor enough breathing room is the difference between a reliable workhorse that lasts for years and a unit that burns out prematurely, causing expensive downtime right when you need it most.

Thinking strategically about where you place the unit can completely change your kitchen's flow. This is your chance to set up an ergonomic "golden triangle" for your pizza makers. The best setups put your refrigerator, your prep surface, and your pizza oven in a tight, efficient cluster. This cuts down on wasted steps and motion, letting your team pivot smoothly from grabbing cheese to prepping a pie to launching it into the oven. When it's done right, the whole pizza-making process just feels fluid.

Building Your High-Speed Topping Station

Once your refrigerator is installed with plenty of airflow, you can dial in the interior organization for peak efficiency. This is where you build the ultimate pizza-making command center. For a deep dive into setting this up, you can learn how to prep like a pizza pro with these topping stations and turn your prep line into a model of speed and organization.

The demand for these thoughtfully designed kitchen workhorses keeps growing. In the U.S. market, undercounter refrigerators with glass doors are projected for solid growth through 2031, powered by a commercial foodservice industry that demands both high function and clean, modern aesthetics for pizza prep. You can get more details on these trends and the market forces behind them over at 6wresearch.

Essential Maintenance to Ensure Food Safety and Longevity

In the controlled chaos of a busy pizzeria, letting your equipment maintenance slide is a recipe for disaster. Just imagine your refrigerator giving up the ghost during a Friday night pizza rush. That means lost profits, wasted food, and a major food safety headache. To keep your undercounter refrigerator with glass door running like a champ, a simple, consistent maintenance plan isn't just a good idea—it's essential.

Think of it as preventative care for one of your pizzeria's most valuable players. This isn't about tackling complicated repairs yourself; it’s about building small, consistent habits that stop big problems before they start. The easiest way to get your team on board is with a simple checklist broken down into daily, weekly, and monthly jobs.

Simple Daily and Weekly Checks

Your daily checks take just a few seconds. First up, keep that glass door sparkling with a streak-free cleaner. This isn't just for looks; it ensures your team can do quick visual inventory checks of pizza toppings without opening the door. While you're at it, give the door handle and surrounding stainless steel a quick wipe-down to keep things hygienic.

Your weekly tasks dig a little deeper:

- Sanitize the Interior: Pull everything out and wipe down the interior walls and shelves with a food-safe sanitizer. This is non-negotiable for preventing cross-contamination and funky odors from strong ingredients like anchovies or garlic.

- Inspect Door Gaskets: Take a close look at the rubber seals around the door. Are there any cracks, tears, or spots where they've become brittle? A bad seal is a secret energy hog, forcing the compressor to work overtime and driving up your utility bills. A quick trick is to close the door on a dollar bill—if you can slide it out easily, that seal needs some love.

The Most Critical Monthly Task

If there's one maintenance job you absolutely cannot skip, it's cleaning the condenser coils. These coils are the unsung heroes of your refrigeration system, responsible for releasing heat. In a pizzeria environment, they become magnets for grease, flour, and dust.

A clogged condenser coil is the number one cause of cooling failures in commercial refrigerators, accounting for an estimated 90% of avoidable service calls. A five-minute cleaning once a month can save you from hundreds of dollars in repairs and disastrous downtime.

Cleaning them is straightforward. Just unplug the unit, find the coils (they're usually behind a grille on the front or back of the unit under your pizza prep table), and use a stiff brush and a vacuum to clear away all the gunk.

Regular upkeep doesn't just add years to the life of your equipment; it’s fundamental to your pizzeria’s performance and profitability. If you're looking for more advice on picking the right equipment from the get-go, check out our guide on choosing the perfect pizza preparation refrigerator to make sure you start with a unit that's built to last. By catching the small stuff early, you ensure your kitchen is always ready for health inspections and peak service hours.

Frequently Asked Questions About Pizza Prep Refrigerators

When you're equipping a pizzeria, every piece of gear has to pull its weight. A glass-door undercounter refrigerator is a fantastic tool, but it often brings up some very practical questions from owners who live and breathe pizza efficiency and food safety. Let's tackle the common ones so you can make a smart choice for your pizza prep line.

How Do I Stop Condensation on the Glass Door?

There's nothing more frustrating than a "clear view" door you can't see through, especially in a hot, steamy pizza kitchen. Condensation happens when that warm, humid kitchen air hits the cold glass, fogging it up instantly. This defeats the whole purpose of having a glass door on your pizza prep refrigerator.

The fix is all in the engineering. You need to look for a unit with either a heated glass door frame or, more commonly, double-pane, argon-filled glass. Think of it like a modern window in your house. The technology creates an insulating barrier, which keeps the outer pane of glass closer to the room's temperature. It's a simple concept that makes a huge difference in preventing fog.

One more thing: always check the door gaskets. Make sure they form a perfect, airtight seal. Any little gap lets humid air sneak in, which not only causes condensation but also makes your fridge work harder and waste energy.

A clear view isn't a luxury; it's a workflow tool for your pizza line. Investing in a unit with anti-condensation features ensures that tool is always available, especially during the high-pressure dinner rush when visibility matters most.

What Is the Best Temperature for Pizza Toppings?

This one is non-negotiable. For both food safety and the quality of your pizza ingredients, you need to be in the right zone. For almost every common pizza topping—from cheese and pepperoni to fresh veggies—the sweet spot is between 36°F and 40°F (2°C to 4°C).

Why this specific range? It's cold enough to drastically slow down bacterial growth, keeping your food safe. But it's just warm enough to avoid freezing, which would ruin the texture and flavor of your toppings. Nobody wants rubbery cheese or mushy peppers on their pizza.

A pro tip: never trust the unit's built-in thermostat alone. Keep a separate, calibrated thermometer inside the fridge and check it daily. It's a simple habit that ensures you're always hitting your food safety targets.

Can I Just Use a Residential Mini-Fridge in My Pizza Kitchen?

I get this question a lot, and the answer is always a hard no. Trying to get by with a residential mini-fridge in a commercial pizza kitchen is one of the biggest mistakes you can make, and it will cost you.

- Durability and Power: Commercial refrigerators are built like tanks. They have beefy compressors designed to handle the constant door openings and high heat of a pro kitchen, where temps can easily top 100°F. A home unit's compressor will burn itself out in no time under that kind of stress.

- NSF Certification: Your health inspector is looking for one thing: an NSF-certified sticker. This proves the unit meets strict public health and sanitation standards. A residential fridge doesn't have it, and using one is a guaranteed health code violation for your pizzeria.

- Recovery Time: When you open the door, cold air rushes out. A commercial fridge is engineered to pull that temperature back down to a safe level, fast. A residential unit just can't keep up, leaving your pizza ingredients sitting in the temperature "danger zone" for way too long.

It might look like you're saving a few bucks upfront, but a residential fridge will end up costing you a fortune in spoiled food, failed equipment, and potential fines. It’s just not worth the risk for a professional pizzeria.

Ready to build a more efficient and profitable pizza prep line? The experts at Pizza Prep Table can help you select the perfect undercounter refrigerator with a glass door designed to withstand the demands of your kitchen. Explore our collection of commercial-grade refrigerators today!