Food truck equipment: Your guide to mobile pizzeria gear (food truck equipment)

Share

Whether you’re a brick-and-mortar pizza restaurant exploring food truck operations or launching a mobile pizzeria, choosing the right food truck equipment—especially your pizza prep table—makes all the difference. Essential gear—from cold storage to prep stations—dictates how fast you can crank out orders and how good each slice tastes.

Quick Overview Of Food Truck Equipment

Picture your pizza setup as a racecar pit crew: every tool has a distinct role in keeping orders moving out hot.

- Refrigeration units that preserve dough and toppings at safe temperatures, including specialized pizza prep tables for topping assembly

- Pizza prep tables that organize ingredients for lightning-fast assembly and streamline pizza restaurant workflows

- Cooking appliances like ovens that guarantee consistent bakes for crust perfection

- Ventilation hoods that keep air clear and maintain compliance

- Three-compartment sinks built for efficient sanitation

- Generators and power systems to prevent service interruptions

It’s not just about cool gear—it’s about a booming trend. The global food truck sector is projected to hit USD 5.8 billion by 2025, then climb to USD 10.9 billion by 2035 at a steady 6.4% CAGR. Lower startup costs—often 50–70% less than a brick-and-mortar kitchen—are fueling this surge. Learn more about food truck market growth insights.

Must Have Equipment For Pizza Food Truck

Here’s a side-by-side look at the core setups every pizza truck—or pizza restaurant on wheels—needs to stay ahead of the rush:

| Equipment | Purpose | Key Feature |

|---|---|---|

| Refrigeration Unit | Preserve dough and toppings | Accurate temperature control |

| Pizza Prep Table | Chill and organize pizza ingredients | Spacious refrigerated pans ideal for pizza restaurants |

| Conveyor Oven | Bake pizzas evenly | Consistent heat distribution |

| Vent Hood System | Remove smoke and grease particles | NSF-certified grease filters |

| Three-Compartment Sink | Clean dishes and utensils safely | Built-in drainboards |

| Generator | Power all onboard equipment | Fuel-efficient and quiet |

Using this snapshot, you can align your space, menu, and budget with the right mix of equipment.

What You Will Explore Next

- In-depth capacity planning to size your truck perfectly

- A closer look at ovens, prep tables, and refrigeration options

- Workflow layouts designed to slash order times

- Budgeting, lease-to-own paths, and financing tips focused on pizza prep tables

- NSF compliance, upkeep routines, and supplier advice

- A downloadable equipment checklist for pizzerias and sandwich shops

This roadmap sets the stage for a deep dive into each essential category.

Key Insight

Running a pizza food truck efficiently depends on synchronizing every gear element just like a precision pit crew.

Benefits Of Well-Chosen Gear

Picking the right kit lays the groundwork for:

- Faster service and higher daily ticket counts

- Less waste thanks to precise temperature control in prep tables

- Uniform pizza quality from first order to last

- Smoother cleaning cycles and simplified maintenance

- Scalable pizza prep table configurations that grow with your menu

Pro Tip

Invest in equipment that grows with your menu for maximum value over time.

Imagining Your Pizza Pit Crew

Visualize a lunch rush with clear stations, labeled ingredient pans, and everything within arm’s reach. When prep, baking, and cleaning line up, a two-person team can crank out 60 pizzas per hour without breaking a sweat.

Next up we dive into capacity planning and layout groundwork systematically.

Understanding Key Concepts

Before you spend a dime on equipment, nail down three fundamentals that shape your mobile pizzeria’s kitchen on wheels. Master these ideas, and you’ll pick gear confidently—no guesswork required.

Picture your prep line as a racetrack. Every station is a turn, every pause a pit stop. The fewer you take, the faster those pizza slices fly out the window.

- Capacity Planning to balance space and service flow

- Power Calculations for ovens and refrigeration

- Workflow Design to eliminate bottlenecks

Capacity Planning Basics

Finding the right footprint is like fitting puzzle pieces together. You need enough bench space, room for your oven, and storage without cramping your crew.

- Menu variety versus prep space ratio—especially for topping-heavy pizzas

- Truck length (in feet) matched to crew size

- Peak-hour batch capacity (pizzas per hour)

Power And Propane Requirements

Ovens demand specific amperage and BTUs. Refrigerated prep tables draw steady electrical loads. Do the math first—nobody wants tripped breakers at the lunch rush.

Key Insight Energy use planning is just as critical as ingredient prep for smooth operations.

In the United States, food trucks generated USD 2.8 billion in revenue by 2025, with 92,257 businesses on the road. Mid-range units (16–25 feet) own 50.95% of the market, striking the sweet spot for prosumer gear like convection ovens and hood systems during 12-hour service days. Discover more insights about food truck trends on IBISWorld.

Modular Designs For Flexibility

When your menu shifts with the seasons, modular stations let you swap in pizza prep tables or ovens in minutes.

- Quick reconfiguration for seasonal menus

- Scalable add-ons to match rising order volumes

- Standardized hookups simplify installation

Follow these steps to build your blueprint:

- Map out your ideal menu workflows.

- Calculate square footage needs for each station.

- Overlay power and gas requirements onto your floor plan.

- Choose modular units that match those hookups.

Main Takeaway Planning space, power, and workflow up front keeps your service tempo humming.

Workflow Pattern Strategies

A smart layout feels a bit like choreography. Arrange your line in a U-shape or straight run so ingredients move logically from prep to plate.

- Position prep tables near refrigeration for fast grabs

- Put the oven right next to your plating station

- Tuck the sink at the end for a smooth cleanup path

- Avoid backtracking for utensils and tools

Review your flow diagrams regularly—spotting a jam early saves you from midnight headaches.

Footprint Balance For Performance

Think of your counter and aisle widths like lanes on a highway. Too narrow, and traffic backs up. Too wide, and you waste precious real estate.

- At least 2.5 feet of aisle space on either side of a 20-foot line

- 36-inch counter height for ergonomic prep

- Open shelving above benches for clear ingredient views

- Mobile prep carts for off-peak menu testing

Pro Tip Treat your layout like Tetris blocks—each piece should slide neatly into place.

Putting It All Together

Now that you’ve covered capacity, power, and modularity, it’s time to sketch your dream setup. Pencil in outlets and gas hookups, then check every detail with your crew.

- Draft rough layouts on paper or digital tools

- Label each station with power and gas specs

- Factor in cleaning zones and NSF compliance

- Get feedback from your team for real-world tweaks

Tweak until every station feels intuitive and your tempo peaks.

Final Insight A balanced food truck layout empowers your team to serve hot, consistent pizzas without missing a beat.

Use these guidelines to select equipment that matches your pizzeria vision—and keep every slice rolling out swiftly.

Enjoy success.

Taste the difference.

Essential Food Truck Equipment Categories

Imagine your food truck as a finely tuned race car. Every piece of gear—like each member of a pit crew—has its moment to shine. Pick the wrong refrigeration unit or power system, and you could lose precious time (and customers) during peak hours.

Refrigeration And Pizza Prep Tables

Cold storage is the backbone of any mobile pizzeria. You need equipment that keeps ingredients at or below 40°F while fitting into tight spaces. A pizza prep table marries workspace and fridge into one seamless station.

- A 72-inch prep table comfortably serves up to six team members side by side.

- Hydrocarbon refrigerants (R290) can cut energy use by 20% compared to older systems.

- Dividers and clear lids make it simple to switch toppings without risking cross-contamination.

- Adjustable pan depths allow pizza restaurants to customize pan sizes for Neapolitan or New York–style pies.

- Look for stainless steel prep table surfaces with rounded corners to streamline cleaning and meet NSF standards.

“After swapping to a 60-inch prep table, we shaved minutes off every order during our downtown lunch rush,” notes a seasoned NY operator.

Comparison Of Equipment Categories

Before you dive deeper, here’s a quick side-by-side look at the major categories, sample gear, and the payoff each delivers.

| Equipment Category | Example Equipment | Key Benefit |

|---|---|---|

| Refrigeration & Prep Tables | 72-inch refrigerated pizza prep table | Fast, organized topping assembly |

| Cooking Appliances | 6-burner gas range and deck oven | Even heat across long service hours |

| Ventilation Systems | NSF-certified stainless steel hood | Captures smoke and grease efficiently |

| Sinks & Sanitation Stations | Three-compartment sink with drainboards | Smooth, code-compliant cleanups |

| Power Units & Generators | 10 kW quiet diesel generator | Steady power without the roar |

This snapshot highlights how each piece plays a vital role in a pizza truck setup.

Cooking Appliances

Nothing defines pizza quality more than heat control. A deck oven with two or three chambers ensures each pie bakes evenly, slice after slice.

Many operators pair their oven with a 6-burner gas range—that’s roughly 200,000 BTU—for sauces, sautés, and finishing touches.

- Match oven capacity to your busiest hour by estimating pizzas per hour.

- Confirm your gas line diameter; a 6-burner setup typically needs at least a ½-inch line.

- If you choose a digital combo oven, double-check electrical specs before you buy.

Small trucks sometimes opt for portable conveyor ovens, which can churn out 40–50 pizzas per hour without hogging space.

Main Takeaway: Gear must align with your daily order volume and service window.

Ventilation Systems

A smoky, greased-up kitchen is a safety risk waiting to happen. Your exhaust hood should deliver at least 100 CFM per linear foot of cooking surface.

- Pick baffle or mesh filters that trap grease in the hood, not your crew’s jackets.

- Schedule cleanings regularly: clogged filters can slash airflow by up to 30%.

- Keep an eye on hood height—too low, and it invites heat build-up; too high, and efficiency drops.

Remember: Proper airflow keeps temperatures manageable and fire hazards at bay.

Sinks And Sanitation Stations

Clean plates and tools keep your line moving and inspectors smiling. A three-compartment sink handles wash, rinse, and sanitize tasks with ease.

- Position a hand sink within 5 feet of your prep zone for quick access.

- Install NSF-approved dispensers for each sanitizer you use.

- Splash guards help protect walls and counters from wayward water.

A Denver truck owner cut cleanup time by 25% after adding drainboards that keep utensils organized and off the floor.

Power Units And Generators

Nothing kills a sale like dark ovens. A 10 kW generator or larger is the bare minimum for ovens, prep tables, and lighting.

- Tally up the wattage for every appliance, then add a 15% buffer for safety.

- An inverter generator keeps noise under 60 dBA at 7 meters—your neighbors will thank you.

- Plan for at least 8 hours of fuel storage so you never run dry mid-service.

Long cords? Be wary of voltage drop—that’s how motors overheat and electronics falter.

Putting It All Together

Choosing kitchen gear is like drafting a custom toolkit for your menu. You need balance—space, power, and workflow must sync up.

- Sketch a floor plan, marking where gas and electric connections land.

- Run a mock service to test aisle clearance and reach zones.

- Leave enough room to access equipment for daily cleaning and repairs.

For a deeper dive into layout tricks, see our guide on optimized equipment layouts.

Sizing Guidelines And Capacity Tips

Right-sizing your gear cuts downtime and wasted inches. Here’s a quick rule of thumb:

- Refrigeration: 3–4 cu ft per staff member on busy shifts.

- Prep tables: match pan count to orders per hour.

- Ovens: allocate 1.5 sq ft of baking area for each pizza you expect to bake per hour.

- Sinks: at least 15 gal per compartment to handle your busiest cleanup cycle.

This math helps you avoid pinch points and wasted capacity.

Precision Matters

A tiny miscalculation in dimensions or power specs can leave you cramped or out of compliance. Double-check every measurement before you sign.

Stay inspection-ready, even on your hottest days.

For more detailed advice, explore our full article on food truck kitchen equipment.

Designing Efficient Food Truck Layout And Workflow

Designing a food truck kitchen is like orchestrating a dance crew—every step must sync perfectly. Begin by seating your deck oven at the center of your stage, then fan out the workflow from refrigerated prep tables to the three-compartment sink.

Also, factor in where customers line up and where your service window sits; you don’t want crew traffic colliding with guests.

- Fit oven, prep, and sink modules together like Tetris blocks to eliminate wasted space

- Maintain 2.5 feet of aisle width on both sides for unimpeded movement

- Place frequently used tools within arm’s reach while preserving clear sightlines

- Block out customer and crew zones so everyone knows where to stand

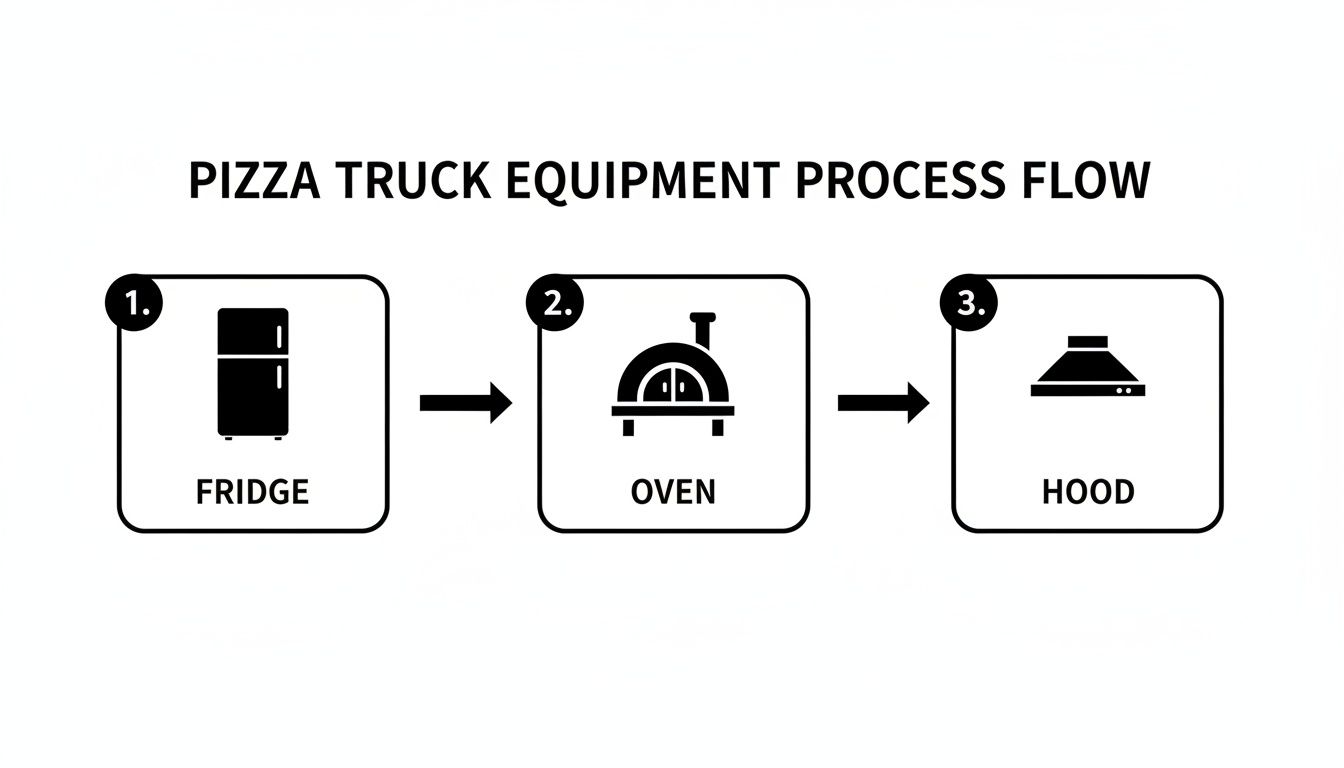

Visualizing Equipment Flow

Think of a process map like the arrows in an airport—guiding traffic and preventing U-turns. Sketching equipment flow on paper helps catch kinks before you build.

This diagram shows how trimming handoffs between fridge, oven, and hood can shave precious seconds off each pizza.

You might find valuable tips in our detailed guide on food truck layouts.

Optimizing Station Placement

Position prep tables directly beside refrigerated bays to cut back-and-forth trips. A good rule of thumb: keep no more than two steps between each station.

Place ovens within arm’s reach of the topping area; even a few extra inches can stall your rhythm.

- Grab labeled pans at the prep table—no hunting around for toppings

- Slide pies straight into the oven—skip the extra handover

- Plate orders beside the oven and hand them off without crossing paths

“Efficient station placement cut our average ticket time by 20% during peak hours,” says a veteran food truck operator.

Maximizing Narrow Spaces

When width is tight, lean on vertical solutions and multifunctional gear.

- Mount magnetic strips for knives and tools, freeing up counter real estate

- Tuck under-counter refrigeration and sliding prep carts into unused nooks

- Install foldable worktops that collapse when not needed

- Use combo ovens or stacked units to handle multiple tasks in one footprint

- Hang color-coded bins on pegboards for quick ingredient swaps

- Trial adjustable shelving and overhead rails to test what fits best

| Layout Feature | Efficiency Gain |

|---|---|

| Station Placement | 20% Faster Ticket Time |

| Narrow Space Strategy | 15% Efficiency Boost |

| Clean Zone Setup | 10% Setup Time Reduction |

Refer to the table above to track your workflow gains. A smart narrow-truck design not only boosts efficiency by 15% but also reduces staff fatigue. With unobstructed aisles and clear sightlines, your crew moves without bottlenecks.

Creating Clean Zones

Contamination risks spike when prep and wash zones overlap. By drawing a literal line between raw ingredients and cleanup areas, you save time and headaches.

- Install a three-compartment NSF-approved sink at the workflow’s end

- Label each sink (prewash, sanitizer, rinse) for clarity

- Mount sanitizer dispensers at every station, including next to your pizza prep table

- Hang color-coded cutting boards within arm’s reach

- Fit splash guards to protect walls and dry floors quickly

Industry reports show that a clear cleaning zone can shave 10% off setup time.

Testing And Refining Layouts

Mock service drills reveal the little frustrations you might miss otherwise. Record video to spot hidden inefficiencies.

- Trace each ingredient’s journey from fridge to plate

- Time every segment and jot down bottlenecks

- Shift station spacing, then repeat to measure improvements

Key Insight: A well-tested layout reduces order cycle time and makes new-staff training a breeze.

Document your final design and share it with the entire team. Review the map monthly, especially after adding new menu items or equipment. This continuous-improvement mindset keeps your workflow fresh and responsive.

By combining ergonomic station layouts, generous sightlines, and space-saving equipment, your food truck can handle peak demand without missing a beat. Enjoy efficient service.

Budget Options And Equipment Financing

Outfitting a pizza truck is as much about smart financing as it is about hot ovens and fresh dough. You need to strike a balance between that initial investment and keeping cash flowing through both peak and slow seasons. In this guide, we’ll walk through the pros and cons of buying outright, lease-to-own plans, and short-term rentals so you can build a budget that holds up.

Along the way, you’ll see real-world numbers, scenario-based examples, and tips on how import tariffs have quietly shifted more operators toward leasing for custom builds.

Comparing Purchase Vs Leasing

Before we dive into details, let’s set the scene. Buying everything outright means no ongoing fees, but it can tie up $50,000 to $100,000 in one go. Lease-to-own spreads a $30,000–$80,000 rig cost over 24–48 months, often including upgrade clauses for ovens or POS systems. Note that pizza prep tables—being critical and long-lived—are often best purchased outright for equity and stability.

Below is a side-by-side look at how these two paths stack up in dollars, flexibility, and long-term impact.

| Option | Upfront Cost | Monthly Payment Range | Pros | Cons |

|---|---|---|---|---|

| Purchase | $50,000–$100,000 | N/A | Builds equity, tax-depreciation | Large capital requirement |

| Lease | $5,000–$15,000 | $800–$3,500 | Predictable costs, upgrade flexibility | Total payments may exceed purchase price |

Key Insight

Recent import tariffs have fueled leasing growth, making custom truck builds more accessible in lease portfolios.

Rental And Upgrade Options

Sometimes you only need gear for a weekend festival or to test a new menu item. Short-term rentals shine in these moments. You can rent a conveyor oven for a three-day event or a 60-inch refrigerated pizza prep table for a holiday pop-up—ideal for pizza restaurants exploring catering gigs.

Typical rental steps:

- Choose your equipment and term (daily to monthly).

- Factor in delivery, setup, and pickup fees.

- Compare the rental cost to a purchase price—for example, $1,200 to rent vs. $15,000 to buy.

- Track rental expenses against revenue projections to see if it makes sense.

For deeper market insights, check out Technavio’s Food Trucks Market Analysis, which forecasts a USD 2.27 billion growth from 2025 to 2029 at a CAGR of 8%.

Creating Your Financing Roadmap

With the big picture clear, plot out your spend and timing to match your launch schedule:

- Start with the must-have purchase (like a pizza prep table).

- Layer in a lease-to-own oven with upgrade options.

- Rent extra POS terminals or special grill attachments during festivals.

This hybrid approach spreads costs, keeps you nimble, and ensures you’re not stuck with outdated tech.

Check out our guide on Financing Restaurant Equipment for detailed templates and scenario breakdowns.

Next Steps And Best Practices

- Request quotes from at least three leasing firms and rental suppliers.

- Compare total cost of ownership to monthly lease payments over 36 months.

- Build in upgrade clauses to keep equipment current.

- Schedule seasonal rentals for peak events to avoid idle gear.

- Reassess your financing plan every 6 months to rebalance buying vs. leasing.

- Align payment dates with your highest-revenue months to smooth cash flow.

By following these steps, you’ll mix purchases, leases, and rentals in the right proportions—keeping your pizza engine humming while scaling up. Always review contract terms for termination penalties to avoid surprises down the road.

Ensuring Compliance and Equipment Maintenance

Routine maintenance is like a health check for your pizza truck. It keeps you rolling and sidesteps costly health-code fines.

Skip a hood filter check and you might invite a fire hazard—or face a surprise shutdown on the busiest night.

Daily Cleaning Basics

Wiping down filters and prep surfaces every day prevents grime from settling into tight corners. Start each service with a quick hood inspection and a thorough filter wipe using NSF-approved degreasers.

- Remove and soak hood filters in warm water with a food-safe detergent

- Scrub grease traps and hood surfaces with a stiff brush

- Sanitize pizza prep table pans and wipe down the countertop before each shift

- Log each task in a paper chart or a digital app

Weekly Deep Clean

Once a week, dive deeper. Empty out prep tables and wipe inside refrigeration units. Sanitize door gaskets, drain pans, and any spot where moisture can collect.

“Proactive hood cleaning prevented a four-hour shutdown during a weekend rush”

Maintenance Documentation Practices

Detailed logs speak volumes during an inspection. Use a simple table or spreadsheet to note the date, task, and who signed off.

| Date | Equipment | Task | Sign-Off |

|---|---|---|---|

| 2024-06-01 | Hood Filter | Cleaned | J. Smith |

| 2024-06-02 | Prep Table | Sanitized | L. Nguyen |

| 2024-06-03 | Refrigerator | Calibrated | K. Patel |

These records show you’re on top of maintenance and ready for any surprise visit.

Calibration Of Refrigeration Units

Keeping the right temperature is non-negotiable. Check digital controls against thermometers twice a day and note the results immediately.

| Date & Time | Temp (°F) | Setpoint | Notes |

|---|---|---|---|

| 2024-06-10 08:00 | 38 | 2°C | Adjusted |

| 2024-06-10 20:00 | 39 | — | No adjustment required |

Professional servicing every six months keeps warranties valid and your coolers—prep tables included—running smoothly.

NSF Certified Surfaces Selection

Choose stainless steel surfaces with an NSF label and rounded corners. The seamless welds and 304-grade steel resist corrosion and bacterial buildup.

- Confirm every work surface bears an NSF certification label, especially pizza prep table tops

- Avoid painted or coated spots where the finish could chip

These specs ease cleaning and earn you brownie points with inspectors.

Setting Up Sanitation Stations

Hand sinks and sanitizer pumps should sit right where your team needs them. Color-coded cloths and clear signage help avoid cross-contamination.

- Stock soap, sanitizer, and paper towels before each service

- Place a sanitizer dispenser next to your pizza prep table for quick hand wipes

- Swap out cloths and wipes at the end of every shift

- Deep-clean station surfaces weekly or as needed

A well-stocked sanitation station speeds up handoffs and keeps service hygienic.

Benefits Of Preventive Maintenance

Regular upkeep can cut emergency repairs by up to 30%. It also extends the lifespan of your equipment.

- Lower repair costs and fewer last-minute service calls

- Higher health-score ratings and stronger customer trust

Start tailoring your maintenance plan today—align it with your menu, equipment lineup, and service calendar reliably.

Frequently Asked Questions

Here, we address the questions pizzeria owners ask most when it comes to choosing, powering, financing, and maintaining food truck equipment for mobile pizza operations.

- How do you pick the right pizza prep table size?

- What should you know about power and propane requirements?

- How do you maintain the temperature settings on a pizza prep table?

- Is leasing or buying the better option for your gear?

- How do you get set for a smooth health inspection?

Selecting The Right Pizza Prep Table

Start by looking at your busiest day. If you’re topping under 100 pies, a 48-inch prep table usually does the trick. It gives you enough workspace without crowding your kitchen.

But if orders climb into the 100–200 range, bump up to a 60-inch model. And when you’re racing past 200 pizzas, that 72-inch station keeps everything within arm’s reach.

| Table Size | Daily Volume |

|---|---|

| 48 in | < 100 pizzas |

| 60 in | 100–200 pizzas |

| 72 in | > 200 pizzas |

This quick breakdown helps you hit your stride without bumping elbows or slowing down your crew.

Power And Propane Requirements

Before you bolt anything in, note your oven’s specs:

- Voltage: 208–240V, plan for 30–50 amps

- Oven output: 30K–40K BTU for a standard deck unit

- Plus a 15% safety buffer for simultaneous runs

A little headroom on your power plan keeps breakers from tripping when you’re slammed with orders.

Leasing Versus Buying Equipment

If you have the cash and want long-term savings, buying outright makes sense—you build equity and claim depreciation. But if you’d rather preserve working capital, a lease or lease-to-own spread over 24–48 months can be a lifesaver. It also gives you room to swap in new gear if your menu changes.

- Buy: Immediate ownership, depreciation benefits

- Lease: Lower upfront cost, easier upgrades

Preparing For A Health Inspection

Nothing beats a solid cleaning routine. Develop checklists covering your hood filters, prep tables, and sinks. Keep daily temperature logs for your fridge and calibration records close at hand. Store everything—printed or digital—in one binder so you can grab it in a flash.

Consistent record-keeping is the simplest way to sidestep surprise violations and keep your doors open.

Ready to streamline your pizzeria prep with durable, efficient NSF-compliant refrigeration?

Visit Pizza Prep Table