Choosing a Commercial Pizza Oven for Your Pizza Restaurant

Share

Picking the right commercial pizza oven isn't just a big decision—it's the decision for any pizza restaurant. Think of it as the engine driving your entire operation. It dictates the quality of every pizza, how many customers you can serve on a slammed Friday night, and ultimately, how profitable your pizzeria can be. This guide is here to help you find the perfect oven that lines up with your vision.

The Heart of Your Pizzeria: The Commercial Pizza Oven

The real magic in a pizza restaurant happens at the intersection of a powerful commercial pizza oven and a well-organized pizza prep table. This duo sets the rhythm for your entire kitchen, turning raw dough and fresh toppings into perfectly cooked pies with speed and consistency. A great oven doesn't just bake; it builds your restaurant's reputation one delicious pizza at a time.

It's no surprise that the market for these workhorses is massive. The global pizza oven market is valued somewhere between $1.84 billion and $2.19 billion, and the commercial side of things makes up a staggering 73.6% of that. That share is driven by pizzerias, restaurants, and food trucks that simply can't function without a reliable, high-performance oven. Discover more insights on the pizza oven market to see just how critical this equipment is.

Aligning Your Oven with Your Restaurant's Vision

Before you start getting lost in BTUs and deck sizes, take a step back and think about your pizza restaurant's identity. The right oven will feel like a natural extension of your entire business model.

Here are the big questions to ask yourself:

- What's your pizza style? An artisanal pizzeria slinging authentic Neapolitan pies needs a completely different oven than a high-volume restaurant famous for its classic New York slices.

- How do you serve your customers? A bustling takeaway and delivery business needs an oven built for pure speed. A sit-down restaurant, on the other hand, might want the theater and unique flavor of a wood-fired oven.

- How does your kitchen flow? The oven has to work hand-in-glove with your pizza prep tables. A smooth, ergonomic workflow from prep to bake saves steps, reduces stress, and pushes more pizzas out the door.

Your oven is more than just a hot box in the corner; it’s a statement about your commitment to quality. It’s the final step that turns your team's hard work at the pizza prep table into a meal your customers will remember.

This guide is designed to be your roadmap. By the end, you'll have a solid grasp of the different oven types, fuel sources, and operational details. You'll be able to invest with confidence in an oven that will be the reliable, hardworking heart of your pizza kitchen for years to come.

Comparing Commercial Pizza Oven Types

Choosing the right commercial pizza oven is a lot like a pizzaiolo picking their signature peel—the tool has to match the task, the style, and the flow of the kitchen. The oven you pick is the heart of your operation. It directly shapes your pizza’s final taste and texture, defining your restaurant's identity and connecting the fresh ingredients from your pizza prep tables to the finished pie you hand to a customer.

In the world of pizzerias, three major players dominate the scene: deck ovens, conveyor ovens, and wood-fired ovens. Each one operates on a completely different principle and is built for distinct restaurant models and culinary goals. Let's break down how each one performs and figure out which one fits your vision.

Quick Guide to Pizza Oven Types

To give you a bird's-eye view, this table breaks down the key differences between the major oven types. Think of it as a cheat sheet for matching an oven's strengths to your pizzeria's goals.

| Oven Type | Best For | Pizza Output | Skill Level Needed | Typical Footprint |

|---|---|---|---|---|

| Deck Oven | Artisan pizzerias, slice shops | Medium (30-50 pizzas/hr) | High (requires skill) | Medium to large |

| Conveyor Oven | High-volume chains, delivery | High (50-100+ pizzas/hr) | Low (set & forget) | Large |

| Wood-Fired | Authentic Neapolitan, show kitchens | Low-Medium (20-40 pizzas/hr) | Very High (a craft) | Large & heavy |

This is just the starting point. The real decision comes down to the kind of pizza you want to make and the experience you want to create for your customers and your staff.

Deck Ovens: The Pizzeria Workhorse

Deck ovens are the soul of the classic pizzeria, from old-school New York slice shops to traditional Italian restaurants. These ovens rely on conduction heat, meaning pizzas bake directly on a super-hot stone or steel surface (the "deck"). This is what creates that signature crisp, perfectly browned crust everyone craves. At the same time, radiant heat from the top element melts the cheese and cooks the toppings just right.

Think of a deck oven as a skilled artisan's tool. It demands an experienced operator who understands how to manage hot spots, rotate pies with a peel, and time everything perfectly. The reward for that skill is total control over the finished product, allowing for those subtle variations in char and texture that keep regulars coming back for more.

- Best For: Pizza restaurants that live and die by their crust texture and a traditional bake, like New York, American, and Sicilian-style pizzerias.

- Workflow Integration: They pair perfectly with standard pizza prep tables. Because every pizza is loaded and unloaded by hand, the prep station can be set up right next to the oven for a seamless hand-off from the prep table to the peel.

- Skill Level: Definitely needs an experienced cook. Juggling multiple pizzas and managing oven temperatures on the fly is a real skill.

Conveyor Ovens: The Champion of Consistency

For high-volume chains, delivery-heavy pizzerias, and fast-casual spots where speed is king, the conveyor oven is the undisputed champion. This machine is engineered for one mission: to pump out a massive number of identical pizzas, fast, and with very little training. You just place a pizza on the conveyor belt, and it moves through a heated chamber at a fixed speed and temperature.

The result is absolute consistency. Every single pizza comes out looking and tasting the same, which is a massive advantage for franchise operations or any pizza restaurant that depends on speed and predictability. They may not have the artisanal charm of a deck oven, but their efficiency during a slammed dinner rush is simply unmatched. They make the production line—from pizza prep table to cutting station—incredibly simple because the output is continuous and predictable.

A conveyor oven takes all the guesswork out of baking. It’s an efficiency engine designed to keep up with relentless demand, making sure the 100th pizza of the night is a perfect twin of the first.

Wood-Fired Ovens: The Heart of Authenticity

A wood-fired oven isn't just another piece of kitchen equipment; it's a centerpiece and a mission statement for your pizza restaurant. It tells your customers you're all about tradition, craft, and incredible flavor. These ovens get blazing hot, often rocketing past 900°F, which allows them to cook authentic Neapolitan pizzas in as little as 60-90 seconds. This intense heat creates that iconic puffy, charred crust (the cornicione) and a subtle smoky flavor that no other oven can replicate.

Running a wood-fired commercial pizza oven is a true craft. The chef has to manage the fire, understand the oven's unique heat zones, and work with incredible speed. It’s pure theater for your customers and a demanding job for the kitchen staff, but for an artisanal pizzeria, that authentic result is the entire brand. If you're exploring other versatile oven options, you can see how a commercial convection oven stacks up for different kitchen needs in our detailed comparison.

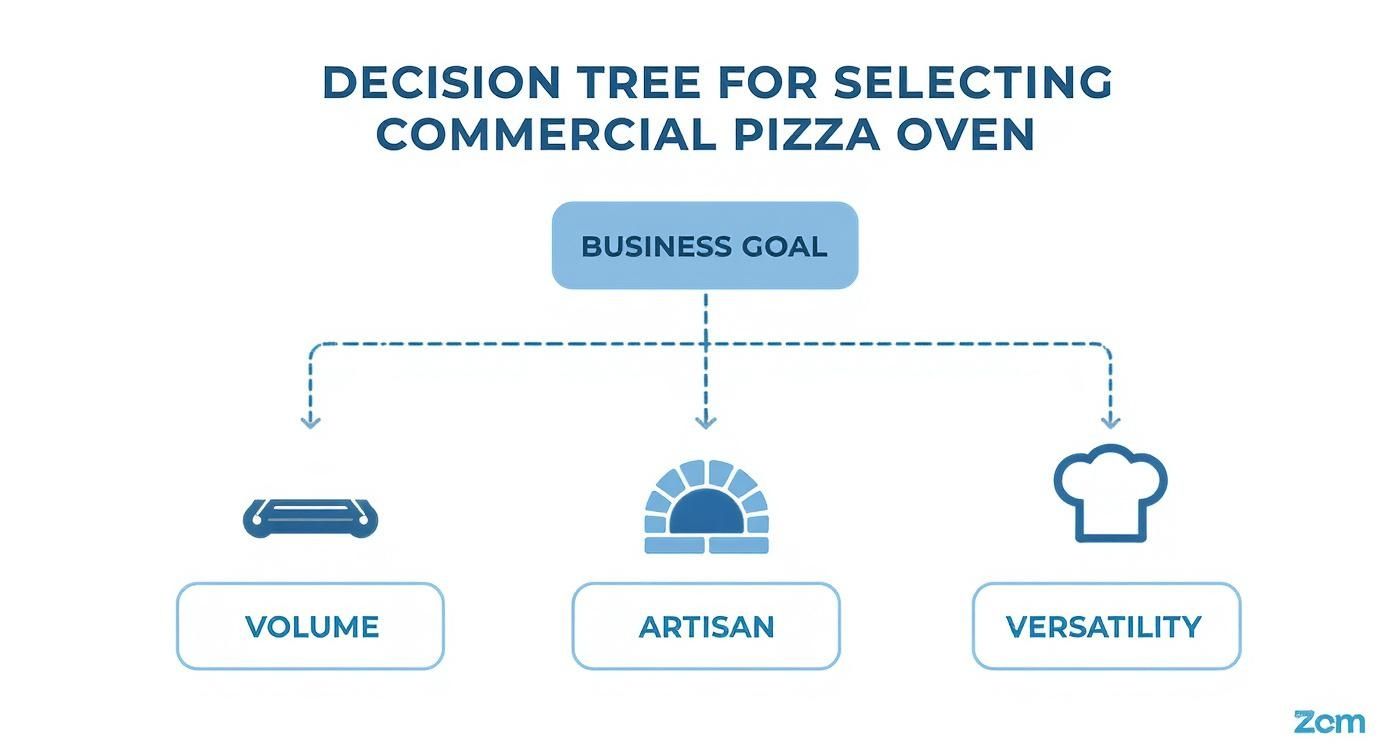

To help you see which path makes sense for your restaurant, this decision tree maps out the choice based on your main business goal.

As you can see, your core objective—whether it's cranking out high volume, creating artisanal quality, or having all-around versatility—is the single most important factor in choosing the right oven for your pizzeria.

Gas, Electric, or Wood: What's Fueling Your Pizza?

The fuel source you choose for your commercial pizza oven is the heart and soul of your pizzeria. It's way more than just a line item on your utility bill; it’s a decision that shapes the taste of your pizza, your daily operating costs, and even the rhythm of your kitchen team as they work the pizza prep table.

Each fuel type—gas, electric, and wood—brings its own personality to the kitchen. An electric oven is all about precision, giving you steady, reliable heat that’s a breeze to control. A gas oven is the industry’s go-to workhorse, loved for its raw power and ability to bounce back quickly during a dinner rush. Then you have the wood-fired oven—the artisan's choice, creating that authentic, smoky flavor that can become your pizza restaurant’s signature.

Gas Ovens: The Industry Standard

There's a reason gas ovens are the undisputed champions in most commercial pizzerias. They heat up fast, react instantly when you tweak the temperature, and recover that heat in a flash after you've opened the door to pull a pie. This responsiveness is perfect for the controlled chaos of a busy pizza kitchen, where pies are flying from the prep table to the oven and out to hungry customers.

You'll find models that run on both natural gas and propane, giving you flexibility based on what’s available at your restaurant. Their solid performance and relatively low running costs make them a dependable and smart choice for any high-volume pizzeria. If you're weighing the two, we break down the details in our guide on natural gas vs. propane for commercial use.

Electric Ovens: Precision and Simplicity

Electric commercial pizza ovens are the masters of "set it and forget it" baking. They deliver incredibly even, radiant heat, which gets rid of the hot spots that can sometimes be a headache with other oven types. This precision makes them dead simple to operate, so you don't necessarily need a highly-trained pizza chef to manage the baking.

This simplicity creates a smooth, predictable workflow from the pizza prep table to the finished product. The trade-off? They can take a bit longer to heat up and recover their temperature compared to gas. For the really high-capacity electric ovens, you might also need a three-phase power installation, which is a key cost to factor into your initial setup.

The greatest strength of an electric oven is its reliability. It removes variables from the cooking process, ensuring the last pizza of a busy night is baked just as perfectly as the first, with minimal oversight.

This makes them a fantastic choice for pizzerias where consistency is king, or for restaurants that want to simplify staff training without sacrificing an ounce of quality.

Wood-Fired Ovens: The Artisan's Choice

If you're aiming to deliver a truly authentic, old-world experience, nothing beats a wood-fired commercial pizza oven. The blistering heat, often soaring past 900°F, cooks pizzas in just a couple of minutes. The result is that classic leopard-spotted, puffy crust you see on a true Neapolitan pie. And that subtle, smoky flavor from the burning wood? It’s something you just can't fake.

That authenticity has made these ovens incredibly popular, and they now command a 48.9% share of the global pizza oven market by fuel type. But they aren't for the faint of heart. These ovens demand real skill to run, requiring a chef who knows how to manage a live fire. They also tend to come with higher installation and ventilation costs for your restaurant.

Laying Out Your Pizza Production Line

A beast of a commercial pizza oven is a beautiful thing, but it’s only as good as the kitchen workflow feeding it. Think of your pizzeria as a finely tuned assembly line. The oven might be the star of the show, but its real power is unlocked by the smooth, logical flow of every action that happens before the bake. This is where the synergy between your oven and your pizza prep tables becomes the absolute backbone of your operation.

The goal is simple: create a seamless journey from raw dough to a perfectly boxed pizza, cutting out every wasted step along the way. A poorly planned layout forces your team to do the kitchen shuffle—taking extra steps, crossing paths, and losing precious seconds during a dinner rush. Over the course of a night, those lost seconds add up to fewer pizzas sold and a stressed-out crew.

The Heart of Your Workflow: The Pizza Prep Table

The pizza prep table is mission control. It’s the direct link to your oven and the launchpad for every single order. A well-organized prep table, stocked with refrigerated ingredients right where you need them, lets a pizzaiolo build pies quickly and consistently. The distance and relationship between this station and your oven will literally set the pace for your entire kitchen.

When you’re mapping out your production line, understanding the core principles for how to layout a functional kitchen can make a world of difference. The key is to arrange your equipment in a logical sequence that mirrors the pizza-making process itself.

- Dough Station: This is where it all starts. Your mixer, proofing boxes, and sheeter should be right at the beginning of the line.

- Pizza Prep Table: This is the main event. It should be positioned right after the dough station, making the hand-off effortless.

- Commercial Pizza Oven: The oven needs to be just a few steps from the prep table. This makes the transfer from peel to oven deck quick, easy, and safe.

- Cutting & Finishing Station: Once the pizza comes out, it needs a dedicated spot to land for cutting, boxing, or plating. This should be right next to the oven's exit.

Planning Your Oven's Footprint and Clearance

Your commercial pizza oven is probably the biggest piece of iron in your kitchen, and it demands serious space planning. It’s not just about the physical dimensions of the oven itself; you have to account for mandatory clearance and ventilation, which are non-negotiable for safety and legal compliance in your restaurant.

A classic rookie mistake is underestimating an oven's total footprint. Forgetting to factor in space for the door swing, service access, and the ventilation hood can create a cramped, inefficient, and dangerous workspace that’s a nightmare to fix later.

Before you even think about installation, dig into the manufacturer's spec sheet for clearance requirements. Most ovens need a minimum of 6-12 inches of breathing room on all sides to prevent heat from transferring to walls or other equipment. Even more important is the ventilation hood, which must extend beyond the oven's footprint to properly capture all that heat and grease-filled air. Our guide offers more in-depth strategies to design a restaurant kitchen that is both compliant and built for speed.

By mapping out this production line with your oven and prep tables as the anchors, you create a workspace that just feels right. This strategic design is what empowers your pizzeria team to handle the pressure of the busiest dinner rush with speed, consistency, and confidence.

Nailing Your Oven Capacity: How Many Pizzas Can You Handle?

Picking an oven that’s too small for your pizza restaurant is like trying to fill a swimming pool with a garden hose. It’s a frustrating, slow-motion disaster that guarantees you’ll drown in angry customer tickets on a busy night. On the flip side, an oven that’s too big is a silent profit killer, sucking up cash and energy during your slow hours.

Getting the size right is one of the most important financial decisions you’ll make for your pizzeria. This isn't about guesswork; it's about doing the math to find that perfect balance between your busiest rush and your quietest afternoon. Your profits and your reputation depend on it.

Forecasting Your Peak Hour Pizza Demand

Before you even glance at an oven, you need to find your magic number: pizzas per hour (PPH) during your absolute peak time. Think Friday or Saturday night, when the tickets just don't stop. A solid estimate here will save you from a very expensive mistake down the road.

To figure out your peak PPH, you have to break down your business:

- Dine-In Orders: Start with your seats. A good rule of thumb in the pizza industry is that you'll turn over each table about 1.5 times during your peak two-hour rush. If your restaurant has 50 seats and you figure half of them will order pizza, the math looks something like this: (50 seats / 2 people per table) * 1.5 turnovers = 37.5 tables. If half order pizza, that’s roughly 19 pizzas per hour.

- Takeout & Delivery: This one’s a bit trickier to nail down but absolutely critical for most pizzerias. Dig into local market data, or if you're already open, pull your own sales reports. For a brand-new spot, a safe bet is to assume your takeout and delivery will match 50-75% of your dine-in volume during that peak rush.

Add it all up. In our example, that's 19 from dine-in plus another 14 or so from takeout, putting you at a target of 33 pizzas per hour. This number is your north star for choosing the right oven.

Matching Your Demand to the Right Oven

Once you have that target PPH, you can start shopping for the right machine. This is where you connect your business plan directly to the equipment, making sure the oven can keep up with the pizzas flying off your pizza prep tables.

A single-deck oven, for example, typically churns out 20-30 pizzas per hour. For our 33 PPH scenario, that’s just not going to cut it. You’d be creating a bottleneck right at the finish line, leaving pizzas waiting on the prep table.

But a double-stacked deck oven? Now we're talking. That setup can easily handle 40-60 PPH, giving you a perfect fit with a little breathing room to grow. The beauty of this setup is its flexibility—use just one deck to save energy on a slow Tuesday, then fire up both when the Friday night chaos hits.

Choosing the right capacity isn't just about surviving the rush; it's about optimizing your entire operation. A properly sized oven ensures that the pizzas flying off your pizza prep table never have to wait, keeping your kitchen in sync and your customers happy.

If you’re a high-volume ghost kitchen or a pizzeria that lives and dies by delivery, a conveyor oven should be at the top of your list. These things are built for one thing: relentless, consistent throughput. It's no surprise the global pizza conveyor oven market, a huge piece of the commercial pizza oven world, was valued at $730.7 million and is still growing. This shows just how critical they are for businesses built on speed. Find out more about the growth of conveyor ovens and their role in the modern pizzeria.

Even an entry-level conveyor can push out 50+ pizzas per hour, making it an absolute powerhouse of efficiency.

Installation, Maintenance, and Total Cost of Ownership

Your new commercial pizza oven has arrived. Now what? Getting that beast uncrated and into your restaurant kitchen is just the first step. The real journey begins with installation, dialing in a maintenance routine, and understanding what this oven will really cost you over the years.

Let’s be clear: professional installation isn't a friendly suggestion. It’s a non-negotiable part of the process that protects your investment, your staff, and your pizzeria. A pro team will make sure your oven is perfectly level for an even bake, properly hooked up to gas or electrical, and safely integrated with your kitchen's ventilation system. This is mission-critical for meeting local fire and health codes, which often demand specific certifications like NSF for sanitation and UL for electrical safety.

Protecting Your Investment with Regular Maintenance

Think of your oven like the engine in a delivery car. You wouldn't skip an oil change, right? Same deal here. Ignoring routine care leads to inconsistent pizzas, skyrocketing energy bills, and eventually, a catastrophic failure right in the middle of a Friday night dinner rush. A little proactive maintenance keeps your oven humming and extends its life for years.

A simple, consistent maintenance routine can save you thousands. Seriously.

- Daily Cleaning: Every night, brush out the oven deck. Get rid of all that burnt flour and stray bits of cheese. Give the exterior a good wipe-down to stop grease from building up.

- Weekly Checks: Take a close look at the door gaskets. If you see cracks or signs of wear, replace them. A bad seal is like leaving a window open in winter—you're just throwing money away on wasted heat. Also, double-check your thermostat’s accuracy with a separate oven thermometer.

- Monthly Inspections: For gas ovens, check the burner flames. You want to see a steady, blue flame, not a flickering yellow one. If you have a conveyor oven, follow the manufacturer’s guide to lubricate the chain and check the belt tension.

Calculating the Total Cost of Ownership

The number on the price tag is just the down payment. The total cost of ownership (TCO) is the real number you need to know for your restaurant's budget. This includes the initial purchase, installation fees, your monthly utility bills, and any maintenance costs. Getting a handle on TCO is what separates the pros from the amateurs when it comes to budgeting.

Thinking beyond the initial purchase price is what separates successful pizza restaurant owners from those who get blindsided by hidden costs. That "cheaper" oven with lousy energy efficiency can easily cost you more in the long run than a premium, well-insulated model.

When you're building your budget, don't forget these factors:

- Installation & Ventilation: This can run you anywhere from a few hundred bucks to several thousand dollars. It all depends on your restaurant's current setup and the type of ventilation hood you need.

- Long-Term Energy Use: An energy-efficient electric or gas oven will shave a significant amount off your utility bills over its lifespan. And if you go with a wood-fired oven, remember you've got the ongoing cost of buying and storing quality hardwood.

- Maintenance & Repairs: Earmark some cash for routine upkeep and the occasional repair. Investing in a durable, well-built oven from a brand with a solid reputation almost always lowers these costs over time.

By planning for life after the purchase, you ensure your oven remains the productive heart of your kitchen—reliably turning ingredients from your pizza prep tables into profit for years to come.

Your Top Commercial Pizza Oven Questions Answered

Making a big investment like a commercial pizza oven always brings up a few last-minute questions, even when you think you've got it all figured out. It’s completely normal. You're not just buying a piece of steel; you're buying the engine for your entire pizza restaurant.

Let's walk through some of the most common questions I hear from pizzeria owners. Think of this as that final conversation you have right before you pull the trigger, making sure every detail connects back to how your kitchen will actually run day-in and day-out.

Can I Bake Anything Besides Pizza in My Oven?

You absolutely can, and you absolutely should! While it's built for pizza, a great commercial oven is one of the most versatile tools in your restaurant kitchen. A classic deck oven, for example, is a dream for baking artisan breads. That intense heat from the stone deck gives you a phenomenal crust and is perfect for roasting vegetables or finishing off a bubbling pasta dish.

A conveyor oven is all about consistency, making it a workhorse for more than just pies. Think toasted sandwiches, batches of chicken wings, or even rows of perfectly baked cookies during off-peak hours. Getting creative with your oven is a fantastic way to expand your menu without buying more equipment.

The real secret is to understand how your specific oven cooks. A wood-fired oven can give a beautiful smoky flavor to fish or steaks, while a precise electric oven can handle delicate pastries when you're not slinging pizzas.

Your oven is a serious asset. Play around with it during slower times. You might just discover a new signature dish or a whole new revenue stream you never expected for your pizzeria.

How Do I Match My Pizza Prep Table to My Oven?

This is a critical partnership. The flow between your pizza prep table and your oven can make or break your pizzeria's efficiency during a rush. The goal is to create a seamless production line where your oven never has to wait for a pizza.

If you’re running a high-volume conveyor oven, you need a prep station that can keep that belt fed. We’re talking a long, multi-station table where several people can work without tripping over each other. But for an artisan-style deck or wood-fired oven, the dynamic changes. Here, it’s all about creating an ergonomic "cockpit" for your pizzaiolo. The prep table needs to be close enough that they can build the pie and slide it into the oven in one smooth motion.

Here are a few classic pizzeria pairings I’ve seen work wonders:

- High-Volume Conveyor Oven: This beast needs a 93-inch or larger pizza prep table. You'll want all the refrigerated rail space you can get to keep the line moving without interruption.

- Double-Stacked Deck Oven: A 67-inch to 72-inch prep table is the sweet spot. It gives you enough room for two cooks to work side-by-side when the orders start flying in.

- Artisanal Wood-Fired Oven: A more compact 44-inch prep table often does the trick. Since the focus is on one beautifully crafted pizza at a time, you don’t need a massive station.

Getting this pairing right from the start eliminates bottlenecks and makes for a much calmer, more productive pizza kitchen.

Ready to build the perfect pizza production line for your restaurant? At Pizza Prep Table, we specialize in providing high-quality, NSF-compliant refrigerated prep tables that pair perfectly with any commercial pizza oven. Explore our extensive collection and find the ideal workstation to streamline your kitchen's workflow.