Freshness Guaranteed with These Sandwich Prep Refrigerators

Share

Why Every Commercial Kitchen Needs a Sandwich Prep Refrigerator

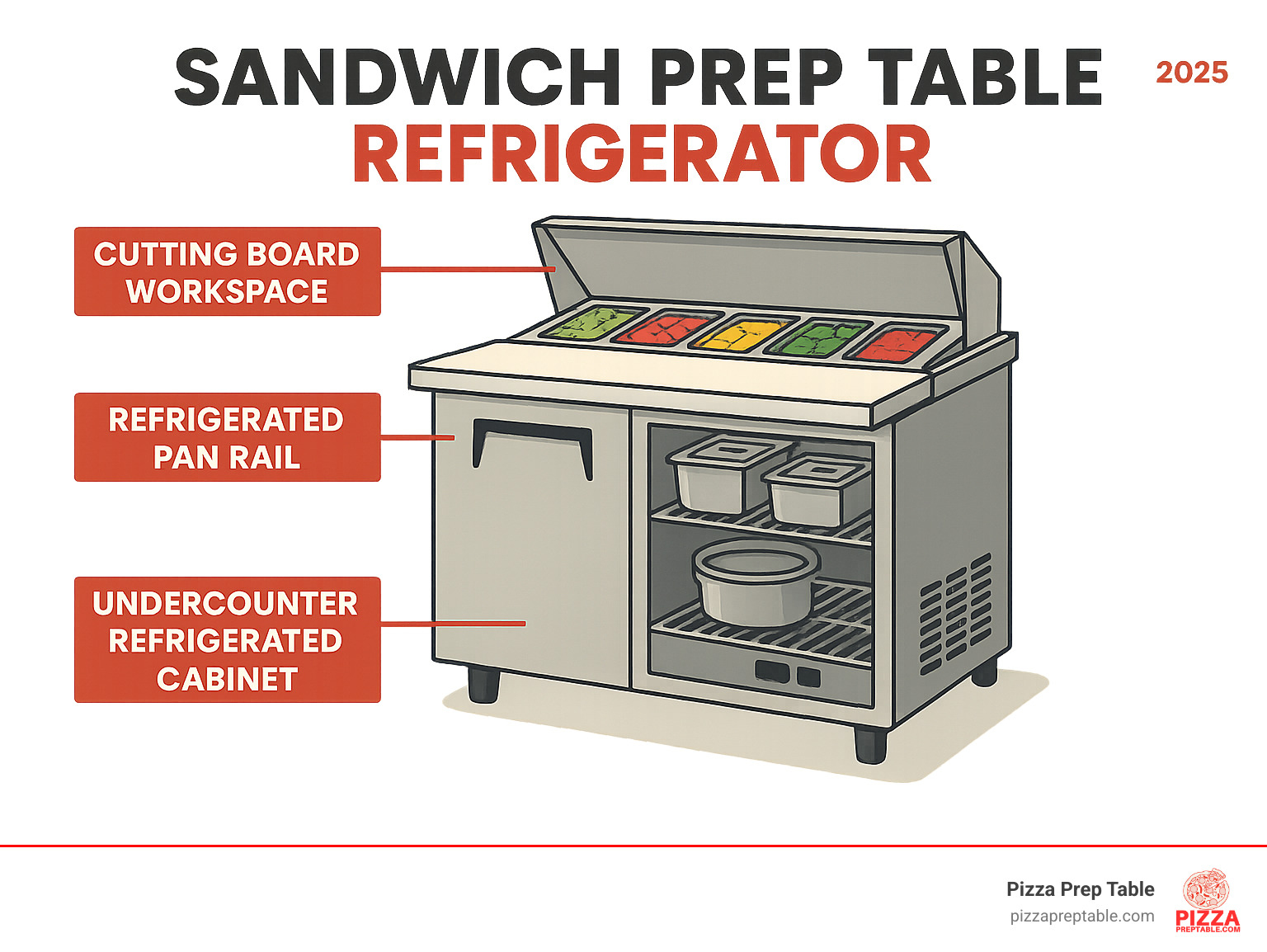

A sandwich prep table refrigerator is the ultimate space-saving solution that combines refrigerated storage, ingredient organization, and prep workspace into one essential unit. These commercial workhorses keep your most-used ingredients at food-safe temperatures while providing an efficient assembly station for sandwiches, salads, and subs.

Key Features of Sandwich Prep Table Refrigerators:

- Temperature Range: 33°F to 40°F for optimal food safety

- Standard Sizes: 27", 48", 60", and 72" widths

- Pan Capacity: 6-18 food pans depending on size

- Storage: Refrigerated cabinet space below work surface

- Materials: Stainless steel construction for durability

These units streamline your kitchen workflow by keeping ingredients within arm's reach while maintaining proper temperatures. Customer Billie Jo Olson from a commercial restaurant notes: "This product is phenomenal and is very convenient for our restaurant as it is a great place to keep all of our product within easy access and also it keeps them cold and fresh."

I'm Sean Kearney, and my sales background from Amazon.com to restaurant equipment has taught me that the right sandwich prep table refrigerator can transform your kitchen's efficiency. I've helped countless pizzeria owners and restaurant managers find equipment that maximizes their limited space while staying within budget.

Sandwich prep table refrigerator helpful reading:

Why a Sandwich Prep Table Refrigerator is a Game-Changer for Your Kitchen

In the lively world of commercial kitchens, where every second and every inch of space is precious, a sandwich prep table refrigerator isn't just another piece of equipment. It's a smart investment that can truly transform how your business operates. From boosting efficiency to making sure your food is super safe, these units are a must-have for delis, cafes, sub shops, and even busy university cafeterias.

The biggest benefit you'll notice right away is a huge improvement in how your team works. Imagine your chef putting together a sandwich, easily grabbing fresh ingredients from perfectly chilled pans, chopping veggies on a built-in cutting board, and then pulling backup supplies from the fridge below – all without taking more than a step or two! This smooth process means your team can whip out orders faster and serve more happy customers. It's all about speed and convenience, letting you get more done in less time.

But it's not just about speed. A super important advantage is how these units help you meet food safety rules. They're designed to keep ingredients at just the right cold temperatures, usually between 33°F and 40°F. This keeps them safely out of the "danger zone" (40°F – 140°F) where bad bacteria love to grow. (See the USDA Danger Zone guidance for more details.) Keeping things perfectly chilled also means less food waste, as your ingredients stay fresh and tasty for longer.

Plus, a sandwich prep table refrigerator keeps everything neat and organized. Every ingredient has its spot, making it easier to manage your stock and stop different foods from mixing (that's cross-contamination!). This organized workstation means you'll consistently make top-quality sandwiches and salads, built with fresh, perfectly chilled ingredients every time. Want to learn more about picking the right cold storage? Check out our guide on Commercial Fridge Shopping Made Easy and Cool. We also have great tips on Prep Sandwich Refrigerators That Keep Your Ingredients Fresh and Your Customers Happy.

Boost Your Workflow and Efficiency

A well-designed sandwich prep table refrigerator quickly becomes the central hub for your sandwich or salad station. It creates a smooth assembly line where all your ingredients are literally at your fingertips. This means your staff moves around a lot less. No more running back and forth to a big walk-in cooler or a separate fridge for each item! Just picture it: all your cheeses, meats, veggies, and sauces are perfectly arranged in chilled pans, right where you need them.

This smarter setup helps you get orders out much faster, which is super important when you're busy. When every ingredient is easy to grab and ready to go, your team can put together orders with amazing speed and accuracy. The cutting board, which is often part of the unit, gives you an instant workspace. This means you don't need extra prep tables. It pulls everything together, making prep not just quicker, but also more enjoyable for your staff. Seeing a chef quickly assemble a sandwich on a prep table is a common sight in kitchens that really know how to get things done!

Uphold Food Safety Standards

Keeping food safe is a top priority for any food service business – there's just no compromising. And a sandwich prep table refrigerator is a crucial part of that defense. These units are built to keep ingredients at consistently safe temperatures, typically between 33°F and 40°F. This temperature range is key because it stops harmful bacteria from growing and helps keep your fresh foods in perfect condition.

Many great models come with NSF certification. This means they meet strict public health and safety standards. An NSF certification tells you that the unit is well-designed, made from quality materials, easy to clean, and won't hide germs. These units often have special features like insulated lids. These lids cover the ingredient pans when you're not using them, adding an extra layer of protection against temperature changes and anything floating in the air. This also helps stop cross-contamination between different ingredients, keeping everything spotless and safe for your customers to enjoy. Preventing your ingredients from staying in the temperature danger zone (40°F – 140°F) is absolutely essential, and these units are champions at that.

How to Choose the Perfect Sandwich Prep Table Refrigerator

Alright, so you're ready to level up your kitchen with a sandwich prep table refrigerator! That's fantastic. But hold on a second – picking the right one isn't just about grabbing the first shiny unit you see. It's like choosing the perfect pair of shoes for a marathon; you need one that fits just right and supports you through every step of a busy service. Making a thoughtful choice here can truly transform how smoothly your kitchen runs, saving you time, effort, and even money in the long run.

When you're looking, think about a few key things. We'll dive into the size and capacity you need, the materials and construction that promise durability, the smart refrigeration system keeping things cool, whether doors or drawers make more sense for your team, and even how deep the cutting board should be. Each detail plays a big role in how well your new unit fits into your daily hustle.

Finding the Right Size and Capacity

The first big question is: how much space do you have, and how much prep do you do? The size of your sandwich prep table refrigerator directly impacts your kitchen's flow and how many ingredients you can have ready to go. You'll find these units in common widths like 27", 48", 60", and 72". A compact 27-inch model might be perfect for a small cafe or food truck, while a 72-inch beast is built for high-volume operations.

Beyond the width, think about pan capacity. This tells you how many ingredient pans (usually 1/6 or 1/9 size, up to 6 inches deep) the top rail can hold. More pans mean more variety right at your fingertips. Some models are called "Mega Top" units. These are fantastic because they offer an extended pan rail, letting you fit even more pans – sometimes 18 or more 1/6 size pans! They often come with a deeper cutting board too, like 15 inches or more, giving you extra workspace.

Don't forget the storage underneath! The cubic feet of refrigerated space below the work surface is super valuable. It's perfect for keeping backup ingredients, bulk items, or anything else you need chilled and close by. When thinking about this storage, consider if doors or drawers would work better for your team. Doors offer wide access, while drawers can be great for organizing specific items and reducing cold air loss. Whether you're eyeing a 2-door or 3-door setup, we've got more tips: check out our reviews on Slice and Dice with Ease: 2 Door Pizza Prep Fridges Reviewed and 3 Door Pizza Prep Fridges That'll Make You Say Cheese.

Understanding Materials and Refrigeration

The backbone of any good sandwich prep table refrigerator is what it's made of and how it keeps things cold. Most commercial units boast a sleek stainless steel exterior, but there's a little secret: not all stainless steel is created equal. 430 type stainless steel is common for the outside because it looks good and resists rust pretty well. But for the inside, especially where food might touch or where you clean often, 304 grade stainless steel is the gold standard. It's super resistant to corrosion and easier to keep sparkling clean, making it a real workhorse for long-term use. Some units might also use an aluminum interior, which is also tough and lightweight.

Good insulation is a total game-changer for keeping temperatures steady and saving energy. Look for units with foamed-in-place polyurethane insulation. It's like a super-efficient thermal blanket that seals in the cold air, so your fridge doesn't have to work as hard. This means more stable temperatures for your ingredients and lower electricity bills for you – win-win!

Now, let's talk about what actually cools your unit: the refrigerant. You'll increasingly see models using R290 (propane). This isn't just a trend; it's a smart, eco-friendly choice! R290 has almost no environmental impact compared to older refrigerants, with an Ozone Depletion Potential (ODP) of 0 and a Global Warming Potential (GWP) of just 3. Plus, it can actually lead to significant energy savings – some systems boast up to 40%! This efficiency often comes from being paired with smart Electronically Commutated (ECM) fan motors, which are super energy-efficient while still moving air quickly to keep everything perfectly chilled. For more on the tech behind top brands, take a peek at our insights on the Atosa Pizza Prep Table.

Our Top Picks: The Best Sandwich Prep Refrigerators of the Year

After years of helping restaurant owners find the perfect equipment, I've learned that the "best" sandwich prep table refrigerator isn't always the most expensive one—it's the one that fits your specific needs. Whether you're running a busy deli or a cozy café, the right unit can make all the difference in your daily operations.

I've narrowed down three standout models that consistently deliver exceptional performance and value. Each serves a different purpose, from high-volume operations to space-conscious kitchens. Here's how they stack up:

| Model Name | Size (Width) | Pan Capacity (1/6 size) | Refrigerant | Price Range |

|---|---|---|---|---|

| Avantco APT-48M-HC | 47" | 18 | R290 | $1,500 - $2,000 |

| True TSSU-48-12 | 48.5" | 12 | R290 | $4,000 - $5,000 |

| Avantco SS-PT-27-HC | 27.5" | 6 (plus 2 1/9 size) | R290 | $1,000 - $1,300 |

Best Overall: Avantco APT-48M-HC Mega Top Sandwich Prep Table

When customers ask me for the best bang for their buck, I consistently point them toward the Avantco APT-48M-HC. This 47-inch powerhouse strikes that sweet spot between capacity, features, and affordability that makes it perfect for most operations.

The Mega Top design is where this unit really shines. With space for 18 full-size 1/6 pans, you can keep an impressive variety of ingredients at your fingertips. Think about it—that's enough room for multiple cheeses, meats, vegetables, and condiments without constantly restocking from the walk-in cooler.

The removable 3/4-inch cutting board gives you a solid workspace that's easy to clean and sanitize. The digital temperature control keeps everything between 33°F and 40°F, while the R290 refrigerant makes it an environmentally responsible choice with zero ozone depletion potential.

Customer feedback has been overwhelmingly positive. Quiana Redd called it "absolutely beautiful" right out of the box, while Michael Koritko praised the "roomy bottom storage" and generous top area for toppings.

Most Durable: True TSSU-48-12 Solid Door Sandwich/Salad Unit

If durability is your top priority and budget allows, True Manufacturing sets the gold standard. The True TSSU-48-12 represents everything I love about American-made commercial equipment—it's built to last decades, not just years.

What sets True apart is their oversized refrigeration system that's factory-balanced for optimal performance. This means faster temperature recovery when you're opening and closing the unit frequently during busy rushes. The all-stainless steel construction isn't just about looks—it's about creating a unit that can handle the daily abuse of a commercial kitchen while maintaining its professional appearance.

The patented forced-air design ensures every corner of your sandwich prep table refrigerator maintains consistent temperatures. Yes, you'll pay more upfront, but True units often run for 15-20 years with minimal maintenance. That's why so many established restaurants swear by them.

For more True options that might fit your specific needs, browse our True Pizza Prep Table collection.

Best for Compact Spaces: Avantco SS-PT-27-HC

Small kitchens deserve big performance too. The Avantco SS-PT-27-HC proves that you don't need to sacrifice functionality when space is at a premium. I recommend this unit constantly for food trucks, small cafés, and operations that need an efficient auxiliary prep station.

At just 27.5 inches wide, this compact unit still manages to accommodate 6 full-size pans plus 2 smaller ones—plenty for a focused menu. The ADA-compliant height of 33 5/8 inches makes it accessible for all staff members, while the 6 cubic feet of refrigerated storage below keeps backup supplies close at hand.

Don't let the smaller size fool you. This unit uses the same R290 refrigerant as its bigger siblings and maintains the same precise temperature range. Customers consistently praise it as "cost-efficient" and a "good value for the money," especially when every square inch of kitchen space counts.

If you're working with limited space, you might also find our guide Keep Cool and Carry On: The Ultimate Commercial Fridge Freezer Combo Guide helpful for maximizing your kitchen's efficiency.

Maintenance, Cleaning, and Warranty Essentials

So, you've found the perfect sandwich prep table refrigerator for your kitchen. That's fantastic! But just like a trusty car, your new equipment needs a little TLC to keep purring along happily. Think of it this way: a small effort now saves you big headaches (and repair bills!) later. Taking care of your unit is key to its long life and consistent performance.

Let's talk about the heart of your unit: the condenser coils. These hardworking coils are like your fridge's lungs, and they can get pretty dusty and greasy in a busy kitchen. When they get clogged, your sandwich prep table refrigerator has to work extra hard, guzzling more energy and even shortening its life. Nobody wants that!

So, how often should you show them some love? While every manufacturer is a little different, a good rule of thumb is to clean them every 1 to 3 months. If your kitchen is a high-volume, greasy wonderland, you might lean towards more frequent cleanings. You'll know they're crying for attention if your unit is running non-stop, not chilling things as well, or feeling unusually hot. Some clever brands, like Everest Refrigeration, even feature "reverse fan motors" that give a little puff of air to help keep those coils cleaner. Pretty neat, right?

Beyond the coils, your unit needs a little daily sparkle. Make it a habit to wipe down all exterior surfaces, clean out the ingredient pans, and give that cutting board a good scrub and sanitize. That cutting board, especially, is a prime spot for germs if not cleaned properly, so make sure it's spic and span every day!

And don't forget the gaskets! Those rubbery seals around your doors and drawers are super important. Give them a quick once-over to check for any tears or worn spots. A leaky gasket is like leaving a window open in winter – cold air escapes, and your fridge works overtime. Plus, it can mess with those crucial food safety temperatures. If you have "snap-in" door gaskets, consider yourself lucky – they're a breeze to remove, clean, or even replace if needed, keeping that cold air locked right where it belongs.

Finally, let's talk about your peace of mind: the warranty. It's easy to overlook this when you're excited about a new piece of equipment, but it's your safety net! Most units come with a standard warranty, usually covering parts and labor for a year or two. This is great for those initial hiccups.

But here's a pro tip: some brands truly stand behind their products. Take Everest, for example. They often offer extended warranties, sometimes covering 3 years for parts and labor, 5 years for electrical components, and even a whopping 10 years for the compressor! Now that's confidence in their build quality! A strong warranty like this isn't just a piece of paper; it can save you a fortune in potential repair costs down the road. Always, always peek at the warranty details before you buy.

Frequently Asked Questions about Sandwich Prep Tables

After helping hundreds of restaurant owners choose their perfect sandwich prep table refrigerator, I've noticed the same questions come up again and again. Let me share the answers that have helped my customers make confident decisions.

What's the difference between a sandwich prep table and a pizza prep table?

This is probably the most common question I get, and it's a smart one to ask. While both units keep ingredients cold and within reach, they're designed for completely different prep styles.

The cutting board depth is the biggest giveaway. A sandwich prep table refrigerator typically has a cutting board that's 8" to 15" deep—perfect for slicing tomatoes, chopping lettuce, or assembling subs. Pizza prep tables need much more real estate, often 19" or deeper, because you're stretching dough and building those 16" pizzas.

The pan rail design tells a similar story. Sandwich prep tables feature straight, accessible rails that let you grab diced onions or sliced cheese quickly. Pizza prep tables often have curved or angled rails that work better with the circular motion of pizza assembly and accommodate larger pans of sauce and toppings.

Finally, refrigeration needs can vary slightly. Pizza prep tables sometimes pack more cooling power in their pan rails because they're dealing with hot dough and intense kitchen heat. For more details on these differences, check out our guide on Sandwich Prep Table Refrigerator.

How often should I clean the condenser coils on my unit?

I wish I had a dollar for every time someone asked me this after their unit started acting up! The honest answer depends on your kitchen environment, but here's what I tell my customers.

In a high-volume kitchen with fryers and lots of grease in the air, you'll want to clean those coils every 1-3 months. If you're running a smaller cafe or have a cleaner environment, every 3-6 months should do the trick.

Your unit will tell you when it needs attention. Watch for signs of a dirty coil like the compressor running constantly, temperatures creeping up, or your energy bills climbing. The unit might also feel unusually hot on the outside.

The manufacturer's manual will give you specific recommendations, but don't ignore what your equipment is telling you. A few minutes of coil cleaning every couple months beats a costly compressor replacement down the road.

Are drawers better than doors for a sandwich prep table refrigerator?

This question usually comes down to workflow preferences and budget, and I've seen successful kitchens using both styles effectively.

Drawers shine in accessibility—you can pull them out and see everything at once without bending over or digging around in the back of a cabinet. This makes inventory checks faster and reduces the back strain on your staff during busy shifts.

For organization, drawers are hard to beat. They're perfect for storing ingredients in specific pan configurations, and many come with dividers that keep everything tidy. If you're constantly working with full-size or half-size pans, drawers accommodate them beautifully.

The cost difference is real, though. Drawer units typically run more expensive because of the engineering required for smooth, durable sliding mechanisms. Traditional doors remain a solid, budget-friendly choice that gets the job done.

Pan compatibility is another consideration. If your operation relies heavily on organized pan storage and quick access to bulk ingredients, the investment in drawers often pays for itself in efficiency. But if you're working with smaller quantities or have budget constraints, doors work perfectly well.

I always tell customers to think about their daily workflow. If quick, organized access will save your team time during rush periods, drawers might be worth the extra investment. Otherwise, doors are a proven solution that thousands of successful kitchens rely on every day.

Conclusion

Investing in a sandwich prep table refrigerator is one of the smartest moves you can make for your commercial kitchen. It's not just another appliance—it's your secret weapon for creating a more efficient, profitable operation. These versatile units transform chaotic prep areas into streamlined workstations where every ingredient has its place and every movement has purpose.

Throughout this guide, we've explored how these game-changing units boost your workflow, keep food safety standards rock-solid, and help you serve consistently fresh products that keep customers coming back. Whether you need the mega top capacity of the Avantco APT-48M-HC, the bulletproof durability of the True TSSU-48-12, or the space-saving efficiency of the compact Avantco SS-PT-27-HC, there's a perfect match for your operation.

The right sandwich prep table refrigerator pays for itself through reduced food waste, faster service times, and happier staff who can work more efficiently. The eco-friendly R290 refrigerant in modern units also means you're making a responsible choice for the environment while potentially saving up to 40% on energy costs.

Don't forget that proper maintenance—especially those condenser coil cleanings—will keep your investment running smoothly for years to come. And with solid warranty coverage, you can focus on what you do best: creating delicious food that keeps customers satisfied.

At PizzaPrepTable.com, we've been helping restaurant owners from New York City to Los Angeles find the perfect equipment solutions. We know that cash flow matters, which is why we offer flexible financing options including our popular "Rent–Try–Buy" program. You can test-drive your equipment and put 60% of your rental payments toward the purchase price—perfect for both independent shops watching every penny and larger establishments planning major upgrades.

Your kitchen deserves equipment that works as hard as you do. Explore our complete collection of Pizza and Sandwich Prep Tables today and find how the right sandwich prep table refrigerator can transform your operation from good to absolutely outstanding.