Hobart Meat Slicer Price for Pizzerias

Share

When you're equipping your pizzeria, the Hobart meat slicer price isn't just a single number you can plug into a spreadsheet. The truth is, prices can swing from just a few hundred dollars for a basic model to several thousand for a heavy-duty, automatic machine that does the work for you. The real cost comes down to what you actually need to slice everything from pepperoni and prosciutto to blocks of cheese for your pizza prep table.

The Real Cost of a Hobart Slicer for Your Pizzeria

When you’re budgeting for your pizza restaurant, thinking about the price of a Hobart slicer is a lot like choosing a pizza oven. A small countertop oven might be fine for a few personal pizzas, but you'll need a high-capacity deck oven if you're serious about handling the Friday night rush. The price tag simply reflects the machine's power to handle your pizzeria's specific workload.

If you're just starting out, a basic manual slicer might look like the most wallet-friendly option. But for a high-volume pizzeria that's cranking out hundreds of pizzas a day, a heavy-duty automatic slicer isn't a luxury—it's a critical investment in speed and consistency right on your pizza prep table. Every minute your crew spends hand-slicing pepperoni is a minute they aren't saucing dough or topping pies, which can kill your momentum during a dinner rush.

A Quick Look at the Price Ranges

To give you a better idea of what to expect, let's break down the typical costs. Here’s a quick glance at the price ranges for new versus used Hobart slicers, which can help you figure out where your pizzeria's budget might land.

Hobart Meat Slicer Price Ranges at a Glance

| Slicer Category | Typical New Price Range | Typical Used Price Range |

|---|---|---|

| Light-Duty / Entry-Level | $500 - $1,500 | $300 - $800 |

| Medium-Duty / Semi-Auto | $2,500 - $5,000 | $1,200 - $2,500 |

| Heavy-Duty / Automatic | $5,000 - $12,000+ | $2,500 - $6,500+ |

As you can see, the price differences are significant. While you might find a new, entry-level model for around $570 to $700 at some stores, the workhorse commercial models built for pizzeria abuse demand a much higher price. For example, a used semi-automatic or automatic slicer like the legendary Hobart 2912 can still fetch anywhere from $1,595 to over $6,200. That staying power alone tells you a lot about their durability and value in a tough pizza kitchen environment.

The true cost of a slicer isn’t just the number on the price tag. It’s an investment in your pizzeria’s workflow, product consistency, and ultimately, your profitability. A reliable slicer minimizes waste and maximizes labor efficiency on your pizza prep table.

Thinking Beyond the Initial Purchase

The total cost of ownership goes far beyond what you pay on day one. A quality Hobart slicer is a long-term asset for your pizza prep table, but you have to protect that asset. An unexpected mechanical failure can bring your entire prep line to a grinding halt, costing you far more in lost business than the repair itself.

This is why savvy pizzeria owners always factor in potential long-term costs. It’s smart to consider protection like equipment breakdown insurance to safeguard your investment against those surprise mechanical issues. This adds a crucial layer of financial security, making sure your slicer stays a productive part of your kitchen for years to come.

Why Hobart Is the Gold Standard for Pizza Prep

Before we get into the nuts and bolts of specific models, let's talk about why so many seasoned pizzeria owners swear by Hobart. A Hobart slicer isn't just another gadget on your commercial food prep equipment list; it's a real investment in the kind of bulletproof reliability that gets you through every single service, rush or no rush.

Think of it as the foundational workhorse of your pizza prep table. Other tools might come and go, but a Hobart is built to survive the beautiful chaos of a Friday night dinner rush. That reputation isn't an accident. It’s earned through rock-solid durability, precision engineering, and safety features you can count on when you’re moving fast.

Built for the Pizzeria Grind

The daily routine in a pizzeria is a marathon. You need a slicer that can power through dense, cured meats like pepperoni and hard salami for hours without breaking a sweat. Hobart slicers are famous for their powerful motors and heavy-duty construction, which means no motor strain or overheating that can bring lesser machines to their knees.

This durability translates directly to less downtime. A broken slicer during the dinner rush can bring your entire pizza line to a screeching halt, and that's a nightmare nobody needs. It's this sheer consistency that makes a Hobart a core part of any well-oiled pizza kitchen.

Precision That Protects Your Profits

In the pizza business, consistency is cash. Every single slice of prosciutto or pepperoni has to be the exact same thickness. If your slices are too thick, your food costs go through the roof. Too thin or uneven, and your customers will notice the drop in quality. Hobart’s precision engineering delivers perfect, uniform slices, time after time.

A Hobart slicer is designed to deliver almost fanatical consistency. This directly impacts your food costs by slashing waste and ensures every pizza that leaves your kitchen meets the high standard your customers expect.

This level of control lets you manage inventory with surgical accuracy, protecting your bottom line. It’s this razor-sharp attention to detail that separates a good pizzeria from a great one. The brand's dominance is a big reason the U.S. meat slicer market was valued at a massive USD 378.4 million in 2024.

Ultimately, choosing a Hobart is a strategic move. You're not just buying a machine; you're investing in the speed, safety, and consistency that are the bedrock of a successful pizza operation.

Key Features That Drive the Hobart Slicer Price

When you're trying to figure out why one Hobart slicer costs more than another, it helps to know what you're actually paying for. The Hobart meat slicer price isn't arbitrary; it’s directly tied to a few core features that have a massive impact on how efficiently your kitchen runs, especially on a busy pizza prep table.

We're not talking about fancy bells and whistles here. We're talking about practical capabilities that save you real time, labor, and money. It boils down to three main things: how it operates (manual or automatic), the size of its blade, and the muscle behind its motor. Let’s break down how each one affects the price tag and, more importantly, your pizzeria's daily grind.

Manual vs Automatic Slicers

The biggest jump in price you'll see is between manual and automatic models. A manual slicer is straightforward—it needs an operator to physically push the product carriage back and forth for every single slice. This works perfectly well for a small pizzeria that only slices meats to order.

An automatic slicer, on the other hand, is a total game-changer for high-volume pizzerias. It has a motorized carriage that does all the work for you. Just imagine prepping for a Friday night rush. An automatic model can chew through an entire log of pepperoni or a large block of provolone with minimal supervision. This frees up your pizza makers to tackle other prep tasks, letting you get more pies out the door with the same number of people.

An automatic slicer is really an investment in labor efficiency. The higher upfront cost is often quickly paid back by the hours of manual work it saves your prep team, especially in pizzerias that slice large volumes of meats and cheeses every day.

Blade Size for Pizzeria Needs

The diameter of the slicer's blade is the next big factor that influences the price. Hobart slicers are available in several sizes, but for most pizzerias, the sweet spot is a 12-inch or 13-inch blade.

So, why this specific size? It’s large enough to handle the wide logs of pepperoni, salami, and big blocks of provolone or mozzarella that are staples in any pizza kitchen. You might save a few bucks on a smaller blade initially, but you'll pay for it in frustration later. Smaller blades often can't handle larger products, forcing you to waste time and product by cutting them down to size first. A bigger blade means you can slice just about any topping you need, quickly and efficiently right on your pizza prep table.

Motor Horsepower for Dense Meats

Finally, the motor's horsepower (HP) is what gives the slicer its real-world power. Slicing soft ham is one thing, but powering through a dense, hard salami or a block of low-moisture mozzarella requires some serious muscle. A wimpy motor will strain, overheat, or just give up when you need it most.

- 1/3 HP Motors: You'll typically find these on lighter-duty models. They're fine for occasional use or for slicing softer products like ham or turkey.

- 1/2 HP Motors: This is the industry standard for most medium to heavy-duty commercial slicers. It provides all the power you need to slice dense pepperoni and hard cheeses consistently for hours on end without breaking a sweat.

A more powerful motor adds to the Hobart meat slicer price, but for any serious pizzeria, it's non-negotiable. It’s your guarantee that the machine can handle your entire menu, from delicate prosciutto to the toughest pepperoni, ensuring your pizza prep work is always smooth and uninterrupted.

Choosing the Right Hobart Model for Your Pizzeria

Alright, let's talk about the right Hobart for your pizzeria. When you’re looking at the Hobart meat slicer price, you’re really choosing between two fantastic, but very different, product lines: the budget-friendly Centerline series and the top-tier, feature-packed HS Series. This decision goes way beyond the initial price tag—it’s about what truly matters on your pizza prep table during a chaotic rush.

Think about it this way: How fast can your crew clean the slicer when switching from prosciutto to provolone on a slammed Friday night? Are the safety features solid enough to give you peace of mind when a new cook is on the line? And the big one: does it crank out perfectly consistent pepperoni slices every single time, protecting your food costs? These are the real-world questions that will point you to the right model.

Centerline vs. HS Series: A Pizzeria Showdown

For a new pizzeria just getting started or a smaller shop with moderate volume, the Centerline by Hobart series is a phenomenal entry point. These slicers deliver that signature Hobart reliability and rock-solid performance at a more accessible price. They are the workhorses built for the essential slicing jobs on your pizza prep table, without all the bells and whistles of their premium siblings.

On the other hand, for a pizzeria that’s growing fast or already managing high volume, the HS Series often turns out to be the smarter long-term investment. These machines are engineered for the most demanding pizza kitchens. They come loaded with superior safety interlocks, much faster and easier cleaning procedures, and beefier motors that will power through dense, hard cheeses and meats without breaking a sweat.

To help you see how the investment scales with performance, we've put together a handy comparison.

Hobart Slicer Model Comparison for Pizza Restaurants

This table breaks down the key differences between the Centerline and the premium HS Series, helping you match the right machine to your pizzeria's specific needs.

| Feature | Centerline by Hobart | Hobart HS Series |

|---|---|---|

| Ideal Use Case | New pizzerias, smaller shops, moderate volume, budget-conscious | High-volume pizzerias, demanding kitchens, businesses focused on long-term ROI |

| Motor | Solid, reliable motor for standard pizzeria use | Heavy-duty, more powerful motor for dense products and continuous use |

| Cleaning | Standard cleaning process; reliable but more time-consuming | Removable carriage systems, simplified disassembly for exceptionally fast and thorough cleaning |

| Safety Features | Good, standard safety features | Advanced interlocks (e.g., no-volt release, knife cover interlock) for maximum operator safety |

| Blade | Quality carbon steel blade | Premium, wear-resistant alloy blades (like Stellite) that stay sharp longer |

| Price Point | $$ | $$$$ |

Ultimately, the choice comes down to balancing your immediate budget against your long-term operational needs. While the Centerline gets the job done reliably, the HS Series is an investment in speed, safety, and durability that pays dividends every single day in a busy pizza kitchen.

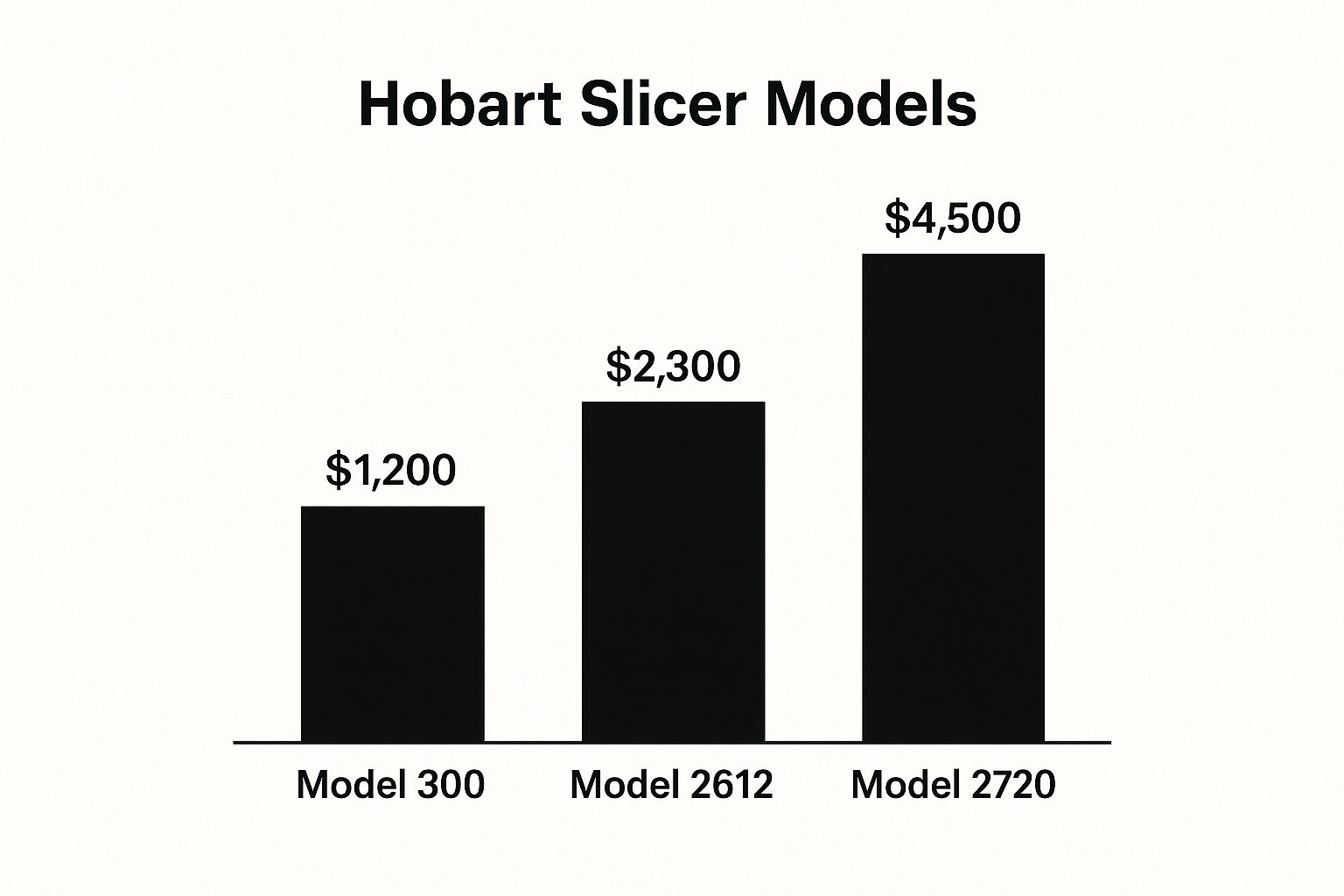

This image shows how the price jumps between different tiers of Hobart slicers.

As you can see, moving into the more robust, commercial-grade models brings a significant price increase, but that jump reflects a serious upgrade in power, safety, and time-saving features essential for a thriving pizzeria.

Why a Higher Price Can Mean Lower Costs

It might sound strange, but spending more on a slicer like the HS9 can actually save your pizzeria money over time. Take the Hobart HS9-1 model, for example. It comes with a 13-inch heavy-duty automatic blade made from a wear-resistant stellite alloy. We've seen reports that this blade stays sharp and lasts two to three times longer than standard blades. That directly cuts down on blade replacement costs and keeps your pepperoni cuts perfect.

Even better, its design features a removable carriage system and a ring guard cover that make cleaning ridiculously easy—a huge deal for a busy pizza prep table where you might switch from meat to cheese. You can learn more about the HS9-1's advanced features on WebstaurantStore.

A premium slicer is an investment in workflow. The time saved on cleaning, the reduction in food waste from consistent cuts, and the lower maintenance needs all contribute directly to your pizzeria's bottom line.

Choosing the right slicer is a critical piece of designing an efficient kitchen. Where you place it on your pizza prep table can make or break your workflow. To optimize your entire kitchen, check out our guide on how to select the best prep tables for your restaurant.

The Smart Choice Between New and Used Hobart Slicers

Deciding between a new or used Hobart slicer is a classic dilemma every pizzeria owner faces. This isn't just about the initial Hobart meat slicer price; it's a strategic choice between the security of a long-term investment and the appeal of immediate savings. The right answer really comes down to your pizzeria's budget, daily volume, and how much risk you're willing to take on.

A brand-new slicer is a lot like a new deck oven. It comes with a full manufacturer's warranty, all the latest safety tech, and the peace of mind that you're the first one to put it through its paces. For a busy pizza prep line, that means no surprise breakdowns or inherited problems, ensuring your prep work runs smoothly from day one.

On the other hand, a used Hobart can offer some serious upfront savings. For a startup pizzeria, freeing up a few thousand dollars in capital can be a game-changer. But this path has its own risks, mainly an unknown service history. You could be getting a fantastic deal on a well-maintained workhorse, or you could be inheriting someone else’s expensive headache.

Your Used Slicer Inspection Checklist

To snag a great deal without the future regret, you have to inspect a used slicer like a detective. This is especially true for a piece of equipment that's as central to your kitchen as the pizza prep table itself. In fact, you should apply the same level of diligence you would when hunting for used pizza prep tables for sale. A thorough check can save you from a very costly mistake.

Here’s a practical checklist to guide you:

- Check the Blade: Look for any nicks, chips, or obvious signs of excessive wear. A dull blade can always be sharpened, but a damaged one means an immediate replacement cost. Carefully run your gloved finger along the edge to feel for any inconsistencies.

- Listen to the Motor: Fire it up and just listen. Does it hum along smoothly, or do you hear any straining, grinding, or rattling sounds? A motor that sounds like it's struggling is a huge red flag that could signal an expensive failure is right around the corner.

- Test the Carriage: Push the product carriage back and forth. It should glide without any catching, sticking, or wobbling. Any sluggishness could point to worn-out bearings or rails that will need to be replaced.

- Inspect Safety Features: Make sure all the guards, interlocks, and safety switches are present and, more importantly, working correctly. Missing safety components are non-negotiable deal-breakers for any pizzeria.

A great deal on a used slicer is one that saves you money both today and tomorrow. A thorough inspection protects your investment and ensures the machine is ready for the demands of a busy pizzeria.

By following this checklist, you can navigate the used market with confidence. You’ll be much better equipped to spot a hidden gem that offers incredible value, securing a reliable slicer that will serve your pizzeria for years without destroying your budget.

Calculating Your Slicer's Return on Investment

It’s easy to get hung up on the Hobart meat slicer price, but let's talk about what really counts on your pizzeria's profit and loss statement: profit. Looking past the initial sticker price is absolutely critical. A quality slicer isn't just another expense; it’s a revenue-generating machine that pays you back, day in and day out on your pizza prep table.

The real value isn't on the price tag—it’s in the long-term gains. Think about it. An automatic model slashes the time your staff spends prepping pepperoni. Precision slicing means less food waste from those inconsistent, chunky cuts. And the legendary Hobart durability? That translates to fewer repair bills and almost no downtime. These are the numbers that define a smart investment for your pizzeria.

A Pizzeria Upgrade Example

Let's put this into real-world terms. Imagine a busy pizzeria finally ditching its cheap, unreliable slicer for a mid-tier automatic Hobart. The initial investment might feel like a big pill to swallow, but let's break down how it actually makes you money over the first year.

- Labor Savings: An automatic slicer easily saves at least 30 minutes of manual prep time every single day. At an average wage of $15/hour, that's $7.50 saved per day. Do the math, and that comes out to $2,737.50 annually.

- Reduced Food Waste: Getting perfectly consistent slices of expensive meats like prosciutto and salami can easily cut your waste by 5%. If your pizzeria goes through $1,000 of sliced meats a week, that's an extra $50 in your pocket every week, or $2,600 per year.

- Lower Maintenance Costs: A durable Hobart just doesn't break down as often. Compared to a budget model, you'll save an estimated $300-$500 per year in avoided service calls, replacement parts, and frustrating downtime.

When you add it all up, you're looking at savings of over $5,600 in the first year alone. Suddenly, that slicer is paying for itself. This simple calculation transforms the purchase from a "cost" into a strategic move for long-term efficiency and success right on your pizza prep table.

Of course, once you've made the investment, you need to track these savings to see the real impact. Knowing how to organize business receipts effectively is key to proving the slicer's value. This simple step helps you connect the dots and see how a quality piece of equipment directly boosts your pizzeria's bottom line.

Got Questions? We've Got Answers.

When you're looking at a Hobart meat slicer, a few key questions always come up. Here are the straight-up answers from our experience helping pizzeria owners like you gear up their pizza prep table.

What’s the Best Hobart Slicer for Pepperoni?

For most pizzerias, a Hobart with a 12-inch or 13-inch blade is your workhorse for pepperoni and those big salami logs. You really can't go wrong with models from the Centerline or HS series—they're built for the daily grind.

But if you’re slicing mountains of pepperoni every day, do yourself a favor and get an automatic model. It's a game-changer for your pizza prep line and frees up your staff for other tasks.

Can I Slice Cheese on My Hobart?

Absolutely. You can definitely slice cheese on a Hobart, but here's the critical part: you must clean the machine from top to bottom between slicing meat and cheese. No shortcuts. Cross-contamination is a serious food safety risk you can't afford in a pizzeria.

In fact, a lot of high-volume pizzerias just buy a second slicer dedicated only to cheese. If that's your plan, look for a model with a beefier 1/2 HP motor. It'll power through dense low-moisture mozzarella blocks without straining and give you those perfect, consistent slices every time.

A busy pizza kitchen can't mess around with cross-contamination. Investing in a dedicated cheese slicer, or at least a model with a removable carriage for lightning-fast cleaning, is just smart business. It’s an investment in safety and speed for your pizza prep table.

How often Should I Sharpen the Blade?

In a busy pizzeria, think about hitting that built-in sharpener every couple of days. It might sound like a lot, but it's a quick job that pays off big.

Hobart’s premium blades are fantastic at holding an edge, but frequent sharpening is what guarantees those clean, consistent cuts on everything from delicate prosciutto to thick-cut pepperoni. Plus, a sharp blade means less wear and tear on the motor, which helps your slicer live a long, happy life on your busy prep line.

Ready to make your kitchen more efficient? Check out our entire collection of commercial kitchen equipment at Pizza Prep Table and find the perfect pizza prep table to go along with your new slicer.