Rolling Kitchens 101: What Equipment Does a Food Truck Need?

Share

Equipping Your Dream on Wheels: Food Truck Essentials

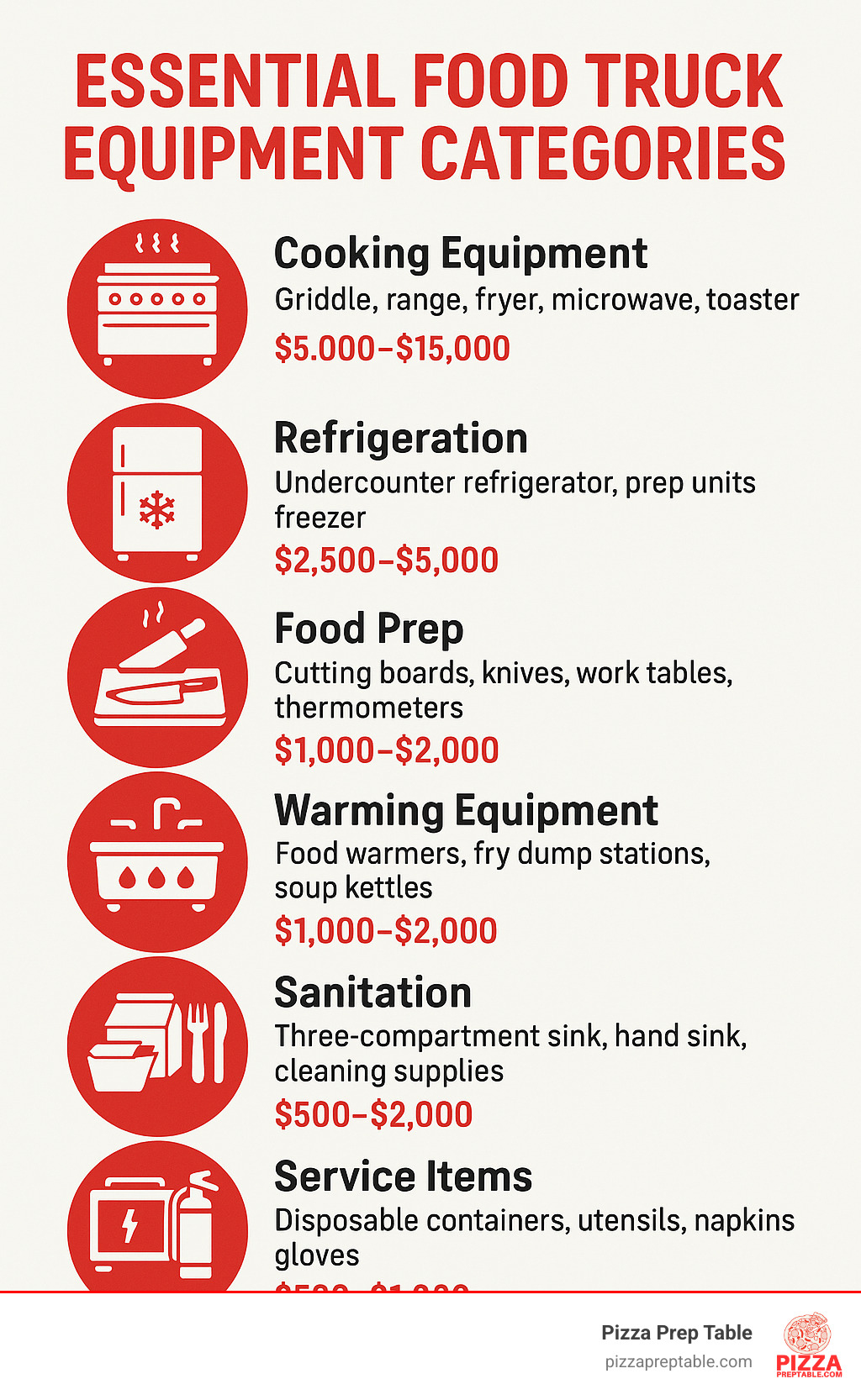

If you're planning to launch a mobile eatery, knowing what equipment does a food truck need is the critical first step to success. Here's a quick overview of the essential categories:

- Cooking Equipment: Griddle, range, fryer, microwave, toaster

- Refrigeration: Undercounter refrigerator, prep units, freezer

- Food Prep: Cutting boards, knives, work tables, thermometers

- Warming & Holding: Food warmers, fry dump stations, soup kettles

- Sanitation: Three-compartment sink, hand sink, cleaning supplies

- Service Items: Disposable containers, utensils, napkins, gloves

- Power & Operations: Generator, fire extinguisher, ventilation system

Starting a food truck business combines culinary freedom with entrepreneurial spirit—but despite lower overhead than a brick-and-mortar restaurant, the average food truck startup cost often exceeds $100,000. The truck itself typically costs $50,000-$100,000, with cooking appliances requiring $5,000-$15,000, refrigeration units $2,500-$5,000, and smallwares $1,000-$2,000.

Space constraints make equipment selection particularly challenging. Every inch counts in a mobile kitchen, so prioritizing multi-functional equipment and creating an efficient workflow is essential. You'll also need to consider power requirements—most trucks rely on generators (typically 10,000W) or propane systems to run their equipment.

I'm Sean Kearney, and my background in sales at Amazon and years helping restaurant owners select appropriate equipment has given me unique insight into what equipment does a food truck need for optimal efficiency and profitability. I understand that having the right tools in your mobile kitchen can make all the difference between struggling and thriving.

What equipment does a food truck need basics: - food truck deep fryer - food truck fryer oil storage

What Equipment Does a Food Truck Need? The Non-Negotiables

Let's face it—you can't serve amazing food without the right tools. When it comes to food trucks, certain equipment simply isn't optional if you want to run a successful operation. These core components form the backbone of your mobile kitchen, regardless of what delicious creations you're planning to serve.

So what equipment does a food truck need at minimum? I've helped dozens of food truck entrepreneurs get rolling, and there are certain items that appear on every shopping list:

Cooking & Holding Essentials — what equipment does a food truck need for the hot line?

Your cooking line is where the magic happens. These are the workhorses that will bring your culinary vision to life day after day:

Your commercial griddle or flat top will likely become the centerpiece of your operation ($1,000-$3,000). Whether you're flipping juicy burgers, searing proteins, or whipping up breakfast favorites, a quality 24-36 inch griddle gives you incredible versatility in a compact footprint.

If fried foods are starring on your menu, a reliable deep fryer is non-negotiable ($500-$2,000). Many of my clients have found that ventless models are worth the investment when hood space is at a premium. As one owner told me, "My fryer paid for itself in the first month of selling loaded fries!"

A range with 2-6 burners gives you the flexibility to sauté, boil, and simmer simultaneously ($800-$2,500). Most successful trucks I've worked with opt for at least a 4-burner setup to handle medium to heavy volume without creating bottlenecks during rush periods.

For that irresistible smoky flavor, especially important for burger or BBQ concepts, a charbroiler might be essential ($1,000-$3,000). The distinctive grill marks and flavor profile can become your signature touch.

Don't overlook the humble commercial microwave ($300-$800). While not glamorous, it's invaluable for quick reheating and certain cooking tasks. Choose a commercial-grade model with higher wattage than what you'd use at home—they're built for the punishment of all-day use.

Rounding out your hot line, consider a soup warmer/kettle ($200-$600) for maintaining safe serving temperatures for soups, chili, or sauces, and a fry dump station ($200-$500) to keep fried foods crisp and ready for service.

Your menu should drive your equipment decisions. If you're not serving soups, you can skip the warmer and allocate that money elsewhere.

Cold Storage & Prep — what equipment does a food truck need to keep food safe?

Food safety isn't just about regulations—it's about protecting your customers and your reputation. Proper refrigeration is absolutely critical:

A worktop refrigerator gives you the best of both worlds: cold storage below and a valuable work surface on top ($1,500-$3,000). In the limited space of a food truck, this dual functionality is worth its weight in gold. Look for models with digital temperature displays for easy monitoring during health inspections.

If your concept involves made-to-order items with multiple toppings or ingredients, a sandwich/salad prep refrigerator will transform your workflow ($1,800-$3,500). These specialized units feature a cold rail on top holding ingredients in separate containers while keeping everything properly chilled. I've seen prep times cut in half when trucks upgrade to these purpose-built units.

An undercounter freezer ($1,500-$3,000) is essential for storing frozen ingredients, ice, and pre-prepared items. Choose a commercial-grade unit that can handle frequent opening during service without temperature fluctuations.

If bottled or canned beverages are part of your offering, a glass-door merchandiser ($1,000-$2,500) allows customers to see options before ordering, potentially increasing add-on sales.

Don't skimp on prep tools like high-quality cutting boards (color-coded to prevent cross-contamination), commercial-grade knives, reliable thermometers, and food processors ($500-$1,500 total). These smaller items can make or break your efficiency during rush periods.

Health departments require refrigeration that consistently maintains temperatures below 41°F, with regular temperature checks and documentation. One food truck owner shared with me: "The health inspector was more impressed with my temperature logs than anything else on the truck!"

Service & Tech Gear — what equipment does a food truck need to get paid fast?

Getting the food made is only half the battle—you also need efficient systems to take orders and process payments:

A reliable Point of Sale (POS) system is the nerve center of your customer interactions ($500-$2,500 plus monthly subscription). Modern food trucks need mobile-friendly POS systems that can process various payment types, track inventory, and provide sales data. Many operators now use tablet-based systems with contactless payment capabilities that work even with spotty internet connections.

For busier trucks with multiple staff members, a Kitchen Display System ($300-$1,000 plus subscription) can dramatically improve order accuracy and timing. These digital ticket systems eliminate the shouting and paper tickets that can lead to mistakes during busy service.

Your serving supplies are a recurring expense ($200-$500 monthly) that includes paper food trays, disposable dinnerware, cups, utensils, take-out containers, portion cups, napkins and dispensers. Running out of these items can force you to close mid-service, so always keep backup stock.

Many successful trucks now use QR code signage ($50-$200) for contactless menu viewing and even ordering/payment. This simple technology can significantly speed up your service line and reduce the need for printed menus.

Complete your customer-facing setup with condiment dispensers like pump dispensers, squeeze bottles, and shakers for sauces and seasonings ($100-$300). These small touches can lift the customer experience and encourage return visits.

Hungry customers appreciate speed and convenience, especially when they're standing in line at a food truck. Consider embedding payment QR codes into your promotional signage for truly seamless transactions, even when Wi-Fi is limited.

The right equipment makes all the difference between struggling and thriving in the competitive food truck world. At PizzaPrepTable.com, we understand the unique challenges of mobile foodservice and can help you select the perfect equipment package for your concept and budget.

Menu, Space & Power: Picking the Right Gear for YOUR Concept

Let's face it – your food truck isn't just a kitchen; it's a puzzle where every piece needs to fit perfectly. Your menu dreams, the reality of your truck's square footage, and the power you can generate all need to work together in harmony.

Calculating Wattage & Generator Size

I've seen it happen too many times – a food truck owner plugs in their equipment for the first day of service, and suddenly everything goes dark. Let's make sure that doesn't happen to you!

Start by creating what I call a "power load sheet." This is simply a list of every electrical device in your truck along with its maximum wattage. A typical food truck might include:

- Griddle (~3,000W)

- Refrigerator (~1,400W)

- Microwave (~1,200W)

- Water heater (~3,000W)

- Lighting (~600W)

- POS system (~100W)

- Exhaust fan (~500W)

Add these numbers up to find your total power needs. Then – and this is crucial – add at least a 10% safety margin. If your calculations show you need 9,200W, don't settle for a 9,000W generator. Go for at least 10,000W to give yourself breathing room when everything's running at once.

Now for the fun part – choosing your generator's fuel type. Each option has its tradeoffs:

| Power Source | Pros | Cons | Best For |

|---|---|---|---|

| Electric | Maintains temperature well, no fumes | Requires substantial power source | Ovens, small appliances |

| Natural Gas | Cheap, efficient | Flammable, installation costs | High-BTU cooking |

| Propane | More efficient than gas, portable | Higher cost, tank storage | Mobile operations |

| Dual-Fuel | Flexibility, backup options | Higher upfront cost | Year-round operations |

Here's a tip from experience: those gas generators might save you money, but they can drive customers away with their noise and exhaust fumes. If your concept involves chatting with customers while you cook, consider investing in a quieter propane model or a sound-dampening enclosure. Your customers (and your voice) will thank you!

Multi-Use & Ventless Solutions for Tight Spaces

When every inch counts, multi-functional equipment becomes your best friend. These space-saving heroes can transform your tiny kitchen into a powerhouse:

Combination ovens are like the Swiss Army knives of food truck equipment. They can bake, steam, and broil all in one footprint, potentially replacing several separate appliances. Yes, they'll cost you $3,000-$8,000, but they might save you twice that in space and additional equipment costs.

Induction burners are magical little devices that provide precise temperature control while generating less heat than traditional gas burners. When you're working in a metal box under the summer sun, that reduced ambient heat is a blessing! Budget around $200-$800 per burner, depending on quality.

Ventless fryers solve one of the biggest headaches in food truck design – ventilation. Traditional fryers need hood systems, but ventless models use built-in filtration to eliminate that requirement. At $2,000-$5,000, they're an investment, but they can make certain concepts possible in trucks where they otherwise wouldn't be.

Vertical prep stations like the one pictured above are game-changers in food truck design. By utilizing wall space instead of precious counter space, you free up room for other essential equipment. Budget between $300-$1,000 for these space-saving wonders.

One more insider tip: a good food processor can be worth its weight in gold. They streamline chopping and dicing, potentially cutting prep time in half. When you're working in a space where you can barely turn around, that efficiency becomes invaluable.

What equipment does a food truck need ultimately depends on your specific menu and concept. The trick is balancing those culinary dreams with the realities of space and power – a challenge, yes, but one that creative food truck entrepreneurs overcome every day!

Layout & Organization Hacks That Maximize Every Inch

In the confined space of a food truck, every square inch matters. The most successful mobile kitchens aren't necessarily the largest—they're the smartest when it comes to layout and organization.

Think of your food truck as a culinary Tetris game where everything needs to fit just right. Start by establishing clear workflow zones for different activities. Your truck should have distinct areas for prep, cooking, assembly, and service. This separation not only prevents cross-contamination but also creates a natural flow that helps your team move efficiently during the rush.

Stainless steel shelving is your best friend in a food truck. Install adjustable shelves above workstations to make use of that valuable vertical space that often goes wasted. Health departments in most areas require food-safe surfaces like stainless steel, so you'll be checking the compliance box while maximizing your storage.

For those truly tight spaces, consider fold-down counters that can be tucked away when not in use. These give you extra prep surface during busy times but can disappear to create walkway space during cleanup or slower periods. Similarly, magnetic strips mounted on walls can hold metal utensils, freeing up precious drawer space for other essentials.

When asking what equipment does a food truck need, don't overlook specialized refrigeration that serves double duty. Prep Sandwich Refrigerators That Keep Your Ingredients Fresh and Your Customers Happy are perfect examples of equipment that combines cold storage with usable prep space—ideal for sandwich-focused concepts or any menu requiring assembly of cold ingredients.

Look for equipment with built-in storage underneath, like refrigerated chef bases that support cooking equipment on top while providing cold storage below. This two-for-one approach eliminates the need for separate equipment pieces and maximizes your limited footprint.

Pro tip: Allocate more space to your most profitable, frequently-used equipment. If your signature item is fried chicken, your fryer deserves prime real estate, while equipment used only occasionally can make do with less optimal positioning or countertop alternatives.

Safe Storage for Oil & Consumables

Beyond just finding places for everything, proper storage in a food truck addresses crucial safety and compliance concerns.

If your concept involves frying, you need a plan for oil management. Keep Calm and Store On: Food Truck Fryer Oil Storage Tips provides essential guidance for safely storing and disposing of cooking oil. Improper oil storage isn't just messy—it creates serious fire hazards and can lead to hefty fines from health inspectors.

For dry goods storage, invest in clear, airtight containers with labels and dates. This simple system helps with inventory management while preventing contamination. Implement a First In, First Out (FIFO) rotation system to minimize waste and ensure you're always using the freshest ingredients first.

Don't overlook climate control in your truck. Proper insulation and temperature management protect ingredients from extreme heat or cold, particularly important if you operate in areas with variable weather conditions. Your equipment works harder (and uses more power) when fighting against poor insulation.

Chemical storage requires special attention. Cleaning supplies and chemicals must never mingle with food items—store them in locked cabinets, typically below sinks and away from any food preparation areas. This separation is non-negotiable from a health code perspective.

In a food truck, organization isn't just about neatness—it directly impacts your operation's efficiency, safety, and ultimately, profitability. A well-organized truck means faster service, happier customers, and a less stressful workday for you and your team.

Safety, Sanitation & Regulatory Must-Haves

Let's talk about the not-so-glamorous but absolutely critical part of your food truck business – safety and sanitation equipment. Trust me, these aren't just suggestions – they're requirements that protect your customers, your staff, and ultimately, your business.

What equipment does a food truck need to stay safe and legal? More than you might think!

A proper fire suppression system sits at the top of this list. Every food truck with cooking equipment must have an automatic system installed above cooking areas. These life-saving systems typically run between $1,000-$3,000, and you'll need professional installation and regular inspections. This isn't an area to cut corners – a single kitchen fire can destroy your entire investment in minutes.

Your ventilation hood is equally important. A commercial-grade hood system removes smoke, steam, and cooking odors, keeping your tiny workspace breathable. Many cities require specialized grease-capture systems and potentially sprinklers too. Budget between $3,000-$8,000 here – yes, it's a significant investment, but it's non-negotiable for both safety and legal operation.

Water management is another crucial area. You'll need a three-compartment sink for washing, rinsing, and sanitizing equipment. Health inspectors will check for this immediately, and without it, you won't pass inspection. These typically cost $500-$1,500. Alongside this, you'll need a separate dedicated handwashing sink with hot and cold running water, soap dispenser, and paper towels. This smaller sink (usually $200-$500) is absolutely required by health codes nationwide.

Don't forget about protecting your team! Personal Protective Equipment (PPE) like heat-resistant gloves, cut-resistant gloves, aprons, and non-slip shoes protect your staff from common kitchen injuries. Budget $200-$500 for these essentials. A comprehensive first aid kit ($50-$150) rounds out your safety gear and is required by both health departments and OSHA.

According to foodborne infections research, proper temperature control is essential to prevent illness. Your warming and holding equipment isn't just about keeping food tasty – it's about keeping your customers safe from foodborne illness.

Compliance Checklist by Category

Navigating the maze of regulations can feel overwhelming when you're just starting out. Here's what you need to know broken down by category:

For permits and licensing, you'll need several documents: a business license, health permit, food vendor license, fire department permit, and often parking permits for each jurisdiction where you plan to operate. Keep a binder with all these documents on your truck – inspectors can show up anytime!

Health code requirements include proper handwashing facilities, food storage at safe temperatures, separate prep areas for raw and cooked foods, proper waste disposal systems, and employee health and hygiene protocols. These requirements exist to prevent cross-contamination and foodborne illness – they're there for a good reason.

Water and waste management is often overlooked but critically important. You'll need a fresh water tank (typically 30-50 gallons), a grey water tank (usually 1.5x the size of your fresh water tank), proper disposal procedures for waste water, and a grease trap with a disposal plan. Improper waste disposal can result in hefty fines and environmental damage.

Accessibility considerations matter too – your service window should be at ADA-compliant height, with clear menu visibility and accessible payment options for all customers.

A word of wisdom from someone who's seen it all: three-compartment and handwashing sinks are absolute game changers for any food truck. These aren't luxury items—they're required by health departments nationwide and essential for maintaining proper sanitation. When health inspectors visit (and they will), these basics will be the first things they check.

Safety equipment might seem expensive upfront, but it's far cheaper than dealing with fines, closures, or worst of all, making someone sick. Think of these investments as insurance for your business's future.

Budgeting, Buying Smart & Ongoing Maintenance

Let's talk money—because outfitting your food truck requires some serious financial decisions that will impact your business for years to come.

When I first helped a client outfit their Korean taco truck, we saved nearly $8,000 by finding gently-used equipment without compromising on quality. The reality is that smart purchasing decisions can dramatically affect both your startup costs and long-term profitability.

New vs. used equipment is often your first big decision. Brand new equipment comes with warranties and the latest energy-efficient features, but quality used equipment can slash your upfront costs by 30-60%. Restaurant auctions, equipment liquidators, and certified pre-owned dealers can be goldmines for budget-conscious entrepreneurs. Just be sure to test everything thoroughly before purchasing!

Financing can help ease the initial burden. Many equipment suppliers (including us at PizzaPrepTable.com) offer financing plans specifically designed for food truck operators. These plans help you preserve precious capital for other startup expenses like permits, marketing, and initial inventory.

Whenever possible, invest in multi-function equipment that serves several purposes. Yes, that combi-oven might cost more upfront, but when it replaces three separate appliances while taking up just one footprint, the math starts making a lot of sense—especially in your cramped truck kitchen.

For major equipment—particularly refrigeration units which are both critical for food safety and expensive to repair—consider service contracts. Think of them as insurance policies against unexpected breakdowns during your busiest season.

Different equipment has different lifespans. Your refrigeration units might last 8-10 years with proper maintenance, while cooking equipment typically needs replacement after 5-10 years. Smallwares like utensils and cutting boards will need replacement every 1-3 years depending on use.

If you're specifically looking at frying equipment, our guide on Crispy Profits Await with These Food Truck Deep Fryers can help you make an informed decision that balances cost, quality, and space constraints.

Stretching Dollars Without Sacrificing Safety — what equipment does a food truck need on a budget?

Starting with limited funds doesn't mean compromising on quality or safety. One of my clients launched her empanada truck on a shoestring budget by being strategic about where to save and where to splurge.

Restaurant auctions can be incredible resources, often yielding commercial-grade equipment at 50-70% below retail prices. I've seen nearly-new refrigeration units go for pennies on the dollar. Just bring someone knowledgeable with you and insist on testing before buying.

Equipment leasing preserves your capital and may offer tax advantages. Monthly payments typically run 2-5% of the equipment's value, making high-end items more accessible when you're just starting out. This approach helped one of my barbecue truck clients access a top-tier smoker that would have been out of reach as an outright purchase.

Implement preventative maintenance plans from day one. Regular maintenance extends equipment life and prevents those soul-crushing emergency repairs that seem to happen right before your biggest event of the year. Schedule quarterly check-ups for critical systems like refrigeration and cooking equipment.

Look for energy-efficient models that reduce your operating costs over time. The initial price tag might be higher, but the savings on your generator fuel or propane costs add up quickly.

My best advice? Start small, scale smart. Begin with the essential equipment for your core menu items, then expand as revenue allows. Your food truck can evolve alongside your business.

Service Intervals & Replacement Signals

The secret to equipment longevity is simple: consistent maintenance. Establish daily cleaning protocols for all equipment at the end of each shift. This isn't just about aesthetics—it directly impacts food safety and equipment performance.

Schedule weekly deep cleaning of hard-to-reach areas and components. Those forgotten corners and crevices can harbor bacteria or become fire hazards.

Every 3-4 months, have critical systems professionally serviced. This quarterly maintenance should include checking refrigeration systems and coolant levels, inspecting fire suppression systems, cleaning or replacing hood filters, and performing generator maintenance. One missed maintenance interval can lead to a preventable breakdown during your busiest season.

Annual comprehensive inspections should cover electrical systems, plumbing, propane lines and connections, and the structural integrity of any modifications to your truck. These thorough check-ups can identify potential issues before they become emergencies.

Watch for these warning signs that equipment needs replacement: increasing frequency of repairs, parts becoming unavailable, rising energy consumption, inability to maintain proper temperatures, or visible rust or damage to food-contact surfaces. When repair costs approach 50% of replacement cost, it's usually time to upgrade.

Here's a pro tip I share with all my clients: Keep a spare parts kit on board with commonly needed items like fuses, gaskets, and filters. This simple preparation can turn a potential day-ending breakdown into a quick 10-minute fix. One client's spare belt for their generator saved them from missing a $3,000 catering job!

What equipment does a food truck need isn't just about the initial purchase—it's about maintaining that equipment for years of reliable service. The right maintenance schedule keeps your equipment running efficiently and your food truck business profitable.

Frequently Asked Questions about Food Truck Equipment

How much does it cost to outfit a food truck with essential equipment?

When budgeting for your food truck venture, equipment costs can quickly add up. Typically, you'll need between $20,000 and $40,000 just for the essential equipment inside your truck (and that's before you even purchase the vehicle itself!).

Here's what you can expect to invest in each category:

Your cooking appliances will likely be your biggest expense at $5,000-$15,000, depending on your menu complexity. Refrigeration units add another $2,500-$5,000, while sinks and plumbing systems generally run $1,500-$3,000. Don't forget the mandatory fire suppression system at $1,000-$3,000 – this isn't optional, but required by law in most jurisdictions.

A reliable generator to power everything costs $2,000-$5,000, and those often-overlooked smallwares and utensils add another $1,000-$2,000. Your POS system might range from a simple tablet setup to a comprehensive system ($500-$2,500), and your initial stock of serving supplies will cost $500-$1,000 just to get started.

When you factor in the truck itself, exterior branding, permits, and initial inventory, most food truck entrepreneurs end up investing well over $100,000 before serving their first customer. This explains why what equipment does a food truck need is such an important question to answer correctly the first time!

What size generator should I buy for my equipment load?

Generator sizing is one area where guesswork can lead to disaster. Too small, and you'll face frustrating power outages during service. Too large, and you've wasted money on capacity you don't need.

To find your perfect match, follow this simple process:

First, make a detailed list of every electrical device in your truck along with its wattage requirements. Common examples include your griddle (typically 3,000W), refrigerator (around 1,400W), microwave (about 1,200W), water heater (approximately 3,000W), and lighting (roughly 600W).

Next, add up the total wattage needed during peak operation. For the example above, that's 9,200W. Then, add at least a 10% safety margin – so for our example, you'd need at least a 10,000W generator.

Many food truck owners find that dual-fuel generators offer valuable flexibility, allowing you to run on either gasoline or propane depending on availability and pricing. Just remember that generator noise and exhaust fumes can seriously impact your customers' experience, so if your budget allows, invest in noise-reduction features or a quieter model.

How often should major appliances be serviced or replaced?

Keeping your equipment in top shape isn't just about avoiding breakdowns – it's about food safety, efficiency, and protecting your investment. Different equipment types have their own maintenance schedules:

For refrigeration units, daily temperature checks and exterior cleaning are essential. Monthly, you should clean those condenser coils and check door gaskets for tight seals. Schedule professional service quarterly, and with proper care, expect 8-10 years of reliable service before replacement.

Your cooking equipment needs thorough daily cleaning of all food-contact surfaces, with deeper weekly cleaning that includes disassembly where possible. Have gas lines and electrical connections professionally inspected quarterly. Quality cooking equipment should last 5-10 years depending on usage intensity.

Don't neglect your generator – it's the heartbeat of your operation! Change the oil every 50-60 hours of operation, replace air filters every 100 hours, and swap spark plugs every 200 hours. Even with perfect maintenance, most food truck generators need replacement after 3-5 years of regular use.

The smartest approach is creating a detailed maintenance calendar and keeping service records for each piece of equipment. This helps you track performance patterns and budget appropriately for inevitable replacements. At PizzaPrepTable.com, we often remind our customers that preventative maintenance is always cheaper than emergency repairs – especially when those emergencies happen during your busiest service hours!

Conclusion

Equipping your food truck is a significant investment, but with careful planning and smart purchasing decisions, you can create an efficient mobile kitchen that supports your culinary vision. As we've explored throughout this guide, knowing what equipment does a food truck need is the foundation of your mobile business success.

Remember these key principles as you build your food truck dream:

Safety First: Never compromise on fire suppression, ventilation, or sanitation equipment. These aren't just good ideas—they're essential for legal operation and keeping your customers safe. That three-compartment sink might seem like it takes up precious space, but it's non-negotiable for health department approval.

Menu-Driven Decisions: Let your unique menu concept drive your equipment choices. If you're launching a gourmet burger truck, invest in the best griddle your budget allows. For a taco concept, quality hot holding equipment will maintain food integrity during busy service periods. Your equipment should support your signature dishes, not limit what you can create.

Space Optimization: In the tight quarters of a food truck, every inch matters. Multi-functional equipment and clever storage solutions aren't luxury upgrades—they're essential strategies for creating a workable kitchen. Those vertical prep stations and magnetic knife strips might seem like small details, but they'll save your sanity during rush periods.

Power Planning: Carefully calculate your electrical needs and invest in a properly sized generator. Nothing kills service faster than blown circuits or equipment that can't run simultaneously. That extra 10% capacity buffer we recommended? It's worth every penny when you're serving a line of hungry customers.

Maintenance Matters: Regular service extends equipment life and prevents costly breakdowns. The small investment in quarterly maintenance checks can save you thousands in emergency repairs and lost revenue. Keep those maintenance records current and create a replacement timeline for major equipment.

At PizzaPrepTable.com, we understand the unique challenges of mobile food service. Our team has helped outfit food trucks in New York City, Los Angeles, Chicago, and across the country with quality equipment custom to their specific needs and space constraints. We've seen how the right equipment transforms a good food truck into a great one.

Whether you're just starting your food truck journey or looking to upgrade your existing setup, our friendly experts can help you select the right tools for your concept and budget. We know that financing a food truck operation can be challenging, which is why we offer competitive financing options and nationwide shipping to get your mobile kitchen rolling quickly.

The food truck industry continues to evolve, and so do the equipment solutions available. From specialized refrigeration units to compact cooking equipment, we're committed to helping you find the perfect balance of functionality, quality, and value as you build your mobile culinary business.

For more information about our food truck equipment solutions and to stay updated on industry trends, check out our blog for more foodservice insights.