7 Food Truck Layouts You Should Know

Share

Designing a food truck is more than just installing equipment; it's about engineering a high-efficiency workspace in a severely constrained environment. For mobile pizzeria operators, the right layout is the foundation of profitability, dictating everything from ticket times and staff fatigue to ingredient waste and customer satisfaction. An intelligent design supports a seamless workflow, while a poor one creates constant bottlenecks, service delays, and unnecessary stress. This article moves beyond generic advice to dissect seven distinct food truck layouts, analyzing real-world applications specifically for pizza-focused operations.

We will break down each layout, from galley kitchens to specialized zone-based designs, highlighting their strategic advantages and operational drawbacks. You'll gain specific tactical insights into optimizing the placement of your pizza prep table, deck oven, and refrigeration units to maximize output. The goal is to provide actionable takeaways you can apply directly to your own mobile kitchen build or remodel. By understanding the core principles behind these proven food truck layouts, you can make informed decisions that directly impact your speed, quality, and bottom line. Let's examine the blueprints for a successful mobile pizzeria.

1. L-Shaped Kitchen Layout

The L-shaped kitchen is one of the most versatile and popular food truck layouts, especially for concepts requiring a distinct separation between cooking and preparation. This design places equipment and counters along two adjacent walls, forming an "L." This configuration naturally creates an efficient work triangle, minimizing the steps staff need to take between key stations like cooking, refrigeration, and prep. It’s a powerful choice for maximizing corner space, which is often underutilized in narrow truck interiors.

This layout is a game-changer for pizza food trucks. Imagine a high-capacity pizza oven installed against the shorter back wall, while a long, refrigerated pizza prep table runs along the perpendicular side wall. This setup allows one person to stretch dough and build pizzas on the prep line, then pivot to slide them directly into the oven without crossing paths with other staff. The workflow is linear and intuitive, reducing service times and preventing bottlenecks during a rush.

Strategic Analysis: Workflow and Efficiency

The L-shaped layout's primary benefit is its ergonomic workflow. By creating a contained work zone, it reduces physical strain and unnecessary movement. For a pizza operation, this means less time spent walking and more time producing.

Key Insight: The corner of the "L" becomes a high-value pivot point. Placing the most critical, interconnected equipment there-like placing a dough sheeter next to the start of the pizza prep table-can shave valuable seconds off every order.

This layout also clearly defines work zones. The cooking equipment is on one leg of the L, and the cold prep and assembly are on the other. This separation is crucial for food safety, preventing cross-contamination between raw toppings and cooked products. Explore more commercial kitchen design principles to see how this separation improves overall safety. You can learn more about how an L-shaped kitchen layout enhances workflow on pizzapreptable.com.

Actionable Takeaways

- Optimize the Corner: Don't let the corner become dead space. Install a corner-mounted sink for hand washing or use it for small, essential equipment like a stand mixer or sauce warmer.

- Vertical Storage is Key: With two full walls available, maximize vertical space. Install overhead shelving for pizza boxes and dry goods, and use magnetic knife strips or hanging racks for tools.

- Plan Your "Triangle": Strategically place your three most-used points: the main cooking appliance (pizza oven), the main prep area (pizza prep table), and refrigeration (under-counter units). Ensure they form a tight, unobstructed triangle.

2. Galley (Straight-Line) Layout

The galley or straight-line layout is the epitome of linear efficiency, making it a cornerstone of food truck layouts designed for speed and simplicity. This configuration arranges all equipment, prep surfaces, and service windows along one or both of the truck's long walls. It creates an assembly-line-style workflow that is highly intuitive and perfect for concepts with a focused, sequential menu. This design excels in narrow truck interiors where maximizing floor space is a top priority.

This layout is a powerful choice for food trucks selling pizza by the slice. Picture a workflow starting with a dough press at one end, followed by a refrigerated pizza prep table where sauce and toppings are added. The line continues directly to a high-speed conveyor pizza oven. As slices emerge fully cooked, they land on a cutting and serving station right next to the service window. This linear path from raw to ready minimizes movement and ensures customers receive their orders in record time, which is critical for high-volume lunch rushes.

Strategic Analysis: Workflow and Efficiency

The galley layout’s strength lies in its uninterrupted, sequential workflow. By organizing tasks in a straight line, it eliminates crossovers and staff congestion. For a pizza-by-the-slice operation, this means one employee can manage the entire production line without ever needing to turn around or sidestep a coworker, optimizing throughput per hour.

Key Insight: The "start" and "end" points are critical. Placing the raw ingredient station (dough, sauce) farthest from the service window and the finished product station (oven, cutting board) closest to it creates a natural, forward-moving process that prevents order mix-ups.

This layout also provides excellent separation between customer interaction and food production. Staff at the point of sale and service window can operate without interfering with the cooking process happening further down the line. This specialization of roles within a tight space is a hallmark of efficient food truck layouts and is crucial for maintaining both speed and order accuracy.

Actionable Takeaways

- Design for a "One-Way Street": Ensure your workflow moves in only one direction, from prep to cooking to service. Label stations clearly to guide new staff and prevent them from backtracking during peak hours.

- Utilize Under-Counter Space: In a galley layout, every inch counts. Equip your pizza prep table with under-counter refrigeration for toppings and cheese, keeping the most-used ingredients directly below the workspace.

- Position Your Window Strategically: The service window should be the absolute last stop in your assembly line. This ensures that the finished, boxed product is handed directly to the customer, minimizing holding time and maintaining quality.

3. U-Shaped Layout

The U-shaped layout surrounds the operator with equipment and workspace on three sides, creating an incredibly efficient work cockpit where everything is within arm's reach. This design is particularly effective for single-operator food trucks or those with a primary chef who needs seamless access to all stations. It is one of the most immersive and productive food truck layouts for complex menus.

This design is a powerhouse for an artisanal pizza operation. Picture a central operator with the main pizza oven on the back wall, a full-length pizza prep table to their left for dough stretching and topping, and a cutting and boxing station to their right, leading directly to the service window. The operator can pivot, not walk, to manage every stage of the order. This setup minimizes movement and maximizes output for a single, highly-skilled pizza chef.

Strategic Analysis: Workflow and Efficiency

The U-shaped layout’s core strength is its command-center ergonomics. It creates a self-contained, high-intensity work zone that eliminates wasted steps. For a pizza concept requiring multiple menu items, this means one person can simultaneously bake a pizza, drop wings in a fryer, and assemble a salad without leaving their post.

Key Insight: The U-shape thrives on a "pivot workflow." The operator becomes the central axis, and the layout must be designed around their turning radius. Placing the most frequently used items—like a pizza peel or a primary sauce ladle—within immediate reach can dramatically increase speed.

This layout also creates a natural barrier between the primary cook and other staff or the service window, enhancing focus and safety. For a pizza operation, this could mean having the oven and fryers on the back wall, a pizza prep table on one side, and a separate station for drinks or sides on the other, allowing a single chef to orchestrate the entire menu.

Actionable Takeaways

- Design for the Pivot: Use a swivel stool to reduce physical fatigue. Arrange your equipment based on the pizza-making sequence so you can turn from the prep table to the oven fluidly.

- Prioritize Ventilation: With equipment on three sides, heat from a pizza oven can build up quickly. Invest in a high-capacity ventilation hood that covers the entire back wall to ensure a safe and comfortable working environment.

- Integrate Multi-Level Surfaces: Use pull-out cutting boards or install an over-counter shelf on your pizza prep table to instantly expand your workspace for boxing pizzas during peak times.

4. Assembly Line Layout

The assembly line layout is the gold standard for high-volume food trucks specializing in customizable, sequentially built menu items. This design organizes the kitchen into a linear progression of dedicated stations, where food moves from one step to the next until it is complete. This is one of the most efficient food truck layouts for concepts like burrito bowls, sub sandwiches, and, with some adaptation, high-volume pizza-by-the-slice operations.

This layout excels in scenarios demanding speed and consistency. For a fast-casual pizza-by-the-slice truck, this might look like a station for saucing pre-baked crusts, followed by a cheese and topping station on a long pizza prep table, and finally, a high-speed conveyor or impinger oven for a quick melt and finish. Each staff member owns their station, creating a production rhythm that can serve long lines of customers without a drop in quality or speed.

Strategic Analysis: Workflow and Efficiency

The assembly line layout's core strength is its specialization-driven throughput. By breaking down the pizza production process into simple, repeatable tasks, each employee becomes an expert at their station. This minimizes cognitive load and physical movement, maximizing output.

Key Insight: The success of this layout hinges on eliminating bottlenecks. The pace of the entire line is dictated by its slowest station. Therefore, balancing the workload and staffing at each stage—from dough stretching to topping on the pizza prep table to the final bake—is critical for maintaining a smooth, fast-moving service flow.

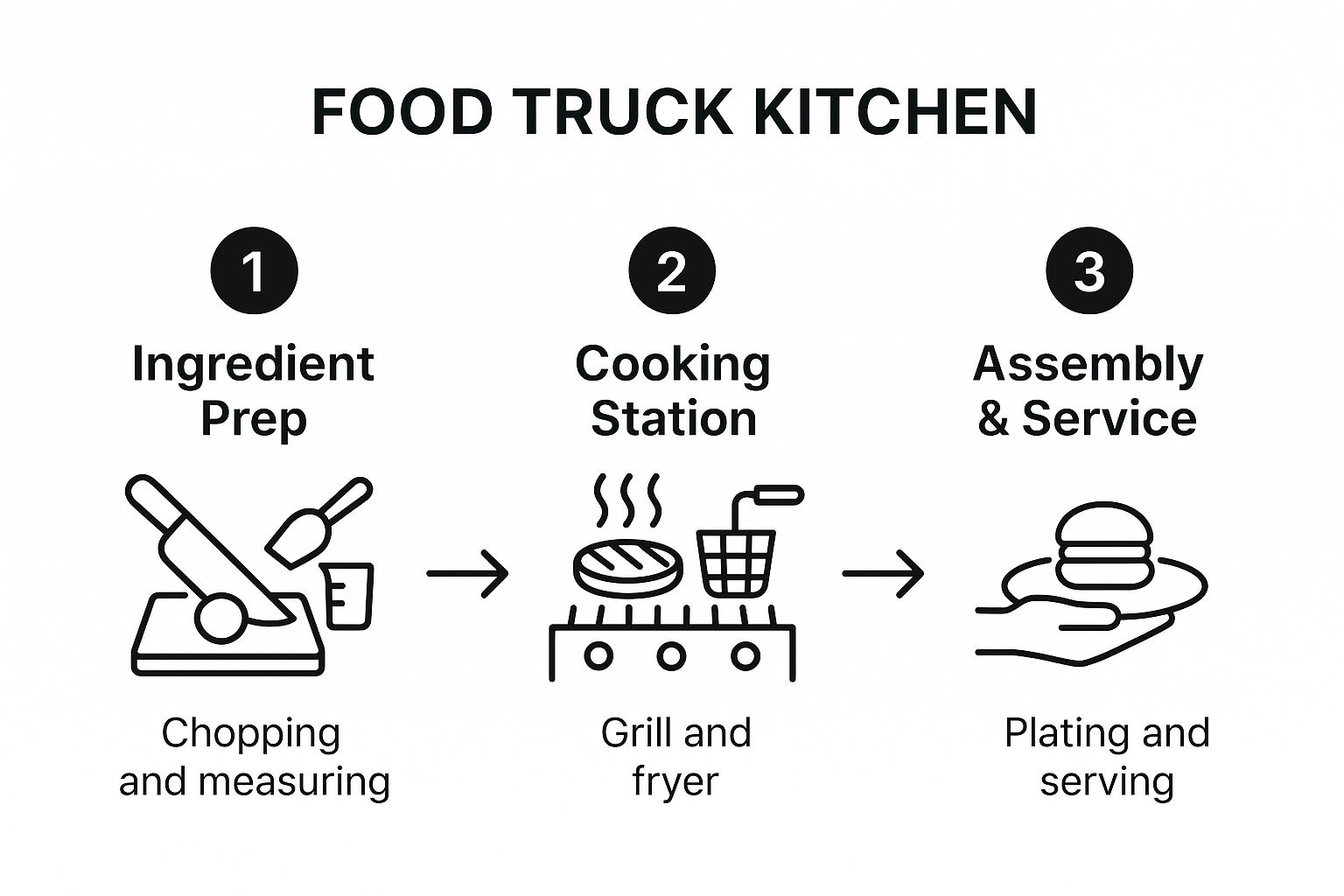

This infographic visualizes the fundamental process flow in a typical high-speed food truck kitchen, highlighting the sequential stages from initial prep to final customer service.

The visualization underscores how a linear flow-from ingredient prep to cooking to assembly-creates a predictable and manageable production system, which is the cornerstone of the assembly line's efficiency. The clear handoff points between stages are essential for preventing chaos during peak hours.

Actionable Takeaways

- Define Clear Handoffs: Designate specific physical zones where an item transitions from one station to the next. For a pizza line, this could be a dedicated landing area after the pizza prep table, just before it enters the oven.

- Standardize Portions: Use portion-controlled spoodles for sauce, measured cups for cheese, and standardized tongs for toppings. This ensures every pizza is consistent and helps manage food costs accurately.

- Implement Ergonomic Station Design: Position all necessary tools and ingredients within immediate reach at each station. A pizza topping station should have refrigerated ingredient pans on the pizza prep table directly in front of the employee to eliminate bending and reaching.

5. Zone-Based Layout

The zone-based layout is a highly specialized approach that divides the food truck interior into distinct, self-contained functional areas. Each zone is optimized for a specific stage of production, such as cold prep, hot cooking, assembly, and service. This modular design is essential for complex menus where food safety protocols and workflow separation are non-negotiable, ensuring tasks with different requirements do not interfere with one another.

This layout is a perfect fit for a gourmet pizza operation that also offers complex sides, like fried appetizers or fresh salads. Imagine a dedicated "dough zone" at one end with a mixer and proofing cabinet, a separate "prep zone" with refrigerated pizza prep tables for topping, a "hot zone" for the pizza oven and fryer, and a "finishing/service zone" at the window. This compartmentalization prevents flour from the dough zone from contaminating the fryer oil and keeps the hot line's ambient heat away from fresh salad ingredients.

Strategic Analysis: Workflow and Efficiency

The core strength of the zone-based layout is its ability to create parallel workflows. Multiple staff members can work simultaneously in their respective zones without creating traffic jams or cross-contaminating ingredients. For a pizza truck, this means one person can stretch dough while another tops a pizza and a third manages the oven and fryer, all in harmony.

Key Insight: This layout excels at mitigating food safety risks. By creating physical or procedural barriers between zones (e.g., raw dough prep vs. ready-to-eat salad assembly), you drastically reduce the chance of critical food safety errors during high-volume service.

This separation forces a methodical and clean process, which is invaluable in a confined space. Each zone can be equipped with precisely the tools it needs, minimizing redundancy and clutter. You can learn more about the specific food truck equipment needed to outfit each zone effectively on pizzapreptable.com.

Actionable Takeaways

- Color-Code Your Zones: Use different colored cutting boards and utensils for each zone (e.g., white for dough, green for fresh produce) to provide clear visual cues for staff and reinforce safety protocols.

- Establish Zone-Specific Sinks: If space allows, install separate hand washing and tool-washing sinks in critical zones—especially between the dough zone and the main pizza prep table—to streamline sanitation.

- Define Clear Protocols: Create a clear, documented process for how staff and ingredients move between zones. For example, a pizza must be fully assembled in the prep zone before it can enter the hot zone.

6. Service Window-Centric Layout

The service window-centric layout places the point of sale and customer interaction at the absolute heart of the food truck’s design. Every piece of equipment and every workflow step is strategically organized to support rapid order fulfillment directly at the window. This approach is ideal for concepts built on speed, high-volume sales, and direct customer engagement, such as coffee, ice cream, or breakfast trucks.

This layout is a powerful choice for a "pizza by the slice" concept. Picture a large display warmer filled with various ready-to-eat pizza slices positioned directly behind the service window. The point-of-sale (POS) system sits right beside it, allowing a single staff member to take an order, grab the requested slice, and complete the transaction in a seamless, fluid motion. The focus is on minimizing the time between customer desire and order delivery.

Strategic Analysis: Workflow and Efficiency

The core advantage of this layout is its transactional velocity. By placing the finished product and payment system at the window, you eliminate internal hand-offs and reduce customer wait times dramatically. For a pizza slice operation, this means the cashier is also the server, creating a single point of contact that speeds up the entire line.

Key Insight: The space immediately surrounding the service window becomes the most valuable real estate in the truck. This area should be treated as a "fulfillment zone," containing everything needed to complete at least 80% of your orders without taking more than a step or two.

This design also enhances the customer experience. For a pizza truck, seeing and smelling the fresh slices in a display case right at the window is a powerful sales tool. It creates an impulse to buy and simplifies the ordering process. For food trucks with a service window-centric layout, clear and appealing menu presentation is crucial; explore some inspiring menu board design ideas to maximize this visual impact.

Actionable Takeaways

- Create a Fulfillment Zone: Install your main display warmer for pizza slices and any side items directly adjacent to the window. The POS system should be within arm's reach of both the window and the warmer.

- Stage for Speed: Use a small staging counter next to the window for boxing orders or adding drinks. This keeps the primary window area clear for the next customer interaction.

- Optimize Your "Back End": While the window is the star, the rest of the layout must support it. Ensure a clear path exists from the pizza oven to the display warmer to allow for efficient restocking during a rush without disrupting the flow at the front.

7. Specialty Equipment-Centered Layout

The specialty equipment-centered layout builds the entire food truck around a single, defining piece of hardware. Whether it's a massive wood-fired pizza oven, a custom smoker, or a large rotisserie system, this piece of equipment is not just an appliance; it's the heart of the business and the focal point of the design. All other stations, from prep to service, are strategically arranged to support and feed this central unit, ensuring its operation is as efficient and dramatic as possible.

This layout is the go-to for artisan concepts where the cooking method is as important as the ingredients. For a Neapolitan pizza truck, the authentic Italian-made oven is the main attraction. The workflow is designed so that the pizza maker can build a pizza on a refrigerated prep table and, with a simple turn, slide it directly into the oven's mouth. This not only maximizes speed but also creates a theatrical experience for customers watching their food being made.

Strategic Analysis: Workflow and Efficiency

The primary strength of this layout is its unwavering focus on the core product. Every element is optimized to serve the specialty equipment, eliminating inefficiencies that could slow down production of the main menu item. The workflow becomes a direct, linear path from the pizza prep table to the main appliance, which is essential for high-volume service.

Key Insight: Positioning the specialty equipment for customer visibility turns the cooking process into marketing. A visible wood-fired oven doesn't just cook pizza; it builds anticipation and communicates authenticity, often justifying a premium price point.

This design also forces a disciplined approach to menu creation. Since the entire space is optimized for one type of cooking, it naturally discourages menu bloat. For instance, a truck built around a high-capacity pizza oven will excel at pizza and calzones, and the layout will reflect that specialization. If you want to learn more about selecting specialized equipment like fryers for sides, you can explore how to find food truck deep fryers that deliver crispy profits on pizzapreptable.com.

Actionable Takeaways

- Plan for Infrastructure: Specialty equipment often has unique power, fuel, and ventilation needs. Ensure your truck's design accounts for the heavy-duty propane tanks for a pizza oven or the high electrical draw of conveyor ovens from the very beginning.

- Create a Support Perimeter: Arrange supporting stations like the pizza prep table and dough proofer in a close-knit perimeter around the main oven. The goal is to allow staff to access everything they need with minimal steps.

- Showcase the Process: If possible, orient the oven toward the service window. This "performance" aspect can significantly enhance the customer experience and boost sales, making your pizza truck a destination.

7 Food Truck Layouts Comparison

| Layout | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| L-Shaped Kitchen Layout | Moderate complexity; requires careful corner planning | Moderate space and standard equipment | Efficient workflow & good storage access | Pizza trucks needing workflow efficiency and multi-staff | Maximizes corner usage; smooth workflow; good for multiple staff |

| Galley (Straight-Line) Layout | Low complexity; linear arrangement | Low to moderate; fits narrow trucks | Streamlined, quick service in narrow spaces | Pizza-by-the-slice or narrow trucks with limited width | Simple workflow; easy supervision; minimal wasted space |

| U-Shaped Layout | High complexity; requires wider truck space | High; extensive equipment on three sides | Maximum equipment density; minimal operator movement | Single-operator pizza trucks or complex menus | Excellent accessibility; efficient for complex tasks |

| Assembly Line Layout | High complexity; detailed station coordination | High; larger trucks & multiple operators | Extremely high throughput & consistent quality | High-volume pizza-by-the-slice operations | High capacity; consistent product quality; efficient staffing |

| Zone-Based Layout | Moderate to high; complex planning for zones | Moderate to high; specialized equipment per zone | Optimized food safety & workflow separation | Pizza operations with complex sides (wings, salads) | Strong food safety; clear task separation; flexible menus |

| Service Window-Centric Layout | Moderate complexity; focus on window flow | Low to moderate; emphasizes service area | Fast service & improved customer interaction | Pizza-by-the-slice or high-turnover locations | Very fast service; reduces order errors; enhances customer engagement |

| Specialty Equipment-Centered Layout | High complexity; custom infrastructure | High; specialty equipment & custom utilities | Unique branding & optimized specialty cooking | Artisan/wood-fired pizza trucks | Unique selling point; premium pricing; strong brand differentiation |

Final Thoughts

As we've journeyed through the diverse world of food truck layouts, from the classic efficiency of the galley to the specialized power of an equipment-centered design, one principle stands out: your layout is the physical blueprint of your business strategy. It's far more than just placing equipment; it’s about engineering an environment for speed, quality, and profitability within a highly constrained space. The examples we’ve explored demonstrate that the most successful food truck layouts are born from a deep understanding of a specific menu and its unique workflow demands.

For a pizza-focused mobile kitchen, this means every inch must serve the intricate dance of dough, sauce, cheese, and toppings. The difference between a chaotic, cramped truck and a high-volume pizza powerhouse often comes down to a few critical layout decisions. Ignoring these details can lead to bottlenecks at the prep station, slow oven cycles, and a frustrated team unable to meet customer demand during peak hours.

Key Strategic Takeaways

Mastering your food truck's interior design isn't just an operational exercise; it's a competitive advantage. Let's distill our findings into core actionable principles:

- Workflow is King: Always start by mapping your menu's production process. For pizza, this is a linear journey: dough stretching, saucing, topping, baking, and serving. Your layout must mirror this flow to prevent backtracking and cross-contamination.

- The "Golden Triangle" Reimagined: Adapt the classic kitchen triangle (sink, stove, fridge) for your specific needs. In a pizza truck, this might be a "Pizza Production Triangle" connecting your refrigerated prep table, your oven, and your service window. Optimizing the distance between these three points is crucial.

- Equipment Dictates Design: High-impact equipment, like a multi-deck pizza oven or a long pizza prep table, will be the anchor of your layout. Design around these core components, not in spite of them. Their placement determines the flow for уютhe entire truck.

Your Actionable Next Steps

With these insights in hand, it's time to move from theory to practice. Begin by sketching out your ideal workflow on paper, treating it like a schematic. List every single step required to make your signature pizza, from grabbing the dough ball to handing the finished box to a customer.

Next, measure your critical equipment, especially your pizza prep table and oven. Use these dimensions to create to-scale cutouts and arrange them within a drawing of your truck’s interior. This low-tech, hands-on approach allows you to physically test different food truck layouts and identify potential chokepoints before you ever install a single piece of steel. Remember, the ultimate goal is to create a space that not only functions but flows, enabling your team to produce consistently excellent pizza at the speed your customers expect.

Ready to build the foundation of your high-efficiency pizza truck? The right pizza prep table is the heart of your operation, directly impacting workflow and speed. Explore the industry-leading, NSF-certified refrigerated units at Pizza Prep Table, designed for the demanding environment of mobile kitchens. Find the perfect size and configuration to anchor your ideal food truck layout at Pizza Prep Table today.