A Guide to Commercial Blast Chillers for Pizzerias

Share

Picture a piece of equipment that locks in the peak freshness of your pizza sauce, gives you pinpoint control over your dough, and makes food safety a non-issue. That’s what a commercial blast chiller brings to your pizzeria. It’s not just a super-powered fridge; it’s a strategic tool for any pizza restaurant that’s serious about quality, consistency, and running a smarter kitchen that works seamlessly with your pizza prep table.

Why a Blast Chiller Is Your Pizzeria's Secret Weapon

For a long time, blast chillers were seen as something only high-end restaurant kitchens needed. That’s changing fast. Today, they're becoming a must-have for modern pizzerias that want an edge.

Think of it less like a simple cooler and more like a quality control hub that slots right into your daily grind. From managing bulk dough fermentation to prepping toppings for your pizza prep table, it touches every part of your operation.

The core job of a blast chiller is to crash the temperature of hot food, rocketing it through the critical “temperature danger zone” (140°F to 40°F) in 90 minutes or less. Your standard walk-in or even the refrigerator in your pizza prep table just isn't built for that. They're designed to hold cold food, not cool hot food down fast.

Ever seen someone put a massive, steaming pot of marinara sauce in a regular walk-in? It’s a classic mistake. The heat from the sauce raises the temperature inside the cooler, putting every other ingredient at risk and forcing the compressor to work itself to death. A blast chiller is purpose-built for this exact task, protecting both your pizza ingredients and your other refrigeration from burnout.

Solving Common Pizzeria Headaches

A commercial blast chiller directly tackles many of the daily frustrations that chip away at a pizzeria's profits and reputation. Bringing one into your kitchen can completely transform your workflow, especially the prep process leading up to the pizza prep table.

Here’s where it really makes a difference:

- Rock-Solid Food Safety: It gives you a reliable, repeatable way to cool batches of cooked sausage, sauces, and chopped veggies, ensuring you nail HACCP guidelines before they ever hit the prep table.

- Unbeatable Pizza Consistency: You can stop the proofing process in your pizza dough at the perfect moment, guaranteeing that same great crust texture and flavor for every single pie.

- Slash Food Waste: Rapidly chilling leftover toppings from the pizza prep table line preserves their freshness, color, and texture for the next day. That’s money you’re no longer throwing in the trash.

- Smarter Labor Use: Your team can cook huge batches of sauce or prep toppings during slower periods, blast chill them for storage, and have everything ready to load into the pizza prep table for the dinner rush.

This isn't just a hunch; it's a major industry shift. The demand is obvious—the global commercial blast chiller market hit USD 1.5 billion in 2023 and is on a steep upward climb. What’s driving it? Tighter food safety rules and the simple fact that pizzeria operators now recognize rapid cooling as essential. You can explore more about these market trends and their drivers.

At the end of the day, this equipment stops being a luxury and becomes the foundation of a safer, more profitable pizzeria. It's the secret weapon that ensures the pizza you serve on a chaotic Saturday is just as perfect as the one you make on a quiet Tuesday.

The Science of Speed and How It Protects Your Pizza

The real magic behind a blast chiller isn't just about making things cold; it's the science of speed. For any pizzeria, the clock starts ticking the second you pull a batch of sausage from the oven or finish a pot of marinara. This is the moment your ingredients enter the notorious "temperature danger zone," that dangerous territory between 40°F and 140°F where bacteria like Salmonella and E. coli multiply rapidly.

Leaving toppings or sauces to cool slowly on a counter or even in a standard walk-in cooler is like rolling out the welcome mat for these pathogens. A walk-in is designed to keep cold food cold, not to wrestle a hot pan of meatballs to a safe temperature. Shoving hot food inside forces the unit’s compressor into overdrive and can dangerously raise the temperature of everything else—including the ingredients destined for your pizza prep table.

A blast chiller, on the other hand, is a purpose-built tool with one critical mission: to rocket your food right through that danger zone as fast as possible. Using powerful fans to blast frigid air across the product, it can take a pan of cooked toppings from a piping hot 160°F down to a food-safe 38°F in less than 90 minutes.

The Microscopic Battle for Texture and Flavor

Speed isn't just about safety—it's also the secret weapon for protecting the quality of your signature pizza ingredients. When food freezes slowly, water molecules have time to form large, jagged ice crystals. These crystals act like tiny knives, puncturing cell walls and shredding the food's structure from the inside out.

Think about a beautiful block of fresh mozzarella. Freeze it the old-fashioned way, and those large ice crystals will destroy its delicate, creamy texture. When you thaw it out, you're left with a watery, rubbery mess. The same thing happens to your pizza dough, sauces, and fresh-cut vegetables, leaving you with mushy toppings and a disappointing final pie.

A blast chiller wages war on these destructive crystals.

- Rapid Cooling: By chilling or freezing so quickly, it prevents those large ice crystals from ever forming. Instead, it creates tiny, harmless microcrystals.

- Cell Wall Preservation: These microcrystals don't damage the cell structure, whether it’s the gluten network in your pizza dough or the fibers in your bell peppers.

- Locked-In Freshness: The process effectively locks in the food's original texture, flavor, and moisture. When you thaw blast-chilled toppings for your pizza prep table, they perform almost identically to their fresh counterparts.

From Scientific Principle to Pizzeria Profit

This scientific edge translates directly to a better, more consistent pizza and a healthier bottom line. For any pizzeria, mastering temperature control for food safety is non-negotiable. The principles behind rapid cooling are a core part of modern food technology, aimed at protecting both quality and safety, a topic covered by resources like Tesco Food Technology.

By preserving ingredient integrity at a cellular level, a blast chiller ensures the pizza your customer gets on a busy Friday night has the same premium taste and texture as one served on a slow Tuesday afternoon. That level of quality control is nearly impossible to pull off with traditional refrigeration alone.

Ultimately, the science is simple: faster is safer, and faster is better. A commercial blast chiller isn't just another box in the kitchen; it’s a scientific tool that gives you precise control over food safety and product quality, protecting your customers and your reputation with every single pizza you serve.

How to Choose the Right Blast Chiller for Your Kitchen

Okay, let's move from theory to action. Picking the right commercial blast chiller for your pizzeria is all about matching the machine to your kitchen’s unique rhythm. It’s not about buying the biggest or flashiest unit; it’s about making a smart investment that fits your space, your menu, and how many toppings you need to prep for your pizza prep table each day.

When you get it right, a blast chiller feels like a natural part of your workflow, not some clunky appliance you have to work around.

The very first thing you need to do is get brutally honest about your daily output. Are you a small shop making a few big batches of sauce and dough once a week? Or are you a high-volume machine, cooling multiple pans of cooked toppings and par-baked crusts every few hours? Nailing this down is the key to picking the right capacity.

In the world of blast chillers, capacity is measured in pounds per cycle. This number tells you exactly how much hot food the machine can bring down to a food-safe 38°F within that critical 90-minute window. A classic mistake is underestimating your needs, which just creates a major bottleneck for your pizza prep table line.

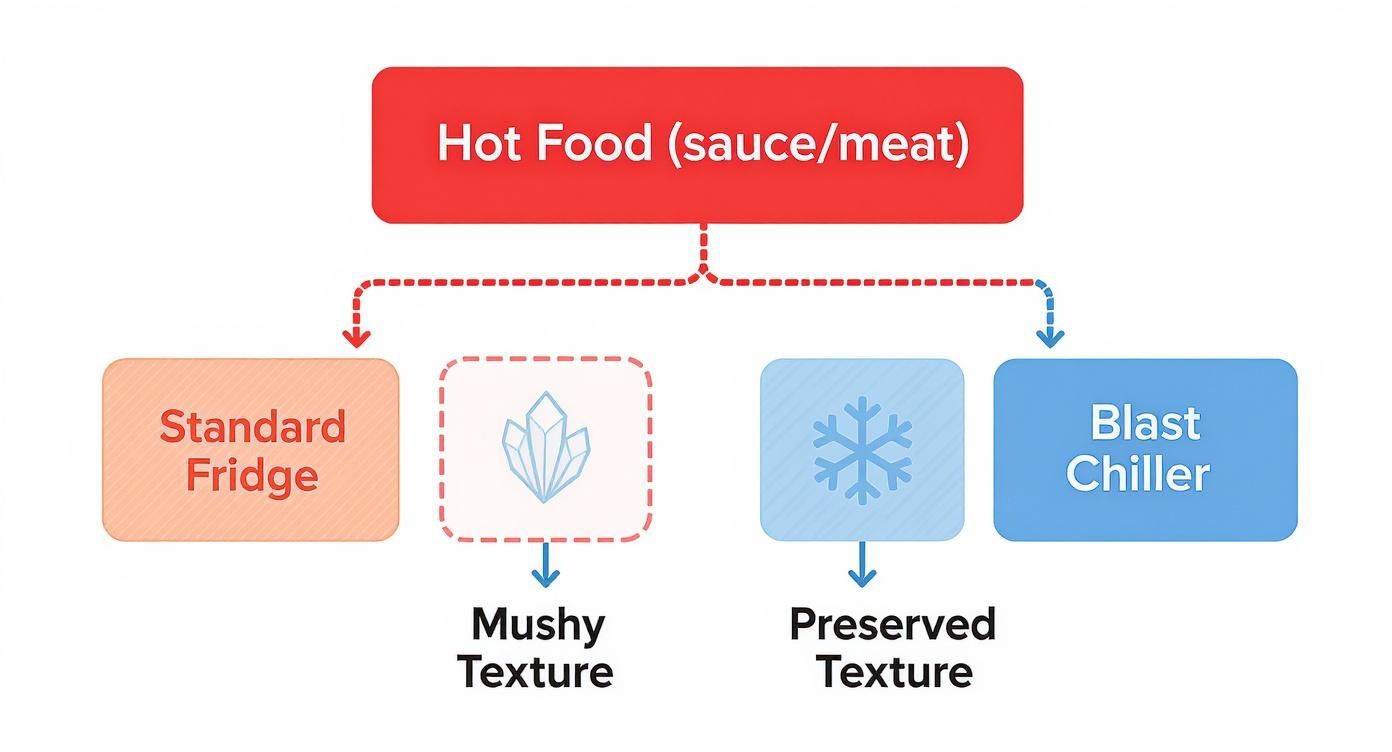

This flowchart really drives home the difference between slow-cooling in a regular fridge and what a blast chiller accomplishes.

You can see how the speed of a blast chiller keeps the food's structure intact. That's how you avoid the mushy texture that plagues food that has been cooled down too slowly.

Sizing Up Your Options

Once you've got a handle on your volume, you can start digging into the different models out there. Commercial blast chillers generally come in a few flavors, each built for different kitchen sizes and workflows.

To help you visualize the options, here’s a quick comparison of the most common types you’ll encounter.

Blast Chiller Models for Pizzeria Needs

| Chiller Type | Typical Capacity (lbs) | Best For | Space Requirement |

|---|---|---|---|

| Countertop | 15 - 50 | Small pizzerias, chilling sauces, or high-value items like specialty meats. | Minimal; fits on existing prep tables or work surfaces. |

| Reach-In | 50 - 200 | Medium-volume pizzerias needing to chill multiple sheet pans of dough or prepped toppings at once. | Similar footprint to a standard upright commercial fridge. |

| Roll-In | 200+ | High-volume pizzerias where entire racks are wheeled from the oven directly into the chiller. | Significant; requires dedicated floor space and clearance for racks. |

Each of these models solves a different problem, so it's all about finding the one that matches your pizzeria's scale and pace.

The market for smaller units is absolutely booming. In fact, the countertop blast chiller segment is projected to hit USD 1.64 billion by 2035, with restaurants leading the charge. This isn't just a trend; it's proof of how effective these compact units are in professional kitchens where every inch of space and every minute counts.

Essential Features to Look For

Beyond sheer size and capacity, a few features are non-negotiable for a modern pizzeria. These are the details that guarantee food safety, save you money on utilities, and make the machine easier to use alongside your pizza prep table.

- A food probe is an absolute must-have. You stick this probe into the thickest part of the food, giving the blast chiller real-time data on the core temperature. The cycle stops automatically the second it hits the safe zone, which means perfect consistency and a bulletproof record for your HACCP plan.

- Next, look for energy efficiency ratings. A blast chiller is a powerful piece of equipment, no doubt about it. But a modern, energy-efficient model can make a serious dent in your utility bills over its lifetime. Spending a little more upfront for a high-efficiency model almost always pays for itself. To see how this fits into your overall kitchen setup, check out our guide on the best commercial refrigeration options.

Crucial Consideration: NSF Certification

Whatever you do, make sure any blast chiller you're considering is NSF certified. This certification is your guarantee that the unit has been rigorously tested to meet strict public health and safety standards. It confirms the materials and design are easy to clean and sanitize—something that’s vital for preventing cross-contamination in your pizza prep area.

By taking the time to really evaluate your production needs, picking the right size, and prioritizing these key features, you can confidently choose a blast chiller that will become one of the most valuable tools in your pizzeria. Think of it as an investment in quality, safety, and a much smoother workflow for your pizza prep table.

Weaving a Blast Chiller Into Your Pizza Prep Workflow

Think of a commercial blast chiller not as just another box in your kitchen, but as the central hub connecting your bulk prep to your service line. It’s the critical bridge between your oven, your mixer, and your pizza prep table. When you get it right, it transforms a chaotic, last-minute prep schedule into a calm, controlled, and seriously productive operation.

The goal is to shift from a stressful "just-in-time" model to a strategic "cook-chill" system. This approach lets you prepare huge batches of pizza ingredients during slower periods, cool them down safely at lightning speed, and have them perfectly preserved and ready to load into the pizza prep table for the dinner rush. This is where pizzerias unlock massive gains in efficiency, consistency, and food quality.

This workflow isn't just about saving time; it's about gaining absolute control over every single component that ends up on your pizza.

From Bulk Dough to Perfect Crust

One of the most powerful ways a blast chiller changes the game in a pizzeria is with dough management. Traditional proofing can be a real headache, with ambient kitchen temperature making it wildly unpredictable. A blast chiller gives you the power to halt fermentation the exact moment your dough hits its peak.

Here’s how that looks in the real world:

- Mix Your Batch: Go ahead and make your standard large batch of pizza dough.

- Portion and Proof: Divide it into individual dough balls and let them start their initial proof.

- Blast Chill: Once the dough has fermented to that perfect point, slide the trays straight into the blast chiller. The intense, rapid cooling slams the brakes on the yeast's activity, locking the dough in its ideal state.

- Store and Use: The chilled dough can then move to a standard refrigerator, where it will hold perfectly for days without over-proofing. When an order comes in, you just pull a dough ball, let it come to temp, and you've got a consistent, perfectly proofed crust every time.

This method completely eliminates the risk of sour, over-proofed dough and is the secret to making every pizza crust taste and feel exactly the way you intended.

Taking Your Topping Management to the Next Level

Your pizza prep table is the last stop before the oven, and its success hinges entirely on the quality of the ingredients in those refrigerated rails. A blast chiller ensures that everything you load into those rails is as fresh, safe, and vibrant as possible, which directly impacts your final product and your bottom line.

Think about your house-made sausage or roasted vegetables. Fresh out of the oven, these items are hot and extremely perishable. Dropping them directly into the pizza prep table's cold wells is a food safety nightmare—it warms up everything else and puts a massive strain on the unit's compressor.

Instead, the workflow becomes simple: Cook -> Blast Chill -> Store -> Load Pizza Prep Table.

By rapidly chilling cooked toppings, you lock in their flavor, texture, and moisture. This process dramatically extends their shelf life, allowing you to prep toppings in larger, more efficient batches. The result is a significant reduction in food waste—one of the biggest operational challenges for any pizzeria.

Sauces, Cheeses, and Batch Production Freedom

This same logic applies to pretty much every prepped item in your pizzeria. Making a 20-gallon batch of your signature marinara is far more efficient than making five small batches throughout the week. A blast chiller is what makes this a practical reality.

- Sauces: Cook a huge pot of sauce, portion it into shallow pans to help it cool faster, and run it through a chill cycle. The sauce is brought to a safe temperature in under 90 minutes and can be stored for days with zero loss in quality.

- Shredded Cheese: When you buy it in bulk, shredded cheese can clump up. By portioning it out and running a quick chill cycle, you help preserve its texture and stop moisture loss, keeping it perfectly separated for easy sprinkling at the pizza prep table.

- Par-Baked Crusts: For catering gigs or high-volume service, par-baked crusts can be a lifesaver. After baking, a quick trip through the commercial blast chiller cools them down fast, preserving the delicate crumb structure and keeping them from getting soggy.

When you build your prep schedule around the capabilities of a blast chiller, you fundamentally change your pizzeria's entire dynamic. You empower your staff to work smarter, not harder, by separating prep time from service time. This creates a calmer, more organized kitchen where quality and safety are baked into the system, ensuring every pizza you serve is consistently excellent.

Getting the Most Out of Your Investment with Smart Upkeep

A commercial blast chiller isn't just another piece of kitchen equipment; it's a serious investment in your pizzeria's quality and speed. Just like a high-performance engine, it needs the right setup from day one and consistent care to deliver a powerful return for years. Protecting this asset starts with a smart installation and a simple, repeatable maintenance routine.

Proper installation is the foundation of peak performance. A blast chiller is a powerhouse that pulls a lot of electricity, which is why it almost always needs a dedicated circuit installed by a qualified electrician. Skimping on this can lead to frustrating circuit overloads right in the middle of a rush. Just as important is giving it room to breathe.

These units work by aggressively pulling heat out of food, and all that hot air has to go somewhere. Sticking your blast chiller in a cramped, stuffy corner is like making a marathon runner train in a sauna. It will constantly struggle, work way harder than it should, and face a much higher risk of burning out early. Make sure there’s plenty of clearance around the unit, especially near the condenser coils, so air can flow freely.

Your Routine Maintenance Checklist

Once your blast chiller is set up correctly, a simple maintenance schedule is your best defense against surprise breakdowns and lagging performance. Think of it as a quick "pre-flight check" for one of your kitchen's most valuable players. Following a plan for comprehensive maintenance for commercial appliances is the secret to extending its life.

Daily Tasks (Less than 5 minutes):

- Wipe Down Surfaces: A quick clean of the interior and exterior with a food-safe sanitizer prevents grime buildup and keeps things hygienic.

- Check the Door Gasket: Glance at the rubber door seal. A tight seal is absolutely critical for locking in cold air and running efficiently.

Weekly Tasks (10-15 minutes):

- Inspect and Clean the Gasket: Go beyond just looking. Wipe the door gasket with a damp cloth to remove any gunk that could break that perfect seal.

- Clear the Condensate Drain: Make sure the small drain line inside is clear of food bits. This prevents clogs and nasty water backup.

Monthly Tasks (20-30 minutes):

- Clean the Condenser Coils: Dust and grease are the enemies of any refrigeration unit. Gently brush or vacuum the condenser coils to keep them clean. This one task allows the unit to shed heat effectively and run like a champ.

A clean condenser coil can improve a refrigeration unit's efficiency by up to 30%. This simple monthly task translates directly into lower energy bills and less strain on the compressor—the heart of your blast chiller.

Calculating the Return and Financing Your Purchase

Understanding the money side of things helps put the initial price tag into perspective. The commercial refrigeration market, which includes blast chillers, is a massive industry. In North America alone, it was valued at USD 16.89 billion in 2024 and is projected to hit USD 22.12 billion by 2030. That growth tells you just how essential this equipment is for any serious foodservice business.

Your return on investment (ROI) really comes from three main places:

- Reduced Food Waste: Think about the value of pizza toppings, sauces, and dough you currently lose to spoilage. A blast chiller can easily cut that waste by 50% or more.

- Labor Savings: By shifting to a cook-chill workflow, your team can prep in bigger, smarter batches. This frees up hours of labor that can be used for other critical tasks, like keeping the pizza prep table stocked.

- Energy Efficiency: A well-maintained blast chiller takes a huge load off your walk-in cooler, leading to lower overall energy consumption. You can find more great tips in our article on energy-efficient commercial refrigeration.

For many pizzerias, financing is what makes this upgrade possible. Options like equipment loans or lease-to-own programs let you get the benefits of a blast chiller right away while spreading the cost over time. It makes this game-changing equipment accessible for almost any budget.

Got Questions About Blast Chillers? We've Got Answers.

Jumping into a new piece of equipment like a blast chiller always brings up a few last-minute questions. It's a serious addition to your kitchen, and being thorough is just smart business. This is where we tackle the common "what ifs" and "how does its" we hear from pizzeria owners just like you.

We'll clear up any confusion about how this machine plugs into your day-to-day, especially when it comes to your pizza dough and your pizza prep table. The goal is to make sure you're ready to hit the ground running from day one.

Can I Use a Commercial Blast Chiller to Freeze Pizza Dough?

You absolutely can, and honestly, it’s one of the best things you can do with it. Most modern blast chillers have a "shock freeze" or "hard chill" setting that’s built for exactly this job. Being able to rapidly freeze your pizza dough balls is a massive win for consistency.

Here's the problem with a standard freezer: the slow temperature drop allows big, spiky ice crystals to form. Those crystals are like tiny knives, shredding the delicate gluten structure you worked so hard to build. The result? When you go to thaw that pizza dough, it's often slack, mushy, and doesn't rise the way it should.

A commercial blast chiller sidesteps that problem entirely. Its super-fast freezing cycle creates tiny microcrystals that leave the gluten network untouched.

This means when you thaw your blast-frozen pizza dough:

- It snaps right back to its original texture and elasticity.

- The flavor is perfect, with none of that funky "freezer burn" taste.

- You get a much more consistent, high-quality crust when you bake it off.

This process lets you make dough in huge, efficient batches, manage inventory like a pro, and know for a fact that the last pizza of the night will have the same incredible crust as the first.

How Is a Blast Chiller Different From My Pizza Prep Table?

This is a fantastic question because it gets right to the core of a smart kitchen workflow. A blast chiller and a pizza prep table are partners in food safety, but they have two completely different jobs.

Think of your pizza kitchen workflow as a relay race:

- The commercial blast chiller is your first runner—the sprinter. Its one job is to take hot foods, like a big batch of cooked sausage or a pot of sauce, and crash them through the temperature danger zone (from 140°F down to 40°F) in 90 minutes or less. This is a critical HACCP step your pizza prep table physically cannot do.

- Your pizza prep table is the second runner—the marathoner. Its refrigerated rails are designed for one thing: "cold holding." Their entire purpose is to keep already-chilled pizza ingredients at a steady, safe temperature while you're slinging pies during a busy service.

You use the blast chiller for the heavy lifting of cooling things down safely at the start, then move those ingredients to the pizza prep table to hold them for service. Trying to make one do the other's job is just asking for trouble.

Is a Countertop Blast Chiller Powerful Enough for My Pizzeria?

For a huge number of small and medium-sized pizzerias, a countertop blast chiller isn't just powerful enough—it's the perfect fit. Don't let the smaller size fool you. These units pack the same powerful cooling technology as their larger counterparts, just in a more compact footprint.

A good countertop model can easily handle several pans of pizza toppings, sauces, or even par-baked crusts in a single cycle. They are the ideal solution for pizzerias that need to meet professional food safety standards but just don't have the floor space for a big reach-in unit. The secret is simply matching the unit's capacity—which is measured in pounds per cycle—to the size of your typical prep batches for the pizza prep table.

What Are the Main HACCP Benefits of Using a Blast Chiller?

The single biggest Hazard Analysis and Critical Control Points (HACCP) benefit is that a blast chiller gives you a reliable, documented, and repeatable process for cooling pizza ingredients. It takes food safety from a guessing game to a science.

A blast chiller with a food probe gives you an undeniable record of your cooling process. This creates a rock-solid Critical Control Point (CCP) in your pizzeria's food safety plan and proves you're actively managing the risk of bacterial growth.

When a health inspector walks in, that precise tracking is your best friend. It’s hard proof that you’re not just meeting, but crushing, the required cooling time limits. This drastically cuts down the risk of foodborne illness and protects the reputation you've worked so hard to build, one safe and delicious pizza at a time.

Ready to build a safer, more efficient pizzeria? At Pizza Prep Table, we specialize in providing the high-quality commercial refrigeration that forms the backbone of any great pizza restaurant. Explore our selection of pizza prep tables and other essential equipment designed to help you serve the best pizza possible. Find the perfect equipment for your pizzeria at Pizza Prep Table.