Fixing Your Pizza Prep Table Without Losing Your Toppings

Share

Why Your Pizza Prep Table Needs Attention Now

When your pizza prep table goes down, it's a huge problem. That's why understanding pizza prep table repair is so important. A broken unit means lost ingredients, wasted time, and potential health code violations. Getting it fixed fast saves your business.

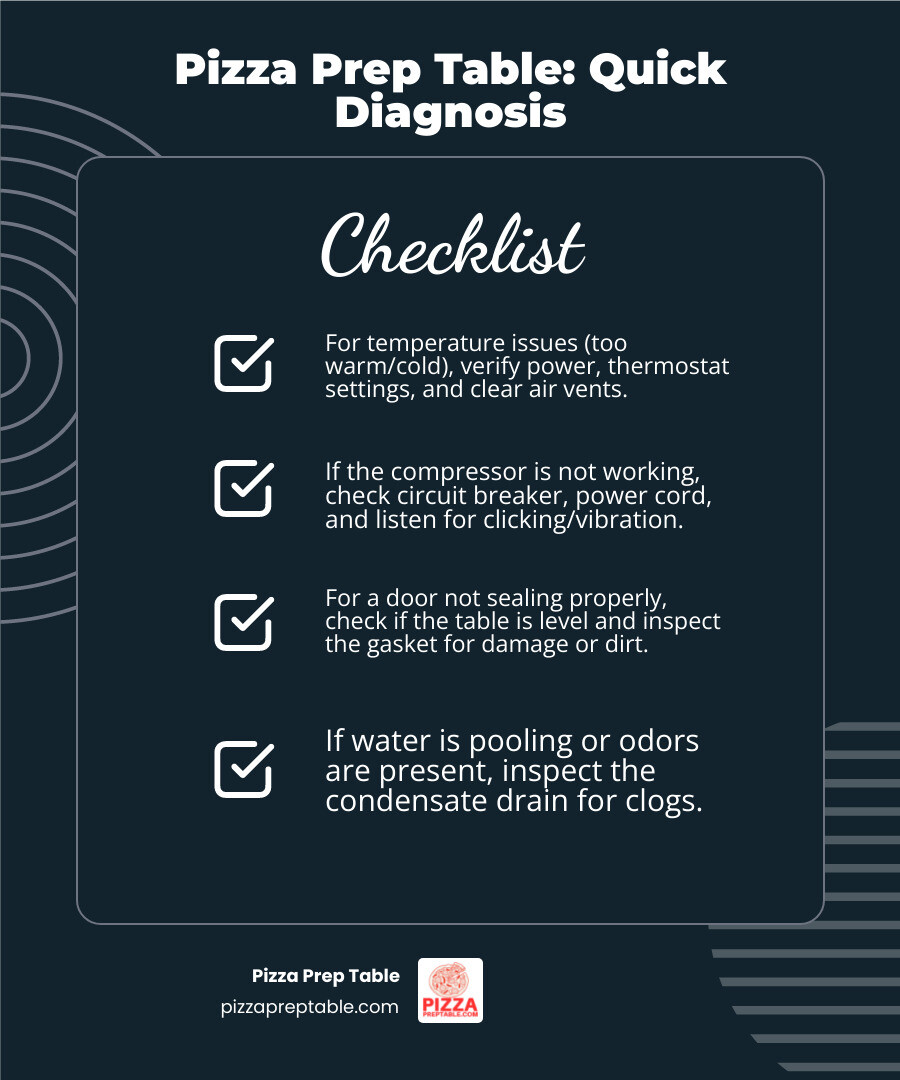

Facing an issue right now? Here's a quick look at common problems and what to check:

-

Temperature Issues (Too Warm or Too Cold):

- Quick Check: Is the unit plugged in? Check the thermostat setting. Make sure vents aren't blocked. Clean condenser coils.

-

Compressor Not Working:

- Quick Check: Is power on? Check for a blown fuse or tripped breaker. Ensure good airflow around the compressor.

-

Door Not Closing Snugly:

- Quick Check: Is the table level? Inspect the door gasket (seal) for damage or dirt.

This guide will walk you through more detailed steps to diagnose and fix many common issues. You'll learn how to keep your valuable equipment running smoothly.

My name is Sean Kearney, and I've spent years in the restaurant equipment industry, seeing the critical role high-quality equipment plays in success, including the intricacies of pizza prep table repair. My background in sales and understanding customer needs gives me a unique perspective on keeping your kitchen efficient.

Pizza prep table repair terms made easy:

Common Pizza Prep Table Problems & Initial Diagnosis

Your pizza prep table is the hero of your kitchen, keeping ingredients fresh and organized. But when issues arise, a quick initial check is the first step in effective pizza prep table repair.

Common issues include temperature fluctuations (too warm or too cold), compressor failure, water leaks, strange noises, or faulty door seals.

When issues pop up, here are some quick checks:

- Check the power source. Is the unit plugged in? Check the outlet and circuit breaker for tripped switches or blown fuses. Ensure it's on a properly sized, dedicated circuit to prevent damage.

- Verify your thermostat settings. Has someone accidentally bumped it? Make sure it's set to the right temperature for keeping your ingredients perfectly chilled.

- Clear air vents. Peek inside and outside – are any food containers or stray items blocking the vents? Restricted airflow is a huge no-no for your prep table's performance.

- Listen for compressor sounds. A happy compressor usually hums along quietly. If you hear anything loud or unusual – like grinding, buzzing, or clicking – it's a sign to investigate further.

Diagnosing Temperature Troubles

Temperature is crucial for food safety. If your unit struggles to hold its temperature, here's what to check:

If your unit is too warm, common culprits include dirty condenser coils (covered in dust, flour, or grease), which prevent heat from escaping and overwork the compressor. Also check for blocked vents (inside or out) and ensure proper ventilation away from walls or hot ovens. Failing gaskets (door seals) let warm air in, forcing the unit to run constantly. Finally, low refrigerant requires a professional and prevents efficient cooling.

If the unit is too cold, a faulty thermostat may not be cycling the compressor off correctly. An iced evaporator coil, often caused by leaky door seals or a clogged drain, can also paradoxically hinder proper cooling.

For more information on ensuring your equipment runs smoothly, explore our guide on commercial food prep equipment.

Troubleshooting a Non-Working Compressor

The compressor is the engine of your prep table's refrigeration system. If it's silent, your unit won't cool. Here's a quick action plan:

First, check the power cord. Make sure it's snug in a dedicated outlet. Avoid using power strips or extension cords, as they can cause voltage drops and damage your equipment. Then, check the circuit breaker and reset it if it's tripped.

Listen for a clicking sound, which could mean the start relay is failing. Gently feel for vibration on the compressor; no vibration means it's not running. Finally, check for overheating signs. A very hot compressor may have shut down to protect itself, often due to dirty coils or poor ventilation.

If these checks don't work, it's likely time for professional pizza prep table repair. In the meantime, you might want to explore different Atosa pizza prep tables if a replacement seems imminent.

Your Step-by-Step Guide to Pizza Prep Table Repair

If your pizza prep table is acting up, you can tackle many common problems yourself. Here are some DIY pizza prep table repair steps.

First, let's cover safety.

- Safety First: Before you touch anything, unplug your unit. This is non-negotiable, as you'll be working with electricity and moving parts.

- Necessary Tools: Gather a stiff brush, a vacuum cleaner with attachments, a screwdriver, and a pipe cleaner.

The Crucial Condenser Coil Cleaning

This is one of the most impactful parts of pizza prep table repair and maintenance. Condenser coils release heat from the refrigerant, keeping your ingredients chilled.

- Why it Matters: Dirty coils (clogged with dust, flour, or grease) can't release heat effectively. This forces the compressor to work overtime, leading to higher energy bills and a shorter lifespan for the unit. Regular cleaning extends your equipment's life and cuts utility costs.

How to Clean Your Coils:

- Disconnect Power: Unplug the pizza prep table from the wall.

- Locate Coils: Find the coils behind a removable grille, usually at the bottom front or back of the unit.

- Brush and Vacuum: Use a stiff brush to loosen dirt, then vacuum it up. For stubborn grease, use a commercial coil cleaner.

- Cleaning Frequency: For busy kitchens with airborne flour and grease, clean coils 2-4 times per year. Even dry flour contributes to buildup. A clean coil lowers energy bills and prevents problems.

Want to dive deeper into saving some cash? Check out more tips on how to cut energy costs in your commercial kitchen.

Fixing Door Seal (Gasket) Issues

The rubber gaskets (or door seals) around your prep table doors are your first defense against warm air. Failing seals cause temperature problems and waste energy.

- What to Look For: Classic signs include condensation around the door, a compressor that's running constantly, or a noticeable temperature loss inside the unit.

- The Dollar Bill Test: Close the door on a dollar bill. If you can pull it out easily, the seal is too loose and letting warm air in.

- Cleaning Gaskets: A dirty gasket can prevent a tight seal. Regularly wipe them with mild soap and water to remove debris, keep them flexible, and prevent mold.

- Replacing Gaskets: Replace torn, cracked, or inflexible gaskets. Many are "press-fit" and require no tools. Use OEM (Original Equipment Manufacturer) gaskets for the best fit and performance.

Don't lose your cool over a leaky door! When it's time for new parts, we can help you find replacement pizza prep table parts.

Clearing a Clogged Condensate Drain

The cooling process creates condensation, which must drain away. A blocked drain line will cause noticeable problems.

- Symptoms: Look for water pooling inside the unit or on the floor, unpleasant, musty odors, or excessive ice formation on the evaporator coil.

-

Your Action Plan:

- Locate Drain Line: This line runs from the evaporator coil to a drain pan.

- Use a Pipe Cleaner: Gently insert a flexible pipe cleaner or thin wire into the drain line to dislodge blockages.

- Flush with Warm Water: Pour a small amount of warm water (with a bit of bleach or vinegar for sanitizing) down the line to ensure it's clear.

Proactive Maintenance: Preventing Breakdowns Before They Happen

Let's be honest, nobody wants to deal with constant pizza prep table repair. The good news? Many common problems can be avoided with a little tender loving care! Think of it this way: an ounce of prevention really is worth a pound of cure (and a lot less headache!). By keeping up with simple maintenance, you can significantly extend the life of your valuable equipment, which typically lasts about seven years.

Mastering Temperature and Food Safety

Keeping your ingredients at the right temperature isn't just about making great pizza; it's absolutely vital for food safety and quality.

- Your pizza prep table should consistently maintain a temperature range between 33°F and 41°F (0.5°C and 5°C). For pizza ingredients specifically, many pros aim for a sweet spot of 37°F. If you're using your table for salads or sandwiches, a slightly cooler 34°F is often ideal.

- Why the strict rules? The FDA requires stored food to be kept below 41°F to prevent harmful bacteria growth. Plus, standards like NSF Standard 7 ensure your commercial prep table meets these requirements, even when your kitchen heats up to 85°F. This standard also makes sure the temperatures in those top ingredient rails stay safe.

- Make checking the internal temperature a part of your daily routine. A reliable thermometer is your best friend here!

- And please, for the love of pizza, keep those lids closed! We know it's busy, but leaving the lids or hoods open over your ingredient wells lets all that precious cold air escape. This forces your compressor to work overtime, costing you more in energy bills and wearing out your machine faster.

For detailed compliance information, you can always refer to NSF Standard 7.

Essential Cleaning and Upkeep for pizza prep table repair prevention

Beyond those important coils and gaskets we talked about earlier, general cleanliness is a game-changer for preventing future pizza prep table repair.

- Make daily wipe-downs a habit. At the end of each shift, give all surfaces – including the cutting board, interior, and exterior – a good wipe with a food-safe cleaner.

- Don't forget to sanitize all food contact surfaces regularly. This helps keep nasty bacteria from setting up shop.

- Your cutting board also needs some love. Keep it clean and free of deep grooves where food particles and bacteria can hide. If it's looking worn or has too many cuts, it's time for a replacement.

- Ingredient management is crucial. Always cover acidic food items like cut onions, pickles, and tomatoes in sealed containers. Why? Because acidic spills can be surprisingly corrosive to internal components, potentially leading to costly refrigerant leaks. If a spill happens, wipe it up immediately!

- And while flour tends to dry out in busy pizza stations, minimizing airborne flour dust is still a smart move. It keeps your coils cleaner and contributes to a more hygienic prep area overall.

Understanding the nuances of different prep tables can further improve your maintenance efforts. Learn more about different prep tables for restaurants.

The Importance of Proper Ventilation

Think of your pizza prep table as needing to breathe. Proper airflow around your unit is super important for it to run efficiently and last a long time.

- Your refrigerated prep table needs at least six inches of clearance on all sides. This space allows for adequate heat dissipation. If you cram it against a wall or another piece of equipment, you're essentially suffocating it.

- Why does this matter? Your compressor generates heat, and that heat needs somewhere to go. Without proper ventilation, it builds up, leading to overheating. This makes your unit inefficient and can cause serious damage over time.

- Good ventilation is key for compressor health. It ensures your compressor can work within its design limits, reducing strain and significantly extending its service life. A happy compressor means less worry about expensive pizza prep table repair down the line!

For more best practices in kitchen ventilation, we recommend consulting resources like Fermag's guide on care and maintenance of prep tables.

Repair or Replace? Making the Smart Financial Decision

Ah, the age-old question for any restaurant owner: fix it or get a shiny new one? Deciding whether to pursue pizza prep table repair or invest in a brand new unit is a common dilemma. It's a big financial decision that requires a bit of detective work and a peek at your budget.

First, consider the age of your unit. Most pizza prep tables are built to last, but their average lifespan hovers around seven years. If your trusty unit is nearing or has passed this milestone, major repairs might not give you enough bang for your buck. It could be like putting new tires on a car with a failing engine.

Next, think about the frequency of repairs. Are you and your repair technician on a first-name basis? If you're constantly calling them out, the cost of all those repairs can quickly add up and even surpass the price of a brand new table. It's a good time to step back and look at the bigger picture.

Don't forget about energy efficiency. Older models can be real energy hogs. A new unit, especially one with modern features like R290 refrigerant and smart adaptive defrost, can offer significant savings on your utility bills over its lifetime. That's money back in your pocket!

Finally, always compare the repair cost vs. new unit cost. Get a detailed quote for the repair. Then, compare it to the price of a similar new unit. A good rule of thumb? If the repair bill is more than 50% of what a new unit would cost, investing in a replacement is usually the smarter move.

When to Call a Professional for pizza prep table repair

While we love empowering you with DIY fixes, some issues absolutely require a certified professional for pizza prep table repair. These aren't just tricky; they can be dangerous or involve specialized tools.

For instance, if you hear a mysterious hissing sound, notice a drop in cooling despite clean coils, or spot an oily residue around the compressor, you likely have a refrigerant leak. Refrigerant is hazardous and needs special handling by licensed pros. Trying to patch up a leak without fixing the root cause is a costly, temporary fix that's also bad for the environment.

Any major electrical issues beyond a simple tripped breaker should also be left to the experts. If you smell something burning or see sparks, unplug the unit immediately and call a professional. Safety first, always!

And then there's the compressor replacement. This is the heart of your prep table's cooling system. It's a complex, expensive repair that demands specialized knowledge and equipment. Definitely not a DIY project for most restaurant owners.

When it's time to call in the cavalry, make sure you choose the right technician. Look for pros with proper certifications, especially for handling refrigerants. Make sure they have plenty of experience specifically with commercial refrigeration and, ideally, pizza prep tables. And always get a few quotes to compare pricing and proposed solutions before committing.

Considering an Upgrade to a New Prep Table

If all signs point to replacing your old unit, congratulations! Investing in a new pizza prep table can bring exciting benefits to your operation.

Think about the potential energy savings. Newer models often boast more efficient compressors, like Embraco, and use eco-friendly refrigerants such as R290. This means lower utility bills for your business. Plus, modern units come with fantastic advanced features! Imagine independently cooled rails for perfect ingredient temperatures, self-cleaning condensers that save you time, and smart digital controllers like Dixell for precise settings. Many also feature press-fit gaskets, making maintenance a breeze.

Peace of mind is priceless, and new units come with a comprehensive manufacturer warranty. This typically covers parts and labor for a few years (often 2-5 years, with compressors sometimes getting a 5-year warranty), protecting your investment.

We know a new commercial pizza prep table is a big step. That's why we offer flexible financing options to help businesses of all sizes, whether you're a small independent shop in Austin or a larger establishment in Dallas.

Ready to see what's new and improved? You can explore new 2 door pizza prep fridges and find the latest innovations that can boost your kitchen's efficiency and your bottom line.

Frequently Asked Questions about Pizza Prep Table Repair

We know you've got questions when it comes to keeping your pizza prep table running smoothly. After all, it's the heart of your pizza operation! Here are some of the most common questions we hear about pizza prep table repair and maintenance, answered simply and clearly.

How often should I clean my pizza prep table's condenser coils?

Think of your condenser coils as the lungs of your prep table – they need to be clear to breathe! For optimal performance and to avoid costly pizza prep table repair, it's best practice to clean them at least twice a year. However, if you run a particularly busy kitchen with a lot of airborne flour, grease, and dust, we highly recommend cleaning them up to four times a year. For pizza stations specifically, you might find that twice a year with a quick annual vacuum or compressed air cleaning, and a more thorough wet cleaning during your off-season, does the trick. Keeping these coils spotless helps your unit run efficiently and extends its lifespan.

What is the ideal temperature for a pizza prep table?

Maintaining the right temperature isn't just about delicious pizza; it's crucial for food safety! To comply with important food safety regulations like NSF Standard 7, your pizza prep table should consistently maintain a temperature between 33°F and 41°F (0.5°C and 5°C). But for true pizza perfection, we find the ideal temperature specifically for a pizza prep table is 37°F (2.8°C). Keeping it in this sweet spot ensures your ingredients stay fresh and safe for your customers.

Can I use an extension cord with my pizza prep table?

This is a big one, and the answer is a firm no. Manufacturers strongly advise against using extension cords or power strips with your pizza prep table. Why? Well, they can cause what's called a "voltage drop." This means your unit isn't getting enough power, which can lead to tripped circuit breakers, put a lot of strain on your compressor, and potentially cause serious damage. We've even seen commercial units burn out because of improper power connections! To avoid major pizza prep table repair or even a fire hazard, always plug your unit directly into a dedicated, properly rated outlet. Make sure that outlet is on a circuit that can handle your prep table's power needs without sharing with other high-draw appliances like microwaves. It's truly safer for everyone!

Your Partner in Pizza Perfection

Phew! We've covered a lot, haven't we? Understanding pizza prep table repair and how to keep these workhorses humming is truly a game-changer for any kitchen. From those quick DIY fixes to knowing when it's time to call in the pros, a little bit of knowledge goes a long way. Think of it as safeguarding your ingredients, your sanity, and ultimately, your bottom line.

Taking a proactive approach to maintenance isn't just about avoiding emergency breakdowns. It's about protecting a vital piece of your kitchen's heart. By keeping your prep table happy and healthy, you're extending its life, saving money on energy bills, and ensuring your pizza (or whatever deliciousness you're crafting) stays perfectly fresh.

Here at PizzaPrepTable.com, we understand the hustle and bustle of your kitchen. We know that a reliable prep table isn't just equipment; it's a partner in your daily success. That's why we're dedicated to being your go-to resource. Whether you're looking to upgrade to a shiny new model, track down that elusive replacement part, or explore flexible financing options, we're here to help you get exactly what you need.

Don't let a finicky prep table ruin your day or, worse, your delicious toppings! You've got the tools and the know-how now. Take action, keep up with that maintenance, when bigger issues arise, we're always just a click or a call away.

Ready to explore how we can help your kitchen thrive?