New York Pizza Style: A Pizzeria's Guide

Share

So, what really makes a New York pizza style slice what it is? For a pizza restaurant, it’s a brilliant piece of food engineering: a large, foldable slice with a thin crust that’s somehow both crispy and chewy all at once. This isn't just about throwing some ingredients together; it's about creating an experience built for a city that never stops, and for a pizzeria, it's about a product that can be served efficiently at scale.

The Anatomy of an Iconic Slice

The magic behind an authentic New York pizza style slice is all in the delicate dance between its core parts. For any pizzeria that wants to nail this classic, getting each element right isn't just a good idea—it's everything. The final product is more than just a meal; it's an edible plate designed for maximum flavor and on-the-go convenience, a model that has defined countless successful pizza restaurants.

I like to think of it like this: the crust is the foundation, the sauce is the soul, and the cheese is the heart. If any one of them is off, the whole thing falls apart. It’s this perfect balance of texture and taste that has turned these giant, foldable wedges into a global icon for pizzerias to emulate.

The Unmistakable Foldable Crust

The first test of a real New York slice is its structure. You should be able to fold it right down the middle, end to end, without the whole thing cracking or collapsing into a mess. That signature pliability comes from a dough made with high-gluten bread flour and water with a very specific mineral makeup, something many swear is the city's "secret ingredient."

The crust has to pull off a tricky balancing act: it needs to be light, crispy, and chewy all at the same time. This doesn't happen by accident. It’s the result of a carefully managed fermentation and an expert hand-tossing technique that creates a thin center strong enough to hold the toppings without getting soggy.

For any pizza shop, hitting this level of consistency, slice after slice, day in and day out, is the ultimate challenge. It takes a serious understanding of dough hydration and how to handle it, from the mixer to the pizza prep table.

Sauce and Cheese: The Classic Combination

Unlike a lot of other pizza styles, a New York slice keeps the sauce simple and bright. It’s usually uncooked, just crushed tomatoes lightly seasoned with the basics—oregano, garlic, salt, and maybe a pinch of sugar. The key is to apply it sparingly. The sauce is there to complement, not to overpower everything else.

The cheese is just as important. The absolute gold standard is low-moisture, whole-milk mozzarella. This specific choice is a game-changer for pizzerias for a few key reasons:

- It melts perfectly evenly without releasing a ton of water, which is what prevents that greasy, soupy mess on top.

- It delivers that classic, satisfying "cheese pull" that every customer secretly hopes for.

- Its rich, milky flavor is the perfect counterpoint to the bright acidity of the tomato sauce.

Put them together, and you get a flavor that is both incredibly simple and deeply satisfying. If you're an aspiring pizzeria owner, you can dive deeper into what makes the New York pizza style so legendary in our full guide. It’s a must-read for any restaurant serious about getting their product just right. This careful choice of ingredients, from the flour all the way to the cheese, is what separates a pretty good slice from one people will line up for.

The Birth of the Slice: A Pizzeria Story

To really get the hang of New York pizza style, you have to understand where it came from. This isn't just a history lesson; it's a story of brilliant business thinking born out of necessity. It all starts in the crowded streets of early 20th-century New York City, where Italian immigrants, mostly from Naples, showed up with more than just their suitcases. They brought resourcefulness.

These newcomers carried the food traditions of their homeland, including flatbread recipes with simple toppings. One of these innovators, Gennaro Lombardi, is widely credited with opening America's first licensed pizzeria in 1905. His story, like those of his peers, is about taking an old-world food and making it work in a new-world economy.

The New York pizza style we love today wasn't just invented—it was shaped by the economic realities of the time. The first business model was simple: sell whole pies. But for many working-class New Yorkers, shelling out five cents for an entire pizza was a luxury they just couldn't afford. This pressure cooker of an economy sparked a simple yet powerful change in strategy for pizza restaurants.

The Game-Changing "By The Slice" Model

This is where the real genius of the early pizzerias shines. Instead of just selling whole pies, they started offering individual slices. It seems like a small change, but it was a massive breakthrough.

Initially, pizzas sold whole for five cents, but when pizzerias started selling individual slices—often just wrapped in paper and tied with string—it changed everything. Suddenly, pizza was accessible to everyone. This single move created the iconic "pizza-by-the-slice" culture that defines New York pizza. You can dive deeper into the history of this iconic food on Wikipedia.

This adaptation turned pizza into the ultimate street food, a perfect fit for the city’s fast-paced, on-the-go lifestyle. A worker could grab a hot, filling, and cheap meal without missing a beat. Pizzerias quickly became neighborhood institutions, cornerstones of the community where people from all walks of life could gather.

This business model demanded a very specific kind of kitchen setup. To sling slices to a long line of customers, everything had to be brutally efficient. The layout of these early shops was built for speed, with the oven as the heart of the operation and a dedicated area for stretching dough and topping pies.

The birth of the slice model fundamentally changed the pizzeria kitchen. It created a need for a linear, assembly-line workflow where speed and consistency were paramount. This laid the groundwork for modern pizzeria equipment like the refrigerated pizza prep table.

The constant need to serve slice after slice during a hectic lunch rush meant ingredients had to be perfectly organized and kept at safe temperatures. They didn't have the high-tech gear we have today, of course, but the core principle was the same: create a workspace that lets the pizzaiolo work without breaking their rhythm.

Building a Legacy One Slice at a Time

The runaway success of the by-the-slice model cemented the pizzeria's place in New York culture. It wasn't just about selling food anymore; it was about creating an institution. This legacy of efficiency and accessibility is something modern pizzerias are still trying to perfect.

The operational flow established in those tiny, bustling shops is the direct ancestor of today's high-volume pizzeria kitchens. The success of a modern pizza restaurant still hinges on its ability to replicate that original speed and quality, which requires a thoughtfully designed workspace.

- Workflow Optimization: The need for rapid service forced early pizzerias to think like engineers. Every movement mattered.

- Ingredient Accessibility: Keeping toppings and cheese ready for action was the only way the slice model could work.

- Consistency Under Pressure: Serving hundreds of slices a day meant creating a repeatable process to ensure every single slice met a certain standard.

Today, a restaurant specializing in New York pizza style relies on equipment like dedicated pizza prep tables to achieve this. These units are the modern evolution of that original, desperate need for an organized, efficient workspace, allowing today’s pizzerias to honor a century-old tradition of serving the perfect slice, fast.

Mastering The Authentic Dough And Crust

The soul of any true New York-style slice is its dough. For any pizzeria serious about authenticity, you have to move beyond simple recipes and get into the science of the crust. Nailing that perfect, foldable, yet crispy base is all about understanding the key ingredients and mastering the hands-on techniques.

This isn't just about mixing flour and water; it's about crafting a foundation that's strong enough to define the entire pizza experience. For a pizza restaurant, the whole process is a blend of chemistry and craftsmanship, where every little detail can make or break the final product.

The Non-Negotiable Ingredients

The journey to a perfect New York crust begins with the right flour. High-gluten bread flour is the undisputed champion for this style, period. Its high protein content, typically 12-14%, is what creates the strong gluten network you need for that signature chew and the structural integrity that allows for the classic fold.

This strength is what keeps the crust from turning into a brittle cracker. Instead, you get a pliable yet crisp base that can be hand-tossed into a large, thin disc without tearing. Sure, other flours can make a pizza, but they can't make a New York pizza.

Then there's the legendary New York water. While its "magic" is often overhyped, the specific mineral content—which is higher in calcium and magnesium—does play a real role in strengthening gluten. Pizzerias outside the five boroughs can get pretty close to this effect by using mineral additives or specialized water treatment systems.

Some pizzerias also play around with the subtle impact of fats. While it’s not strictly traditional, a small amount of olive oil can add a little extra flavor and help create a more tender crumb. If you're curious, learning about using olive oil for baking can offer some valuable insights for creating a truly memorable crust.

The Art Of Hand-Tossing

A machine can press dough flat, but it can't replicate the touch of a skilled pizzaiolo. Hand-stretching and tossing are absolutely critical for creating the ideal New York-style crust. This technique does several important things at once:

- Creates a Thin Center: It gently pushes the dough outward from the middle, creating a uniformly thin base that cooks evenly without getting soggy.

- Preserves the Cornicione: It protects that outer edge, allowing it to puff up in the oven to form the perfect airy and chewy cornicione, or crust rim.

- Develops Texture: The process helps align the gluten strands, which contributes directly to that desirable chewy texture in the final bake.

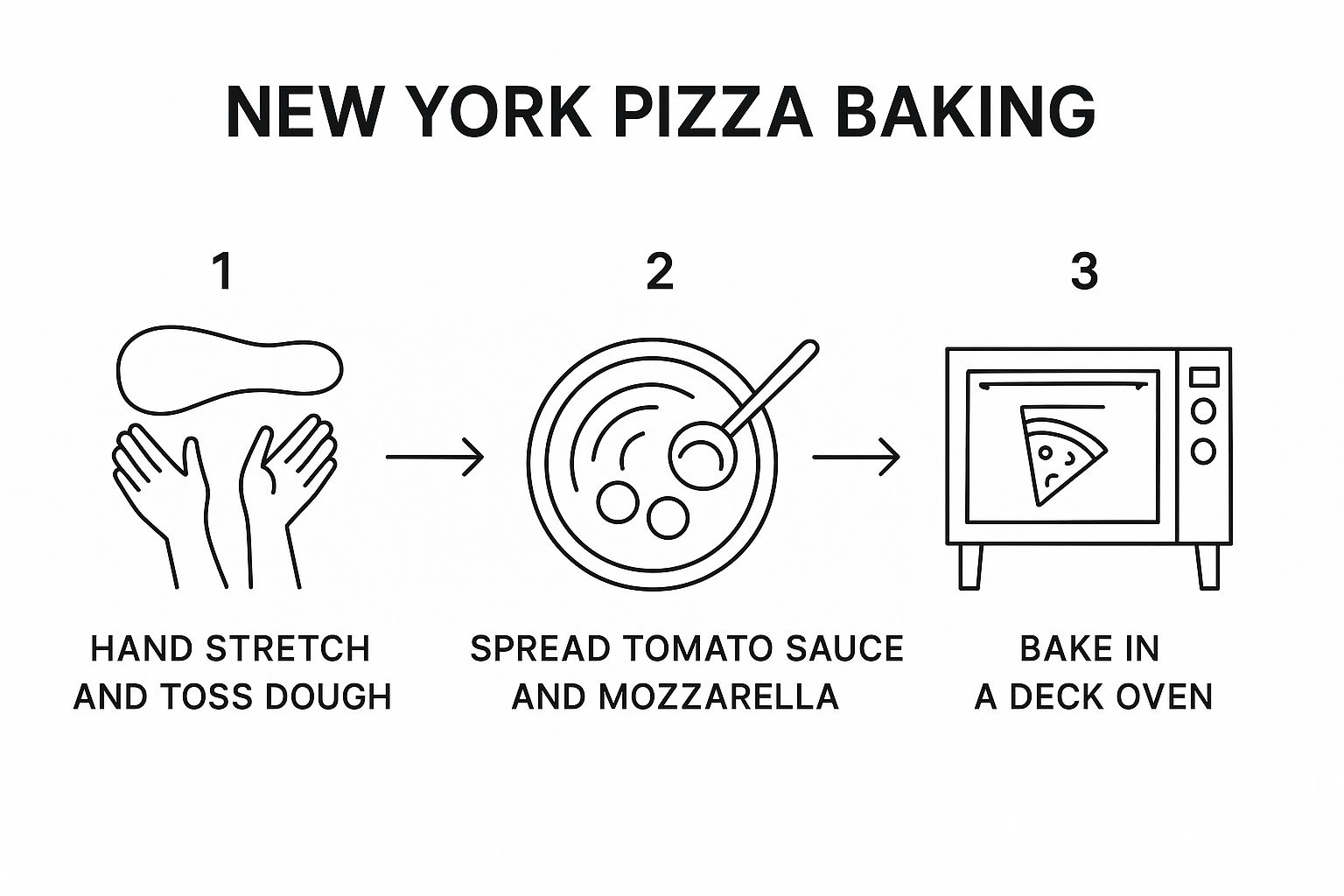

This infographic breaks down the core workflow for getting a New York-style pizza from a dough ball into the oven.

As you can see, hand-stretching is that crucial first step that sets the stage for the simple toppings and the final, perfect bake.

Achieving Pizzeria-Level Consistency

For any pizza restaurant, consistency is king. Customers come back for that same great experience, and the dough is where it all begins. This means you need a repeatable process, from mixing all the way to baking.

A long, cold fermentation—often 24 to 72 hours—is the secret weapon for developing complex flavors and getting that ideal texture. For a deeper dive into dough prep, you can find some fantastic expert advice on mastering pizza dough kneading in a stand mixer, a technique many pizzerias rely on for consistency.

A common headache for pizzerias is dough that's too slack or "blows out." This is almost always caused by over-proofing or getting the hydration levels wrong. Keeping a controlled environment, especially during the proofing stage, is crucial for preventing these problems and making sure every single crust meets your standard.

Ultimately, mastering the dough is a real commitment to the craft. It’s about respecting the ingredients, honing your technique, and understanding the science behind what makes a perfect crust. For any pizzeria dedicated to the authentic New York style, this mastery is what separates a good slice from a legendary one.

Perfecting Toppings and Baking Techniques

So, you've got the perfect dough. Now what? The next step in nailing that authentic New York pizza style is all about a philosophy of "less is more." A true New York slice is a masterclass in restraint, where the toppings don't bury the crust—they complement it.

This isn't just about tradition; it's about balance. The goal for a successful pizza restaurant is to create a flavor profile where every single ingredient gets its moment in the spotlight, from the bright, tangy sauce to the rich, gooey cheese.

The Gold Standard Toppings

When it comes to a classic New York slice, the topping choices are beautifully simple. It all starts with a bright, uncooked tomato sauce. This isn't some heavy, long-simmered marinara. It’s typically just crushed tomatoes, seasoned lightly with a touch of oregano, garlic, and salt. Applying it thinly from the pizza prep table is the secret to avoiding a soggy, floppy crust.

Next up is the real star of the show: the cheese. For any pizzeria serious about authenticity, low-moisture, whole-milk mozzarella is completely non-negotiable. This specific cheese is critical for a few key reasons:

- Optimal Melt: It melts down smooth and even, but crucially, it doesn't release a ton of water. That means you avoid that dreaded greasy pool of liquid on top of your pie.

- Perfect Cheese Pull: This is the stuff that delivers that iconic, stretchy "cheese pull" that every customer secretly hopes for when they take their first bite.

- Rich Flavor: Its creamy, full-bodied taste is the perfect counterpoint to the sharp acidity of the tomato sauce. It’s a classic pairing for a reason.

And while pepperoni might be the quintessential topping, the true test of any New York pizzeria is the plain cheese slice. If the plain slice is perfect, you know everything else is going to be fantastic.

The Shift to Modern Ovens

Baking is where the magic happens—it’s the moment the dough, sauce, and cheese all come together. The choice of oven isn't just a technical detail; it’s a defining factor in getting that signature New York texture. While the earliest pizzerias were firing pies in blisteringly hot coal ovens, a major technological shift completely redefined the style.

The evolution from traditional Neapolitan pizza to the New York style was heavily shaped by a crucial operational shift in the early 20th century: the move from coal to gas-fired deck ovens.

This change, which really took hold around 1934, was a game-changer. Gas ovens allowed pizzerias to bake multiple pies at once at lower, more stable temperatures between 500°F and 650°F. This created a crust with a perfectly crisp exterior and a tender, foldable interior—exactly what was needed for the city's grab-and-go culture. You can read more about this slice of pizza history from Flour + Coffee.

This development was absolutely critical for the "by-the-slice" business model to even exist. Gas deck ovens provided the consistency needed to serve a never-ending line of customers, baking each slice to crispy, foldable perfection.

Why Deck Ovens Dominate

Fast forward to today, and the gas-fired deck oven is still the undisputed workhorse of most New York pizzerias. Its design is just perfectly suited for the job. The stone or ceramic "deck" blasts intense, direct heat from below, which is what gives the bottom of the crust its signature crispness. At the same time, the ambient heat swirling around the oven cavity melts the cheese and cooks the toppings.

This dual-action baking is what creates that perfect textural contrast: a firm, crispy bottom that can be folded without cracking, a chewy interior, and a beautifully browned top. For any restaurant aiming to truly master the New York pizza style, investing in the right deck oven isn't just a suggestion—it's a requirement for getting it right and running an efficient operation.

Choosing Your Pizzeria's Most Valuable Player

For any serious pizzeria, the kitchen's success hinges on workflow. While ovens get all the glory and the dough gets all the attention, the real heart of a high-volume operation is the pizza prep table. This single piece of equipment is the command center where efficiency, food safety, and consistency all meet. It’s not just another workspace; it’s the most critical investment you can make for serving authentic New York pizza style at scale.

Think of it as the pizzaiolo's cockpit. Everything needed to build a perfect pie is organized, chilled, and within arm's reach. This is what empowers a pizza maker to work with speed and precision, even when the order tickets are piling up during a chaotic Friday night rush. Without one, a kitchen quickly descends into a scramble of reaching, cross-contamination risks, and inconsistent topping portions.

For a restaurant specializing in the fast-paced, high-turnover world of New York pizza style, a refrigerated prep table is absolutely non-negotiable. It’s the difference between a smooth, profitable service and one that constantly struggles to keep up.

Anatomy of a Perfect Prep Station

Not all pizza prep tables are created equal, and the right features can make or break your kitchen’s output. When you're picking out a unit, you aren't just buying a refrigerator with a cutting board on top; you're designing your production line. Certain key components directly influence how fast and effectively your team can work.

The first thing to look at is the cutting board depth. This is your primary work surface where dough gets sauced and topped. A deeper board, typically 19 inches or more, gives you enough real estate to handle a large, hand-tossed New York-style skin without ingredients spilling everywhere. A cramped workspace just forces sloppy work and slows everything down.

Next up is the refrigerated rail. This is the series of cooled pans holding your cheese, pepperoni, and other toppings. The capacity and layout of this rail are vital. A well-designed rail keeps every single ingredient at a food-safe temperature below 41°F (5°C), which is a non-negotiable for passing health inspections and serving quality food. It also ensures every topping is a simple arm's reach away, minimizing movement and maximizing speed.

A pizzeria’s workflow is a direct reflection of its equipment. A properly sized and configured pizza prep table streamlines the assembly process, cutting down production time per pizza and allowing for a higher volume of sales during peak hours. It’s a direct link to profitability.

Key Features for Pizzeria Success

Beyond the basics, a few other features separate a standard prep table from one truly built for the demands of a real pizzeria. Making the right choice here is about future-proofing your operation and giving your team the tools they need to maintain high standards, shift after shift.

When you're shopping around, keep these critical elements in mind:

- Refrigerated Cabinet Space: The under-counter storage is just as important as the rail. It's where you'll stash backup ingredient pans, dough boxes, and other essentials. Make sure the capacity matches your daily prep volume to avoid constant trips to the walk-in cooler.

- Airflow and Cooling System: Look for units with a forced-air refrigeration system. This technology is designed to push cold air evenly throughout the rail and cabinet, getting rid of those dangerous hot spots that can spoil expensive ingredients like cheese and meats.

- NSF Certification: This is an absolute must-have for any commercial kitchen. An NSF-certified unit meets strict public health and safety standards, which means it's easy to clean, durable, and designed to prevent foodborne illness.

- Ergonomics and Durability: The table should be built from high-quality stainless steel for longevity and easy cleaning. Also, think about the working height. An ergonomically sound station reduces staff fatigue, which is a major factor in maintaining speed and morale during long, grueling shifts.

I've seen too many pizzeria owners try to save a few bucks on a prep table, only to regret it later. A quality unit is a serious piece of equipment that directly supports the consistency of your New York pizza style product, shores up your food safety, and empowers your staff to perform at their best.

When you're comparing models, it's easy to get lost in the details. This table breaks down the most important features and explains why they matter for a New York-style pizza operation.

Pizza Prep Table Feature Comparison

| Feature | Importance for NY Pizza Style | What to Look For |

|---|---|---|

| Cutting Board Depth | High - Essential for handling large 18"+ pizza skins without making a mess or feeling cramped. | Look for a depth of 19 inches or more. A raised rail design also helps contain toppings. |

| Refrigerated Rail Capacity | High - Needs to hold all your core toppings (cheese, sauce, pepperoni) plus popular extras. | A 6 to 9 pan capacity is a good starting point for most pizzerias. High-volume spots may need 12+. |

| Forced-Air Refrigeration | High - Ensures consistent and food-safe temperatures across the entire rail, preventing spoilage. | Look for models that explicitly mention "forced-air" or "air-cooled" systems for even temperature distribution. |

| Under-Counter Storage | Medium to High - Crucial for holding backup ingredients, dough boxes, and sauces to minimize trips to the walk-in. | Choose a capacity (in cubic feet) that matches your daily volume. Two-door models offer more flexibility. |

| Stainless Steel Construction | High - Provides durability against acidic sauces, constant cleaning, and the general abuse of a busy kitchen. | Aim for 304-grade stainless steel for both the interior and exterior for maximum corrosion resistance. |

| NSF Certification | Essential - A non-negotiable for passing health inspections and ensuring the unit is safe for commercial use. | The unit must be NSF/ANSI 7 certified. Don't even consider a table without it. |

Choosing the right features from the get-go saves you countless headaches down the road. It ensures your team has a functional, safe, and efficient station that can handle the pressure of a dinner rush, which is ultimately what makes you money.

Lessons From New York's Legendary Pizzerias

The story of New York pizza is really a collection of brilliant business blueprints masquerading as humble slice shops. To truly get what makes this style so timeless, you have to look at the legendary pizzerias that built its reputation, places like the iconic Joe's Pizza or the historic Totonno's. These spots offer real-world lessons in branding, consistency, and running a tight ship.

Their success isn't just about a secret recipe; it's about delivering uncompromising quality at a massive scale. Every choice they make, from hand-stretching each dough on a well-floured board to firing it in a specific deck oven, directly reinforces their promise of an authentic, reliable slice. It's a masterclass in how sticking to your guns can build a loyal following that spans generations.

The Power of Simplicity and Consistency

Think about it: legendary pizzerias built their empires on the simple cheese slice. They knew that if the plain slice is perfect—with its balanced sauce, quality mozzarella, and flawless crust—everything else just falls into place. This obsession with nailing the fundamentals, day in and day out, is the most important lesson they teach.

When a customer walks into Joe's Pizza, they expect the exact same fold, crisp, and flavor they got ten years ago. That kind of trust is an incredibly powerful branding tool that turns first-timers into lifelong fans. For any restaurant opening a pizzeria today, this is the key takeaway: before you start dreaming up fancy toppings, make sure your classic cheese slice is an unforgettable experience. That's the foundation you build a brand on.

Adapting While Honoring Tradition

But the New York pizza style isn't some relic frozen in time; it's always evolving. While the old-school legends hold down tradition, a new wave of innovators is pushing the style forward, adapting to modern tastes without forgetting what makes it great in the first place. These newer pizza restaurants show us how to honor tradition while still getting creative.

For example, the game-changing decision in the mid-20th century to sell pizza by the slice made it cheap and convenient for busy New Yorkers. That business model alone helped the New York pizza style explode into a huge industry, with over 400 pizzerias in NYC by 2010. Over time, toppings expanded beyond pepperoni to include things like buffalo chicken or white pizza, reflecting the city’s diverse palate. You can learn more about this evolution and how the slice became an icon at Little B’s Starry Town.

The most successful modern pizzerias don't abandon the rules; they bend them thoughtfully. They might use a unique blend of three cheeses or source artisanal pepperoni, but they never sacrifice the core elements: the foldable crust, the simple sauce, and the perfect bake.

At the end of the day, the lessons from New York's greatest pizzerias are about more than just food. They’re about building a lasting business on a foundation of quality, efficiency, and a deep respect for the craft. To learn more about creating that perfect foundation for your own pizzeria, check out our guide on the essentials of New York pizza. It's this approach that turns a simple slice into a powerful and enduring brand.

Your New York Pizza Questions Answered

We get it. Making the jump from being a pizza lover to a pizzeria owner brings a whole new set of questions to the table. We’ve heard them all over the years, so let's tackle some of the most common ones we get from aspiring restaurant professionals.

Here’s some straight-up advice to help you get that authentic New York pizza style just right in your pizzeria.

How Can I Replicate NY Water For My Dough?

Ah, the legendary New York City water. It’s a story every pizza maker has heard. But here’s the secret: you can get incredibly close without having to move your shop to Manhattan. The magic isn't in the water itself, but in its specific mineral content, which is fantastic for strengthening gluten.

The trick is to first filter your local water, then add back what you need. You can find commercial products, sometimes called "New York Pizza Dough Water Kits," that do the heavy lifting for you. Or, if you're more of a DIY type, you can add very small, precise amounts of calcium sulfate and magnesium sulfate to replicate the water hardness that gives NY dough its famous elasticity and chew.

What Is The Ideal Deck Oven Temperature?

A classic New York slice isn't blasted with crazy-high heat like a Neapolitan pie. It's a slower, more controlled bake. For that iconic crisp-yet-pliable crust, you want to set your gas-fired deck oven somewhere between 550-600°F (285-315°C).

This temperature range is the absolute sweet spot. It’s hot enough to turn the crust a beautiful golden brown and get it crisp without burning, but it's also gentle enough to give that low-moisture mozzarella the time it needs to melt perfectly. This moderate heat is also what makes reheating slices to order so quick and effective.

This consistent, manageable heat is the engine behind any successful by-the-slice operation. It’s how you guarantee that every single slice has the reliable texture your customers are coming back for.

Is A Pizza Prep Table Really Necessary For A Small Pizzeria?

Yes. 100% yes. I don't care if you're opening a tiny slice shop or a full-scale restaurant—for any commercial pizza restaurant, a dedicated pizza prep table is one of the most fundamental pieces of equipment you can buy. It comes down to two things: speed and safety.

A good prep table consolidates your entire assembly line into one efficient unit. It gives you a dedicated workspace while keeping all your toppings perfectly chilled and literally at your fingertips. This kind of organized setup is non-negotiable for preventing cross-contamination and making sure every ingredient stays at a safe temperature.

Trying to run a service without one will absolutely crush your ticket times, especially when you get slammed. A quality prep table isn't an expense; it's an investment in speed, consistency, and food safety—the three pillars of any pizzeria that plans on staying in business.

Ready to build the heart of your kitchen? At Pizza Prep Table, we provide the high-quality, NSF-certified equipment that powers successful pizzerias. Find the perfect workstation to streamline your workflow and perfect your New York pizza style at https://pizzapreptable.com.