A Pro's Guide to Commercial Kitchen Freezers for Pizzerias

Share

For any pizzeria, the real difference between a good pizza and a great one often hides behind a stainless steel door. The best commercial kitchen freezers are so much more than just cold boxes; they're strategic assets that guard the quality of every single ingredient, from bulk mozzarella to perfectly proofed dough balls.

Your Pizzeria's Secret Ingredient for Success

Think of your commercial freezer as the silent partner in your pizza-making operation. It’s the unsung hero that guarantees the consistency and quality your customers come back for. From the moment ingredients walk in your back door to the second they hit the pizza prep table, precise temperature control is what keeps them at peak freshness and flavor.

This journey from storage to service is where the right equipment really proves its worth. A freezer that can't keep up with the constant door openings during a dinner rush can compromise food safety and lead to spoiled ingredients—a direct hit to your bottom line.

Protecting Quality from Dough to Topping

The soul of a memorable pizza starts long before it ever sees an oven. The texture of your dough and the vibrant taste of your toppings are directly tied to how they’re stored. Improper freezing can create big, nasty ice crystals in your dough, wrecking its delicate structure and leaving you with a subpar crust.

For a pizzeria, consistent freezing isn't just about preservation; it's a fundamental part of recipe execution. It ensures that the dough you prepped on Monday performs just as perfectly as the dough you use on a busy Friday night.

Effective freezing locks in the integrity of everything you store. It keeps the moisture in your veggies, preserves the rich flavor of cured meats like pepperoni, and stops cheese from losing its creamy texture. This consistency is the bedrock of any reliable and successful pizzeria. A well-chosen freezer essentially becomes a quality control hub for your entire menu.

Streamlining Workflow at the Pizza Prep Table

Efficiency is everything in a fast-paced pizzeria. The right selection and placement of commercial freezers can dramatically improve your kitchen's entire workflow. When ingredients are stored logically and are easy to grab, your team can assemble pizzas faster and with fewer mistakes.

This is especially true for pizza prep tables, which cleverly combine refrigerated storage with a dedicated workspace. These units are designed to keep essential toppings chilled and within arm's reach, cutting down on the time your staff spends walking back and forth to a main freezer. A seamless workflow means:

- Faster Order Fulfillment: Shaving critical seconds off each order by reducing the steps needed to build a pizza.

- Improved Kitchen Organization: Everything has its place, which cuts down on clutter and confusion during peak hours.

- Enhanced Food Safety: Toppings stay at safe temperatures right up until they hit the oven.

Ultimately, the freezer you choose is a cornerstone of your operation. To build a truly efficient pizzeria, it's vital to understand the full scope of commercial food prep equipment and how each piece works together to create a productive environment.

Choosing the Right Freezer for Your Pizza Operations

Not all commercial kitchen freezers are built the same, especially when you throw them into the fast-paced, high-heat world of a pizzeria. The right unit isn't just a box to keep things cold; it's a critical piece of your production line. Getting a handle on how different freezers fit into your day-to-day workflow is the secret to unlocking serious efficiency and consistency.

For any pizzeria, the name of the game is moving ingredients from bulk storage to the prep line without a hitch. Each type of freezer has a specific job in this journey, kind of like players in different positions on a team. Let's break down the essential gear that keeps a pizza kitchen humming.

The Workhorse Pizza Prep Table Freezer

The pizza prep table freezer is the absolute heart of the assembly line. It’s where all the action happens, rolling refrigerated ingredient rails and undercounter freezer storage into one beast of a workstation. Think of it as the command center for your pizza makers.

The refrigerated rail on top keeps your must-have toppings like pepperoni, mushrooms, and onions chilled and ready to grab. This completely cuts out the time-wasting walks to a separate freezer, shaving precious seconds off every single order. Down below, the undercounter freezer base is perfect for stashing backup toppings, pre-portioned dough, or specialty cheeses.

A well-designed pizza prep table is a complete game-changer for both speed and safety. By keeping ingredients organized and at the perfect temperature right where you need them, you slash ticket times and seriously reduce the risk of food sitting in the temperature danger zone.

It’s this seamless blend of workspace and cold storage that makes these units so essential. They are purpose-built for the linear, repetitive flow of building pizzas, making them arguably the most important commercial kitchen freezer for any pizzeria.

Reach-In Freezers The Everyday Pantry

If the prep table is your command center, then the reach-in freezer is your frontline pantry. These upright units are the versatile workhorses of the kitchen, built to hold ingredients you need often throughout the day but not necessarily right on the prep line itself.

They are perfect for holding trays of proofed pizza dough, big bags of shredded mozzarella, and containers of your house-made sauce. Their upright design is a smart use of floor space, and the adjustable shelves let you organize your inventory for quick visual checks. When you're in the middle of a busy service, a well-stocked reach-in lets your crew restock the prep table in seconds without breaking stride.

You can see just how vital these units are by looking at their market growth. The global market for reach-in freezers was valued at around $2.37 billion in 2025 and is expected to climb to about $3.34 billion by 2035. This steady growth just goes to show how fundamental these efficient, compact freezers are for the entire foodservice industry.

Walk-In Freezers For High-Volume Operations

For pizzerias drowning in orders or those that handle big catering jobs, the walk-in freezer is non-negotiable. This is your deep storage warehouse—the place where you keep pallets of frozen dough, cases of cheese, and boxes of bulk toppings.

A walk-in freezer lets you cash in on bulk purchasing discounts, which can make a huge dent in your food costs over the long run. It acts as the main hub for your inventory, feeding ingredients out to your smaller, more accessible reach-in and pizza prep table freezers. While not every little pizzeria needs one, for any growing operation, a walk-in is a critical investment for scaling up. To see how smaller units can bridge the gap, check out our guide on the benefits of a commercial undercounter freezer.

When you get the right mix of these commercial kitchen freezers, you create a powerful cold-chain ecosystem in your kitchen. Here’s a quick look at how they work together.

Pizzeria Freezer Types At a Glance

| Freezer Type | Primary Pizzeria Use | Best For | Key Benefit |

|---|---|---|---|

| Pizza Prep Table Freezer | Active pizza assembly and topping storage | The main production line | Combines workspace and cold storage to maximize speed and efficiency. |

| Reach-In Freezer | Daily-use ingredient storage | Restocking the prep line quickly | Keeps frequently accessed items close by without cluttering the line. |

| Walk-In Freezer | Bulk, long-term inventory storage | High-volume operations and bulk purchasing | Lowers food costs through bulk buying and acts as a central inventory hub. |

The flow is simple and logical: ingredients move from the walk-in (long-term storage), to the reach-in (daily supply), and finally to the pizza prep table (immediate use). This system ensures every single pizza is made with fresh, safe, and perfectly preserved components.

Key Factors When Selecting Your Pizzeria Freezer

Buying a new commercial freezer is a serious investment for any pizzeria. It's not just about finding a box that gets cold; it's about making a smart decision that fits your kitchen's real-world demands. To get this right, you need to look at capacity, energy costs, and the kind of durability that can survive the daily grind of a busy pizza shop.

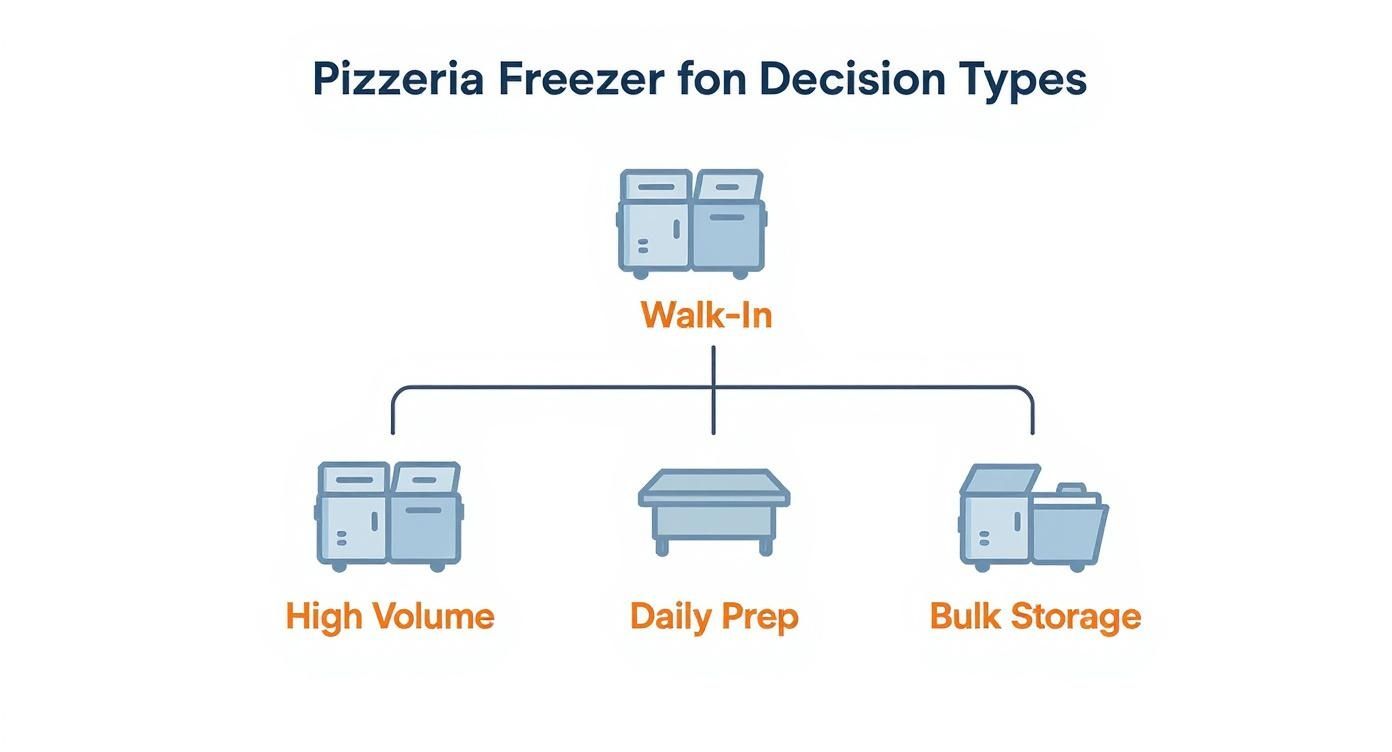

This decision tree infographic is a great way to see how different kitchen needs point you toward specific types of commercial kitchen freezers, from massive walk-ins to the workhorse pizza prep tables.

The main takeaway here is simple: your choice should solve your biggest problem, whether that's storing bulk ingredients or streamlining your daily prep.

Sizing Up Your Capacity and Footprint

Before you even start browsing models, you have to answer two basic questions: How much dough, cheese, and toppings do I need to freeze, and where the heck am I going to put it? Think of this as the blueprint for your cold storage.

Start by figuring out your capacity needs based on your weekly food orders and delivery schedule. A shop that gets deliveries twice a week can get by with less freezer space than one that buys in bulk once a month to save money.

Next, get out the tape measure. The actual footprint of commercial kitchen freezers is a make-or-break detail that people often forget. Measure the spot where you want it to go, but don't forget to add room for clearance. Freezers need to breathe, with space around the back and sides for proper ventilation. Jamming it into a tight corner will make the compressor overheat—a classic problem in hot pizza kitchens. That unit will work harder, suck up more electricity, and die an early death.

Energy Efficiency and Compressor Location

Your freezer is going to run 24/7, 365 days a year, making it a major player on your monthly utility bill. This is why looking for an ENERGY STAR certified model is a total no-brainer. These units are built for efficiency with better compressors and insulation, and they can easily save you hundreds of dollars a year.

The compressor's location is another detail that's especially crucial in a pizzeria.

- Top-Mount Compressors: We usually recommend these for pizzerias. Why? Because the compressor is up and away from all the flour, dust, and other gunk that settles on the floor. This keeps the condenser coils from getting clogged, which is a common cause of overheating.

- Bottom-Mount Compressors: These are sometimes easier for a technician to work on, but they are magnets for flour dust in a pizza shop. On the plus side, the lower shelves are easier for your staff to reach, which is a nice ergonomic perk.

In a hot kitchen, a top-mount unit also has a slight advantage because it pulls in cooler air from higher up. A bottom-mount has to work a bit harder because it's pulling in warmer air rising from the floor.

For a pizzeria, the compressor's location isn't just a design choice—it's a strategic decision that directly impacts the freezer's long-term health and efficiency. A top-mounted unit is generally the safer bet to combat the airborne flour that defines a pizza kitchen.

Material and Durability

Let's be honest, pizzeria kitchens are brutal environments. Your freezer has to be tough enough to handle doors slamming, heavy boxes of cheese bumping into it, and constant cleaning. The undisputed champ for durability in commercial kitchen freezers is stainless steel.

But not all stainless steel is created equal.

Look for a freezer made from a high-quality grade like 304 stainless steel, which is known for its incredible resistance to rust and corrosion. This is especially important for the interior, where it will be exposed to moisture and acidic foods like tomato sauce. Cheaper steel might save you a few bucks upfront, but it’s far more likely to rust and pit over time.

The little things matter just as much. Pay attention to the sturdiness of the doors, hinges, and shelves. In a pizzeria, that freezer door is going to be opened and closed hundreds of times a day. Heavy-duty components aren't just a nice feature; they're non-negotiable if you want your investment to last.

Optimizing Your Kitchen Layout for Peak Performance

Unboxing a new commercial freezer is just the start. Its real value comes from how well it fits into your kitchen's daily rhythm. Where you put this workhorse can mean the difference between a seamless production line and a chaotic bottleneck, especially during that Friday night rush.

Strategic placement is about more than just finding an open spot. It’s about mapping out the most efficient path for ingredients to travel from storage to the pizza box. You have to think about how your team moves and how each piece of equipment, especially the pizza prep table, talks to the others.

And this equipment is more vital than ever. The global market for commercial refrigeration, which includes commercial kitchen freezers, is already valued at nearly $47 billion in 2025 and is expected to hit roughly $79.4 billion by 2034. With North America making up over 31% of that market, the demand here is huge.

Setting the Stage for Success

Before you even think about plugging it in, a few setup steps are absolutely non-negotiable. Think of this as laying a solid foundation for your freezer’s long and productive life in your pizzeria.

Proper ventilation is probably the most critical factor, yet it's the one most often overlooked in cramped spaces. Your freezer's compressor generates a ton of heat. If it can't breathe, it has to work harder, which jacks up your electricity bill and leads to premature failure. This is especially true if you're tempted to shove it next to a pizza oven—don't. Always leave several inches of breathing room around the back and sides for airflow.

Your new freezer also needs its own dedicated electrical circuit. These units are power-hungry, and plugging one into a shared circuit with other appliances is just asking for tripped breakers and potential damage to your new investment. When you're optimizing your pizzeria, every major appliance needs this kind of careful planning, which is a key part of following commercial kitchen equipment installation best practices.

The Golden Triangle of Pizza Production

The most efficient pizzerias I've seen all have one thing in common: they arrange their layout around a "golden triangle" of workflow. It flows from bulk storage, to daily-use storage, and finally to the prep station. Placing your commercial kitchen freezers strategically within this flow is how you shave precious seconds off every single order.

Here’s how to picture the ideal journey for your ingredients:

- Bulk Storage (Walk-In/Large Reach-In): This is where deliveries land. It should be close to your delivery door to make unloading and inventory a breeze.

- Daily Prep Storage (Reach-In Freezer): Position a smaller reach-in freezer much closer to the action. This unit holds what you need for the day, like trays of proofed dough or backup sauce.

- The Pizza Prep Table: This is the heart of the operation, where the magic happens. It should be the last stop before the oven, stocked with toppings pulled directly from the nearby reach-in.

An intelligently positioned pizza prep table freezer acts as the final link in the cold chain. It minimizes the steps your staff needs to take, reducing physical strain and cutting down on the time it takes to build a pizza.

This logical flow turns your kitchen from a bunch of disconnected stations into a fluid, high-speed assembly line. A well-thought-out layout is one of the most powerful tools you have for boosting productivity. To really dig into this, check out our complete guide on commercial kitchen layout design.

Essential Maintenance to Protect Your Investment

A middle-of-the-rush freezer breakdown is every pizzeria owner’s worst nightmare. Your commercial kitchen freezers are the unsung heroes of your operation, humming along 24/7 to protect thousands of dollars in cheese, dough, and toppings. A little proactive maintenance is your best defense against spoiled inventory and catastrophic repair bills.

Think of it like this: you wouldn't run your delivery car for months without an oil change. Ignoring your freezer is the same gamble. A few minutes of care each day, week, and month will keep it running strong and save you a world of hurt down the road.

Your Actionable Maintenance Checklists

Consistency is everything. The best way to make maintenance stick is to build simple checklists into your daily opening and closing routines. It turns a chore into a habit that protects your gear, your food, and your bottom line.

Daily Tasks (Less than 5 minutes)

- Wipe Down Surfaces: Clean up spills on the inside and outside right away. It keeps things sanitary and prevents nasty stains from setting in.

- Check the Temperature: A quick glance at the external display is all it takes. Make sure it’s holding steady at 0°F (-18°C) or colder.

- Clear the Vents: Check that no boxes are pushed up against the interior air vents. Blocked vents mean poor airflow and dangerous warm spots.

Weekly Tasks (10-15 minutes)

- Inspect Door Gaskets: Run your hand along the rubber door seal. If you feel even a hint of cold air escaping, that gasket is worn out and costing you money. A bad seal forces your compressor to work overtime.

- Clean Door Handles and Gaskets: Wipe down the gaskets and handles with mild soap and water. Removing grime helps the rubber last longer.

Monthly Tasks (20-30 minutes)

- Clean the Condenser Coils: This is the single most important task you can do for your freezer's health, especially in a pizzeria kitchen full of airborne flour.

- Check for Ice Buildup: If you have a manual-defrost unit, look for frost. If it’s thicker than a quarter-inch, it’s time to schedule a defrost.

In a flour-dusted pizzeria, condenser coils are like magnets for airborne particles. A clogged coil suffocates the compressor, forcing it to overheat and work much harder to cool the unit, which is a leading cause of premature equipment failure.

A Quick Troubleshooting Guide

Even with perfect maintenance, things can go wrong. Before you pick up the phone for an expensive service call, here are a few common issues with simple fixes you can try first.

| Common Problem | Potential Cause | Easy Fix to Try |

|---|---|---|

| Temperature is Too High | Blocked airflow or dirty condenser coil | Check for blocked interior vents and make sure there's enough clearance around the unit. Clean the condenser coils. |

| Freezer is Constantly Running | Worn or dirty door gasket | Clean the gasket thoroughly. If it's cracked or torn, it needs to be replaced to create a proper seal. |

| Water on the Floor | Clogged drain line | Find the drain line (usually inside or at the back) and carefully clear any gunk with a small brush or pipe cleaner. |

Knowing When to Call a Professional

While you can handle the basic stuff, it’s critical to know your limits. Cleaning and quick checks are one thing; major repairs are another.

You need to call a qualified refrigeration tech if you notice:

- Strange Noises: Any loud grinding, clanking, or buzzing is a bad sign, often pointing to a failing compressor or fan motor.

- Persistent Leaks: If clearing the drain line doesn’t fix the puddle, you’ve likely got a bigger problem on your hands.

- Electrical Problems: If the freezer keeps tripping a breaker or just won’t power on, don't mess with it. This is a job for an expert.

Treat your commercial kitchen freezers like the valuable assets they are. A simple, consistent maintenance plan is the best way to ensure all your cooling equipment, from the big walk-in to your pizza prep table, stays reliable for years to come.

The Future of Commercial Freezers in Pizzerias

The humble freezer is getting a serious upgrade. It’s no longer just a simple cold box tucked in the corner; big shifts in technology are turning commercial refrigeration on its head. For pizzeria owners, this means your next freezer isn't just an appliance—it's an investment in where the industry is headed. The two biggest forces driving this change are sustainability and smart tech.

Sustainability isn't just a feel-good word anymore. It's a business reality, pushed by new regulations and the simple desire to slash operating costs. The commercial kitchen freezers of tomorrow are being built with eco-friendly refrigerants like R-290 propane, which has a much smaller environmental footprint. When you pair that with hyper-efficient compressors and better insulation, these new models cut down on energy use in a big way, which shows up as real savings on your monthly utility bills.

Smarter Freezers for a Smarter Kitchen

Beyond just being efficient, the next wave of refrigeration is getting brainy. Imagine a pizza prep table freezer that shoots an alert to your phone if the temperature starts creeping up, saving you from losing a mountain of cheese and toppings before it's too late. That's the power of smart technology in action.

You'll see the term "Internet of Things" (or IoT) thrown around, and for freezers, it's becoming a feature that offers real-world benefits that used to be unthinkable:

- Remote Temperature Monitoring: Check on your freezer's status from home or on the go, making sure your inventory is safe 24/7.

- Predictive Maintenance Alerts: The freezer can basically diagnose itself, warning you about a failing part before it dies and brings your kitchen to a screeching halt.

- Automated Compliance Logs: Smart freezers can log temperature data automatically, which takes a huge headache out of health inspections and paperwork.

The rise of smart freezers is a move from putting out fires to preventing them in the first place. For a busy pizzeria, that means less downtime, less food waste, and a whole lot more peace of mind.

This tech wave is part of a much bigger picture. The global market for upright commercial freezers is sitting at around $5 billion in 2025 and is expected to grow by about 5% each year through 2033. That growth is coming straight from the food service industry's need for cold storage that's reliable and efficient. You can discover more insights about the expanding upright commercial freezer market and its key drivers. Getting a handle on these changes now ensures your next freezer is an asset built for the future, not a relic of the past.

Frequently Asked Questions

Pizzeria owners always have a few key questions about getting the most out of their commercial freezers. Here are some straightforward answers to the things we get asked the most, designed to help you protect your gear and your ingredients.

How Often Should I Defrost My Pizzeria Freezer?

Most modern commercial kitchen freezers are frost-free, so they take care of this automatically. But if you’re working with a manual-defrost unit, you need to step in when ice buildup hits about a quarter-inch thick.

In a pizza shop, all that airborne flour can mix with moisture and speed up frost formation. It’s a smart move to check your unit every month.

Letting ice get too thick is like making your freezer run a marathon in winter gear. It forces the compressor to work much harder, which wastes a significant amount of energy and can lead to premature failure.

What Is the Ideal Temperature for Pizza Dough and Cheese?

The gold standard for any commercial freezer is 0°F (-18°C) or a touch below. This temperature is especially critical in a pizzeria for a couple of big reasons.

First, it keeps your pizza dough perfectly dormant. This prevents large ice crystals from forming, which can destroy the gluten structure and completely ruin the final texture of your crust. For your bulk cheese and other toppings, holding them at 0°F is the only way to lock in their flavor and quality for the long haul.

Can I Use a Residential Freezer in My Pizza Shop?

Putting a residential freezer in a commercial kitchen is a huge mistake—one you should absolutely avoid. Home freezers are simply not built to survive the demands of a busy pizzeria.

Their compressors can't recover cold temperatures quickly enough after the door is opened and closed dozens of times during a shift. This creates wild temperature swings and puts your ingredients squarely in the food safety danger zone. On top of that, using a residential model for your business will almost certainly void its warranty and could get you in hot water with your local health inspector.

Ready to build a more efficient and reliable kitchen workflow? Pizza Prep Table offers a curated selection of high-quality commercial kitchen freezers and pizza prep tables designed for the demands of a modern pizzeria. Explore our durable, energy-efficient equipment and find the perfect fit for your operation at https://pizzapreptable.com.