Food Truck Power Solutions: Ensuring Your Fridge and Freezer Stay On

Share

Why Reliable Power Is Critical for Food Truck Success

A food truck fridge and freezer system is only as good as the power that keeps it running. In mobile food service, electricity isn't a luxury; it's the lifeblood of your operation. Without a consistent and reliable power source, your high-quality ingredients can quickly spoil, your service grinds to a halt, and your hard-earned customers will look elsewhere. A power failure isn't just an inconvenience—it's a direct threat to your profitability and reputation.

Imagine this: it's the peak of the lunch rush, a line of hungry customers is forming, and suddenly your generator sputters and dies. The silence is deafening. Your refrigerator and freezer stop humming, and the temperature inside begins to rise. Every minute that passes pushes your perishable inventory—meats, cheeses, fresh produce—closer to the temperature danger zone (40°F to 140°F), where bacteria multiply rapidly, per USDA food safety guidance. This scenario leads to devastating consequences: hundreds of dollars in spoiled inventory, lost sales for the day, and the potential for serious health code violations that could shut you down.

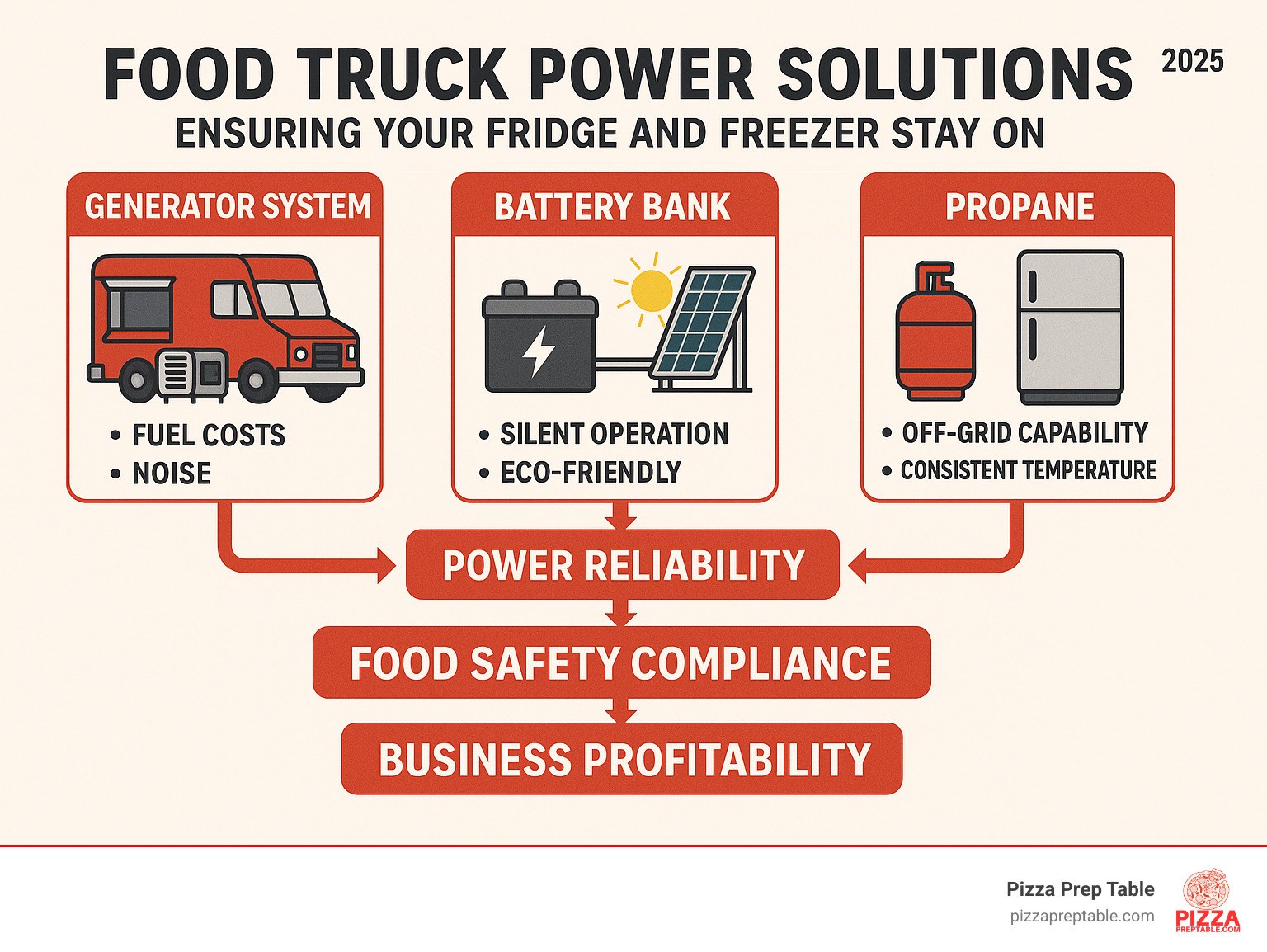

Essential power options for food truck refrigeration:

- Generator Power: The industry standard, these units are powerful enough to run an entire kitchen with standard AC appliances, but come with noise and fuel considerations.

- Battery + Inverter Systems: The silent and eco-friendly choice, perfect for noise-sensitive locations. They power efficient 12V DC or flexible AC/DC units, often paired with solar panels.

- Propane Refrigeration: The ultimate off-grid solution, using absorption technology to provide rock-solid temperatures without any electricity.

- Hybrid Setups: The best of all worlds, combining multiple power sources (like a generator for peak hours and a battery bank for quiet prep time) for maximum reliability and flexibility.

The global food truck market reached $12.5 billion in 2022 and is projected to hit $25.7 billion by 2030. This explosive growth means more competition. To stand out, operational excellence is key. Reliable refrigeration is the cornerstone of that excellence, ensuring you can maintain impeccable food safety standards and serve consistently fresh, high-quality food, which directly impacts customer satisfaction and your bottom line.

When your fridge fails, you don't just lose today's sales. You risk health code violations, wasted inventory, and a damaged reputation that can spread quickly through online reviews. That's why smart food truck operators plan their power systems first, then choose refrigeration that matches their setup.

I'm Sean Kearney, and my background in sales has taught me that understanding customer needs is everything - especially when it comes to food truck fridge and freezer systems that can make or break a mobile food business. I once worked with a new operator who bought a top-of-the-line prep table but tried to save money on a cheap, underpowered generator. On their grand opening weekend, it failed, and they lost nearly all their inventory. We helped them switch to a properly sized inverter generator, and they've been thriving ever since. From selling equipment to helping food truck owners choose the right power solutions, I've seen how the right setup separates successful operators from those who struggle.

Quick food truck fridge and freezer terms:

- food truck kitchen equipment cost

- what equipment does a food truck need

- food truck deep fryers and propane power

Powering Your Mobile Kitchen: Generators, Batteries, and Propane

Your food truck fridge and freezer needs consistent power to keep ingredients fresh and customers happy. Unlike your home refrigerator that simply plugs into the wall, mobile kitchens face unique challenges - you're moving, working in different environments, and operating without guaranteed electrical connections.

Understanding your power needs starts with calculating your total electrical load. This isn't just about adding up the running wattage of your appliances. You must also account for startup wattage (also known as inrush current or locked rotor amps), which is the extra surge of power a motor needs to get started. A refrigerator compressor, for example, might draw 3-5 times its running amperage for a few seconds when it cycles on. Failing to account for this surge will trip your breakers or overload your power source. Most commercial refrigeration units run on AC (Alternating Current) power at 115 Volts, but mobile-specific units often offer DC (Direct Current) options or combination AC/DC capability. The choice of power source directly impacts your operational costs, noise levels, and where you can set up shop.

Here's how the three main power sources stack up for food truck fridge and freezer operations:

| Power Source | Pros | Cons | Typical Cost (Unit Only) | Best Use Case |

|---|---|---|---|---|

| Generator | Reliable power for commercial refrigeration; Can power multiple appliances; Efficient for constant power needs; Ideal for long operating hours | Noise levels; Fuel costs; Ventilation requirements; Regular maintenance needed | $2,000 - $8,000+ | High-volume operations with multiple appliances and long service hours |

| Battery Bank | Quiet and clean operation; Sustainable with solar charging; Environmentally friendly; Can pair with AC/DC units; Energy savings over time | Higher upfront investment; Limited runtime; Inverter capacity requirements; Weather-dependent solar charging | $3,000 - $12,000+ | Noise-restricted areas, eco-conscious operations, shorter service periods |

| Propane | Complete off-grid capability; Energy efficient; Consistent temperature control; True portability; Lower operational costs than generators | Propane refill logistics; Safety considerations; Limited appliance options; Initial equipment investment | $1,500 - $4,000+ | Remote locations, extended off-grid operations, areas with propane supply access |

Generators: The Workhorse Option (AC Power)

Generators remain the most popular choice for powering food truck fridge and freezer units because they handle standard AC refrigeration without conversion losses. A quality generator provides reliable power for your entire kitchen setup, not just refrigeration.

Power requirements vary by refrigerator size, but most undercounter units need 3-8 amps (345-920 watts) to run, while larger prep tables can draw 10-15 amps (1150-1725 watts). Remember to factor in the startup surge. If your fridge needs 8 amps to run, it might need 24-40 amps for a moment to start. Your generator must have a high enough surge wattage capacity to handle this. For this reason, inverter generators are highly recommended over conventional models. They produce a "cleaner" electrical signal (a pure sine wave) that is safer for sensitive electronics like digital thermostats and compressors, and they are significantly quieter.

Fuel choice (gasoline, propane, or diesel) and regular maintenance are also key. Gasoline is widely available but has a shorter shelf life. Propane burns cleaner and is stable, but requires carrying tanks. Diesel is efficient but the generators are often heavier and more expensive. Regardless of type, a strict maintenance schedule of oil changes, filter cleaning, and spark plug checks is non-negotiable for reliability.

Battery Banks & Inverters: The Silent Solution

Battery-powered systems are gaining popularity among food truck operators who value quiet operation and environmental responsibility. Modern 12V DC refrigerators designed for mobile use are incredibly efficient, while AC/DC combination units offer flexibility.

The heart of this system is the deep-cycle batteries. Unlike car batteries, they are designed to be discharged and recharged many times. Common types include AGM (Absorbent Glass Mat), which are maintenance-free, and Lithium-ion (LiFePO4), which are lighter, last longer, and can be discharged more deeply, but come at a higher initial cost. To power standard AC appliances, you'll need a pure sine wave inverter, which converts the batteries' DC power to clean AC power, protecting your equipment's motors and electronics.

Solar panel integration makes battery systems even more attractive. By installing panels on your truck's roof, you can recharge during the day while serving customers. A solar charge controller is essential to manage the flow of energy from the panels to the batteries, preventing overcharging. A well-designed system with quality batteries and a proper inverter can run a food truck fridge and freezer setup for 8-12 hours, depending on size and ambient temperature. The investment pays off in reduced operational costs (no fuel!) and the ability to work in noise-restricted areas. Check out our guide on food truck kitchen equipment costs for budgeting insights.

The Benefits of Propane Refrigeration

Propane-powered refrigeration offers true independence from electrical grids. These systems use absorption cooling technology, a fascinating process where heat from a small propane flame is used to circulate a refrigerant (typically ammonia), creating cold without a compressor. This makes them incredibly reliable, vibration-resistant, and able to maintain consistent temperatures even in challenging conditions.

Energy efficiency is excellent—propane refrigerators often cost less to operate than electric units powered by generators. They're built for portability and designed to handle the rigors of mobile operations. However, propane safety is paramount. This means professional installation is a must, ensuring proper ventilation to the outside and the installation of carbon monoxide and propane leak detectors. You'll also need to plan your propane logistics, ensuring tanks are securely mounted for travel and that you have a reliable way to refill or exchange them.

While perfect for refrigeration, propane is less versatile for powering an entire kitchen. But for operators who prioritize off-grid capability and low running costs for their cold storage, it's an unbeatable solution. For more insights on propane-powered equipment, see our article on commercial deep fryers that bring the heat.

The key is matching your power choice to your operation's specific needs—service hours, location flexibility, noise restrictions, and budget all play important roles in finding the right solution for your food truck fridge and freezer setup.