Mastering New York Pizza for Your Restaurant

Share

When you think of New York pizza, what comes to mind? For most people, it’s that classic large, hand-tossed, thin-crust slice that’s somehow both crisp and perfectly foldable. It’s an icon, a staple for countless pizza restaurants across the city.

This pizza is built on a foundation of high-gluten flour, giving it a signature balance of chew and crunch. It's then topped with a simple, bright tomato sauce and a generous layer of low-moisture mozzarella, all assembled on a dedicated pizza prep table for consistency.

What Truly Defines New York Pizza

To really nail this style for your pizzeria, you have to go beyond just "a foldable slice." The magic is in the details—a specific combination of ingredients, time-tested techniques, and the right equipment that all come together in that final product customers line up for. This is what separates an authentic New York slice from a pale imitation.

It all starts with the crust. The secret weapon here is high-gluten flour, which creates a strong, elastic dough. But the real game-changer is the fermentation process. This isn't a quick-rise dough; it undergoes a slow, cold fermentation that often lasts from 24 to 72 hours. This isn't just a waiting game. It’s a critical step that develops the complex, slightly tangy flavors that a successful pizza restaurant is known for.

The Signature Flavor Profile

Once you have the perfect crust, the toppings are all about restraint. The sauce isn't a complex, herby concoction. It’s typically just uncooked, crushed tomatoes seasoned with a bit of salt, maybe a touch of oregano or garlic. The goal is to let that bright, fresh tomato flavor be the star.

The cheese choice is just as critical—and it’s non-negotiable for any serious pizza restaurant. You have to use full-fat, low-moisture mozzarella. Here’s why:

- It melts evenly: This is how you get that classic, picture-perfect cheesy pull without releasing a ton of water and making the pizza soggy.

- It prevents greasiness: Compared to fresh mozzarella, its lower fat content means you won't have pools of oil on the surface.

- It browns beautifully: You’ll get those coveted toasted, golden-brown spots without the cheese burning.

From Humble Origins to Global Icon

You can’t talk about New York pizza without talking about its immigrant roots. The story kicks off in 1905 when Gennaro Lombardi opened what’s widely recognized as America's first pizzeria in Manhattan's Little Italy. He started by selling simple but delicious tomato pies to factory workers, creating a food that was both affordable and deeply satisfying.

This culinary tradition was carried on by legendary pizzaiolos like Antonio Totonno Pero, who would later open the iconic Totonno's Pizzeria on Coney Island.

A key takeaway for any aspiring pizzeria owner is that authenticity matters. Customers can taste the difference. Replicating the texture and flavor of a true New York slice requires sweating every detail, from the dough's long, cold ferment to the sauce's beautiful simplicity.

Understanding these foundational elements is your first step. For a deeper dive into the nitty-gritty, check out our guide on crafting the perfect New York style pizza at a professional level. This knowledge sets the benchmark for everything else, including how you set up your kitchen and your pizza prep table for peak performance.

Crafting High-Volume New York Pizza Dough

The very soul of an authentic New York pizza is its dough. For any pizzeria aiming to serve dozens—or hundreds—of pies a day, mastering a high-volume dough recipe isn't just an art. It's a science of consistency.

Forget those small-batch home recipes. We're talking commercial-grade production where every single dough ball must perform identically, from the first order of the day to the last. This level of quality control starts with the right ingredients and professional equipment. Each one plays a specific, critical role in creating that signature chewy-crisp bite that defines a true New York slice.

The Professional Baker's Ratios

In a commercial pizza restaurant, precision is everything. While home bakers might measure by the cup, a pizzeria measures by baker's percentages. This method ensures that no matter how big the batch is—from 50 pounds to 200 pounds of flour—the dough's characteristics remain absolutely constant. This is the only way to guarantee consistent hydration, texture, and flavor at scale.

A reliable starting point for a classic New York-style dough uses these core ingredients in precise ratios:

- High-Gluten Flour (100%): This is your baseline and the structural backbone of your pizza. With a protein content of 13-14.5%, this flour provides the strength needed for a large, thin, foldable crust that won't tear.

- Water (60-65%): Hydration is key. A lower hydration (around 60%) produces a dough that's easier for less experienced staff to handle. Pushing it up to 65% can yield a lighter, airier crust, but it definitely requires more skill to manage.

- Salt (1.8-2.5%): Salt is so much more than flavor. It's a control mechanism for the yeast, preventing over-fermentation, and it also tightens the gluten structure, adding crucial strength to the dough.

- Instant Dry Yeast (0.4-0.6%): For a long, cold fermentation, you need very little yeast. This tiny amount works its magic slowly in the refrigerator, developing incredible flavor without over-proofing the dough.

- Oil (1-2%): Just a touch of olive oil adds a hint of flavor, helps the crust brown evenly, and makes the dough slightly softer and easier to stretch.

- Sugar (1-2%): A little bit of sugar gives the yeast something to eat, but more importantly, it helps with browning. This is especially useful in ovens that bake at slightly lower temperatures.

This balanced formula ensures every batch has the same feel, the same fermentation rate, and the same baking characteristics—an absolute must for a smooth workflow in a busy pizzeria.

The Cold Fermentation Imperative

One of the biggest mistakes a new pizza restaurant can make is rushing the dough. True New York pizza flavor is developed over time, not in a few hours on a warm countertop. Cold fermentation is the non-negotiable process of letting the dough develop slowly in a refrigerator for at least 24 hours, and ideally up to 72 hours.

During this slow, cold proof, enzymes get to work breaking down complex starches and proteins in the flour. This process doesn't just create a more complex, slightly tangy flavor; it also makes the dough more extensible and easier to stretch without snapping back. It's the secret to that classic texture.

A dough that has undergone a proper cold fermentation is noticeably more flavorful and has a superior, bubbly crust structure. You simply cannot skip this step if you want to produce a genuinely premium product that stands out.

Commercial Mixing and Handling Techniques

When you're making huge batches for your pizza restaurant, a commercial spiral mixer is your best friend. Unlike a planetary mixer, a spiral mixer's hook moves in concert with a rotating bowl. This action is much more gentle and efficient, developing the gluten without generating the excessive friction heat that can kill your yeast and ruin the batch.

The key is to avoid overworking the gluten. You want to mix just until the dough comes together and looks smooth—a stage we call the "gluten window." You can test this by taking a small piece of dough and gently stretching it. If you can stretch it thin enough to see light through it without it tearing, your gluten is perfectly developed. Stop mixing.

Once mixed, the dough is divided into individual portions (an 18-20 ounce ball is perfect for a classic 18-inch pizza), balled tightly, and placed into dough boxes. These boxes are then sent to the walk-in cooler or a dedicated refrigerated pizza prep table to begin their long, cold sleep, ensuring that when your pizza makers grab a dough ball during a busy service, it's perfectly proofed and ready to go.

Putting Your Pizza Prep Table to Work

In the theater of a high-volume pizza restaurant, the prep table is center stage. This is where a perfectly fermented dough ball gets its shot at becoming a menu masterpiece. A disorganized station leads to inconsistent pizzas, wasted ingredients, and slow ticket times. But a well-oiled workflow turns your pizza prep table into an engine of speed and precision, which is non-negotiable when you’re slinging authentic New York pizza at a relentless pace.

It all boils down to a classic kitchen principle: mise en place, or "everything in its place." Before the first order of the day hits the printer, every single ingredient, tool, and surface needs to be perfectly positioned for a seamless assembly line. This prep work is the thin line between a kitchen that flows and one that flounders.

Laying Out Your Station for Maximum Speed

Your pizza prep table isn't just a hunk of stainless steel; it's the command center of your pizza restaurant's kitchen. The layout has to be a logical, ergonomic sequence that cuts down on wasted movement. For a classic New York pie, the flow should feel second nature, moving from left to right (or right to left, if your pizzaiolo is a lefty).

Picture the workflow: your pizza maker grabs a proofed dough ball from a refrigerated drawer built right into the pizza prep table, slaps it on the floured work surface, and starts stretching. Once stretched, the base slides to the sauce station. From there, it glides over to cheese, then toppings, all within arm’s reach.

This straight-line progression eliminates crossed arms and frantic searching. Every second you shave off at the prep table adds up, especially during a Friday night rush.

Key Layout Elements:

- Dough Access: Keep proofed dough balls in under-counter refrigerators or dedicated dough drawers built right into the pizza prep table. No running to the walk-in.

- Flour Bin: A small, easy-to-reach bin for dusting flour should live right next to the stretching area.

- Work Surface: A cold surface like marble or stainless steel is your best friend. It keeps the dough from getting warm and sticky, which is critical for handling.

- Ingredient Rails: These refrigerated rails are the heart of the operation. They hold all your sauces and toppings at a safe, cool temperature, ready for action.

The Art of the Ingredient Rail

A cluttered ingredient rail on your pizza prep table is a one-way ticket to disaster. Organizing it is about more than just looking tidy; it's about speed and food safety. Your most-used items need to be in the most accessible spots. Period.

For a typical New York-style restaurant, the order should be intentional:

- Sauce: This is the first stop after stretching the dough. It needs to be in a large, deep pan for quick and easy ladling.

- Cheese: Right next to the sauce. Grated low-moisture mozzarella should be in the biggest container, as it goes on nearly every pizza.

- Core Toppings: Your biggest sellers, like pepperoni, should be next in line.

- Specialty Toppings: Things like mushrooms, onions, and peppers follow, arranged by popularity.

This setup ensures that building your most common pizzas requires the least amount of movement.

An organized pizza prep table does more than just speed up service; it directly impacts food quality and cost. When toppings are easy to grab, your team is less likely to over-portion, reducing food waste which can save a pizza restaurant thousands of dollars annually.

Work Surface and Essential Tools

The surface of your pizza prep table matters more than you might think. Stainless steel is the industry standard—it’s tough and NSF-certified. Marble, however, has a key advantage for pizza restaurants: it stays naturally cooler, which helps keep delicate pizza dough from sticking or getting overworked while you stretch it.

Beyond the surface, a few simple tools are non-negotiable for an efficient setup:

- Sauce Ladle: A flat-bottomed ladle is what you need to spread sauce quickly and evenly. A 4-ounce ladle is pretty standard for an 18-inch pie.

- Pizza Screens: These are a lifesaver, especially for new staff. They help guarantee a perfectly round shape and make sliding the pizza into the oven much easier.

- Pizza Peels: You'll need at least two. A wooden peel for building and a metal peel for turning and pulling the finished pizza from the hot oven.

When you treat your prep station with this level of detail, you empower your team. For more expert tips, you can learn more about the secret sauce behind efficient pizza prep stations and how to dial in your own setup. This obsession with workflow is a core ingredient in any successful pizza restaurant.

You’ve made it. Your dough is perfectly proofed, your station is organized, and now it’s time for the magic. This is the moment where all that careful preparation—from the long fermentation to setting up your pizza prep table—truly pays off. The hands-on assembly and the blast of high heat are what turn simple ingredients into a genuine New York pizza.

First thing's first: put the rolling pin away. An authentic New York crust gets its texture from being gently stretched by hand. This technique is crucial because it pushes the air from the center of the dough out to the edges, forming that iconic raised cornicione (the crust). A rolling pin just crushes all those delicate air pockets, leaving you with a dense, cracker-like crust.

Perfecting the Hand Stretch and Toppings

Grab a proofed dough ball and place it in a small mound of flour on your work surface. Using just your fingertips, gently press down in the center, leaving a one-inch border untouched.

Once you’ve formed a small disc, it’s time to let gravity do the heavy lifting. Pick up the dough and drape it over your knuckles. As you gently rotate it, the dough will naturally stretch itself into a wide, even circle. This is where a cold work surface, like the marble or stainless steel top of a quality pizza prep table, becomes your best friend. It keeps the dough from getting warm and sticky.

With the base stretched, it’s time for toppings. And when it comes to a classic New York slice, less is always more.

- The Sauce: Use a 4-ounce flat-bottomed ladle. Apply a thin, even layer of your simple tomato sauce in a spiral motion, leaving that one-inch border clean.

- The Cheese: Generously cover the sauce with whole-milk, low-moisture mozzarella. Even distribution is key to getting that perfect cheesy pull.

- The Toppings: Place your toppings evenly for a balanced flavor in every single bite.

From Peel to Oven: Mastering the Launch

For any new pizzaiolo, the launch—sliding the assembled pizza from the peel onto the hot oven deck—can be the most nerve-wracking step. The secret? A light dusting of flour or semolina on your wooden peel. A classic rookie mistake is letting a sauced pizza sit on the peel for too long; the moisture glues the dough to the wood.

Right before you launch, give the peel a little shimmy. The pizza should slide freely. When you’re ready, position the tip of the peel toward the back of your pizza stone, tilt it, and use a quick, confident pull to slide the pizza smoothly onto the deck.

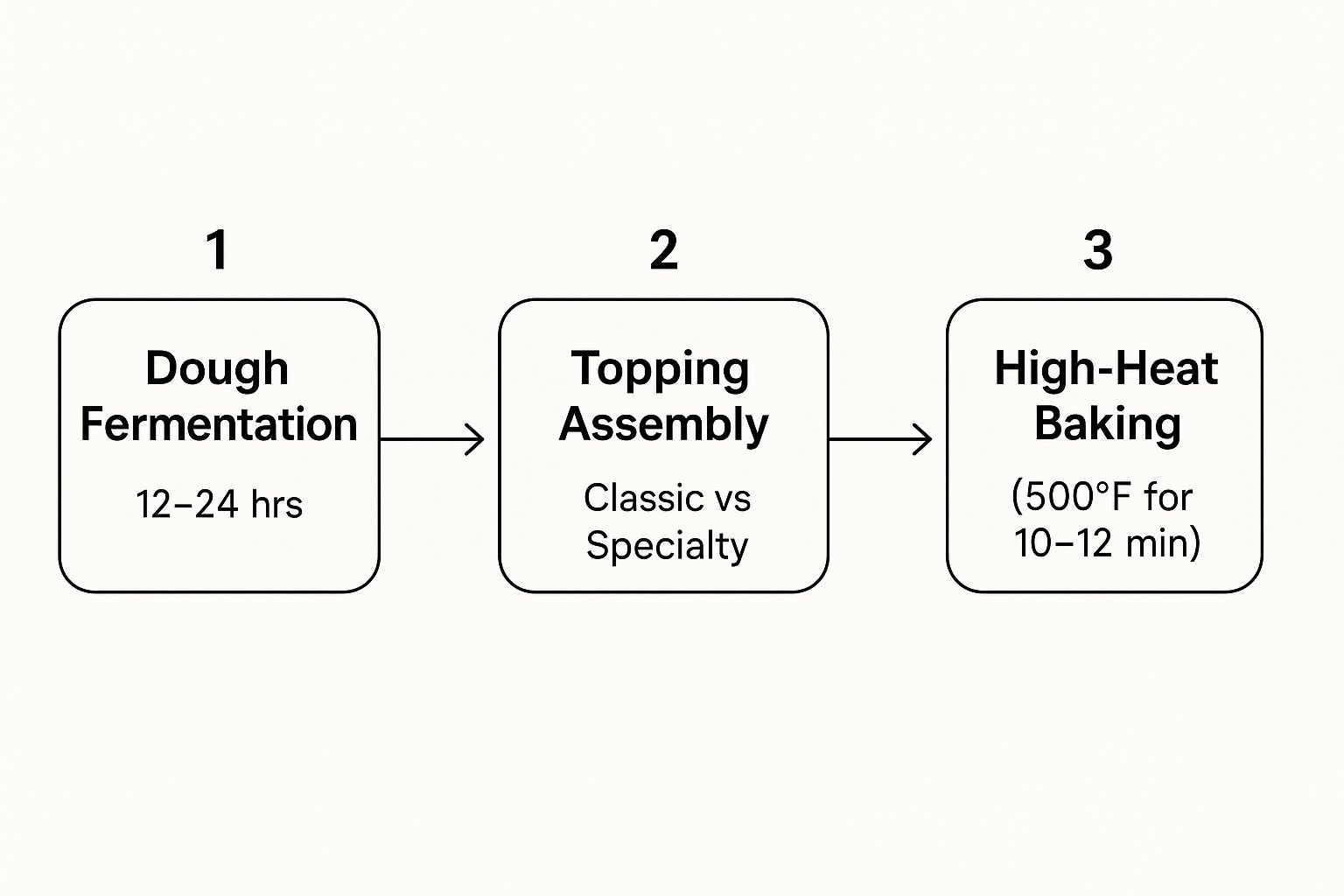

This process, from fermentation to the final bake, is a finely tuned dance.

As you can see, every phase—from a patient dough ferment to a swift, high-heat bake—is a critical link in the chain of producing an authentic New York pizza that will keep customers coming back to your restaurant.

Achieving the Perfect High-Heat Bake

The final piece of this puzzle is the bake. Professional deck ovens, the gold standard in every great NYC pizza restaurant, cook with intense, direct heat from the bottom stone (the deck). You want to get your oven roaring between 500°F and 550°F. This blistering heat cooks the pizza fast, in about 10-12 minutes, creating the texture we’re all chasing: a crisp, slightly charred bottom, a chewy interior, and perfectly melted, bubbly cheese.

The real secret to a great bake is oven management. You have to know your oven's hot spots. About halfway through, use a metal peel to give the pizza a quick rotation. This ensures it bakes evenly and prevents one side from burning while the other is still doughy.

It’s this dedication to the craft that separates the good pizzerias from the legendary ones. In a city like New York, the competition is unbelievably fierce. It's a market where only the best pizza restaurants survive.

This table shows just how popular pizza is across the five boroughs, illustrating the high concentration of pizzerias that makes the market so competitive.

NYC Pizza Restaurant Distribution by Borough

| Borough | Number of Pizza Restaurants | Notable Fact |

|---|---|---|

| Manhattan | 623 | The most pizzerias, but also the highest competition and operating costs. |

| Brooklyn | 585 | Home to some of the most iconic and historic pizzerias in the city. |

| Queens | 322 | Known for its diverse range of pizza styles reflecting its multicultural population. |

| The Bronx | 179 | A strong market for traditional, neighborhood-focused pizzerias. |

| Staten Island | 104 | Has the highest number of pizzerias per capita among the boroughs. |

In 2022, the city was home to an incredible 1,813 pizza restaurants serving its 8.8 million residents. Standing out in that crowd requires an unwavering commitment to quality at every single step. It's a high bar, proven by the 115 pizzerias that have managed to earn a perfect 5-star rating from some of the world's toughest critics: New Yorkers. You can explore more fascinating data about this competitive market and what it truly takes to succeed.

Choosing Your Commercial Pizzeria Equipment

For any serious pizza restaurant owner, your equipment is the engine of your business. Investing in the right tools is a cornerstone decision that directly impacts the quality of your New York pizza, your kitchen's workflow, and your bottom line. Building a professional kitchen is really about matching the machinery to your ambition, space, and budget.

The competition is fierce out there, especially in a place like New York City, where there are 1,813 pizza restaurants. Standing out requires a commitment to excellence that starts with the gear you choose, especially a quality pizza prep table and oven.

Selecting the Right Pizza Oven

The oven is the heart and soul of your pizza restaurant. Your choice here will define your crust's texture and how many pies you can produce during a dinner rush. There are three main types to consider for your restaurant.

- Deck Ovens: This is the classic, the traditional choice for authentic New York-style pizza. The stone deck blasts intense, direct heat into the bottom of the crust, creating that signature crisp-yet-chewy base that people crave. They demand skill to master, but the results are second to none for a serious pizza restaurant.

- Conveyor Ovens: These are built for speed and consistency. A conveyor oven pulls pizzas through a heated chamber on a belt, and they're incredibly easy to use. They're a perfect fit for high-volume shops where getting pizzas out the door fast is the top priority.

- Brick Ovens: While they look stunning, true wood-fired brick ovens cook at scorching-hot temperatures and are really better suited for Neapolitan-style pizza. A deck oven is generally the better tool for a classic New York pizza restaurant.

Powering Your Dough with a Commercial Mixer

Hand-mixing dough is simply not an option when you're running a commercial pizza restaurant. A powerful commercial mixer is non-negotiable for producing consistent, high-quality dough day in and day out.

A spiral mixer is the undisputed industry standard for pizza dough. Its gentle mixing action develops the gluten structure perfectly without overheating the dough. When choosing, you need to match the mixer's capacity to your restaurant's daily output. A small shop might get by with a 60-quart mixer, but a high-volume pizzeria will need an 80 to 140-quart workhorse.

Your mixer's horsepower (HP) is just as critical as its size. An underpowered motor will strain with large batches of stiff dough. Always opt for a mixer with enough power to handle your toughest recipes without breaking a sweat.

Choosing the Best Pizza Prep Table

Your pizza prep table is where your kitchen's efficiency is won or lost. It's the command center for assembly, and picking the right one can make or break your entire workflow.

Size is the first thing to nail down. Models range from compact 48-inch units to sprawling 96-inch workstations. Measure your kitchen space carefully, but also think about your menu. A larger pizza prep table gives you more refrigerated rail space, which means you can offer a wider variety of fresh toppings.

The work surface is another crucial choice. Stainless steel is the reliable standard—it’s durable and easy to sanitize. However, many seasoned pizzaiolos swear by a marble work surface on their pizza prep table. Marble stays naturally cooler, which helps keep the dough from getting sticky and becoming a nightmare to stretch during a busy service.

For a complete rundown of all the options, you can dive into our guide to choosing commercial kitchen equipment for your restaurant. It’ll help you weigh the pros and cons to find the perfect fit for your pizzeria.

Common Questions About New York Pizza and Equipment

When you're first opening a pizza restaurant, the questions come thick and fast. From the nitty-gritty of dough chemistry to the practical realities of kitchen hardware like the pizza prep table, every detail plays a part. Getting these details right can be the difference between a struggling startup and a pizzeria that becomes the talk of the town for its incredible New York pizza.

Let's dive into some of the most common questions from aspiring restaurant owners.

What Is the Ideal Dough Hydration?

Dough hydration—the ratio of water to flour—is a constant debate in pizza circles. For a classic New York-style dough in a restaurant setting, the sweet spot is a hydration level between 60% and 65%.

A lower hydration of around 60% creates a dough that's stiffer and much easier for a new team to handle. It's dependable and produces a fantastic, foldable crust. As your restaurant staff gets more comfortable, you can push the hydration closer to 65%, which can give you a lighter, airier crust. My advice? Start at 60-62% and slowly dial up the water as your team's confidence grows.

A huge part of running a successful pizza restaurant is making sure hungry locals can actually find you. A great first step is to optimize your Google Business Profile so you show up when they're searching for the best slice nearby.

How Do You Prevent Oily Pizza?

Nothing ruins a great slice faster than a pool of orange grease. The problem almost always comes down to the cheese. The fix is simple for any pizza restaurant: use whole-milk, low-moisture mozzarella.

This specific type of mozzarella has the perfect balance of fat and moisture for a high-heat pizza oven. It melts smoothly and browns beautifully without releasing a ton of extra oil or water. Using fresh mozzarella might sound fancy, but its high water content is the main culprit behind a soggy, greasy mess on a New York-style pie. Stick with the low-moisture stuff.

Choosing a Pizza Prep Table for a Small Kitchen

In most restaurant kitchens, space is gold. When your kitchen is tight, a 44-inch or 60-inch pizza prep table is often the perfect fit. These compact units are workhorses, combining refrigerated storage, ingredient rails, and a workspace into one efficient piece of equipment.

When you're picking a pizza prep table for your restaurant, here’s what to look for:

- Refrigerated Base: Models with under-counter drawers are absolutely perfect for storing dough boxes, keeping them perfectly chilled and right where you need them.

- Cutting Board Depth: A deeper cutting board (19 inches or more) on your pizza prep table gives you plenty of room to stretch an 18-inch pie without feeling cramped.

- NSF Certification: This is non-negotiable. Make sure any pizza prep table you buy is NSF-certified. It's a requirement to meet health codes and ensures the unit is built for commercial food safety.

Is a Deck Oven Really Necessary?

For a truly authentic New York pizza restaurant? Yes. A resounding yes. A deck oven’s stone hearth is what creates that signature crust. It blasts intense, direct heat into the bottom of the dough, giving you that perfectly crisp, slightly charred base that still has the classic New York fold.

A high-quality conveyor oven can pump out a consistent product, but it bakes with circulating hot air. That method cooks evenly, but it just can't replicate the unique texture you get from a blazing hot stone deck. For that unmistakable New York bite that defines a top-tier pizza restaurant, a deck oven is the gold standard.

At Pizza Prep Table, we get it—the right equipment is the foundation of any great pizza restaurant. We offer a huge selection of new and used pizza prep tables, ovens, and mixers designed to fit any kitchen and any budget. Let us help you find the perfect equipment to build your pizza empire at https://pizzapreptable.com.