Essential Guide: How to Store Meat Without Refrigeration Safely in a Pizzeria

Share

Let's be real—the old-school methods of storing meat like curing, salting, smoking, and drying were incredible feats of survival before refrigeration. They work by yanking moisture out to stop bacteria in its tracks. While fascinating, for a modern pizzeria, these techniques are completely off the table for daily operations. They’re not practical for the speed of a commercial kitchen, and more importantly, they’re not compliant with modern health codes without a specific, approved plan.

Handling a Power Outage in Your Pizzeria

It’s every pizzeria owner's nightmare. The middle of a dinner rush, the ovens are blazing, and suddenly... silence. The lights die, the hum of your pizza prep table vanishes, and a knot forms in your stomach. A power outage is a direct threat to thousands of dollars in perishable inventory, especially all those premium meat toppings like pepperoni, sausage, and prosciutto.

This isn’t about some romantic, off-grid fantasy. This is about emergency management in a fast-paced pizzeria where every minute counts. Your immediate actions will decide whether you're looking at a minor headache or a catastrophic financial loss from spoiled toppings. The mission is simple: protect your product, keep your food safe, and ride out the crisis until the power comes back on.

First Moves When the Power Goes Out

The second the power cuts, your only priority is temperature control for the ingredients in your pizza prep table. Every single second matters.

The number one rule: Do not open your pizza prep table or any other cooler. A well-insulated commercial unit is your best friend here. It can hold a safe temperature for about four hours, but only if it stays sealed tight. Opening the lid for even a "quick peek" at the pepperoni is a costly mistake. You’re letting precious cold air escape and inviting warm, bacteria-friendly air inside.

Grab a notepad or your phone and immediately jot down the exact time the outage started. This isn't just busywork; it's critical for tracking how long your meats have been creeping into the "temperature danger zone"—that nasty window between 40°F and 140°F where bacteria throw a party on your toppings.

Your response needs to be disciplined and immediate. Yell it from the rooftops if you have to: "Nobody opens the pizza prep tables!" That trapped cold air is the most valuable asset you have right now.

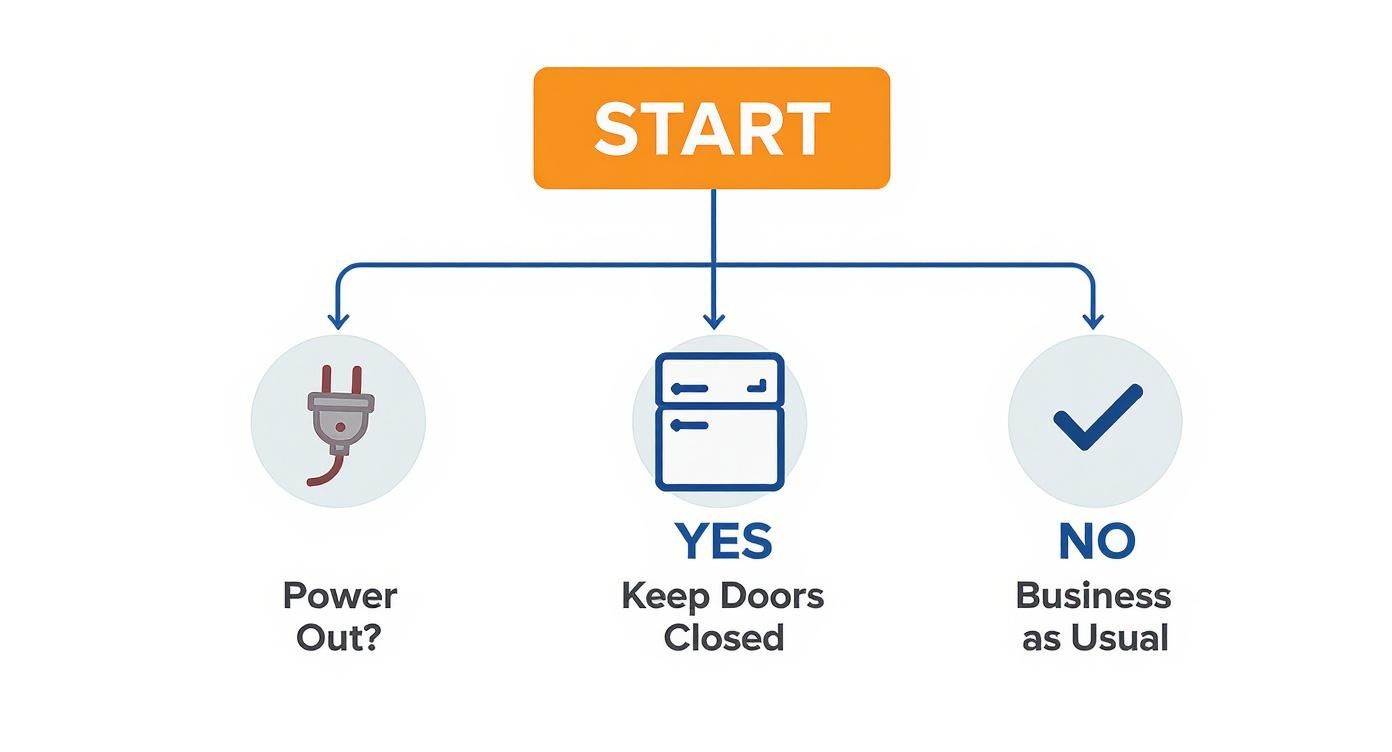

This flowchart lays it out perfectly for a pizzeria scenario. It’s the first, most critical decision you need to make.

This visual just hammers home the most important rule for minimizing product loss and keeping your pizza ingredients safe: keep those lids and doors shut.

Assessing the Damage and Cutting Your Losses

After you’ve locked down your pizza prep tables and coolers, it's time to play detective. Figure out the potential length of the outage. Is it just your pizzeria, or is the whole grid down? Your next moves depend entirely on that information.

Here’s a quick-reference table your pizza-making staff can use the moment the lights go out. It prioritizes the most critical actions to save your meat toppings.

Immediate Actions for Meat During a Pizzeria Power Outage

| Priority | Action Item | Rationale & Key Consideration |

|---|---|---|

| 1 (Immediate) | Keep All Pizza Prep Table Lids Closed | A sealed commercial unit holds its temperature for about 4 hours. Every opening drastically shortens this window. This is non-negotiable for your toppings. |

| 2 (First 5 Mins) | Note the Exact Time of Outage | Crucial for tracking exposure to the temperature danger zone (40°F - 140°F). This log is vital for your HACCP plan and any insurance claims. |

| 3 (First 15 Mins) | Assess Outage Duration | Contact the power company. A 1-hour outage requires a different response than an 8-hour blackout. This information dictates your entire strategy. |

| 4 (Contingency) | Source Dry Ice or Ice Blocks | If the outage looks like it will last longer than 2-4 hours, start sourcing supplemental cooling to place inside your pizza prep table's storage. |

| 5 (Long-Term) | Identify Off-Site Storage | For extended outages, have a plan to move high-value meats to another pizzeria or cold storage facility. A local partner can be a lifesaver. |

A plan on paper helps keep everyone calm and focused when chaos hits the pizzeria. Make sure your team knows these steps by heart.

So, how do you play it?

- Short-Term Outage (Under 2 Hours): Just keep everything sealed in the prep tables. Your toppings should be perfectly fine. Once the power is back, use a thermometer to check temps before resuming service.

- Long-Term Outage (Over 2-4 Hours): Now you need to execute your backup plan. This is where you might use dry ice to keep your prep tables cold or start making calls to transfer your most expensive meats to a buddy's pizzeria or an off-site refrigerated facility.

For any pizzeria running a mobile operation or working in an area with an unreliable power grid, having a solid backup is non-negotiable. We dive deep into this in our guide to food truck power solutions.

Ultimately, while these emergency tactics can save your bacon (literally), they all point to one simple truth for any pizzeria: nothing beats reliable, consistent refrigeration from a quality pizza prep table. It's the only real standard for daily operations.

The History Behind Your Pizza Toppings

Long before electricity buzzed through kitchens and powered the reliable chill of a pizza prep table, keeping meat safe to eat was a matter of pure survival. The techniques our ancestors perfected weren't just culinary traditions—they were life-saving innovations that built the foundation of modern food safety.

Thinking about these old-school methods really drives home why trying to store meat without a proper pizza prep table is a fascinating science experiment but a terrible business practice for any modern pizzeria.

The basic idea behind every single one of these techniques is simple: control moisture. The nasty bacteria that cause foodborne illness need water to grow and multiply. By taking that water away, our ancestors slammed the door shut on spoilage. This is the exact science that turns fresh pork into the pepperoni, salami, and prosciutto that are staples on your pizzeria's menu today.

The Power of Salt and Smoke

Salting is probably the oldest trick in the book. When you pack meat in salt, osmosis gets to work, aggressively pulling water out of the meat's cells. This creates an environment so dry that most bacteria simply can't survive. The process doesn't just preserve the meat; it also concentrates its flavor, giving cured pizza toppings that rich, savory taste we all know and love.

Smoking was another stroke of genius. It does way more than just add that delicious, smoky flavor. The smoke itself is loaded with natural compounds that kill microbes, adding another layer of defense. On top of that, the gentle, low heat of a smokehouse slowly dries the meat out, reducing the moisture even further and creating a tough, protective outer layer.

For centuries, these methods were the pinnacle of food safety technology. In the 19th century, before refrigeration became common, families depended on these skills to get through the lean months. Techniques like salting, drying, smoking, and pickling were essential. As you can read in this fascinating overview of historical food preservation, these processes could extend the usability of meat from just a few days to many weeks or even months, ensuring a stable food supply year-round.

This history is why we have names like "summer sausage." It was a product designed to be made in the cold winter months and safely eaten during the summer heat, all without needing a cold cellar.

Curing: From Ancient Times to Modern Pizza Toppings

Curing takes these basic ideas and turns them into an art form. It’s a sophisticated blend of salting, spicing, and sometimes smoking, often involving specific curing salts like sodium nitrite. These salts are incredibly effective at stopping the growth of the really dangerous stuff, most notably Clostridium botulinum, the bacteria that causes botulism.

- Dry Curing: This is where you rub the meat with a salt-and-spice mix and let it age over a long period. This process is how you get classic pizza toppings like pepperoni and prosciutto.

- Brine Curing: For this method, the meat is submerged in a saltwater solution (a brine), which soaks into the muscle to preserve it from the inside out. This is common for meats like bacon or Canadian bacon.

These are the direct ancestors of the cured meats that are non-negotiable in a pizzeria. The pepperoni on your top-selling pie is a product of this rich history—it's dry-cured, seasoned, and fermented, a process that makes it shelf-stable before it's opened.

But here’s the critical part for your pizzeria: the second you slice open that vacuum-sealed package of pepperoni, the game changes. The protective barrier is gone. It’s immediately exposed to airborne contaminants and must be kept under constant, reliable refrigeration in your pizza prep table.

Knowing these origins gives you a deeper respect for the pizza prep table you depend on every single day. While salting and smoking were revolutionary for their time, they were also labor-intensive and incredibly risky if not done with absolute precision. They underscore a fundamental truth for any pizzeria: modern refrigeration isn't a luxury. It's the absolute, non-negotiable standard for guaranteeing public health.

Emergency Preservation Techniques for Your Pizzeria's Kitchen

Let's be honest: when the power goes out in your pizzeria for more than a few hours, every minute is a race against the clock. The threat of losing thousands of dollars in high-value meat toppings is very real. This is where a little old-school knowledge stops being historical trivia and becomes a critical last-ditch effort to save your product.

These techniques are your emergency brake—not a replacement for your pizza prep table. We’re talking about crisis management for raw, unprocessed meats like sausage or ground beef only. The goal is simple and singular: stop spoilage in its tracks and buy yourself some time.

People have been preserving meat without refrigerators for millennia, driven by pure necessity. The earliest records from Mesopotamia around 3000 BC show methods of drying, salting, and submerging meat in sesame oil. By 200 BC, the Roman Empire had turned salt curing into a widespread practice. This isn't new science; it's survival. You can explore more of the rich history of cured meats on eatcuredmeat.com.

Mastering the Salt Cure in a Pinch

For a modern pizzeria caught in a power outage, a dry salt cure is probably the most accessible method for bulk raw meats. You don't need fancy gear, just a whole lot of salt and a cool, dry place. The science is simple: the salt pulls moisture out of the meat through osmosis, creating an environment where bacteria just can't multiply.

You’ll need a massive amount of non-iodized salt, like kosher or sea salt—enough to completely bury the meat.

- Prep is key: Pat every piece of meat completely dry with paper towels. Any surface moisture will sabotage the process from the start.

- Get burying: In a non-reactive container (a stainless steel hotel pan is perfect), lay down a thick bed of salt. Place the meat on top and then cover it completely, making sure every inch of the surface is packed in salt.

- Find a cool spot: Store the container in the coolest, driest, and best-ventilated corner of your pizzeria kitchen, away from pests.

This isn't a fast process. Depending on the cut's thickness, it can take days or even weeks. It demands attention, but it can be the one thing that saves your expensive bulk sausage or meatballs from the dumpster.

Creating an Emergency Brine

Brining, or using a saltwater solution, is another powerful tool in your emergency kit. It’s often quicker than a dry cure for smaller cuts like chicken breasts. A basic brine is just salt and water, but in a crisis, you're not just flavoring the meat—you're preserving it.

A successful preservation brine has to be incredibly concentrated, far saltier than anything you'd use for regular cooking.

An emergency brine is all about taking control. By surrounding the meat with a high-salinity solution, you force water out of the cells while the salt rushes in. This two-pronged attack is brutally effective at stopping microbial growth.

The big challenge for a pizzeria, of course, is keeping the brine cool without a fridge. You can submerge your brining container in a larger bin filled with cold tap water and any ice you can scrounge up. If you happen to have a portable ice maker, now's the time to run it until the power is gone for good. Our guide on the best portable electric ice makers shows just how valuable these little machines can be in a pinch.

Comparing Emergency Preservation Methods

Deciding what to do when the pressure is on comes down to what you have on hand and what kind of meat you're trying to save. This isn't a time for guesswork; you need a clear plan for your pizzeria.

| Method | Time Required | Equipment Needed | Best For (Pizzeria Meats) | Safety Level |

|---|---|---|---|---|

| Dry Salt Cure | Days to weeks | Large pans, lots of non-iodized salt | Bulk raw sausage, pork shoulder | High (if done correctly) |

| Brining | Days | Food-grade buckets, salt, water | Chicken breasts, smaller pork cuts | Moderate (requires cooler temps) |

| Dehydration | 8-12 hours | Convection oven (intermittent power) | Thinly sliced meats for jerky | High (if fully dried) |

Each method has its place in a crisis. The dry cure is reliable for big, valuable cuts of raw meat, while brining works faster on smaller items.

If you’re lucky enough to have intermittent power, don't overlook your pizza convection oven. By setting it to its lowest temperature (140-160°F) and propping the door open for airflow, you can turn it into a makeshift dehydrator. Slicing meat very thinly and drying it is an incredibly effective preservation method, but it hinges entirely on having that flicker of electricity.

Ultimately, these ancient techniques are a stark reminder of the safety and convenience we get from modern refrigeration. They are your absolute last resort, proof of why that pizza prep table is one of the most vital pieces of equipment in your entire pizzeria.

Navigating Food Safety and HACCP Compliance in Your Pizzeria

While the old-school preservation methods are fascinating, they belong to a completely different world than the one you manage in your pizzeria. In a commercial kitchen, there’s zero room for error. Your legal and ethical duty is to serve safe pizza, and that means leaving historical practices in the past and embracing the strict, non-negotiable reality of modern food safety regulations.

This is where good intentions collide with hard science. When raw meat toppings aren't stored correctly, your pizza prep table quickly becomes a five-star resort for dangerous pathogens like Salmonella, E. coli, and Listeria. These aren't just names you see on a food safety poster; they’re the culprits behind severe foodborne illnesses that can destroy your customers' health and your pizzeria's reputation.

The Unforgiving Temperature Danger Zone

At the very heart of pizzeria food safety is one critical concept: the temperature danger zone. This is the range between 40°F and 140°F (4°C and 60°C) where bacteria don't just survive—they thrive, multiplying at an alarming rate. For any pizzeria, keeping toppings like sausage, chicken, and meatballs out of this zone is the single most important job of your entire operation.

Letting meat sit in this zone is a gamble you simply cannot afford to take. Every minute it spends there, the risk of pathogenic growth skyrockets, turning perfectly good pizza toppings into a serious health hazard. This isn't just a friendly suggestion; it's a critical control point that forms the entire foundation of any legitimate food safety plan.

Your pizza prep table isn't just a workspace; it's a fortress built to defend your toppings against the danger zone. Its sole purpose is to hold a constant, safe temperature below 40°F, ensuring every single pizza you serve meets the highest safety standard.

Understanding Your Pizzeria's HACCP Responsibilities

Every professional kitchen, including your pizzeria, operates under a system known as HACCP (Hazard Analysis and Critical Control Points). It's a systematic way to find and control any potential hazard in your pizza-making process, from receiving ingredients to serving the final pie. Storing meat without proper refrigeration doesn't just bend the rules—it shatters the core principles of any HACCP plan.

- Hazard Analysis: This is where you identify what could go wrong. A power outage that knocks out your pizza prep table is a classic example of a biological hazard.

- Critical Control Points (CCPs): These are the steps where you can stop a hazard. Refrigerated storage in your prep table is the most fundamental CCP for meat toppings.

- Monitoring Procedures: This means regularly checking your CCPs. Think daily temperature logs for every single pizza prep table and cooler in your kitchen.

These principles aren't optional. They are the framework that keeps your pizzeria safe, legal, and trusted by the people who eat your food. To really get a handle on this, check out our in-depth guide on what HACCP food safety means for your pizzeria, which breaks down these crucial responsibilities.

Recognizing the Warning Signs of Spoilage

Even with the best pizza prep table in the world, nothing replaces vigilance. You and your team need to be experts at spotting meat that has turned. Relying only on expiration dates is a rookie mistake; your own senses are the final line of defense.

Train your pizzeria staff to look for these undeniable signs:

- Off-Odors: Spoiled meat has a distinct, pungent smell—it might be sour, or even have an ammonia-like tang. If a topping doesn't smell right, it's not right.

- Discoloration: Fresh meat has a vibrant, healthy color. Any patches of gray, green, or brown on your sausage or chicken are a massive red flag.

- Slimy Texture: A sticky or slimy film on the meat's surface is a clear sign that a bacterial colony is already well-established.

When you find spoiled meat in your prep table, there is only one move: throw it out immediately. Don't ever try to "cook it off" or salvage parts of the product. The risk to your customers and pizzeria is just too immense.

Ultimately, while the history of storing meat without refrigeration is rich, it serves as a powerful reminder of why we depend on modern technology. Your pizza prep table is your partner in this, helping you uphold the highest standards of safety, quality, and compliance day in and day out.

Why Your Pizza Prep Table Is Irreplaceable

After digging into the intense labor and serious risks of old-school preservation, we have to bring the conversation back to the undisputed heart of any modern pizzeria. The historical methods for storing meat without refrigeration are a fascinating look at human ingenuity when faced with no other choice.

Dehydration and curing go way back—as early as 12,000 BC—while canning was a huge leap forward in the 1790s. But the game completely changed when artificial refrigeration hit the scene in the 1800s. It set a new gold standard for safety and scale that traditional methods just can't touch. As you can read in this detailed history of food preservation on Madgetech.com, modern refrigeration is what makes the entire food service industry possible today.

This brings us to a foundational piece of equipment in your pizzeria: the pizza prep table. It isn't just a stainless steel counter with some cold storage underneath; it's the command center for quality control, workflow, and staying on the right side of the law. It is, without a doubt, an irreplaceable asset for any pizza business.

The Guarantee of Consistent Temperature Control

The single most critical job of your pizza prep table is its unwavering ability to hold a precise, cold temperature for your toppings. Unlike the risky and variable alternatives we've discussed, a quality unit creates a stable environment that keeps your pepperoni, sausage, and chicken safely below the 40°F danger zone.

This isn't just about avoiding spoilage. It's about delivering a consistent, high-quality pizza every single time. Ingredients held at the right temperature keep their texture, flavor, and integrity, which means the last pizza of the night is just as delicious and safe as the first.

A pizza prep table is not an expense; it's a critical investment in your pizzeria's reputation. Every customer who walks through your door trusts that you've handled their food with the highest possible standard of care. Your prep table is the silent workhorse that makes fulfilling that promise possible.

Streamlining Workflow for Faster Pizza Service

Picture your dinner rush without a pizza prep table. Your team would be running back and forth to the walk-in, swinging doors open and shut, and wasting precious seconds that absolutely kill ticket times. The design of a modern pizza prep table is a masterclass in kitchen ergonomics.

Everything your pizza makers need is right there within arm's reach, perfectly chilled and organized in refrigerated pans. This setup slashes wasted motion and decision-making, letting your crew build pizzas with speed and precision.

- Forced-air refrigeration systems make sure cold air circulates evenly around the food pans, getting rid of the warm spots that can compromise food safety.

- Insulated lids are crucial for protecting ingredients from ambient kitchen heat when not in use, locking in temperature and freshness on the pizza line.

- Integrated cutting boards provide a dedicated, sanitary workspace directly above your chilled ingredients, maximizing every inch of your line.

This streamlined process means faster pizza service, happier customers, and a less chaotic kitchen—all of which directly boost your bottom line.

Meeting and Exceeding Health Department Codes

At the end of the day, your ability to legally operate your pizzeria hinges on meeting strict health department codes, and your refrigeration is front and center during any inspection. A commercial pizza prep table is built specifically to satisfy these demanding standards.

Look for the NSF (National Sanitation Foundation) certification on any unit you're considering. This mark is your guarantee that the equipment is built with safe materials, is easy to clean, and performs reliably under the stress of a commercial pizzeria. Trying to get by with a residential unit—or worse, trying to store meat on the line without refrigeration—is a fast track to health code violations, hefty fines, or even a forced shutdown.

Your pizza prep table is the physical proof of your commitment to food safety. It’s the tool that lets you uphold your HACCP plan, protect your customers, and build a successful, trusted pizzeria.

Common Questions About Pizzeria Meat Storage and Safety

Navigating the rules of meat storage can feel a little tricky, but getting it right is fundamental to running a safe and successful pizzeria. We get a lot of questions from owners about what to do in emergencies, how to handle specific meats, and how to stay on the right side of the health department.

Let’s tackle some of the most common ones. You'll see a running theme here: for a pizzeria, nothing beats a consistent, reliable pizza prep table.

How Long Are Meat Toppings Safe in a Pizza Prep Table During a Power Outage?

A well-maintained commercial pizza prep table, with its doors and insulated lids kept shut tight, can typically hold a safe temperature for about four hours. The absolute golden rule is to keep the unit closed. Every time someone opens a lid to "check" on the pepperoni, precious cold air escapes and the clock starts ticking faster.

As soon as the power kicks back on, your first move should be to grab a calibrated food thermometer and check the internal temperature of the meat. If anything has been sitting above 40°F (4°C) for two hours or more, it has to be thrown out. No exceptions. This is a critical control point in your HACCP plan and is non-negotiable for customer safety.

Can I Use Cured Meats Like Pepperoni Without Refrigeration?

This is a really common point of confusion in pizzerias, and it’s a crucial one to get right. It's true that cured meats like pepperoni and salami are preserved through salting and drying, but that only applies before the package is opened. An unopened, shelf-stable cured sausage is perfectly fine stored in a cool, dry pantry.

But the moment you slice that package open and put it in your prep line, it becomes vulnerable to airborne bacteria. In a commercial pizza prep line, every single opened meat—cured or not—must be kept under constant, proper refrigeration. End of story. This protects both the quality and the safety of your pizza toppings.

Think of the vacuum-sealed packaging as a protective shield. Once that shield is broken by opening it, the meat is exposed and its storage requirements change instantly. Refrigeration in your pizza prep table then becomes its only line of defense against spoilage.

What Is the First Thing to Do When the Pizzeria's Power Goes Out?

Your first and most important action is to note the exact time the outage began. This creates a clear, documented timeline for your HACCP records. Your next step is to tell all staff, in no uncertain terms, to keep every single refrigeration unit completely closed—especially your pizza prep tables.

If you have a backup generator, getting your pizza prep tables back online should be your top priority. For a longer outage, you'll need to make a quick decision: either move high-value inventory to a working off-site facility or use dry ice to maintain internal temperatures. Your primary goal is to keep all meat toppings below that 40°F (4°C) threshold. Always, always prioritize safety over trying to save a few dollars of inventory.

Are Traditional Preservation Methods Legal in a Pizzeria?

Trying to use traditional methods like salt curing or smoking to preserve fresh meat on-site is a whole different ballgame—and it’s not something you can legally do during an emergency power outage.

To properly and legally cure meat in a licensed pizzeria, you need a detailed, pre-approved HACCP plan, tons of documentation, precise environmental controls, and explicit permission from your local health department. The methods we discussed earlier are for understanding the science of food preservation, not for regular practice in a commercial pizzeria.

For any pizzeria, the real answer to "how do you store meat without refrigeration?" is simple: you don't. A reliable, NSF-certified pizza prep table isn't a luxury; it's the bedrock of your business. Pizza Prep Table provides the high-quality, dependable refrigeration you need to protect your inventory, streamline your workflow, and guarantee the safety of every pizza you serve.