Choosing Your Perfect Mega Top Sandwich Prep Table

Share

Why Mega Top Sandwich Prep Tables Are Essential for Efficient Food Preparation

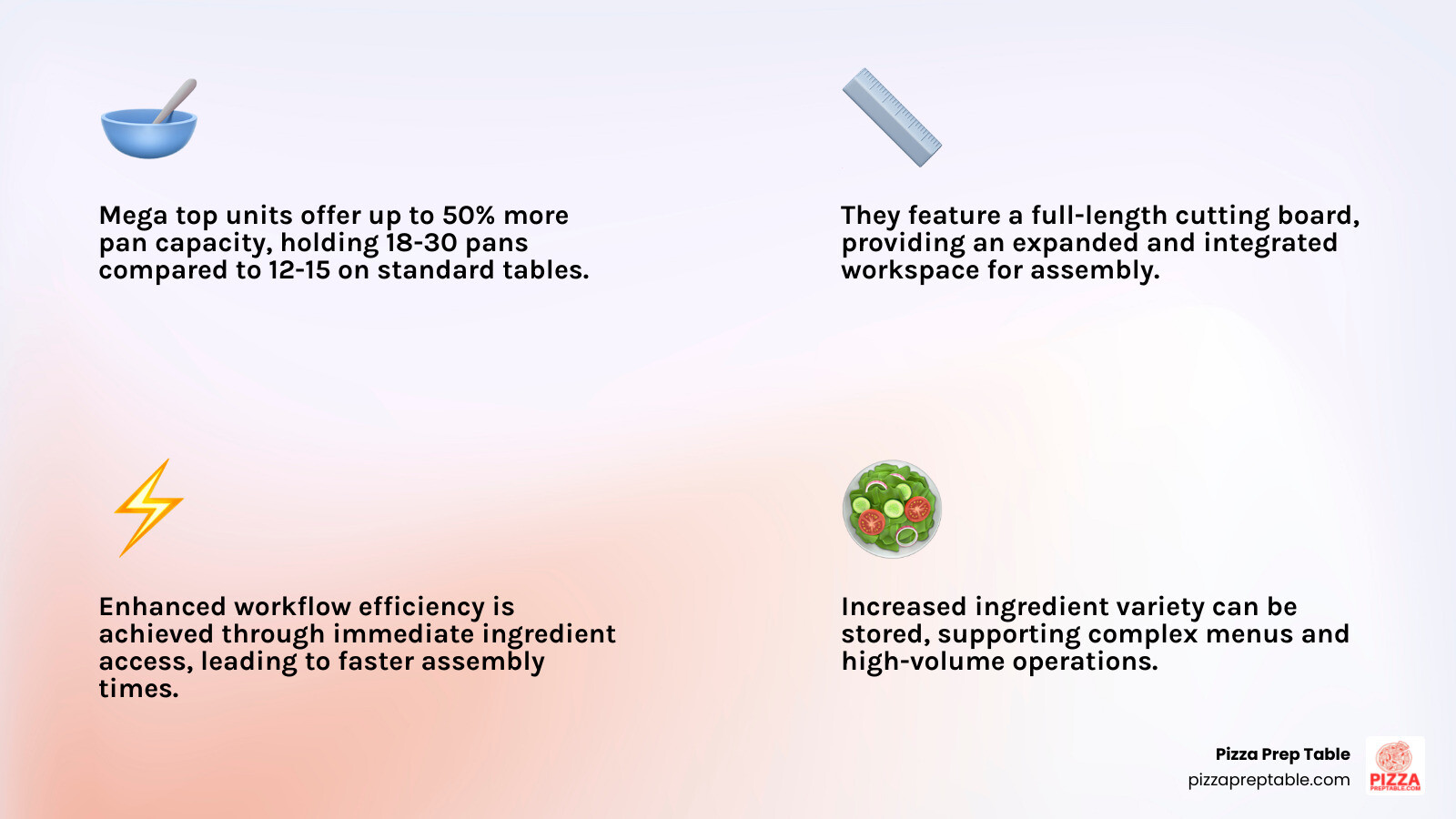

A mega top sandwich prep table is a commercial refrigerated workstation that combines expanded ingredient storage with an integrated workspace, offering up to 50% more pan capacity than standard prep tables. These units feature an enlarged refrigerated rail on top that can hold 18-30 ingredient pans, plus undercounter refrigerated storage and a full-length cutting board.

Key benefits of mega top sandwich prep tables:

- Increased ingredient capacity - Hold 50% more toppings and ingredients than standard units

- Improved workflow efficiency - Everything within arm's reach reduces prep time

- Better food safety - Maintains temperatures between 33-41°F with digital controls

- Space optimization - Combines refrigeration and prep space in one compact unit

- Improved organization - Clip-on divider bars and dual-level pan guides keep ingredients sorted

The mega top design is particularly valuable for busy kitchens preparing complex sandwiches, salads, or pizzas that require multiple ingredients. As one industry expert noted, these units act as "a catalyst for improved efficiency and food quality" in commercial kitchens.

Popular configurations include:

- 48" models with 16-18 pans and 12 cubic feet storage

- 60" models with 24 pans and 15+ cubic feet storage

- 72" models with 30 pans for high-volume operations

I'm Sean Kearney, and my years in restaurant equipment sales have shown me how the right mega top sandwich prep table can transform kitchen operations, especially for pizzerias and sandwich shops dealing with limited space and high ingredient variety. My experience helping businesses choose equipment that maximizes both efficiency and profitability has taught me the critical importance of selecting the right prep table configuration for each kitchen's unique needs.

Mega Top vs. Standard Prep Table: What's the Key Difference?

Picture this: you're in the middle of lunch rush, and a customer orders your signature sandwich with eight different toppings. With a standard prep table, you might find yourself doing a little dance back and forth, grabbing ingredients from multiple locations. But with a mega top sandwich prep table? Everything you need is right there, perfectly organized and within arm's reach.

The core difference between these two workhorses comes down to pan capacity. While a standard sandwich prep table typically holds one row of ingredient pans – usually 12 to 15 pans on a 60-inch unit – a mega top design features an expanded refrigerated rail that can accommodate significantly more. We're talking about 50% more storage capacity in the same footprint.

Here's where it gets interesting: that extra row of pans isn't just about quantity. It's about ingredient variety and workflow efficiency. When you can stock 24 pans instead of 15, you're not just holding more ingredients – you're holding different ingredients. This means you can offer more menu options without constantly restocking from your walk-in cooler.

The cutting board depth is another game-changer. Mega top units typically feature larger, deeper cutting boards that give you more workspace. When you're assembling multiple orders simultaneously, that extra real estate makes all the difference between smooth operations and kitchen chaos.

From a workflow optimization perspective, mega top units reduce the number of steps in your food preparation process. Less walking means faster service, and faster service means happier customers and better profit margins. The food safety benefits are equally important – when ingredients stay in their designated refrigerated spots instead of being constantly moved around, temperature control becomes much more reliable.

| Feature | Standard Prep Table | Mega Top Prep Table |

|---|---|---|

| Pan Capacity | 12-15 pans (60" unit) | 18-24 pans (60" unit), 50% more |

| Cutting Board Size | Standard depth | Larger, deeper workspace |

| Ingredient Variety | Limited menu options | Extensive topping selection |

| Ideal Use Cases | Small cafes, simple menus | Busy pizzerias, gourmet sandwich shops |

The beauty of a mega top design really shines in high-volume operations. If you're running a pizzeria with dozens of toppings or a sandwich shop known for customization, that extra capacity isn't just convenient – it's essential for maintaining speed and quality during peak hours.

For a deeper dive into how these refrigerated workstations maintain perfect temperatures for food safety, check out our comprehensive guide: More info about sandwich prep table refrigerators.

Key Features That Boost Kitchen Efficiency

In a commercial kitchen, efficiency is paramount. A mega top sandwich prep table is a key tool for creating a smooth, clockwork-like operation.

By creating a self-contained workstation, it eliminates wasted motion and keeps everything within arm's reach. This improved food prep organization boosts labor productivity and ensures ingredients stay fresh and safe at consistent temperatures throughout the busiest shifts.

Improved Ingredient Access & Organization

The key advantage of a mega top sandwich prep table is the extra row of pans, which provides superior ingredient variety. A typical unit holds 16 to 30 pans depending on its size: 48-inch models hold 16-18 pans, 60-inch units handle 24, and 72-inch models accommodate up to 30. This expanded capacity allows for more menu options and customization.

Clip-on divider bars are a smart feature for customizing the pan layout, allowing you to separate different ingredients within a single pan. This level of organization dramatically reduces assembly time, as every ingredient has a designated spot. When your team can build orders without searching for ingredients, service is faster and food is fresher. For more insights on creating an efficient sandwich operation, check out our guide on Sandwiches Made Simple with Countertop Prep Stations.

Integrated Workspace & Refrigeration

A mega top unit is a complete workstation. The full-length cutting board, made from durable, food-grade polyethylene material, is designed for heavy commercial use. A key feature is that it's removable for cleaning, allowing for thorough sanitizing and preventing bacteria buildup in hard-to-reach corners.

Below the workspace is the undercounter refrigerated storage, available with doors or drawers. Doors offer larger storage for bulk items and sheet pans, while drawers provide quick, organized access to specific ingredients. Look for smart engineering details like self-closing doors that stay open past 90 degrees and magnetic snap-in gaskets for a tight, energy-efficient seal. These features create equipment that works with your kitchen's flow. For more guidance on choosing the right materials and construction, explore our article on Slice in Style: Choosing a Stainless Steel Pizza Prep Table.

Advanced Cooling & Temperature Control

Proper temperature control is crucial for keeping ingredients fresh and safe. Modern mega top sandwich prep tables use advanced cooling technology to maintain the ideal food-safe range of 33°F to 41°F.

Digital controls and clear temperature displays remove guesswork and ensure consistent food quality. Unlike standard refrigerators, these units use forced-air refrigeration to circulate cold air around and below the food pans, eliminating hot or cold spots.

Advanced models may feature a Cold Bunker system, which creates a protective shield of cold air around ingredients, maintaining proper temperatures even when the lid is open during service. Insulated roll covers work with this technology to provide multiple layers of protection. These features ensure ingredients remain fresh from morning prep to the end of the dinner rush, helping you comply with health codes and serve high-quality food.

The Ultimate Buyer's Guide to Your Next Mega Top Sandwich Prep Table

Choosing the right mega top sandwich prep table means matching the unit to your kitchen's specific needs for reliability and efficiency.

Before buying, assess your kitchen space, food volume, and budget. Measure your available area, including room for door swings and cleaning. Consider your peak-hour food volume to determine the capacity you need. Your budget should account for the initial price plus long-term costs like energy, maintenance, and the value of reliability.

Size, Capacity, and Configuration

Mega top sandwich prep tables come in various sizes to fit different needs. Compact 27-inch units are great for tight spaces, while popular 48-inch models (e.g., Maxx Cold MXCR48MHC) balance capacity and footprint. Busier kitchens may opt for 60-inch units (e.g., Avantco APT-60M-HC), and high-volume operations often need 72-inch models (e.g., Victory VSPD72HC-30B-6), which can offer 20.0 cubic feet of storage.

Undercounter storage capacity ranges from about 6.6 to over 20 cubic feet. The door versus drawer decision affects workflow. Doors provide flexible storage for bulk items and sheet pans, as seen in the Maxx Cold X-Series. Drawers, like those on the Turbo Air TST-60SD-24-D4-N, offer superior organization for quick access.

Most units include caster wheels (3-inch or 5-inch) for mobility, which is useful for cleaning and repositioning. For more sizing guidance, see our article on The Perfect Fit: Choosing a 48-Inch Pizza Prep Table offers additional insights.

Understanding Pan Configurations for Your Mega Top Sandwich Prep Table

The pan configuration is what makes a mega top sandwich prep table so efficient.

Most units use standard 1/6 size food pans. Your choice of pan depth affects capacity. Standard 4-inch deep pans are common (the Maxx Cold X-Series includes 16), but some ingredients may require 6-inch deep pans. Models like Delfield's 4400 series can accommodate both.

Premium models may feature dual-level pan guides, which lower pans into the refrigerated rail for better cooling and food safety. Clip-on divider bars are essential for customizing your layout and keeping pans organized during busy service, creating a well-organized command center.

Materials, Construction, and Durability

A quality mega top sandwich prep table is built for durability in demanding commercial kitchens. Look for a stainless steel exterior (typically 304-grade) for corrosion resistance and easy cleaning. Interior construction varies, with some models using stainless steel and others using ABS liners; galvanized steel backs and bottoms provide structural integrity.

High-density polyurethane foam insulation (often 2 inches thick) is crucial for temperature consistency and energy efficiency. Quality hardware details also matter. Recessed door handles prevent snagging, self-closing doors ensure a proper seal, and magnetic snap-in door gaskets are easy to clean and replace. These elements ensure reliable performance for years. For more on construction, explore our guide on Food Tables 101: Digesting the Facts and Figures.

Energy Efficiency and Refrigerants (R290)

Modern mega top sandwich prep tables offer significant cost savings and environmental benefits through advanced refrigeration. R290 hydrocarbon refrigerant is a key advancement; it's a natural, non-toxic refrigerant with zero ozone depletion potential and a low global warming potential (GWP of 3). R290 systems can provide energy savings up to 40%.

For example, Delfield's 4400 series with its R290 GreenGenius system is 39-55% more energy-efficient. ENERGY STAR certification verifies these efficiency claims. Look for features like adaptive defrost systems and Electronically Commutated (ECM) fan motors (found in models like the Everest Refrigeration EPBWR2) that reduce energy use. Some units, like the Everest model, also feature slide-out cooling cartridges for easy maintenance. For detailed specs, View a detailed product spec sheet to see how these improvements translate to savings.

Maintenance, Cleaning, and Warranty Considerations

A mega top sandwich prep table is a significant investment that requires proper care to perform at its best. Regular maintenance is key to your equipment's longevity and reliability.

Fortunately, modern prep tables are designed for easier upkeep. Proper cleaning will reward you with years of reliable service, consistent temperatures, and safe food storage.

Routine Maintenance and Cleaning for Your Mega Top Sandwich Prep Table

Regular cleaning of your mega top sandwich prep table is essential for food safety and smooth operation. For cleaning stainless steel, use a mild detergent and soft cloth daily; avoid abrasive cleaners that can scratch the finish.

The polyethylene cutting board should be removed and sanitized after each shift to prevent cross-contamination. Clean the magnetic snap-in door gaskets regularly to ensure a tight seal; snap-in designs like Delfield's are easy to replace when worn.

Many modern units simplify maintenance with features like a self-cleaning condenser (e.g., Turbo Air), which automatically brushes the coil daily. If your unit lacks this, clean the condenser periodically to maintain efficiency. Other valuable features include corrosion-resistant epoxy-coated evaporator coils (e.g., True) and integrated condensate evaporators that eliminate the need for a drain line. For replacement parts or troubleshooting, our guide Don't Lose Your Cool: Where to Find Pizza Prep Table Parts can help.

Understanding Your Warranty

A solid warranty protects your investment in a mega top sandwich prep table. Understanding the coverage can prevent unexpected future costs. The typical structure includes parts and labor coverage for 1 to 3 years against manufacturing defects.

The compressor warranty is especially important, with most manufacturers offering 5 to 7 years of parts coverage. Some brands offer even more, like True's 7-year warranty (TSSU-48-18M-B-HC) or Everest's 10-year warranty (EPBWR2). Look for specific component warranties that add value, such as Victory Refrigeration's 2-year warranty on gaskets and a lifetime warranty on handles and hinges (parts only) for their VSPD72HC-30B-6 model.

Be aware of conditions that could void your coverage, such as ambient temperature requirements. Always register your product and keep your purchase documents. For a detailed look at warranty terms, read an example warranty statement to make an informed decision.

Frequently Asked Questions about Mega Top Prep Tables

Over the years, I've fielded countless questions about mega top sandwich prep tables from restaurant owners, kitchen managers, and chefs. These are the three questions that come up most often, and I'm happy to share the answers that can help you make the best decision for your kitchen.

How cold does a mega top prep table keep ingredients?

Your ingredients need to stay in what we call the "safe zone" – and a quality mega top sandwich prep table delivers exactly that. The typical temperature range is 33°F to 41°F (0.5°C to 5°C), which is the sweet spot for food safety and preventing bacterial growth.

What makes these units so reliable is their forced-air refrigeration systems. Think of it like having a gentle, constant breeze of cold air circulating around and below your food pans. This eliminates those dreaded warm spots that can compromise food safety. No more worrying about whether that corner pan is staying cold enough!

The digital thermostats found on most modern units take the guesswork out of temperature control. You can see exactly what's happening inside your unit with clear temperature displays, and make precise adjustments when needed. It's like having a temperature guardian watching over your ingredients 24/7.

Can I use deeper pans in my mega top unit?

This is a great question because pan depth can really impact how much you can store and how efficiently you can work. Most mega top sandwich prep tables come ready for 4-inch deep pans right out of the box – that's the standard depth that works perfectly for most operations.

But here's where it gets interesting: many units, particularly those from Delfield, can actually accommodate 6-inch deep pans. This extra depth means you can hold more of each ingredient, which is fantastic for high-volume kitchens or when you're prepping for a busy weekend.

Some of the more advanced models feature dual-level pan guides – a clever system that lets you lower the pans deeper into the refrigerated well. This isn't just about fitting bigger pans; it actually improves cooling performance because the pans sit closer to the cold air source.

My advice? Always check your manufacturer's specifications before investing in deeper pans. What works for one model might not work for another, and you want to make sure you're getting the most out of your investment.

What is the main advantage of a mega top over a standard prep table?

If I had to pick just one game-changing advantage, it's the dramatically increased pan capacity. We're talking about 50% more ingredient storage space compared to a standard prep table of the same width. That's not just a small upgrade – it's a complete change of how your kitchen operates.

Picture this: instead of having 15 ingredient pans at your fingertips, you suddenly have space for 24 or even 30 pans. That means you can keep every sauce, topping, cheese, and vegetable right where you need it, when you need it. No more running back and forth to the walk-in cooler during the dinner rush.

This expanded capacity becomes absolutely crucial when you're building complex sandwiches, elaborate salads, or gourmet pizzas that require multiple components. Your prep time gets cut dramatically because everything is within arm's reach. Your kitchen staff stays in their flow, customers get their orders faster, and everyone's happier.

The beauty of a mega top sandwich prep table is that it transforms your prep station from a basic workspace into a command center for culinary creativity. More ingredients at your fingertips means more menu possibilities and faster service – and that's what really drives success in this business.

Conclusion

After diving deep into mega top sandwich prep tables, it's clear that these units are game-changers for commercial kitchens. Think of them as the Swiss Army knife of food prep – combining efficiency, capacity, and food safety into one sleek package that can transform how your kitchen operates.

The benefits we've covered speak for themselves: dramatically increased ingredient capacity (often 50% more than standard units), streamlined workflow that keeps everything within arm's reach, and advanced temperature control that maintains food safety standards between 33°F and 41°F. These aren't just nice-to-have features – they're the foundation of a more profitable, efficient kitchen operation.

But here's the thing: the right choice really does depend on your kitchen's unique volume and menu complexity. A busy pizzeria churning out dozens of specialty pies needs a different setup than a cozy deli making classic sandwiches. That 72-inch model with 30 pans might be perfect for your high-volume operation, while a compact 48-inch unit could be the sweet spot for your neighborhood sandwich shop.

At PizzaPrepTable.com, we understand that every kitchen has its own personality and needs. That's why we've built our reputation on offering a wide selection of commercial prep tables along with flexible financing options that work for everyone – from small independent shops just starting out to larger establishments looking to upgrade their entire operation.

We're not just selling equipment; we're helping you invest in your kitchen's future success. Whether you're in busy downtown Chicago or a quiet suburb in Texas, we're here to guide you toward the perfect mega top sandwich prep table that'll have your team working more efficiently and your customers coming back for more.

Ready to take your food prep to the next level? Explore our collection of commercial prep tables and find how the right mega top unit can revolutionize your kitchen operations. Your future self (and your staff) will thank you!