Choosing Your Industrial Meat Slicer for the Perfect Pizza

Share

For any pizzeria, an industrial meat slicer isn't just a piece of equipment—it's a core investment in speed, consistency, and efficiency. It takes the grueling task of hand-slicing pepperoni and cured meats and turns it into a smooth, automated process. The result? Every single pizza gets uniform, perfectly cooked toppings. This tool is your secret weapon for handling high-volume orders while keeping quality sky-high.

Why Your Pizzeria Needs an Industrial Meat Slicer

Picture the controlled chaos of a Friday night rush. Orders are flooding the kitchen, and the biggest bottleneck is the prep table. One of your team members is furiously hand-slicing pepperoni, but the slices are all over the place—some thick, some thin. That means inconsistent cooking and an unpredictable flavor in every bite. This is exactly where an industrial meat slicer completely changes the game.

This isn't just another appliance; it's a strategic asset for your pizzeria's entire workflow. The moment you upgrade from manual slicing, you'll feel the impact across your whole operation. It transforms a labor-intensive, time-sucking task into a streamlined part of your assembly line.

Elevate Quality with Unmatched Consistency

Consistency is the bedrock of a great pizzeria. It’s what brings customers back again and again for that same delicious experience. An industrial meat slicer delivers razor-thin, perfectly uniform slices of pepperoni, salami, and prosciutto every single time. No exceptions.

This level of consistency brings a few huge advantages to the table:

- Even Cooking: Uniformly thin toppings cook evenly across the pizza. Say goodbye to burnt edges or undercooked centers that ruin an otherwise perfect pie.

- Superior Flavor Release: Thinner slices tend to release more flavor and crisp up beautifully in the oven, seriously enhancing the overall taste and texture of your pizza.

- Portion Control: When every slice is identical, you can dial in your portioning. This ensures every pizza meets your cost standards without sacrificing quality.

An industrial slicer guarantees that the last pizza of the night has the same quality and topping distribution as the first. That's how you build brand trust and customer loyalty with every single order.

Boost Efficiency and Reduce Labor Costs

In any kitchen, time is money—especially in a high-volume pizzeria. Manually slicing pounds and pounds of cured meats is a massive drain on your labor budget. An industrial slicer automates this job, freeing up your valuable staff to focus on more critical tasks like prepping dough, assembling orders, and managing the ovens.

The market for these machines shows just how vital they are. The industrial food slicers segment is on track to grow from USD 590 million in 2025 to USD 870 million by 2035. This boom is fueled by the food service industry's constant push for standardization and efficiency—exactly what these slicers deliver. You can learn more about the market evolution of industrial food slicers and their impact on modern kitchens.

By slashing prep time and labor hours, the slicer quickly pays for itself, making it a smart financial move for any pizzeria looking to grow.

Choosing Your Slicer: Manual Versus Automatic

Once you've decided an industrial meat slicer is a non-negotiable for your pizzeria, the next big question pops up: manual or automatic? The easiest way to think about it is like a car's transmission. A manual slicer puts you in complete control, giving you a real feel for the process, while an automatic takes care of the repetitive, heavy lifting for you.

Your final decision really comes down to the day-to-day reality of your kitchen. How much meat are you actually slicing? What does your staffing look like? And, of course, what's your budget? Let's dig into the two main types to see which one will be the MVP of your pizza prep table.

The Case for Manual Slicers

A manual slicer, which you'll often hear called a gravity-feed slicer, is the reliable workhorse you’ll find in countless small to mid-sized pizzerias. With these machines, your prep cook physically pushes the product carriage back and forth across that spinning blade. This design gives you absolute control over the speed and rhythm of every single slice.

This hands-on approach is perfect for shops that slice meats to order or in smaller batches. If you take pride in slicing prosciutto paper-thin for a specialty pie right before it goes into the oven, a manual slicer gives you that artisan-level precision. They’re also friendlier on the wallet upfront, making them a fantastic starting point.

But let's be real—it's a labor-intensive process. If your pizzeria is churning out hundreds of pepperoni pies on a Friday night, a manual slicer can quickly become a bottleneck, leading to tired staff and slower prep times.

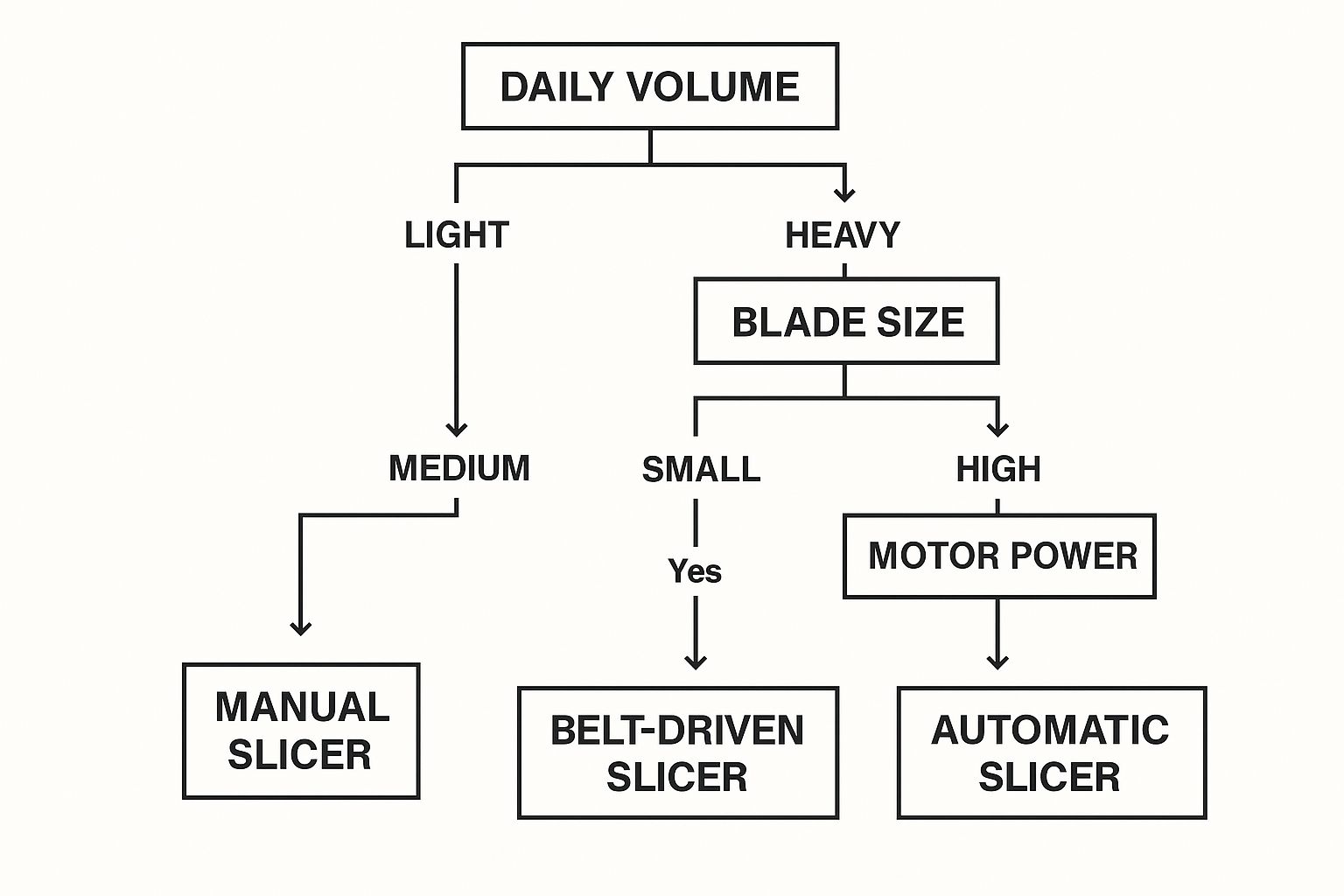

This chart helps visualize how your daily output directly influences the kind of machine you need.

As you can see, the more you slice, the more you'll need a bigger blade and a stronger motor—a path that often leads directly to an automatic model.

When to Upgrade to an Automatic Slicer

An automatic slicer is where efficiency truly kicks into high gear. These machines have a motorized carriage that automatically moves the product across the blade, allowing for continuous slicing without constant supervision. You just set the thickness, flip a switch, and let the machine handle the grunt work.

This is the obvious choice for any high-volume pizza restaurant. Picture this: you need to prep 30 pounds of pepperoni for the dinner rush. An automatic slicer can knock that out flawlessly while your kitchen crew focuses on other mission-critical tasks, like portioning dough or getting the sauce ready. That ability to multitask is a massive win in any busy kitchen.

An automatic slicer transforms a time-consuming prep task into a "set it and forget it" process. This frees up your most valuable resource—your staff's time—to focus on assembling pizzas and fulfilling orders, directly boosting your kitchen's overall output and profitability.

Sure, automatic slicers have a higher price tag, but the return on investment comes from serious labor savings and a huge boost in productivity. Many models even come with a manual mode, giving you the best of both worlds. For any pizzeria with dreams of growing, an automatic slicer isn't just a piece of equipment; it's an investment in scaling your business.

Manual vs Automatic Slicers: A Pizzeria's Guide

Choosing the right slicer can feel like a big decision. This table breaks down the key differences to help you figure out which machine best fits your pizzeria's daily grind.

| Feature | Manual Slicer | Automatic Slicer |

|---|---|---|

| Best For | Small to medium volume, slicing to order, specialty meats. | High-volume pizzerias, bulk prep, kitchens focused on efficiency. |

| Operation | Operator physically pushes the carriage back and forth. | Motorized carriage moves product automatically. |

| Control | Complete control over speed and rhythm for precision slicing. | Consistent, uniform slices every time; set it and forget it. |

| Labor | Labor-intensive; can lead to staff fatigue during busy periods. | Frees up staff for other tasks; significantly reduces physical effort. |

| Upfront Cost | Lower initial investment, more budget-friendly. | Higher initial investment, but with long-term labor savings. |

| Throughput | Slower; can create a bottleneck during high-demand rushes. | High throughput; can slice large quantities of meat quickly. |

Ultimately, the right choice syncs up with your operational needs. A small shop with a focused menu can absolutely get by with a trusty manual model. But a bustling restaurant will see that an automatic slicer pays for itself over and over again through sheer power and efficiency.

Essential Slicer Features for Peak Performance

Picking between a manual and an automatic slicer is a good starting point, but the real magic that makes your prep line sing during a chaotic dinner rush lies in the details. These technical features aren't just numbers on a spec sheet; they translate directly into faster prep, safer operation, and a much longer life for your hard-earned investment.

Think of it like choosing tires for a race car. You wouldn't slap standard street tires on a Formula 1 machine, right? The same logic applies here. You can't afford to settle for undersized or underpowered components on your pizzeria's most important workhorse. Let’s get into the features that really matter.

The Blade: Unlocking Slicing Power

The blade is the heart and soul of any slicer, making its size and material absolutely critical. For most pizzerias, a 12- to 14-inch diameter blade is the undisputed industry standard, and for good reason. This size is beefy enough to power through wide logs of pepperoni, salami, and mortadella in a single, clean pass. A smaller blade forces you to trim down your product first, adding an extra, time-sucking step to your prep.

The material is just as crucial. Carbon steel blades are the go-to because they hold an incredibly sharp edge for much longer. This means you get clean, precise cuts that don't tear or shred your cured meats, which is key to preserving their texture and flavor. A sharp, high-quality blade is what ensures every slice of pepperoni is perfect.

Motor Horsepower: The Engine of Efficiency

If the blade is the heart, the motor is the engine. Its power, measured in horsepower (HP), determines the slicer's stamina. A light-duty slicer might hum along with a 1/4 or 1/3 HP motor, which is fine for a place that only slices a few things a day. But a busy pizzeria needs something more robust—typically 1/2 HP or more—to chew through the relentless demands of daily prep.

Imagine trying to drive a tiny car up a steep mountain; it struggles, overheats, and eventually grinds to a halt. That’s exactly what happens to an underpowered slicer motor when it’s forced to cut dense, cured meats for hours on end. A strong motor prevents slowdowns, reduces strain on the machine's other parts, and guarantees consistent slicing speed, even when your ticket machine is spitting out orders nonstop.

A strong motor is your best defense against bottlenecks. It ensures your industrial meat slicer can keep pace with your order volume without overheating or failing, directly contributing to a smoother, more productive kitchen workflow.

Smart Design Features That Save Time

Beyond the core components, a few other design elements can make a world of difference in your day-to-day operations. These smart features are all about convenience, safety, and maintenance—and they save you precious time and effort.

- Product Carriage Size: The carriage (the tray that holds the meat) needs to be big enough to comfortably hold the largest logs you use. A spacious, sturdy carriage provides better support, leading to more stable and uniform slices from the first cut to the last.

- Built-In Sharpener: Manually sharpening a slicer blade is a tedious job that requires a specialized touch. A built-in sharpener is a non-negotiable feature for any commercial kitchen. It lets your staff hone the blade's edge in seconds at the start of each day, ensuring top performance and safety.

- Easy Disassembly: Proper sanitation is non-negotiable. A slicer designed for easy disassembly, with removable parts like the blade guard and carriage, makes daily cleaning faster and much more thorough. This simple feature is a massive factor in preventing cross-contamination.

The market for these machines just keeps growing, proving how vital they are in professional kitchens. The U.S. meat slicer sector alone was valued at USD 378.4 million in 2024 and is expected to climb steadily. We're even seeing smart slicers with remote monitoring and advanced titanium blade coatings for extra durability. You can discover more insights about the U.S. meat slicer market and its evolution. Investing in a machine with the right features today sets you up for tomorrow's growth.

Optimizing Your Slicer and Pizza Prep Table Workflow

Buying the right industrial meat slicer is a huge step, but it's only half the battle. Where you actually put that machine in your kitchen can make or break your entire workflow. Get it right, and your slicer and pizza prep table become a synchronized team, creating a seamless path that boosts speed and slashes wasted effort.

The goal is simple: create a logical flow for your ingredients. They should move from the cooler, through the slicer, and onto a pizza with the fewest possible steps. A poorly placed slicer creates bottlenecks, introduces safety risks, and grinds your assembly line to a halt, no matter how powerful the motor is.

Designing an Ergonomic Slicing Station

An ergonomic setup isn't just about making your staff comfortable; it's about keeping them productive and safe. Repetitive motions over a long shift lead to fatigue, which means slower performance and a higher risk of injury. A well-designed station keeps your team moving efficiently.

Keep these simple ergonomic factors in mind:

- Counter Height: Your slicer should sit on a surface that lets the operator stand naturally, without hunching over or reaching up. The sweet spot is usually between the operator's waist and chest.

- Clearance and Space: Don't cram it into a corner. Make sure there’s plenty of room around the slicer for safe operation and, just as importantly, for easy cleaning. Your staff should be able to move freely without bumping into anything or anyone.

- Ventilation: All motors generate heat. Placing your slicer in an area with good air circulation is crucial for preventing overheating. This simple step extends the motor's life and ensures it performs consistently during those crazy dinner rushes.

Smart Layouts for Your Pizza Prep Line

So, where's the perfect spot for your slicer? It really depends on your kitchen's unique layout. Most pizzerias adopt one of two main strategies, and the key is to watch how your team works and pick the setup that eliminates unnecessary walking.

Option 1: The End-of-Line Integration

One of the most effective layouts is placing your industrial meat slicer right at the beginning or end of your refrigerated pizza prep table. Imagine this: an employee pulls pepperoni from a nearby low-boy fridge, slices it, and immediately drops the fresh toppings into the prep table's cold wells.

This setup creates a direct, uninterrupted flow. You’re not carrying trays of freshly sliced meat across a busy kitchen, which cuts down on the risk of spills and cross-contamination. This tight integration is a core principle we talk about in many guides for setting up a commercial pizza prep table, because it consolidates all your topping activities into one hyper-efficient zone.

Option 2: The Dedicated Slicing Station

For high-volume kitchens, creating a dedicated slicing station near the walk-in cooler can be a game-changer. In this setup, one team member can be assigned the task of bulk-slicing all the meats needed for the day in a single, focused batch.

A dedicated station transforms slicing from a reactive, on-demand task into a streamlined prep activity. This frees up your pizza assembly staff to focus only on building pies, knowing they have a fully stocked and organized prep table ready to go.

This approach is perfect for shops that go through dozens of pounds of pepperoni, ham, and salami before the dinner rush even starts. The sliced meats can then be portioned into food-safe containers and loaded into the pizza prep table as needed. It’s a fantastic way to batch-process ingredients and maintain a clear separation between raw prep and final assembly—a huge win for both kitchen organization and food safety.

Mastering Slicer Safety and Sanitation Routines

An industrial meat slicer is a workhorse, but that razor-sharp, spinning blade demands serious respect. Getting your safety and sanitation routines down isn't just a good idea—it’s a non-negotiable part of running a professional pizzeria. Solid, repeatable routines protect your crew from injury and make sure every slice of pepperoni is safe for your customers.

Think of these protocols as the foundation of your kitchen's integrity. You wouldn't compromise on the quality of your dough, and you can't cut corners on equipment safety, either. A simple, consistent process takes the guesswork out of using the machine and empowers every staff member to handle it with confidence.

Essential Safety Protocols Before You Slice

Before that motor even starts to hum, safety has to be the first thought. The speed and sharpness of that blade mean a single moment of distraction can lead to a serious accident. Building a strict, safety-first culture around your industrial slicer is the most important step you can take.

Always start with the right gear. Cut-resistant gloves are mandatory for anyone operating or cleaning the slicer. These specialized gloves provide a critical layer of defense against accidental contact with the blade, turning a potential disaster into a close call.

Next, make sure every built-in safety feature is used correctly, every single time.

- Safety Guards: The blade guard is there for a reason. It should never be removed or tinkered with during operation. Period.

- Food Pusher: This tool, also called the product holder, lets you guide the meat without your hands ever getting near the blade. Never, ever use your bare hands to push the product.

- Zero-Volt Release: This is a crucial feature that prevents the slicer from automatically restarting after a power outage, protecting an employee who might not realize the power is back on.

A Step-by-Step Guide to Daily Cleaning

A clean slicer is a safe slicer. Daily sanitation is absolutely critical for preventing the growth of nasty bacteria like listeria and avoiding cross-contamination between different meats. This process should be a standard part of your end-of-day closing routine, no exceptions.

A rigorous cleaning schedule is your pizzeria's first line of defense against foodborne illness. By treating sanitation with the same seriousness as safety, you protect your customers, your staff, and your restaurant's reputation.

Follow these steps to ensure your slicer is perfectly clean and ready for the next day's prep.

- Power Down and Unplug: Always disconnect the slicer from the wall before you start cleaning. This is the single most important step for preventing accidental startup.

- Initial Wipe-Down: Use a scraper to get rid of any large bits of food. Then, set the blade thickness to zero and wipe down both sides of the blade, always moving from the center outward.

- Disassemble Removable Parts: Carefully take off the product tray, slice deflector, and blade guard, following the manufacturer's instructions. These are the parts that collect the most gunk.

- Wash, Rinse, and Sanitize: Take the disassembled parts to a three-compartment sink. Wash them thoroughly with hot, soapy water, rinse them with clean water, and then let them soak in a sanitizing solution. You can explore our guide on the three types of sanitizer solutions to make sure you're using the right one for your kitchen.

- Clean the Slicer Body: With the parts removed, carefully clean the body of the slicer. Pay close attention to any small cracks or crevices where food particles can hide.

- Air Dry and Reassemble: Let all the parts air dry completely before carefully putting the machine back together. Rushing this step can trap moisture, which is an open invitation for bacteria to grow.

The growing consumer demand for ready-to-eat products like cured meats puts an even bigger spotlight on food safety. This trend is what drives so many pizzerias to adopt industrial meat slicers—they help meet demand while making it easier to manage sanitation and reduce cross-contamination. Beyond just cleaning your slicer, maintaining a pest-free kitchen is essential for overall food safety. You can learn more about comprehensive restaurant pest control strategies.

Common Questions About Industrial Meat Slicers

Even with all the specs and features laid out, you probably still have a few practical questions bouncing around your head before you pull the trigger on a new slicer. That's completely normal. This section is all about tackling those common "what ifs" and "how tos" we hear from pizzeria owners all the time. Let's clear up those final details so you can feel 100% confident you're picking the right machine for your kitchen.

What Size Slicer Is Best for a Small Pizzeria

For most small to medium-sized pizzerias, a medium-duty slicer with a 12-inch blade is the sweet spot. It strikes the perfect balance between footprint, capacity, and cost. It’ll slice through standard pepperoni logs and other cured meats all day long without hogging precious counter space on your prep table.

Think of the 12-inch model as your daily workhorse. But, if you find your crew is slicing for several hours straight every single day, it’s a smart move to step up to a heavy-duty model with a 13 or 14-inch blade. This prevents you from overworking the smaller motor, ensuring your slicer has a long, reliable life.

How Often Should I Sharpen the Slicer Blade

A razor-sharp blade is non-negotiable. It’s a matter of both safety and the quality of your product. In a busy pizzeria, you should get in the habit of using the slicer’s built-in sharpener for about 15-20 seconds at the end of each day. If you've had a particularly busy shift with hours of continuous slicing, do it then, too.

A dull blade doesn't slice—it tears and shreds meat. This not only makes your toppings look sloppy but also creates waste and puts a ton of unnecessary strain on the motor. That strain can lead to expensive repairs you really don't want to deal with.

Think of blade sharpening as a daily tune-up. A few seconds of maintenance ensures your industrial meat slicer performs flawlessly, delivering perfect slices while protecting the machine's motor from premature wear and tear.

To keep learning from the pros, a dedicated industry blog can be an incredible resource for expert tips and answers to common questions about kitchen gear. To stay on top of best practices, you can read more industrial kitchen equipment insights.

Can I Slice Cheese on My Meat Slicer

While it might seem like a good idea in the moment, you should absolutely not slice cheese on a slicer that's also used for meat. Softer cheeses like mozzarella will gum up the blade and get into all the internal parts, making the machine a nightmare to clean properly. Worse, it can bog down and damage the motor.

On top of the mechanical issues, it’s a huge risk for cross-contamination and food allergies. The best and safest practice, hands down, is to invest in a separate, dedicated slicer if you plan on slicing a lot of cheese.

Belt Driven vs Gear Driven Slicers

This question really gets to the core of how the slicer works, specifically how the motor's power gets to the blade. Knowing the difference helps you match the machine's guts to your pizzeria's daily grind.

- Belt-Driven Slicers: These are the most common type you'll find in light and medium-duty models. They run quieter and use a belt to connect the motor to the blade. Over the slicer's life, that belt might need to be replaced, but they are generally a more budget-friendly option upfront.

- Gear-Driven Slicers: Found in heavy-duty machines, these use interlocking gears to transfer power. This provides more consistent torque, which is perfect for slicing through dense products like aged salami without the blade slowing down. They're built to last, require less maintenance, but do come with a higher initial price tag. You can learn more about how equipment costs relate to features in our guide to Hobart meat slicer price considerations.

So, which one is for you? It really boils down to your volume. For most pizzerias, a solid belt-driven model will do the job just fine. But if you're a high-volume shop that slices all day, the long-term durability of a gear-driven machine is a smart investment.

Ready to find the perfect slicer to up your pizza prep game? At Pizza Prep Table, we offer a curated selection of industrial meat slicers designed to meet the demands of any pizzeria, big or small. Explore our collection and find the ideal machine to boost your efficiency and perfect your product.