Don't Get Burned: The Best Commercial Pizza Oven Parts

Share

Why Every Pizzeria Owner Needs to Know About Commercial Pizza Oven Parts

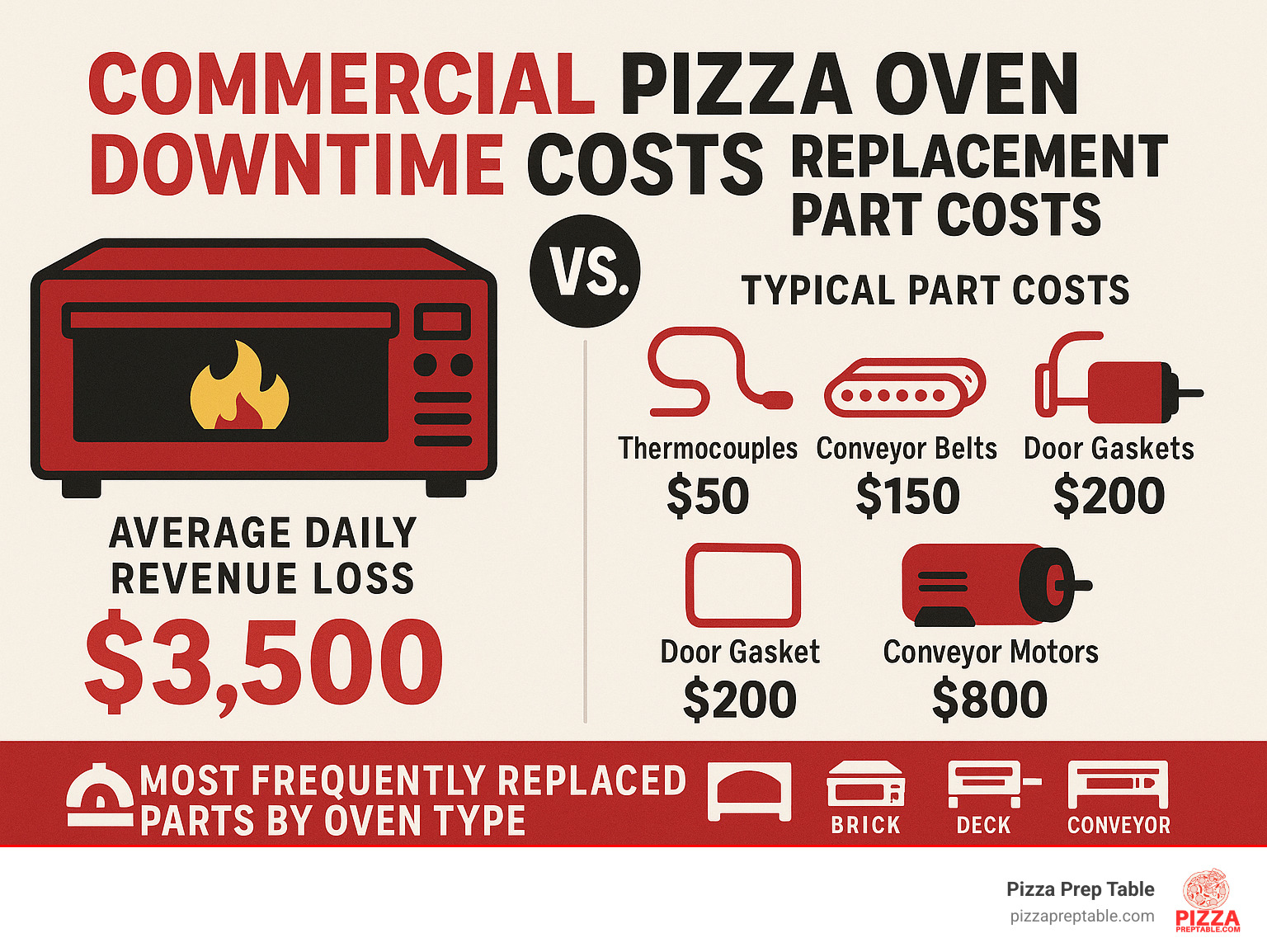

Commercial pizza oven parts are the lifeline of your kitchen operations — when they fail, your business stops making money. Restaurant owners face an average loss of $2,000–$5,000 per day when their main pizza oven goes down, making it crucial to understand which parts wear out most often and how to replace them quickly. (If you’re curious about how pizza ovens evolved into today’s high-tech workhorses, this history of pizza ovens offers a quick external primer.)

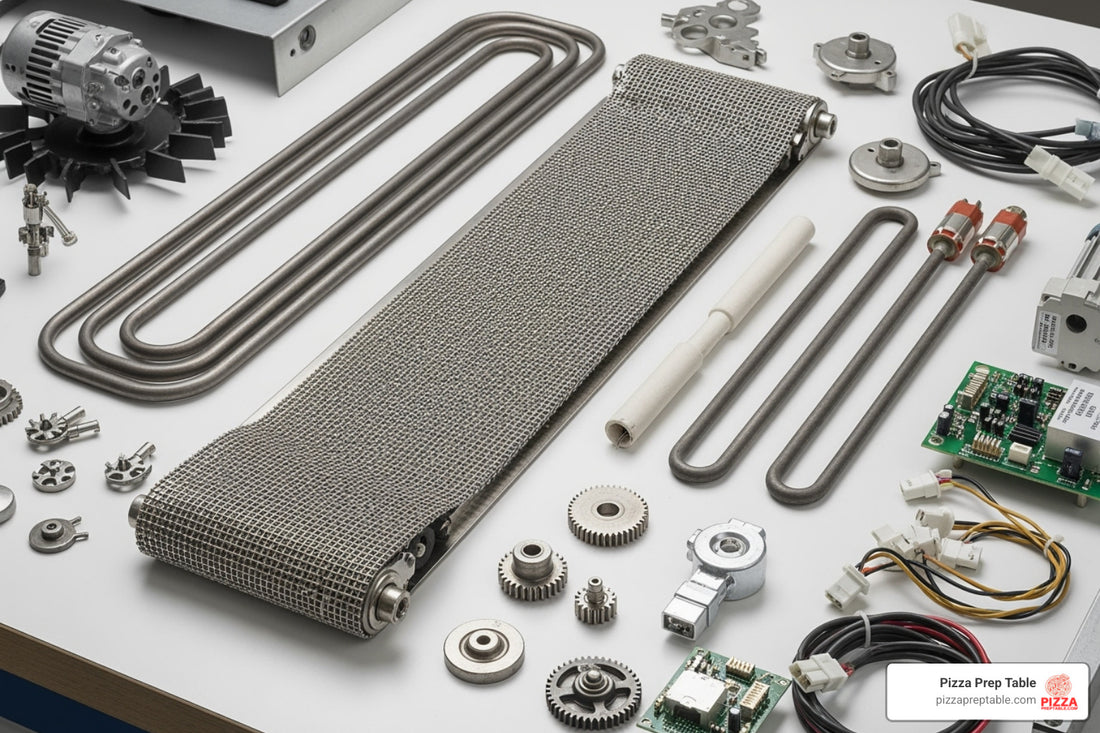

Most Common Commercial Pizza Oven Parts That Need Replacement:

- Conveyor belts – wear out from constant use and high heat

- Heating elements – burn out over time, causing uneven cooking

- Thermostats and thermocouples – fail and cause temperature control issues

- Door gaskets and seals – crack from heat cycles, losing efficiency

- Motors and fans – mechanical parts that wear down with use

- Pizza stones and baking decks – crack from thermal shock

- Gas valves and igniters – safety components that must work perfectly

As one industry expert notes: "Nothing is worse than your equipment malfunctioning" — especially when you have hungry customers waiting for their orders. The smart move is keeping essential spare parts on hand and knowing reliable suppliers who can ship replacement parts the same day.

I'm Sean Kearney, and my background in sales and deep understanding of the foodservice industry has taught me that having the right commercial pizza oven parts available can mean the difference between a minor hiccup and a major business disaster. In this guide, I'll walk you through the most critical parts you need to know about and where to find them fast.

Basic commercial pizza oven parts terms:

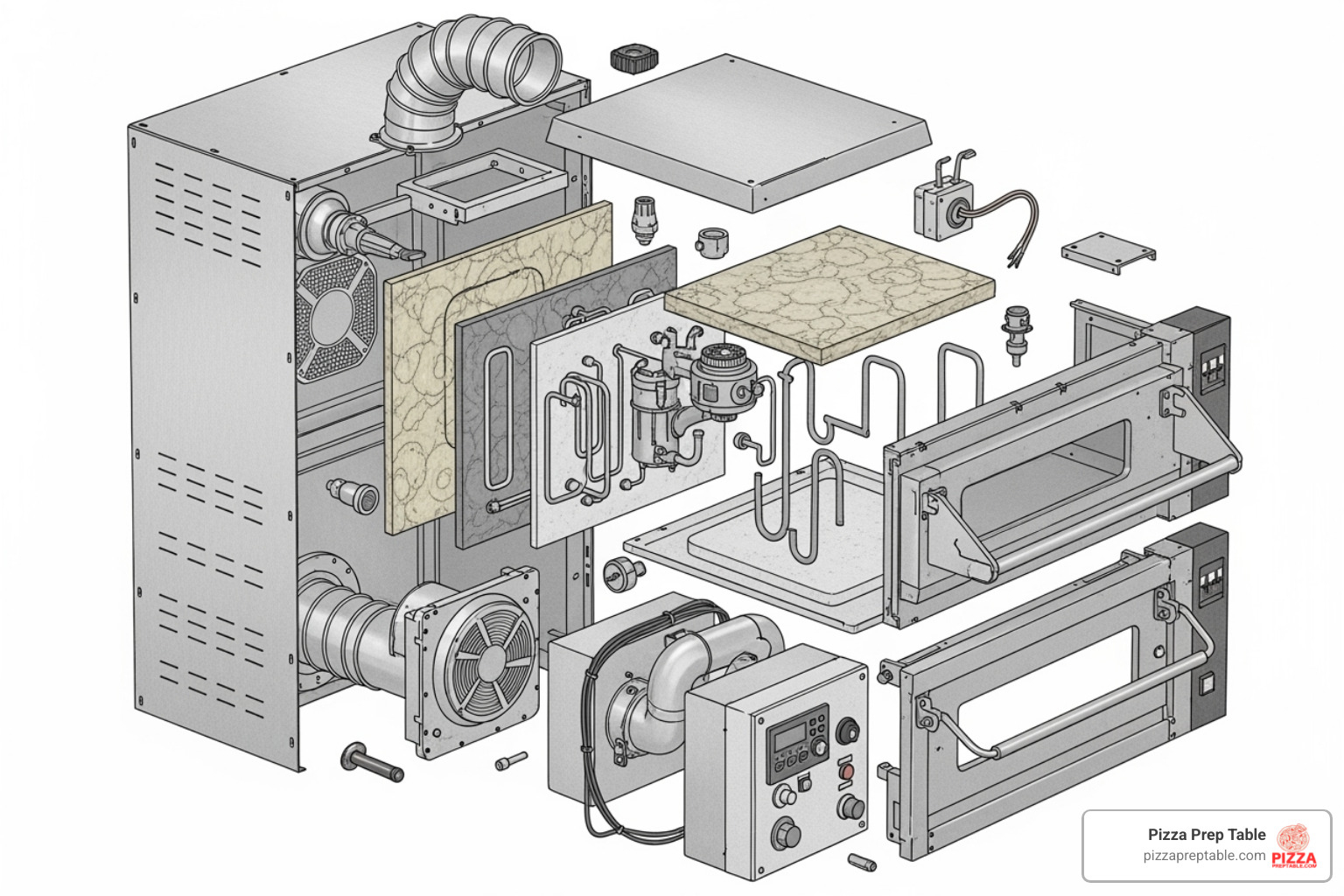

Anatomy of a Commercial Pizza Oven: Common Replacement Parts

Think of your commercial pizza oven like the engine of a high-performance car - it's built to run hard and fast, but certain parts are going to wear out faster than others. The key to keeping your kitchen humming is understanding which commercial pizza oven parts are most likely to fail and why.

At the heart of every pizza oven, you'll find the heating elements or burners doing the heavy lifting. These workhorses generate the intense heat needed to cook pizzas in minutes, not hours. But all that heat takes its toll - elements burn out over time, creating those dreaded cold spots that leave you with half-cooked pizzas.

Working alongside the heating elements are your oven's thermostats and thermocouples - think of them as your oven's internal thermometer and thermostat rolled into one. When these temperature sensors go bad, your oven becomes like a moody teenager - one minute it's running too hot, the next it's stone cold. This leads to inconsistent pizza quality, which is every pizzeria owner's nightmare.

The control boards in modern ovens are essentially sophisticated computers managing everything from temperature to timing. While they're built tough, they can still fall victim to power surges or simply wear out from constant use. When your control board fails, it's like losing the conductor of an orchestra - everything falls apart.

For gas ovens, igniters and gas valves are your safety-critical components. A faulty igniter means your oven won't light up at all, while a malfunctioning gas valve can create serious safety hazards. These aren't parts you want to mess around with - when they fail, you need professional-grade replacements fast.

Don't overlook the smaller but equally important parts like gaskets, door handles, and seals. A worn-out gasket might seem minor, but it's like leaving your front door open in winter - all that expensive heat just walks right out, driving up your energy bills and extending cook times.

Essential commercial pizza oven parts for Conveyor Ovens

Conveyor ovens are the marathon runners of the pizza world - they're designed to keep moving pizzas through the cooking chamber all day long. This constant motion means certain parts take a real beating.

The conveyor belts themselves are probably the most obvious wear item. These belts face a perfect storm of high heat, constant friction, and continuous movement. Over time, they stretch, fray, or even snap completely. When your belt goes down, your entire operation stops until it's replaced.

Behind every moving belt is a hardworking drive motor that keeps things rolling. These motors are built for endurance, but they're not immortal. When they start to fail, you'll notice the belt moving in jerky motions or stopping altogether. Upgrading from an older motor might even require a new speed sensor kit to ensure everything works together properly.

Blower fans are what make conveyor ovens so efficient at cooking pizzas quickly. They create those high-velocity air streams that cook your pizzas from all angles. When these fans fail, your cooking times increase dramatically, and you'll end up with unevenly cooked pizzas that don't meet your standards.

The speed sensors ensure your conveyor moves at exactly the right pace for perfect cooking. Think of them as the cruise control for your oven - when they malfunction, your cooking times become unpredictable.

Modern control modules are the brains of the operation, managing temperature, belt speed, and overall performance. These electronic components are individually programmed and tested, but when they fail, your oven can become completely unresponsive or behave erratically.

For a deeper understanding of how different oven types work, check out our comprehensive guide on commercial pizza ovens.

Key commercial pizza oven parts for Deck Ovens

Deck ovens are the traditionalists of the pizza world - they rely on time-tested methods of radiant heat and thermal mass to create those perfect crispy crusts that pizza purists love.

The pizza stones or baking decks are the soul of any deck oven. Made from materials like cordierite or ceramic, these surfaces absorb and hold tremendous amounts of heat while drawing moisture from pizza dough to create that signature crispy bottom. The constant heating and cooling cycles create thermal shock that eventually leads to cracks and chips - it's not a matter of if, but when.

Thermocouples might be small, but they're mighty important. These temperature sensors are constantly monitoring your oven's internal heat and sending signals to keep everything running at the right temperature. When they fail, your oven loses its ability to maintain consistent heat, leading to unpredictable results.

Thermostats work hand-in-hand with thermocouples to regulate heat output. A failing thermostat creates wild temperature swings that affect both pizza quality and energy efficiency - neither of which is good for your bottom line.

Deck oven doors are heavy-duty affairs designed to seal tightly and retain heat. The door springs ensure proper closure and positioning. When these springs wear out, doors start to sag, allowing precious heat to escape and driving up energy costs.

For gas deck ovens, gas safety valves are critical safety components that control gas flow to the burners. These valves are designed to shut off gas automatically if there's a problem with the pilot light or flame. Their proper operation isn't just about performance - it's about keeping your kitchen safe.

The burners themselves create the flames that heat your oven. Over time, they can become clogged with debris or corroded, leading to uneven heating or poor flame distribution that affects cooking quality.

Understanding these differences helps you anticipate what parts you'll need to keep on hand - conveyor ovens typically need more mechanical parts like belts and motors, while deck ovens require more thermal-related components like stones and temperature sensors.

Choosing the Right Commercial Pizza Oven Parts: A Buyer's Guide

When your pizza oven breaks down during the dinner rush, panic sets in fast. But here's the thing - rushing to buy the first replacement part you find online can actually make things worse. Choosing the right commercial pizza oven parts isn't just about getting your oven running again; it's about making sure it keeps running reliably for years to come.

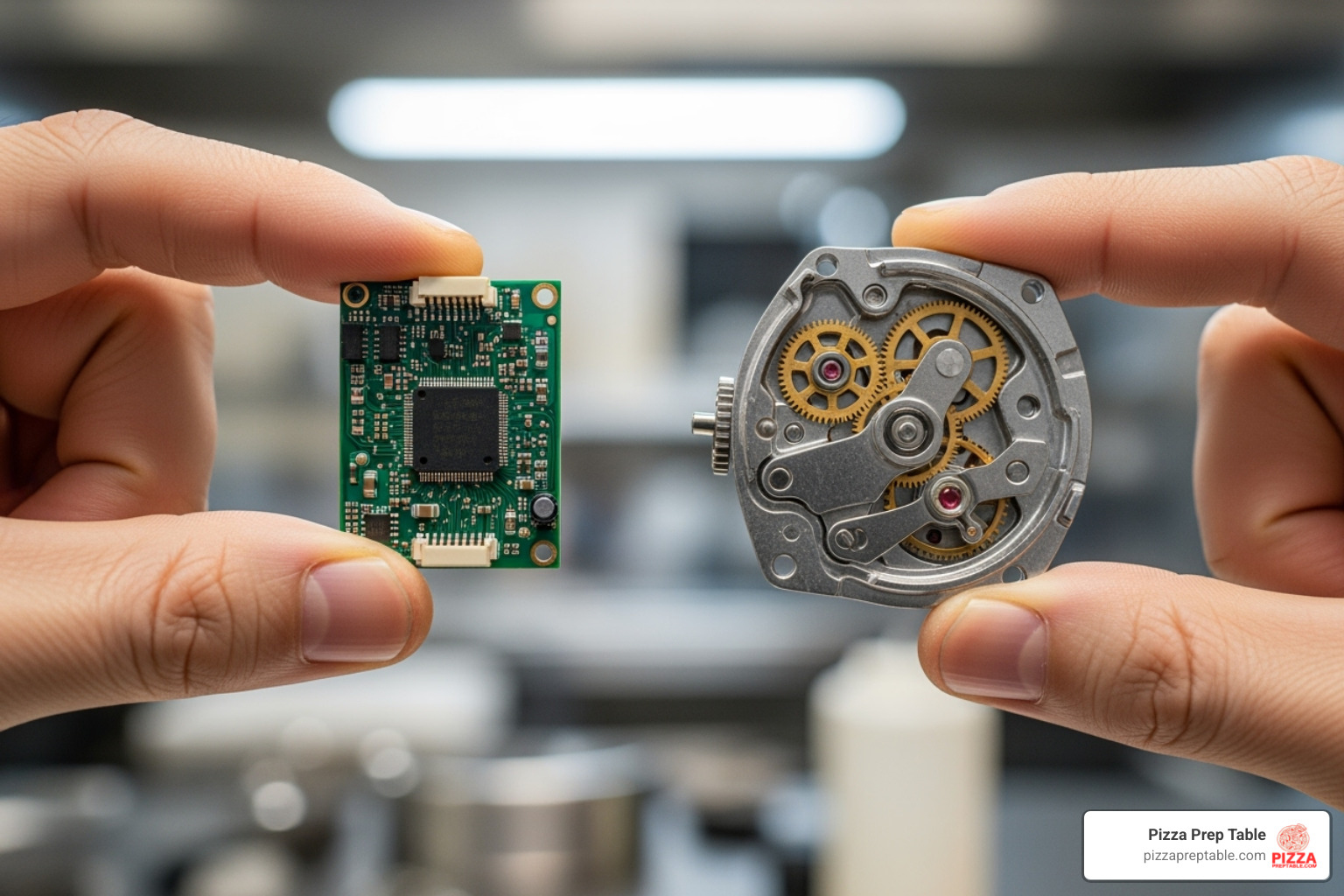

The smart approach involves four key considerations: getting the part identification absolutely right, deciding between OEM and aftermarket options, evaluating the material quality and durability, and understanding what kind of warranty protection you're getting. Think of it like buying tires for your car - you wouldn't just grab any tire that looks about right, would you?

How to Find the Correct Part for Your Oven

Getting the wrong part is like trying to fix a watch with hammer parts - it just doesn't work. The good news is that finding the exact right part is easier than you might think if you know where to look.

Your serial number is your best friend when hunting for parts. As parts suppliers will tell you, using the exact serial number - including every capital letter and hyphen - can lead you straight to the precise component you need. No guesswork, no "close enough" parts that might cause problems later.

The model number comes in second for reliability. You'll usually find this information on a metal data plate somewhere on your oven. Many suppliers let you search their catalogs by model number, which narrows down your options to parts that actually fit your specific oven.

Don't overlook your manufacturer manual - it's basically a treasure map for parts identification. These manuals typically include detailed parts lists, diagrams, and part numbers specific to your exact model. If you've misplaced yours, most manufacturers have digital copies available online.

Exploded parts drawings are incredibly helpful visual tools that some suppliers provide. Picture a diagram showing your oven "blown apart" with every component visible and labeled. You can often click directly on a part in the drawing to find its part number - it's like having X-ray vision for your oven.

When in doubt, call in the experts. A qualified oven repair technician can save you time, money, and frustration by accurately identifying what's actually broken and what you need to fix it. Sometimes what looks like a failed heating element is actually a bad thermostat - and buying the wrong part means more downtime and wasted money.

OEM vs. Aftermarket: What's the Best Choice?

This is the classic dilemma that keeps restaurant owners up at night: spend more on Original Equipment Manufacturer (OEM) parts, or save money with aftermarket alternatives? The answer isn't always black and white, but understanding the trade-offs helps you make the right choice for your situation.

| Factor | OEM (Original Equipment Manufacturer) Parts | Aftermarket Parts |

|---|---|---|

| Price | Higher cost, but predictable pricing | Lower cost, significant savings possible |

| Quality Assurance | Guaranteed to meet original specifications | Quality varies by manufacturer |

| Warranty | Typically longer, more comprehensive coverage | Shorter warranties, limited coverage |

| Perfect Fit | Exact match for your oven, no modifications needed | May require adjustments, potential compatibility issues |

OEM parts are like getting the original recipe - they're made to the exact same specifications as the part that came with your oven. You pay more, but you get the peace of mind that comes with knowing it will fit perfectly and perform exactly as expected. The warranty coverage is usually better too, which matters when you're running a business that can't afford unexpected breakdowns.

Aftermarket parts can offer real cost savings, especially for older ovens where OEM parts might be expensive or hard to find. However, the quality can vary significantly between manufacturers. Some aftermarket suppliers produce excellent parts that match or even exceed OEM quality, while others cut corners to keep prices low.

The smart approach? For critical components like gas valves or control boards, stick with OEM parts - the safety and reliability benefits outweigh the cost savings. For less critical parts like door handles or simple gaskets, quality aftermarket options can save you money without compromising safety or performance.

The cheapest part isn't always the best deal if it fails quickly and leaves you buying replacements more often. Sometimes spending a bit more upfront saves you money and headaches in the long run.