The Pizzeria Owner’s Guide to Kitchen Prep Table Stainless Steel

Share

In any high-volume pizzeria, the kitchen prep table stainless steel is the heart of the operation. It's the durable, hygienic, and efficient command center for everything from dough stretching and saucing to topping assembly. For a pizzeria, this isn't just another piece of furniture; it's the central hub where speed, consistency, and quality are born, making it one of the most critical investments for your success.

The Unsung Hero of Every Great Pizzeria

Step into any thriving pizzeria during the dinner rush, and you'll see it: the stainless steel prep table, right in the thick of the action. It's more than just a surface—it's the command center where dough gets stretched, sauces are spread, and every pizza masterpiece is built from the ground up. This guide is built on one simple truth: the right prep table can transform a chaotic kitchen into a high-efficiency pizza production line.

We're going to move beyond generic advice and give you practical, pizzeria-specific insights. Understanding why this single piece of equipment is so vital is the first step toward making a smart purchase that directly boosts your bottom line and builds customer loyalty.

Why This Table Is Your Pizzeria's MVP

A kitchen prep table stainless steel is the absolute cornerstone of a pizzeria's workflow. This isn't just about having a place to put things; it's about creating a system that supports your pizza makers when the orders are flying in. The non-porous surface of stainless steel is non-negotiable for hygiene, especially when you're working with raw dough and fresh ingredients all day long.

This one piece of equipment has a direct impact on:

- Speed and Efficiency: A well-placed table cuts down on wasted steps, allowing your pizza makers to work faster and push out more pies per hour.

- Product Consistency: When you have a dedicated, organized space, every pizza gets the same meticulous attention to detail, from sauce distribution to topping placement.

- Sanitation and Food Safety: That smooth, easy-to-clean surface is crucial for preventing cross-contamination and sailing through health inspections without a headache, especially when dealing with flour and raw ingredients.

In the fast-paced world of pizza kitchens, these tables have become indispensable. Market analysis shows the global pizza prep tables market, overwhelmingly dominated by durable stainless steel models, was valued at USD 0.4 billion in 2019 and is expected to climb to USD 0.6 billion by 2030.

For a pizzeria, the prep table isn't just furniture—it's a tool that dictates the entire rhythm of your kitchen. The right one enables seamless pizza production, while the wrong one creates constant friction and bottlenecks.

Of course, beyond the pizza prep table, a successful kitchen relies on a full suite of other vital kitchen essentials to keep things running smoothly. We get the unique challenges you face, and this guide will equip you to make an investment that pays off with every single pizza you sell.

Decoding Stainless Steel Grades for Your Pizzeria

Not all stainless steel is created equal, a fact that becomes painfully obvious when it’s up against acidic tomato sauce and constant, rigorous cleaning. When you're picking out a new kitchen prep table stainless steel for your pizzeria, understanding the different grades isn't just about technical specs; it’s about choosing the right armor for the job.

Making the wrong choice can lead to rust, pitting, and a much shorter lifespan for your investment. Think of it like choosing between a rain jacket and a winter parka. Both keep you dry, but one offers way more protection against harsh conditions. In the world of stainless steel pizza prep tables, the two main players you'll see are 304 and 430 grade.

The Workhorse vs. The Budget-Friendly Option

304 grade stainless steel is the undisputed champion for any food-contact surface in a pizzeria. It’s packed with chromium and nickel, which gives it superior resistance to corrosion from acids and salt. That tomato sauce, salty pepperoni, and olive brine? Grade 304 handles it all without flinching, day in and day out. It's the "all-weather workhorse" you want for the tabletop where the pizza magic happens.

On the other hand, 430 grade stainless steel is a more economical choice because it contains no nickel, making it less corrosion-resistant. While you definitely don't want it for your main pizza prep surface, it’s perfectly fine for other parts of the table, like the legs, base, and undershelves. This "hybrid" approach—a 304 top with a 430 base—is a smart way to get durability where it counts while keeping your budget in check.

A key takeaway for any pizzeria owner is to prioritize a 304-grade stainless steel top. The incremental cost is a small price to pay for the long-term durability and hygiene it provides against the unique challenges of pizza ingredients.

There's a reason you see so much stainless steel out there. The pizza prep tables market, which relies heavily on it, hit USD 0.4 billion in 2019 and is projected to reach USD 0.6 billion by 2030. Stainless steel models are dominating the scene, making up 42% of sales in 2023, largely because they're so hygienic and non-porous. You can discover more insights about the pizza prep table market on htfmarketinsights.com.

To help you see the difference clearly, here’s a quick breakdown:

Stainless Steel Grade Comparison for Pizzerias

| Feature | 304 Grade Stainless Steel (18/8) | 430 Grade Stainless Steel (18/0) |

|---|---|---|

| Best Use | Pizza prep tabletops, food-contact surfaces | Legs, base, undershelves, non-contact areas |

| Corrosion Resistance | Excellent. Resists rust from acidic foods (tomato sauce, vinegar) and salts. | Fair. Can be prone to rust with prolonged exposure to acidic or salty ingredients. |

| Durability | High. Very tough and long-lasting in demanding pizzeria environments. | Good. Suitable for structural components but less resilient on the surface. |

| Cost | Higher initial cost, but better long-term value for pizza prep areas. | Lower initial cost, making it a budget-friendly choice for non-critical parts. |

| Key Ingredient | Contains chromium and nickel (18% chromium, 8% nickel). | Contains chromium but no nickel (18% chromium, 0% nickel). |

In short, never compromise on the tabletop where you build your pizzas. Always go for 304 grade where your food is going to be.

Understanding Steel Gauge: The Thickness Factor

Beyond the grade, you'll see numbers like 14, 16, and 18 gauge. This can be a bit confusing, but the rule is simple: the lower the number, the thicker and stronger the steel.

- 14-Gauge: This is the heavyweight champion. It’s incredibly thick and dent-resistant, making it perfect for high-volume pizzerias where heavy dough bins, mixers, or other equipment might get slammed down on the surface.

- 16-Gauge: A very common and reliable choice, 16-gauge steel offers a fantastic balance of durability and cost. It can easily withstand the daily grind of a busy pizza kitchen without the premium price of 14-gauge.

- 18-Gauge: This is the lightest option, typically found on budget-friendly tables or those meant for light-duty prep work. It’s much more likely to get dented and probably isn't the best choice for a demanding pizzeria.

Choosing the right gauge is all about matching the table's strength to your pizzeria's intensity. An 18-gauge table might be fine for a small coffee shop, but a bustling pizzeria needs the resilience of 16- or 14-gauge steel to handle the constant action.

For a deeper dive into material selection, you might be interested in our guide on commercial stainless steel tables. Ultimately, getting the right grade and gauge ensures your pizza prep table isn't just a purchase, but a long-term, reliable asset for your business.

Refrigerated vs Non-Refrigerated Pizza Prep Tables

Picking between a refrigerated and a non-refrigerated kitchen prep table stainless steel is one of the biggest calls a pizzeria owner has to make. This isn't just about keeping things cold; it’s a decision that directly shapes your kitchen's speed, workflow, and how you handle food safety. Get it right, and you create a seamless pizza production line that hums through the dinner rush.

Think about your team during peak hours. With a refrigerated prep table, every critical topping—pepperoni, cheese, mushrooms, bell peppers—is right there, perfectly chilled and within arm's reach. This simple change eliminates all those time-wasting trips to a separate walk-in cooler, effectively turning your prep station into a self-contained, high-speed pizza factory. Every second you shave off is a faster ticket time and a happier customer.

The Strategic Edge of Refrigerated Pizza Prep Tables

The real magic of a refrigerated pizza prep table is its ability to create a food-safe environment exactly where the action happens. Health codes are strict: perishable toppings have to be kept below 41°F to stop bacteria from growing. An integrated refrigerated unit ensures you nail this requirement without even thinking about it, keeping ingredients fresh and dramatically cutting down on spoilage.

This is where the investment really starts to pay off. Sure, the upfront cost is higher, but the long-term savings are impossible to ignore.

- Less Food Waste: When ingredients are consistently chilled, they last longer. That means less product in the trash can at the end of the night.

- Faster Pizza Assembly: With everything organized in chilled pans right in front of them, your staff can build pizzas much, much faster.

- Better Consistency: An organized, chilled setup helps your team maintain perfect portion control, ensuring every pizza that leaves the kitchen is just right.

The industry is definitely moving in this direction. The global stainless steel kitchenware market hit USD 23.5 billion in 2023, and the refrigerated prep table segment is expected to jump from USD 3.48 billion in 2024 to USD 5.20 billion by 2035. That growth tells you everything you need to know: smart pizzeria operators are choosing integrated cooling to boost efficiency and safety. You can read the full research about kitchenware market trends on dataintelo.com.

For a closer look at how these units work in similar high-speed kitchens, check out our guide on refrigerated sandwich prep tables. They share many of the same workflow benefits.

When a Non-Refrigerated Table Makes Sense for Pizza Prep

Despite all the perks of refrigeration, a simple non-refrigerated table can still be the smarter play in certain situations. It’s all about matching the tool to the job and your pizzeria's unique layout. A non-refrigerated kitchen prep table stainless steel gives you a straightforward, durable, and more affordable surface for specific tasks.

A non-refrigerated model might be the right call if:

- You need a dedicated dough station. A big, flat, non-refrigerated surface is perfect for stretching, kneading, and saucing dough, keeping it separate from your main topping line.

- Your kitchen is tight on space. If you already have under-counter refrigerators right below or next to your prep area, adding another refrigerated unit could be overkill.

- You're on a tight budget. For new pizzerias or lower-volume shops, a non-refrigerated table is a fantastic, cost-effective starting point. You can always upgrade later as business grows.

Ultimately, this decision boils down to one thing: workflow. If your cooks are constantly walking away from the line to grab ingredients, a refrigerated table will pay for itself in saved time and reduced food waste. If your workflow is already dialed in with nearby cooling, a simple stainless steel surface may be all you need for your pizza prep.

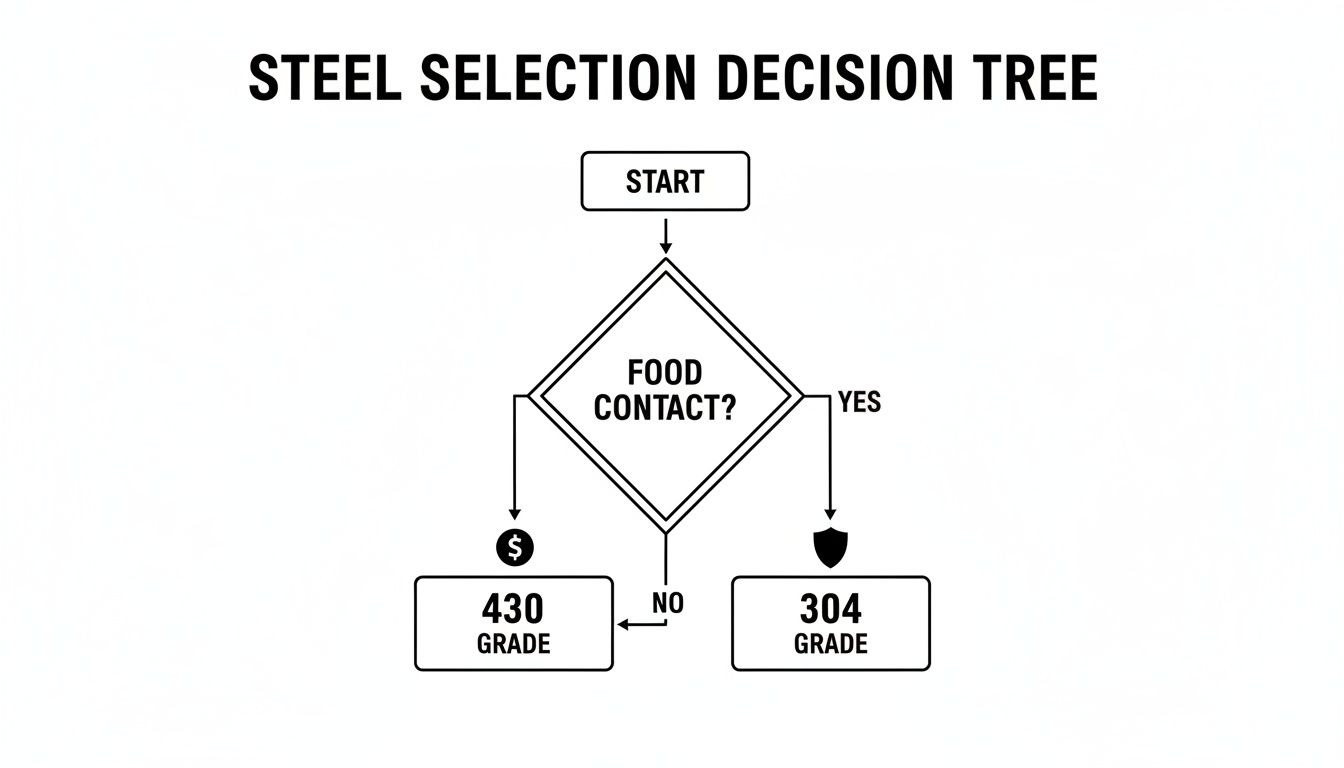

This infographic simplifies another key decision: your steel grade.

As you can see, the path is clear. If the surface will have direct contact with food—especially acidic stuff like tomato sauce—choosing the more corrosion-resistant 304 grade steel is a must for hygiene and long-term durability.

Making the Final Decision

To make the best choice, literally walk through your pizza-making process. Where does the dough come from? Where are toppings stored right now? How many steps does your team take to build one pizza? Answering these questions will shine a spotlight on the bottlenecks in your current system.

If you find wasted motion and potential food safety issues, a refrigerated pizza prep table is a powerful fix. But if your process is already streamlined with cooling close at hand, a high-quality non-refrigerated table will give you a durable and economical workspace for years to come.

Sizing Your Prep Table for Maximum Pizza Production Flow

Picking the right size for your kitchen prep table stainless steel isn’t about just filling an empty spot on the floor. It’s about choreographing an efficient pizza-making workflow. A table that’s too small will instantly create a cramped, frustrating workspace where your cooks are constantly bumping elbows. Go too big, and you're just wasting valuable real estate and adding unnecessary steps to every single pizza made.

The real goal is to find that perfect sweet spot that supports your team, especially when the orders are flying in. It's not just about the table's footprint; it's about protecting the sacred "dance floor" around it. Your staff needs at least 36 inches of clearance to move safely and efficiently—and even up to 48 inches in those main kitchen highways. This space is absolutely non-negotiable for a kitchen that flows instead of clogs.

Mapping Your Pizzeria's Workflow

Think of your kitchen layout like a battlefield map where every inch matters. The most successful pizzerias operate on a version of the "pizza triangle," a tight, efficient loop connecting three key zones: the dough station, the prep table, and the oven. The size and placement of your stainless steel prep table are what make or break this triangle.

Before you even start browsing for models, grab a tape measure and ask yourself these critical questions:

- How many cooks are making pizza at this table at once during our peak rush? This will tell you the length you need to avoid frustration and bottlenecks.

- What’s our real-world pizza volume, both average and on a crazy Friday night? Higher output simply demands more surface area to keep up.

- What else is happening here? If it's just for topping pizzas, a narrower table might do the trick. But if it’s also where you’re boxing them up, you’ll need that extra depth.

Answering these honestly will steer you toward a size that solves problems instead of creating them. A perfectly sized table acts as a force multiplier for your team's pizza output.

Matching Table Size to Pizzeria Output

It's common sense, but the needs of a small corner slice shop are a world away from a high-volume restaurant pumping out hundreds of pies a night. Choosing a table based on your actual output is the smartest way to invest in a solution that fits your operation like a glove. For a deeper dive, our guide to the commercial pizza prep table breaks down different models in more detail.

To get you started, here’s a straightforward guide to help you match table size to your pizzeria's daily hustle.

Pizza Prep Table Size Guide by Output

| Table Size | Ideal for (Pizzas per Day) | Typical Staff | Best Use Case |

|---|---|---|---|

| 44-Inch Models | 50 - 150 | 1 Cook | Perfect for small slice shops, cafes with a limited pizza menu, or food trucks where space is at a premium. |

| 67-Inch Models | 150 - 300 | 1-2 Cooks | An excellent all-rounder for most independent pizzerias, providing enough space for one cook to work comfortably or two during a rush. |

| 93-Inch Models | 300+ | 2-3+ Cooks | The powerhouse for high-volume operations, offering ample room for multiple cooks to assemble pizzas simultaneously without getting in each other's way. |

This table gives you a solid starting point. Remember to factor in not just your current output, but where you plan to be in a year or two. Buying a table that you can grow into is often smarter than having to upgrade sooner than you expected.

The right size isn’t just a dimension; it's a strategic choice. It's the difference between a pizza kitchen that flows like a well-oiled machine and one that's a constant source of bottlenecks and frustration.

By taking the time to measure your space, map your workflow, and be realistic about your output, you can choose a kitchen prep table stainless steel that becomes one of your most valuable assets. It will empower your team to work faster, build more consistent pizzas, and ultimately, drive your pizzeria’s success.

Mastering NSF Compliance and Maintenance for Your Pizza Prep Table

Passing your health inspection isn't the finish line; it’s just the start. Keeping your kitchen prep table stainless steel in top shape is an everyday commitment to the safety and quality of your pizza.

When you spot that little circular NSF (National Sanitation Foundation) logo on a piece of equipment, it’s not just a sticker. Think of it as a guarantee. It tells you the table was built specifically for the chaos of a commercial pizzeria, with a surface that’s non-porous, fights off corrosion, and is a breeze to sanitize properly.

That simple mark means the table was designed without the tiny cracks or crevices where bacteria and old flour love to hide—a non-negotiable feature in a busy pizzeria. It’s your proof to inspectors that you’ve invested in equipment that meets strict public health standards. At the end of the day, NSF compliance is the bedrock of a safe, hygienic pizza kitchen.

A Battle-Tested Cleaning Protocol

Proper cleaning is more than just wiping down a surface at the end of the night. It's a systematic approach to protecting your investment and keeping your pizzas safe. Stainless steel is a workhorse, but it's not invincible. The right daily, weekly, and monthly habits will keep your pizza prep table looking and performing like new for years.

A simple but strict routine makes all the difference. For a complete overview of best practices, this comprehensive guide to cleaning commercial kitchens is a fantastic resource.

Here’s a schedule that can stand up to the demands of any pizzeria:

- Daily (End of Every Shift): Get all the food debris, flour, and sauce off. Wash the surface with warm water and a mild detergent, rinse it completely, and then hit it with a food-safe sanitizer. Pro tip: always wipe in the direction of the steel's grain to prevent micro-scratches.

- Weekly: Time for a deeper clean. Use a non-abrasive cleaner, like a simple paste of baking soda and water, to gently lift any stubborn gunk or stains. This is also the perfect time to polish the surface with a food-grade stainless steel polish, which helps restore its protective layer.

- Monthly: Do a full inspection. For refrigerated pizza tables, this means checking and cleaning the condenser coils. Keeping them free of dust and grease is critical for making the unit run efficiently and last longer.

Here's the most common mistake I see: assuming "clean" is the same as "sanitized." Cleaning removes the flour and sauce you can see. Sanitizing kills the bacteria you can't. This two-step process is absolutely essential for food safety and staying on the health inspector's good side.

Avoiding Permanent Damage from Harsh Chemicals

It can be tempting to reach for the strongest cleaner you can find to blast away a tough mess, but some chemicals will cause irreversible damage to your stainless steel. Using the wrong product can lead to pitting, rust, and weird discoloration, effectively wrecking the hygienic surface you paid a premium for.

Chemicals to NEVER Use on Stainless Steel:

- Chloride-Based Cleaners: Anything with bleach or hydrochloric acid is stainless steel's mortal enemy. These chemicals strip away the protective layer, causing pitting and rust spots to form.

- Abrasive Powders: Harsh scouring powders will scratch up the surface, creating microscopic grooves where bacteria can thrive. It actually makes the table harder to clean in the long run.

- Steel Wool or Steel Brushes: Just don't. They will scratch the surface and can leave behind tiny iron particles that will rust and stain your beautiful pizza prep table.

Crucial Maintenance for Refrigerated Units

If you have a refrigerated kitchen prep table stainless steel, your maintenance duties go beyond just the work surface. The cooling system is the heart of the unit, and if you ignore it, you're just asking for high energy bills and spoiled toppings. One of the most critical—and most often overlooked—components is the door gasket.

The gaskets are the rubber seals around the refrigerator doors that lock in the cold air. Over time, they get brittle, cracked, or torn.

- Try the Dollar Bill Test: This is an old-school trick that works every time. Close the refrigerator door on a dollar bill. If you can pull the bill out with zero resistance, your seal is shot and needs to be replaced. A good seal will grip the bill firmly.

- The Cost of a Bad Seal: A leaky gasket makes the compressor work overtime just to keep the temperature in a safe zone. This directly leads to a higher energy bill and causes critical components to wear out way too fast.

By combining a tough cleaning schedule with proactive maintenance, you’re not just keeping the health inspector happy. You're protecting your investment and ensuring your pizza prep table remains a reliable, safe workhorse for years to come.

Customizing Your Workstation with Essential Pizza Prep Accessories

The best kitchen prep table stainless steel isn't just a flat surface—it’s a command center, a fully customized workstation built for serious pizza output. The right accessories can take a standard table and turn it into a high-efficiency pizza-making machine, solving real-world problems before they even start.

Think of a basic table as a blank canvas. By strategically adding components, you're tailoring the entire station to your specific menu and workflow. This means every tool, ingredient, and pizza box has a home, cutting out wasted motion and speeding up ticket times.

Building Your Ideal Pizza Prep Station

Every accessory you add needs to serve a purpose in the pizza-making process. The goal is to create a seamless flow from dough to toppings to oven, all within arm's reach. That kind of organization is what separates a good pizzeria from a great one.

Here are the essential add-ons that no pizzeria should be without:

- Overshelves: These are absolute game-changers for vertical storage. A double overshelf is perfect for keeping stacks of pizza boxes, shakers of parmesan and red pepper flakes, and other non-perishables off your valuable workspace but still right there when you need them.

- Undershelves: Critical for bulk storage, an undershelf is the perfect home for trays of proofed dough, backup bags of flour, or big containers of sauce. This keeps your main prep surface completely clear for active orders.

- Pan Rails: If you have a refrigerated table, pan rails are non-negotiable. They hold your fractional pans filled with cheese, pepperoni, and veggies, keeping everything organized, chilled, and ready for rapid-fire topping.

Mobility and Functionality Boosters

Beyond storage, some accessories are all about enhancing the table's core function and your pizzeria's overall hygiene. These are the additions you'll be thankful for every single day, especially during deep cleaning or when you need to reconfigure the kitchen layout.

Adding casters (heavy-duty wheels) is one of the smartest upgrades you can make. A mobile kitchen prep table stainless steel can be rolled away from the wall in seconds, letting your staff deep clean the floors and walls behind it. This simple feature makes keeping a spotless kitchen so much easier and helps you ace those health inspections.

Another vital accessory is an integrated cutting board. It gives you a dedicated, food-safe surface for slicing toppings like vegetables or cooked meats. By embedding it right into the stainless steel surface, you create a contained prep zone that helps prevent cross-contamination and makes cleanup between tasks a breeze.

At the end of the day, these accessories aren't just "nice-to-haves." They're investments in speed, organization, and sanitation. By carefully picking the add-ons that solve your pizzeria's unique challenges, you're designing a workstation that empowers your team to work faster, smarter, and more consistently—delivering a better pizza with every order.

Frequently Asked Questions

Choosing the right stainless steel pizza prep table can feel like a big decision, especially when you're busy running a pizzeria. Here are some quick, practical answers to the questions we hear most often from pizzeria owners.

Getting these details right from the start means your new table will be a workhorse, not a headache.

Which Stainless Steel Grade Is Best for a Pizzeria?

For almost any pizzeria, a prep table with a 304-grade stainless steel top is the smartest long-term investment you can make. It has a higher nickel content that gives it serious muscle against corrosion—a must-have when you're dealing with acidic tomato sauce, salty meats, and strong cleaning chemicals every single day.

Want to be savvy with your budget? Look for a model with a 430-grade stainless steel base and legs. Since those parts aren't in the direct line of fire from sauce and toppings, this hybrid approach gives you rock-solid durability where it counts without overspending.

How Much Clearance Do I Need Around My Pizza Prep Table?

The golden rule here is to leave a minimum of 36 inches of clear space around the working sides of your pizza prep table. This gives your team enough elbow room to move without constantly bumping into each other, which is a lifesaver during a chaotic dinner rush.

If the table sits in a major kitchen walkway, bumping that clearance up to 48 inches is even better to prevent traffic jams between the prep line and the oven. And don't forget to account for swinging refrigerator doors and easy access to anything stored on the undershelves, like dough trays.

A classic mistake is only measuring for the table's footprint. The "dance floor" around it is just as critical for a smooth-running kitchen. Forgetting this can create frustrating bottlenecks that slow down your entire pizza-making operation.

Can I Put Hot Pizza Pans Directly on the Table?

Even though stainless steel is incredibly heat-resistant, it's not indestructible. Constantly slapping pans straight from a 500°F oven onto the surface can cause thermal shock, which might lead to warping over time. A warped table is a nightmare for stretching dough and prepping pizzas.

It's a great habit to use heat-resistant silicone mats or trivets as a buffer. This simple step protects the steel's integrity and will add years to the life of your pizza prep table.

Is a Backsplash Necessary for My Pizza Prep Table?

We highly recommend a backsplash for any pizza prep station. Think of it as a crucial barrier that stops sauce, flour, and cheese from splattering all over your wall, making cleanup a whole lot faster.

Even more importantly, it prevents utensils and stray toppings from falling into that hard-to-reach gap behind the table. For both hygiene and sanity, choosing a kitchen prep table stainless steel with an integrated backsplash is one of the smartest small decisions you can make for your pizzeria.

Ready to build the perfect pizza-making station for your restaurant? At Pizza Prep Table, we offer a wide range of NSF-compliant stainless steel prep tables designed to meet the demands of any pizzeria. Explore our collection and find the ideal model for your kitchen today!