The Pizzeria's Guide to Commercial Vegetable Slicers

Share

A quality commercial vegetable slicer is more than just another piece of kitchen gear. Think of it as a secret weapon that directly boosts your pizzeria's speed, consistency, and bottom line. For any busy pizza shop, it takes the tedious, time-sucking task of hand-slicing veggies for your pizza prep table and turns it into a fast, automated process that guarantees every single topping is perfect.

Why Manual Prep Is Costing Your Pizzeria Money

Picture this: It's the peak of a Friday night dinner rush. The ticket printer is spitting out orders, dough is flying, and your pizza prep table is the center of the universe. But there's a bottleneck. One of your line cooks is desperately trying to hand-slice onions and peppers, but they just can't keep up with the pace of the orders.

The slices are all over the place—some are paper-thin, others are way too thick. This doesn't just look sloppy; it means inconsistent cooking times and a pizza that's not quite right. This scene plays out every day in pizzerias that still rely on knives for heavy prep work. The hidden costs go way beyond the price of the vegetables. Every minute your staff spends chopping is a minute of paid labor that could be spent assembling pies, managing the oven, or keeping the pizza prep table stocked.

The True Cost of Inefficiency

The real price you pay for manual prep is measured in lost time, inconsistent quality, and a cap on how many pizzas you can push out the door. A commercial vegetable slicer completely flips this script. A prep task that once ate up 30 minutes of an employee's time can now be done in less than five, keeping your pizza line fully stocked.

This isn't just about making one job faster. It revolutionizes your entire pizzeria's workflow.

The investment in a commercial slicer isn't just about faster slicing. It's about reallocating your most valuable resource—your staff's time—to activities that directly generate revenue and improve customer satisfaction.

Instead of getting bogged down by a boring, repetitive chore, your team can focus on the details that make a great pizza. This efficiency boost translates directly into faster ticket times, happier customers who aren't kept waiting, and a healthier profit margin for your pizza shop.

A Strategic Investment in Quality and Speed

Switching from a knife to a machine also brings a level of precision that’s impossible to achieve by hand. Every slice of mushroom, every ring of pepper, and every sliver of onion is identical. This ensures toppings cook evenly across the pizza, so every pie you serve delivers that same fantastic, high-quality experience your customers expect.

This kind of consistency is the hallmark of a professional pizzeria, and more and more operators are catching on. The global market for commercial vegetable slicers is expected to hit roughly $563.922 million by 2025, a huge leap from $442.711 million in 2021. You can dig deeper by reviewing the growth trends in the vegetable slicing machine market.

Let's be honest, it also does wonders for staff morale. Nobody enjoys the mind-numbing task of chopping pounds of onions day after day. By replacing that job with a fast, efficient process, you create a better work environment, cut down on prep-related fatigue, and free up your team to be more effective. The slicer quickly becomes a silent but invaluable partner on your pizza prep line.

How to Choose the Right Slicer for Your Pizza Toppings

Picking out a commercial vegetable slicer for your pizzeria isn't just another equipment purchase. It's about finding the perfect prep partner for your pizza toppings. The machine that works wonders for a high-volume sandwich shop might be all wrong for an artisan pizzeria that needs perfectly uniform mushrooms and bell peppers for its pizza prep table. It all comes down to matching the slicer's strengths to your menu and your daily prep volume.

The first big fork in the road is choosing between a manual and an electric model. Think of a manual slicer, like a V-slicer or mandoline, as a precision tool. It’s fantastic for smaller batches or for ingredients that need a delicate touch—like ripe tomatoes that a high-speed machine would turn to mush.

But trying to rely on a manual slicer during a Friday night pizza rush? That's like trying to bail out a boat with a teaspoon. It works, but it's painfully slow and will create a serious bottleneck in your kitchen. For the vast majority of pizzerias, an electric model is the undisputed workhorse.

A Pizzeria's Guide: Manual vs. Electric Slicers

For a small pizzeria just getting started, a manual slicer might look like a smart, budget-friendly choice. They offer incredible precision and are a breeze to clean and store.

But as soon as your order volume starts climbing, you'll feel the pain. An electric commercial vegetable slicer is built for the long haul, capable of chewing through pounds of onions, peppers, and olives in minutes, not hours. This raw efficiency is what keeps your pizza prep table stocked and ready to go when the tickets start flying.

There's a reason the electric slicer market is booming. The global vegetable slicer industry is on track to grow from $1.2 billion in 2024 to $2.5 billion by 2033. Electric models are leading that charge because their speed in a pizzeria kitchen is simply unmatched.

Let's break down the practical differences for a pizza shop.

Slicer Type Comparison for Pizzerias

When you're weighing your options, it helps to see a direct comparison of how each slicer type performs in a real pizzeria setting. Here’s a look at the key factors that will impact your daily operations and your pizza prep table.

| Feature | Manual Slicer (e.g., V-Slicer) | Electric Slicer (Continuous Feed) |

|---|---|---|

| Best For | Low-volume, delicate items (tomatoes) | High-volume, everyday toppings (onions, peppers) |

| Speed & Volume | Slow, small batches | Fast, pounds per minute |

| Consistency | Good, but depends on user skill | Excellent, perfectly uniform slices every time |

| Labor Cost | High (requires constant staff attention) | Low (set it and let it run) |

| Upfront Cost | Low | High |

| Footprint | Small, easy to store | Larger, requires dedicated counter space |

| Ideal Use Case | Startup pizzerias, specialty toppings | Most growing and established pizzerias |

As you can see, while a manual slicer has its place for specific tasks, an electric model is the clear winner for handling the core prep work that keeps a pizzeria running smoothly and its pizza prep table stocked.

Continuous Feed vs. Batch Bowl Models

Once you've settled on an electric slicer, you’ll run into two main styles: continuous feed and batch bowl. A batch bowl processor is what many people have at home; it slices or chops ingredients into a contained bowl. This is great if you're making a sauce, but it's a clumsy choice for prepping individual toppings for a pizza line.

For pizzerias, the continuous feed slicer is the undisputed champion. Just like the name implies, you feed whole vegetables into a chute, and the machine slices them directly into a waiting food pan or container. This design is built for workflow. You can slice five pounds of onions, swap out the blade, and immediately start on ten pounds of bell peppers without ever stopping to empty a bowl.

The whole point is to create a seamless path from a whole vegetable to a perfectly sliced topping, ready to go into the bins on your pizza prep table. A continuous feed machine is engineered for exactly this kind of linear, high-volume prep.

This uninterrupted process is essential for keeping the ingredient bins on your refrigerated pizza prep table full and ready for action.

While our focus here is on veggies, don't forget about your meats. Many pizzerias need a separate, heavy-duty slicer for pepperoni, salami, and ham. For a closer look at that side of the prep line, check out our guide on selecting the right industrial meat slicer for your kitchen.

Ultimately, the right slicer does more than just cut vegetables—it brings consistency to your entire operation. Every slice is the same thickness, which means every topping cooks perfectly in the oven, every single time. This level of precision elevates your final product and streamlines your kitchen, from the pizza prep table to the pizza box. For more expert takes on choosing commercial kitchen gear, the folks over at TitanEdge Titanium's blog often have great insights. By thinking through your daily volume and workflow, you can find a slicer that becomes a valuable asset, not a frustrating roadblock.

Matching Blades and Power to Your Menu

Choosing the right commercial vegetable slicer is a lot like a pizzaiolo picking the right knife. It's all about the blade and the power behind it. For a pizzeria, where toppings can make or break a pie, this decision is everything. The secret to getting those perfectly uniform onion rings, crisp bell pepper strips, and flawless mushroom slices is simple: match the machine’s specs directly to your pizza menu.

It all starts with the cutting discs. These are not one-size-fits-all accessories; each one is built for a specific job. A slicer's real value comes from its library of interchangeable blades, letting you jump from prepping 50-pound bags of onions for the pizza line to thinly slicing cucumbers for salads with a quick swap.

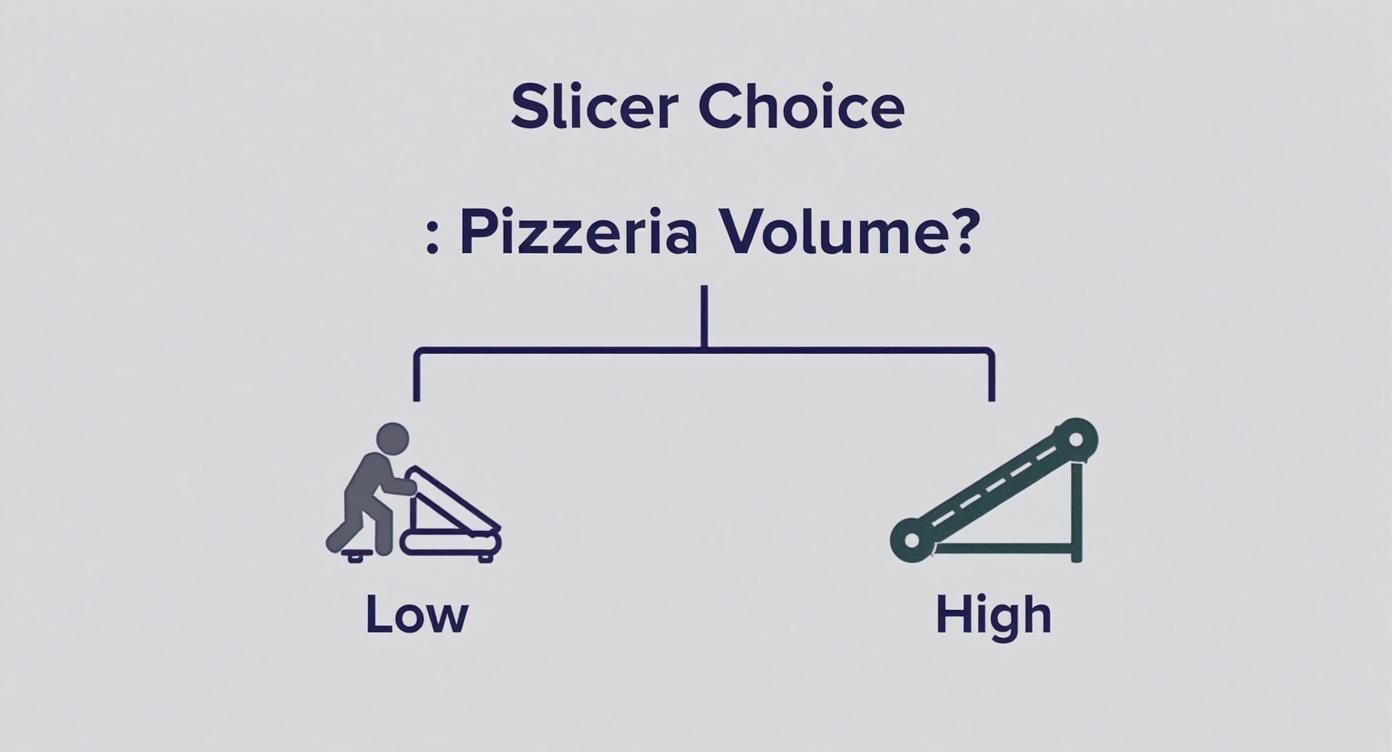

This infographic breaks down that first big decision, helping you choose a path based on how many pizzas you’re slinging each day.

As you can see, letting your production volume guide your equipment choice is the smartest way to go. It keeps you from either getting stuck with an underpowered machine or dropping too much cash on capacity you just don't need for your pizza prep table.

Decoding Blade Types for Perfect Toppings

Think of your slicer blades as specialized tools in your prep arsenal. Using the wrong one is a recipe for disaster—it can crush delicate ingredients or give you sloppy, inconsistent cuts. Nailing which blade to use for which pizza topping is fundamental to quality control.

Here are the essential blade types every pizzeria needs to know:

- Straight Blades: This is your daily workhorse. It’s perfect for firm veggies like onions, bell peppers, and cucumbers, giving you clean, crisp slices every single time.

- Serrated Blades: If you’ve ever tried slicing a ripe tomato with a straight knife, you know it can turn into a pulpy mess. A serrated blade gently saws through the skin without squashing the soft insides, making it a must-have for delicate produce for your Margherita pizza.

- Julienne Discs: These are the secret to creating those perfect, thin matchstick strips for bell peppers or shredded carrots. They’re a game-changer for salads and specialty pies.

- Dicing Grids: For pizza shops that offer diced onions or peppers, a dicing grid attachment is a massive time-saver. It produces uniform cubes that cook evenly and look professional.

Matching the blade to the vegetable means every topping that hits your pizza prep table is perfectly cut, consistent, and ready for the oven.

Understanding Motor Power and Throughput

Beyond the blades, the motor is the heart of your slicer. Its power, measured in horsepower (HP), dictates what kind of vegetables it can handle and, just as importantly, how fast it can process them. A weak motor will bog down on dense items like carrots, leading to jams and ugly, inconsistent cuts.

A slicer's motor power is the difference between effortlessly gliding through a 50-pound bag of onions and fighting the machine every step of the way. More power means cleaner cuts and less strain on the equipment, especially during peak prep hours for your pizzeria.

This power directly affects the machine's throughput—the amount of product it can process in a set time, usually measured in pounds per hour. For a small neighborhood pizzeria, a slicer that can handle 200-300 pounds per hour might be plenty. But a high-volume pizza shop prepping hundreds of pounds of veggies daily needs a heavy-duty model that can chew through 500 pounds per hour or more.

When you’re looking at slicers, pay attention to both HP and RPMs (revolutions per minute). A higher RPM isn't always better; what you want is the right combination of power and blade speed to get a clean slice without turning softer ingredients like mushrooms into mush. You need a machine with enough muscle to power through your busiest prep days without slowing down your pizza prep table's rhythm.

Creating the Perfect Pizza Prep Station Workflow

The real magic of a commercial vegetable slicer isn't just how fast it chews through a case of onions. It’s how it slots into the rhythm of your pizza kitchen. Where you put this machine can mean the difference between a smooth, profitable prep line and a chaotic scramble of wasted steps around your pizza prep table.

The goal is to create a straight line from whole vegetables to perfectly filled topping bins on your pizza prep table. Think of your kitchen layout like a roadmap. The shortest route is always a straight one. Every extra step a prep cook takes adds seconds to a task, and over a busy week, those seconds bleed into hours of lost labor. A smart workflow turns your prep area into a lean, mean, pizza-topping-producing machine.

Strategic Slicer Placement Options

Most pizzerias land on one of three common placement strategies for their slicer. There’s no single "right" answer—it all boils down to your kitchen's size, layout, and the location of your pizza prep table.

- Next to the Walk-In Cooler: This is your bulk prep headquarters. Staff can pull cases of peppers, wash them at a nearby sink, and slice them on the spot. This keeps all the messy work contained and away from the main pizza line, but it does mean someone has to ferry the finished toppings over to the prep table.

- At the Start of the Pizza Prep Table: This setup creates a direct, seamless path. Wash, slice, and slide the toppings straight into the refrigerated ingredient bins. It's incredibly efficient for prepping toppings as you need them, but it eats up valuable counter space on your most critical piece of real estate.

- On a Mobile Cart: This is the ultimate flexible solution. A stainless steel cart lets you roll the slicer out for the big morning prep session and then tuck it away to free up space. This is a lifesaver for smaller pizzerias where every square foot around the pizza prep table is gold.

The best spot for your slicer is the one that demands the least movement. An ideal setup lets a cook wash, slice, and store toppings without taking more than a couple of steps in any direction.

No matter where you place it, make sure it’s close to a power outlet. The last thing you want is a dangerous extension cord snaking across a wet pizzeria floor.

Designing a Step-by-Step Process

A well-designed workflow is methodical and easy to repeat. It should feel second nature, allowing your team to move from raw ingredients to finished product with zero friction, ensuring the pizza prep table is always ready.

- Wash Station: Designate a sink area just for washing produce. Keep your colanders and drying racks here so vegetables are prepped and ready for the main event.

- Slicing Zone: This is where your slicer lives. Have clean, food-safe containers ready to catch the fresh toppings right as they come out of the machine’s chute.

- Bin Filling and Transport: As soon as a container is full, it gets moved directly to the pizza prep table and loaded into the right refrigerated wells. This keeps the line stocked and ready for the rush.

This simple, three-stage process cuts down on confusion and builds a predictable rhythm for your prep crew. Thinking through these details is a huge part of building a killer pizzeria kitchen, a topic we dive into deeper in our guide on the secret sauce behind efficient pizza prep stations. By carefully planning your workflow, you turn that slicer from a simple tool into the engine of a highly organized pizza prep system.

Mastering Slicer Safety and Sanitation

A commercial vegetable slicer is a beast in the kitchen. It can chew through a 50-pound bag of onions in minutes, saving you tons of labor for your pizza prep. But with that kind of power comes a serious responsibility. In a fast-paced pizzeria, treating this machine with respect isn’t just a good idea—it’s non-negotiable.

Let's be clear: we're talking about protecting your staff from nasty injuries and keeping your customers safe from foodborne illness. The good news? Modern slicers are built with safety baked right in. They aren't just motors with spinning blades; they're engineered systems with layers of protection. Getting to know these features is the first step to making that slicer a safe and productive part of your pizza prep table workflow.

Essential Safety Features to Look For

When you're shopping for a slicer, don't just get hypnotized by the horsepower and how many pounds of peppers it can process per hour. The safety mechanisms are what will save you headaches—and a trip to the emergency room—down the line.

- Blade Guards: This is your first line of defense. A solid guard, whether it's fixed or removable, should cover the cutting disc completely. It's a simple barrier that prevents fingers from accidentally meeting that razor-sharp edge.

- Interlock Switches: Think of these as the machine's brain. An interlock switch is a kill switch that physically prevents the motor from firing up if the hopper or pusher plate isn't locked in place. It makes it impossible to run the machine in an unsafe state.

- Food Pushers: This one is a hard and fast rule: an employee’s hand should never go anywhere near the feed chute. A food pusher is the designated tool for guiding vegetables toward the blade, keeping hands and fingers a safe distance away from the action.

A slicer's safety features are like the seatbelt in your delivery car. You hope you never truly need them, but you'd be crazy to operate the machine without them engaged and working perfectly.

The A-to-Z Cleaning and Sanitizing Protocol

A slicer that sparkles isn't just for show; it's a critical checkpoint for food safety in your pizzeria. Proper cleaning stops bacteria in its tracks and kills any chance of cross-contamination between, say, onions for a pizza and cucumbers for a side salad. This needs to happen at the end of every single day. No excuses.

- Disconnect Power: First thing's first—unplug the machine from the wall. You should never, ever attempt to clean a slicer that’s still connected to electricity.

- Disassemble Removable Parts: Carefully take off the pusher plate, feed hopper, and the cutting disc itself. These parts are designed to come apart easily for a reason.

- Wash, Rinse, Sanitize: Get these parts into your three-compartment sink. Wash them with hot, soapy water, then give them a thorough rinse with clean water. Finally, let them soak in a food-safe sanitizing solution. Not sure which to use? You can learn more about the 3 types of sanitizer solutions to see what works best for your setup.

- Clean the Main Unit: With a clean, sanitized cloth, wipe down the entire body of the slicer. Get into all the nooks and crannies where tiny bits of food love to hide.

- Air-Dry Completely: Lay all the parts out to air-dry before you even think about putting the machine back together. Trapped moisture is a breeding ground for bacteria.

Building a Culture of Safety Through Training

Safety features and cleaning checklists are great, but they're useless if your team doesn't turn them into habits. Every single employee who will touch that slicer at the pizza prep table needs to be trained on your specific model.

This isn't a "watch me do it once" kind of training. They need to know how to handle and change blades safely, what every single safety feature does, and exactly where the emergency shut-off is. And for any food prep task, especially operating or cleaning a slicer, a good pair of hygiene protection gloves is an absolute must.

There's a reason the commercial vegetable slicer market is set to grow at a 5% CAGR and hit $2.5 billion by 2033. Pizzerias are getting smarter, and operators are demanding equipment that's both fast and sanitary. Nail down your safety and cleaning procedures, and your slicer will be a money-making asset for years to come.

Calculating the ROI on Your Commercial Slicer

Shelling out for a new piece of equipment can feel like a big leap, especially for an independent pizzeria. But here's the thing: a commercial vegetable slicer isn't just another bill to pay—it’s a strategic investment that starts paying you back from day one. To really see its value, you have to look past the price tag and figure out its return on investment (ROI).

This isn't just about a gut feeling. It's about turning that feeling into a solid business case with real numbers. By tracking a couple of key metrics, you can see exactly how this machine pumps up your profitability by saving time on your pizza prep, cutting down waste, and making your labor more efficient. It’s how you prove the savings that show up on your bottom line.

Quantifying Savings from Labor and Waste

The most obvious and immediate payback comes from labor. Let's be honest, manual prep work is one of the biggest time-sucks in any pizzeria kitchen. A good electric slicer can slash that prep time by a staggering 80-90%.

Think about it this way: your prep cook spends two hours a day just slicing onions, peppers, and mushrooms for the pizza prep table. A machine knocks that task down to about 15 minutes. Suddenly, you've freed up nearly two hours of paid labor every single day. That's time that can be spent on things that actually make you money, like making dough, prepping sauces, or getting more pizzas out the door.

Then there's the hidden cost of food waste. Hand-slicing is never perfect. You get uneven cuts, weird end pieces, and a surprising amount of veggies that end up in the trash. A slicer gives you perfectly uniform pieces every single time, which means you get the most out of every tomato and onion you buy.

A commercial vegetable slicer pays for itself in two primary ways: by drastically cutting down the hours your staff spends on manual prep for the pizza line and by minimizing food waste through perfectly consistent slices.

That consistency means less product in the bin and more on your pizzas, directly improving your food cost percentage. It's a simple, powerful win for any pizzeria.

A Realistic Pizzeria ROI Scenario

Let's crunch some numbers for a typical mid-volume pizzeria to see just how fast this investment can pay off.

The Scenario:

- Prep Cook's Wage: $15 per hour

- Manual Prep Time: 1.5 hours per day, 7 days a week

- Slicer Prep Time: 15 minutes (0.25 hours) per day

- Food Waste Reduction: Estimated at $5 per day (a conservative guess)

- Slicer Cost: $1,500

Now, let's break down the daily savings:

- Labor Savings: You're saving 1.25 hours of labor each day. At $15 an hour, that's $18.75 saved daily.

- Food Waste Savings: You're pocketing an extra $5 per day.

- Total Daily Savings: $18.75 + $5.00 = $23.75 per day.

To figure out the breakeven point, just divide the slicer's cost by your daily savings:

$1,500 (Slicer Cost) ÷ $23.75 (Daily Savings) = ~63 days

In this very realistic scenario, the slicer pays for itself in just over two months. After that, it's pure profit for your pizzeria, day in and day out. It's not just a convenience; it's an essential tool for any pizzeria that's serious about running an efficient and profitable kitchen with a well-stocked pizza prep table.

Got Questions? We've Got Answers.

Jumping into the world of commercial kitchen gear always brings up some real-world questions. When you're thinking about adding a new slicer to your pizza prep line, you need straight answers, not sales fluff. Here are some of the most common things we hear from pizzeria owners.

How Much of a Headache Is Cleaning This Thing?

Honestly, not much. Most modern commercial slicers are designed with busy pizzerias in mind. Key parts like the feed hopper, pusher plate, and the cutting discs themselves usually pop right off and are safe for the dishwasher. The main body just needs a quick wipe-down with a food-safe sanitizer.

A full cleanup routine shouldn't take you more than 5-10 minutes. When you think about the hours of hand-slicing that saves you, it's a no-brainer. Pro tip: look for models with stainless steel construction and smooth, seamless designs—they're even faster to get sparkling clean.

Can One Slicer Really Handle All My Pizza Toppings?

Absolutely, as long as you have the right attachments. A good commercial slicer with a set of interchangeable discs can go from slicing onions to julienning bell peppers to shredding mozzarella cheese in minutes. The secret is picking a model that offers the variety of blades your pizza menu actually needs.

Now, some old-school pizzaiolos might still prefer to hand-slice a super-ripe, delicate tomato, and that's fair. But for the vast majority of your pizzeria's topping prep, a powerful electric model with the correct blade is your best friend. It turns one machine into a multi-purpose workhorse for your entire pizza prep table.

What’s the Real Lifespan of a Commercial Slicer?

Think of a well-made slicer from a trusted brand as a long-term member of your kitchen crew. With proper care, you can easily expect it to last 7-10 years or even more in a busy pizza shop. The lifespan really comes down to build quality, consistent cleaning, and using it the way the manufacturer intended.

The motor is the heart of the machine and is built to last. The blades, on the other hand, are like your pizza knives—they're consumables that will need to be sharpened or replaced every so often to keep those cuts perfect. Sticking with a well-known brand means you'll always be able to find replacement parts when you need them.

How Much Counter Space Am I Giving Up for a Slicer?

It varies, but most of the popular countertop electric models have a footprint of around 1-2 square feet. Before you click "buy," grab a tape measure and check the space on your pizza prep table or a dedicated cart.

But don't just measure the machine itself. Remember to account for the space you'll need for a big bowl or hotel pan to catch all those perfectly sliced veggies. You also want enough room for your team to work safely and comfortably around it. Many pizzerias get a small, stainless steel mobile cart just for the slicer. They can roll it out during peak prep hours and then tuck it away to free up that valuable pizza prep table space.

Ready to see what a difference the right equipment can make on your pizza prep line? At Pizza Prep Table, we live and breathe this stuff. We help independent pizzerias find the tools they need for speed, consistency, and a healthier bottom line. Check out our hand-picked selection of kitchen equipment and find the perfect fit for your place at https://pizzapreptable.com.