Mix It Up: Finding the Perfect Spiral Dough Mixer for Your Business

Share

Why Spiral Mixers Are Taking Over Commercial Kitchens

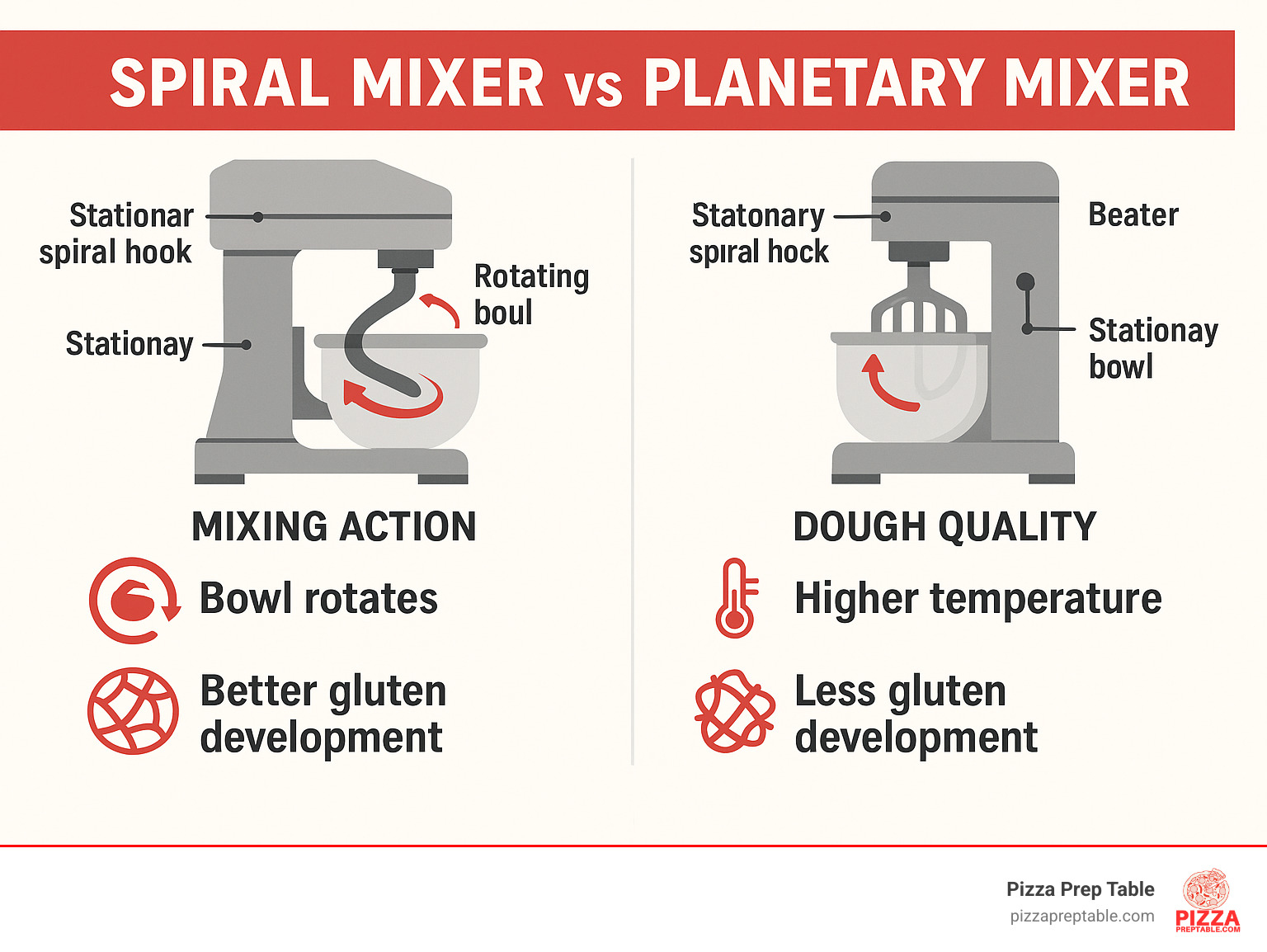

Spiral mixers are specialized commercial dough mixing equipment that use a rotating bowl and stationary spiral hook to create superior dough quality with minimal heat buildup. Unlike planetary mixers that move the mixing tool around a stationary bowl, spiral mixers rotate the bowl while keeping the spiral arm in place, resulting in gentler mixing action and better gluten development.

Key differences between spiral and planetary mixers:

- Mixing action: Spiral mixers rotate the bowl, planetary mixers rotate the tool

- Specialization: Spiral mixers excel at dough, planetary mixers handle multiple tasks

- Temperature control: Spiral mixers keep dough cooler during mixing

- Batch flexibility: Spiral mixers can handle batches as small as 10% of capacity

- Noise levels: Spiral mixers operate quieter due to pulley systems vs. gears

The surge in artisan bread popularity and Neapolitan pizza demand has made dough quality more critical than ever. As one industry expert noted: "Artisan breads and Neapolitan pizzas have never been more popular! As the chef, you want the gentle incorporation that a spiral mixer provides with the consistent performance required to make great dough each time."

For pizza shop owners and bakery managers, spiral mixers offer several advantages:

- Maintain lower dough temperatures for proper yeast activation

- Handle high-hydration doughs (80-90% absorption rates)

- Reduce mixing time by half compared to traditional mixers

- Available in capacities from 130 to 440+ pounds

- Produce consistent results batch after batch

I'm Sean Kearney, and my background in sales and deep understanding of foodservice equipment has given me extensive experience helping restaurant owners select the right spiral mixers for their operations. Whether you're opening your first pizzeria or upgrading your bakery equipment, I've seen how the right mixer can transform dough quality and operational efficiency.

Spiral vs. Planetary Mixers: The Dough Showdown

Picture two boxers in the ring, each with completely different fighting styles. That's exactly what we have with spiral mixers and planetary mixers – both are heavyweights in commercial kitchens, but they approach dough mixing in fundamentally different ways.

Here's where things get interesting. A planetary mixer works like our solar system – its mixing tool spins on its own axis while orbiting around a stationary bowl. It's like watching a planet dance around the sun. This mixer is the Swiss Army knife of the kitchen world, powered by a single motor that can handle everything from whipping cream to kneading pizza dough.

Spiral mixers take a completely different approach. Instead of the tool doing all the moving, the bowl rotates while a stationary spiral hook stays put. Think of it as the bowl doing the dancing while the hook just sits there, gently working the dough. This design uses two separate motors – one for the bowl, another for the spiral arm.

The specialization difference is huge. Planetary mixers are like that friend who's good at everything – they can slice vegetables, chop meat, grate cheese, and yes, make dough too. But spiral mixers? They're the dough specialists. They do one thing, and they do it incredibly well.

This specialization pays off big time when it comes to gluten development. The gentle, consistent motion of a spiral mixer develops gluten slowly and evenly. Your dough comes out with perfect elasticity and structure, every single time.

Temperature control is where spiral mixers really shine. That aggressive planetary mixer action creates friction, which means heat. Too much heat can wake up your yeast too early and mess with fermentation. Spiral mixers keep things cool and controlled, which is exactly what artisan breads and Neapolitan pizza doughs need.

Here's a bonus you might not expect – spiral mixers are actually quieter than planetary mixers. Those pulley systems create way less noise and vibration than the gear-driven planetary mixers. Your kitchen staff will thank you during those busy dinner rushes.

If you're curious about planetary mixers and want to dive deeper, check out our detailed comparison guide: The Ultimate Guide to Comparing Planetary Mixers.

The bottom line? If you need versatility and mix lots of different things, planetary mixers are your friend. But if dough quality is your main concern – and let's be honest, it should be for any serious pizzeria or bakery – spiral mixers are the clear winner.

The Unbeatable Advantages of Using a Spiral Mixer

When you dive into spiral mixers, you quickly find why so many professional bakers and pizza makers swear by them. These machines aren't just another piece of kitchen equipment – they're game-changers for anyone serious about creating exceptional dough.

The magic starts with their gentle mixing action. While other mixers might aggressively beat your dough into submission, spiral mixers take a more thoughtful approach. The bowl rotates slowly while the spiral hook stays put, creating a rhythm that works the dough without stressing it out. It's like the difference between a gentle massage and a vigorous workout – both get the job done, but one leaves you feeling much better afterward.

This gentle approach leads to superior gluten development, which is where the real science happens. Gluten is the protein network that gives your pizza crust its perfect chew and helps your bread rise beautifully. Spiral mixers develop this gluten structure slowly and evenly, creating a stronger, more uniform network. The result? Dough that stretches like a dream and passes the windowpane test every time.

Here's where things get really interesting: low-friction heat generation. Traditional mixers can work up quite a sweat, literally heating up your dough through friction. But spiral mixers keep things cool – and that's crucial for perfect dough. When dough gets too warm too fast, yeast goes into overdrive, rushing the fermentation process and robbing you of complex flavors.

By maintaining proper dough temperature, spiral mixers give you complete control over fermentation. Your yeast activates at just the right pace, developing those deep, complex flavors that separate good bread from great bread. It's like having a thermostat for your dough quality.

So what types of dough absolutely love spiral mixers? Pretty much anything that benefits from gentle handling and temperature control. Artisan breads with their delicate crumb structures thrive under this treatment. Pizza dough, especially for those coveted Neapolitan-style pies, develops the perfect balance of strength and extensibility. Bagels get their characteristic dense-yet-chewy texture, while high-hydration doughs – those wet, sticky mixtures that can reach 80-90% water absorption – become manageable masterpieces.

These mixers particularly shine with high-hydration doughs because they can handle all that moisture without breaking a sweat. More water means lighter, airier bread that's easier to digest. Plus, using more water and less flour can actually save you money – a win-win situation.

In commercial applications, spiral mixers are the workhorses of serious bakeries and pizzerias. They're built for businesses that need to produce large batches of consistent, high-quality dough day after day. Whether you're running a small artisan bakery or a busy pizzeria, these mixers deliver the reliability and quality your customers expect.

The bottom line? If your business reputation rides on the quality of your baked goods, a spiral mixer isn't just an investment – it's your secret weapon for consistency and excellence. For more insights on perfecting your dough technique, check out our guide: Mixing It Up: Mastering Pizza Dough Kneading in Your Stand Mixer.

A Buyer's Guide to Commercial Spiral Mixers

Choosing the right spiral mixer for your business can feel overwhelming with so many excellent options available. But here's the thing – making the right choice now will pay dividends for years to come. Let me walk you through what really matters when you're ready to invest in one of these game-changing machines.

The first question I always ask my clients is simple: what's your production volume, and how much space do you have? As our industry experts put it, "The volume and weight of ingredients is key to choosing the right mixer and the size required." But here's a pro tip from years of helping restaurant owners – don't just buy for today's needs. "Buy a mixer for what you intend to grow into."

That said, spiral mixers are typically substantial floor-standing units, so "space should always be taken into consideration prior to investing in one." I've seen too many excited bakery owners fall in love with a mixer online, only to realize it won't fit through their kitchen door!

Key Features to Look For in a Spiral Mixer

When I'm helping clients evaluate spiral mixers, there are several must-have features that separate the good machines from the great ones. Let's start with the obvious one – capacity. This isn't just about the maximum dough weight; it's about flexibility too.

Modern spiral mixers come in impressive size ranges. Hobart offers models "from 180 pounds to 440 pounds, as well as the new 130 pound capacity HSL130!" Globe focuses on "130 and 175 lbs. for large batches," while VMI's SPI 53 & 63 models handle "small volumes of dough ranging from 1.6 kg to 40 kg." Even the home-professional Ooni Halo Pro boasts a "7.3 quart capacity" with a "Max Dough Capacity: 5kg."

Here's what many people don't realize – most spiral mixers can handle batches as small as 10% of their maximum capacity. That 180-pound Hobart? It'll happily mix an 18-pound batch just as well as a full load. For detailed capacity specs, check out the Hobart Spiral Mixers Capacity Chart.

The motor system is where the engineering magic happens. Unlike planetary mixers with their single motor, spiral mixers use "one motor to rotate the bowl and another motor to rotate the spiral arm." But not all dual-motor systems are created equal. "Consider a spiral mixer that features a dual-pulley system design. This design produces more torque with less stress on interior components," which means your mixer will last longer and run smoother.

Speed settings might seem basic, but they're crucial for different mixing stages. You'll want at least two speeds – a slower one for incorporating ingredients without creating a flour dust storm (trust me, your staff will thank you), and a faster speed for proper kneading. Hobart's models "have programmable timers and can automatically shift from first to second speed," while the Ooni Halo Pro takes it to another level with "58 levels of precision control."

One feature that really sets quality spiral mixers apart is bidirectional bowl rotation. "A spiral mixer that can rotate the bowl in both directions helps improve dough consistency and provides the capability to produce batches as small as 10% of maximum capacity." Plus, it makes cleaning so much easier – the dough practically spirals right off the hook when you reverse the bowl direction.

Modern digital controls and programmable timers are game-changers for consistency. "Look for a mixer with electronic controls and a digital readout, which provides greater accuracy and ease of use." Some advanced models like the VMI SPI 63 Digy even offer "recipe programming" through an intuitive touch panel, which means your staff can achieve perfect results every time, regardless of their experience level.

Safety features are non-negotiable in commercial kitchens. Quality spiral mixers include robust safety guards – "a wireform, stainless steel bowl guard with interlock [that] prevents spiral arm operation when the guard is up." VMI even addresses baker health concerns with "a transparent cover to limit flour dust emissions, which is the primary factor of bakers' asthma."

When it comes to construction materials, stick with "fully stainless steel construction with zero retention areas for easier washing." Not only does stainless steel last longer, but it's also much easier to keep clean and sanitized. "Heavier spiral mixers often indicate more robust gears and components," so don't shy away from substantial machines – they're built to handle years of heavy use.

Maintenance considerations vary between models, particularly regarding fixed versus removable bowls. Some spiral mixers feature removable bowls like the VMI Kneadster® mixer, which can simplify thorough cleaning. Regardless of bowl type, look for features like "easy-to-clean kneading zones," "slanted front frames for easier draining of water," and "removable housings for easier maintenance." The bidirectional bowl rotation also "facilitates easier and faster cleaning by reversing the bowl."

Energy efficiency might not be your first concern, but it adds up over time. The Kneadster® mixer "incorporates energy recovery in its tool drive circuit, reducing consumption." Plus, spiral mixers help you achieve higher hydration ratios, which means using more water and less flour – a nice cost savings that compounds over thousands of batches.

For more detailed guidance on choosing equipment that fits your specific needs, check out our comprehensive guide: How to Choose a Large Mixer That Fits Your Kitchen and Your Needs.

Top Spiral Mixer Models to Consider

After years in this industry, I've seen certain brands consistently deliver exceptional performance and reliability. Let me share the standouts that have earned their reputation in professional kitchens.

Hobart remains the gold standard for many commercial operations. Their spiral mixers are "designed to give you maximum control over the mixing of your dough" and are widely considered "the perfect engines for creating the highest-quality dough for your customers." With models ranging from the "130 pound capacity HSL130" up to 440 pounds, they offer robust construction and sophisticated electronic controls with programmable timers that take the guesswork out of perfect dough.

Globe brings a "traditional European design" philosophy to their spiral mixers, focusing on "quality and quantity" for "large batches of dough." Their approach emphasizes "developing the gluten structure slowly and reducing heat caused by friction," which is exactly what you want for artisan breads and premium pizza dough. Their 130 and 175-pound models strike an excellent balance between capacity and craftsmanship.

VMI/Kneadster® offers some of the most innovative features in the market. Their SPI 53 & 63 fixed bowl mixers are perfect for "small volumes of dough ranging from 1.6 kg to 40 kg" and are proudly "certified to be made in France." For larger operations, the Kneadster® mixer stands out as being "designed for bakers who want to make quality artisan bread on an industrial scale." Its unique "removable bowl and a double mixing tool of exclusive design" makes it incredibly efficient and easy to maintain. I particularly appreciate VMI's attention to baker health with transparent covers that limit flour dust exposure.

Ooni Halo Pro represents something special – it "brings spiral mixing technology from professional bakeries and pizzerias to your home kitchen countertop." While primarily designed for serious home users, it showcases how advanced spiral mixing technology is becoming more accessible. With its "dual-kneading spiral mixing technology," "7.3 quart capacity and 58 levels of precision control," plus features like a "detachable rotating bowl, tilt-head mechanism and patent-pending Removable Breaker Bar," it proves that professional-grade mixing doesn't always require industrial-sized equipment.

Each brand brings distinct strengths to the table, and the right choice depends on your specific production needs, available space, and budget. The key is matching the mixer's capabilities to your business goals – both current and future.

Frequently Asked Questions about Spiral Mixers

Over the years, I've fielded countless questions about spiral mixers from restaurant owners and bakery managers. Let me share the most common concerns and clear up any confusion you might have about these specialized machines.

What types of dough are best suited for spiral mixers?

Here's where spiral mixers really shine - they're the specialists of the dough world. Think of them as the artisan craftsmen among mixing equipment. Their gentle, low-friction action makes them perfect for doughs that need a delicate touch and careful gluten development.

Artisan breads are where these mixers truly excel. Whether you're making sourdoughs, crusty baguettes, or rustic country loaves, the slow and controlled mixing develops that strong gluten network without beating your dough to death. The result? That perfect open crumb structure and chewy texture your customers crave.

Pizza dough is another natural fit, especially those high-hydration varieties used for Neapolitan or New York-style pies. The gentle mixing preserves the dough's elasticity while creating that light, airy texture that makes great pizza crust. Bagels also benefit from this careful handling - you'll get that characteristic chewy bite without overworking the dough.

Now, here's something that surprises many people: spiral mixers are actually fantastic with high-hydration doughs. You know those sticky, wet doughs with 80% or more water content that can be a nightmare with other mixers? Spiral mixers handle them like champions, ensuring uniform mixing despite the challenging consistency.

Don't think they're only for delicate work, though. Advanced models like VMI's Genius can tackle even the most resistant doughs made with solid flours. Some spiral mixers can handle everything from bread and pastries to pizzas, donuts, bagels, cereal bars, and even veggie steaks for small and large productions alike.

Can I mix small batches of dough in a large spiral mixer?

This question comes up all the time, and I love giving this answer because it showcases just how versatile modern spiral mixers have become. The short answer? Absolutely yes, and it works beautifully.

Thanks to bidirectional bowl rotation, many spiral mixers can efficiently handle batches as small as 10% of their maximum capacity. Picture this: you've got a hefty 180-pound capacity mixer, but you only need to make 18 pounds of dough for a special order. No problem at all.

The magic happens because that bowl can rotate in both directions. This ensures even those smaller quantities get thoroughly mixed and kneaded, achieving the same consistent results as a full batch. You're not sacrificing quality for flexibility.

This feature is a game-changer for businesses with varying demand or those producing multiple dough types throughout the day. You don't need a whole fleet of mixers for different batch sizes - one well-chosen spiral mixer can handle your entire range. Some bakers actually prefer mixing smaller portions at a time, letting the rest rest between batches to improve gluten structure even further.

How do I clean and maintain a spiral mixer?

Let me ease your mind right away - modern spiral mixers are designed with cleaning and maintenance as top priorities. The manufacturers know you're running a busy operation and can't spend hours scrubbing equipment.

Most quality spiral mixers feature fully stainless steel construction with zero retention areas. This means fewer nooks and crannies where dough can hide and turn into cleaning nightmares. Look for designs with slanted front frames that help water drain easily during cleaning.

The removable bowl option is a real blessing if you can get it. Being able to lift out the bowl for thorough cleaning makes the job so much easier. Even with fixed bowls, many models like the VMI SPI 63 Digy have automatic lifting heads that give you better access to the mixing zone.

Here's a clever feature: that same bidirectional bowl rotation that helps with small batches also makes cleaning faster and easier. Running the bowl in reverse helps dislodge any stuck-on dough, saving you scrubbing time.

Safety matters too. Many spiral mixers now come with transparent covers that limit flour dust emissions - a major factor in baker's asthma. This keeps your team healthier while making it easier to monitor the mixing process.

For ongoing maintenance, these machines are built to be serviceable. Many feature removable housings that give technicians easier access for regular checks and repairs. The SPI line is particularly noted for being ideal for bakers because of their excellent cleanability and easy maintenance.

The key is establishing a consistent cleaning routine and following the manufacturer's maintenance schedule. Do that, and your spiral mixer will be mixing perfect dough for years to come.

Conclusion: Making the Right Choice for Your Business

After diving deep into spiral mixers, one thing becomes crystal clear: these machines aren't just another piece of kitchen equipment. They're precision instruments that can transform your dough quality and, ultimately, your business success. The gentle mixing action, superior temperature control, and consistent results we've discussed aren't just technical features – they're the foundation of exceptional artisan breads, perfect pizza crusts, and satisfied customers who keep coming back.

The beauty of spiral mixers lies in their specialization. While they may not whip cream or mix cookie batter like their planetary cousins, they excel at what matters most for bakeries and pizzerias: creating outstanding dough. Whether you're crafting high-hydration sourdoughs, stretching Neapolitan pizza dough to that perfect windowpane, or kneading dense bagel dough, a spiral mixer delivers the quality, consistency, and efficiency that can set your business apart from the competition.

But here's the thing – buying the right spiral mixer isn't a one-size-fits-all decision. The importance of matching mixer to business needs cannot be overstated. That busy pizzeria turning out hundreds of pies daily has different requirements than the artisan bakery focusing on small-batch sourdoughs. Consider your production volume carefully, measure your kitchen space twice, and think about where you want your business to be in two years, not just today.

The investment you make today in a quality spiral mixer with features like dual-pulley motor systems, programmable timers, and bidirectional bowl rotation will pay dividends in reduced labor costs, improved product consistency, and the kind of superior baked goods that build loyal customer bases. When you're comparing models from trusted brands like Hobart, Globe, or VMI, the right choice is the one that aligns with your specific operational needs and growth plans.

At Pizza Prep Table, we've seen how the right equipment can transform a struggling operation into a thriving business. We understand that every pizza shop and bakery has unique challenges, whether you're working with limited space, tight budgets, or demanding customers who know quality when they taste it. That's why we're committed to helping you find not just any spiral mixer, but the right one for your specific situation.

Ready to take your dough game to the next level? We're here to help you steer the options and find the perfect spiral mixer that will have you mixing with confidence and baking with pride.