Explore Authentic New York Style Pizza New York Today!

Share

You can’t talk about pizza in America without talking about New York–style. It’s more than just food; it’s an institution. For pizza restaurants, mastering this iconic dish is the ultimate goal. We're talking about those massive, foldable slices with a thin, crisp-yet-chewy crust, a slick of bright, uncooked tomato sauce, and a generous blanket of low-moisture mozzarella, all assembled with speed and precision on a well-organized pizza prep table.

What Makes New York Pizza an Icon?

To really master making authentic New York pizza, a restaurant must understand its cultural DNA. This isn't just another menu item. It was born out of the city's fast-paced, on-the-go lifestyle. That huge, foldable slice wasn't just a gimmick; it was a practical solution for a quick meal, a model that successful pizza restaurants still follow today.

It all started back in the early 1900s when Italian immigrants brought their culinary genius to the city. By the 1920s, pizzerias selling hand-tossed, thin-crust pies had become a local obsession. Today, with 5,719 pizza outlets documented in New York state alone, it's clear this isn't just a food trend—it's a competitive industry where efficiency and authenticity are paramount.

The Non-Negotiable Elements

Authentic New York pizza is built on a few core principles. If you're a pizzeria owner, these are your commandments. Stray from them, and you're making a good pizza, maybe, but you're not making a New York pizza. The goal is a perfect harmony of texture and flavor, where no single ingredient steals the show.

Before we dive into the nitty-gritty of making it, let's break down what separates a true New York slice from all the imposters. This quick-reference table is your quality control checklist—the non-negotiable elements that define authenticity for any pizza restaurant.

Anatomy of an Authentic New York Slice

| Component | The New York Standard | Why It Matters for Authenticity |

|---|---|---|

| The Crust | High-gluten flour, long cold fermentation. Sturdy enough to fold, tender enough to chew. | The high protein develops a strong gluten network for that signature chew and foldable structure without flopping. Cold fermentation builds complex, slightly tangy flavors you can't get from a quick dough. |

| The Sauce | Uncooked, crushed tomatoes, simply seasoned with salt, oregano, and maybe garlic. Bright and tangy. | A raw sauce provides a fresh, acidic counterpoint to the rich cheese and savory crust. A heavy, cooked-down sauce would overwhelm the other components and make the pizza taste generic. |

| The Cheese | Low-moisture, whole-milk mozzarella. Grated, not fresh. It should melt smoothly with a satisfying pull. | Low-moisture is critical to avoid a soggy, watery pizza. Whole milk provides the necessary fat content for that perfect melt and rich flavor. It’s all about the cheese pull without the grease pool. |

Getting this trifecta right is what separates a legendary slice from just another pizza. It's a delicate balance that customers who know their pizza will spot immediately.

The perfect New York slice is a masterclass in balance. The crust must be sturdy enough to fold but tender enough to chew, the sauce bright and acidic, and the cheese perfectly melted. Getting this trifecta right is what separates legendary pizza restaurants from the rest.

From Street Corner to Global Symbol

New York pizza's journey from a local favorite to a global icon is tied directly to the city's cultural gravity. Pizzerias like Joe's Pizza, Bleecker Street Pizza, and John's of Bleecker Street are more than just restaurants—they're landmarks. Tourists and locals line up for a slice of history.

This global reputation sets a high bar for new pizza restaurants. To compete, you have to honor the tradition while delivering unwavering quality. That process starts long before a pizza ever hits the oven; it begins with sourcing the right ingredients and setting up your kitchen—especially your pizza prep table—for ruthless efficiency.

Understanding these core elements is the first step. For a deeper dive, check out our complete guide on authentic New York Style Pizza.

Creating Your Signature New York Pizza Dough

The soul of any authentic New York style pizza in New York isn't the sauce or the cheese—it's the dough. For a pizza restaurant, a great crust is your reputation, the foundation your entire business is built on. For commercial success, you have to move beyond simple home recipes. That means mastering large-scale production without sacrificing that iconic flavor and texture.

The secret to that legendary crust starts with the right flour. Commercial kitchens live and die by high-gluten bread flour, which typically has a protein content of 13-14%. This high protein is non-negotiable. It’s what gives you the power to develop a strong, elastic gluten network, the very thing that gives the crust its signature chew and lets you stretch it paper-thin without tearing.

Building Your Dough from Scratch

Forget all the myths about New York's "secret" water. While water quality and mineral content do play a small part, what truly matters for pizza restaurants is consistency. For a true New York-style pie, hydration level is king. The sweet spot is a hydration of around 60-65%. This just means that for every 1000 grams of flour, you'll use 600-650 grams of water. This ratio creates a dough that's easy to handle but soft enough for that perfect crisp-yet-pliable crust.

In a commercial kitchen, hand-kneading is completely out of the question. Your workhorse here is a heavy-duty spiral mixer. Unlike planetary mixers, spiral mixers gently knead huge batches of dough, developing the gluten just right without overheating or overworking it. A solid 10-12 minutes of mixing and kneading is all it takes to build the dough’s structure.

The real magic of New York pizza dough isn't just in the ingredients; it's in the process. Cold fermentation is the single most important step for developing the complex, slightly tangy flavor and perfect texture that defines an authentic New York crust.

This is where the real craft comes in, and it's where so many pizzerias fall short.

Mastering Cold Fermentation at Scale

Cold fermentation is the slow, patient proofing of dough in a refrigerator, usually for 24 to 72 hours. This process is critical for two reasons:

- Flavor Development: It slows down the yeast's party, giving enzymes time to break down starches into sugars. The result is a much deeper, more complex, and slightly sweet flavor profile.

- Texture Improvement: The long, slow ferment relaxes the gluten. This makes the dough incredibly easy to stretch and creates a crust with a beautiful, airy crumb and that satisfying chew.

To manage this with large batches, pizza restaurants need a system. After mixing, divide your dough into individual portions (a 450-500 gram ball is perfect for an 18-inch pie), ball them up tightly, and place them in dough proofing boxes. These boxes then go straight into a dedicated refrigerator.

This is where your kitchen layout, especially your pizza prep table, becomes vital. Many refrigerated pizza prep tables have under-counter space designed specifically to hold these dough boxes at the perfect temperature. This keeps your fermented dough perfectly chilled and ready to go, right where you need it. For those scaling up, understanding your equipment options is key. You can explore our ultimate guide to choosing the best pizza dough mixers to match your restaurant's volume.

The result of all this careful work is a dough that's not just a base, but a main attraction. When a customer bites into a slice, they’re tasting the time and technique you've invested. It’s what makes a pizza from a dedicated New York style pizza New York restaurant stand out from the crowd. It’s the chew, the flavor, and the craft—all starting with a perfectly fermented dough.

Setting Up Your Pizza Prep Table for Maximum Speed

In a packed New York pizzeria, every single second is money. The line between a smooth, profitable rush and total chaos often comes down to one piece of equipment: your pizza prep table. This isn't just a fancy fridge; it's the command center of your entire pizza-making operation. An efficient setup here is your assembly line for turning dough into dollars.

The whole game for pizza restaurants is built around mise en place, which is just a French way of saying "everything has its place." For a pizzeria, this means every single ingredient, from your perfectly proofed dough balls to the final shake of oregano, has a dedicated spot. The goal is simple: minimize movement, maximize output. A well-organized pizza prep table keeps your pizzaiolos building pies, not wasting precious seconds hunting for toppings.

Designing Your Kitchen Workflow

Your prep table should follow a straight line that mimics how a pizza is built. Think of it as a one-way street. Your dough, which has been cold-fermented and proofed, should live in under-counter refrigerators or dedicated dough drawers right where you need it. This keeps it at the perfect temperature until the exact moment it's stretched.

From there, the flow should move logically—usually left to right, but you can flip it if your pizza maker is a lefty or your kitchen layout demands it.

- Dough Station: This is where it all starts. A clean, lightly floured surface for stretching.

- Sauce and Cheese: Right next to the stretching area. The sauce ladle and a big container of low-moisture mozzarella should be right there, ready to go.

- Topping Rail: This is the most vital part of a commercial pizza prep table. The refrigerated rail holds all your toppings in standard pans, keeping them at food-safe temps.

Here's a pro tip for any pizza restaurant: arrange your toppings by popularity. Pepperoni, the undisputed king of toppings in the U.S., should be in the easiest spot to reach. Follow that with your other heavy hitters like mushrooms, sausage, and onions. This tiny bit of organization shaves seconds off every pie, and during a dinner rush, those seconds add up fast.

The journey from dough to oven is a high-speed, high-temperature sprint, which is why your pizza prep table has to be dialed in to keep up.

As you can see, the process is quick. Your prep station needs to be just as fast.

Choosing the Right Commercial Prep Table

Let's be clear: not all pizza prep tables are built the same. The right model for your shop depends entirely on your kitchen size, how many pizzas you plan to sling, and how complex your menu is. A small slice joint just has different needs than a huge, full-service restaurant.

Picking the right pizza prep table is a direct investment in your restaurant's speed and consistency. The right unit doesn't just keep ingredients fresh; it empowers your team to work faster and more efficiently, which hits your bottom line directly.

When you're shopping around, think about the features that will actually help your workflow. If you want a masterclass on what’s out there, you can learn how to prep like a pizza pro with these topping stations and find the perfect unit for your kitchen.

To make things a bit easier, I've put together a quick comparison to help you figure out what to look for.

How to Choose Your Commercial Pizza Prep Table

This table breaks down the common types of pizza prep tables, helping you match a model to your restaurant's specific needs and budget.

| Table Type | Ideal For | Essential Features to Look For | Typical Price Point |

|---|---|---|---|

| Standard Prep Table | High-volume pizzerias with a diverse menu. | A deep cutting board (19 inches or more), extensive refrigerated pan rails, and significant under-counter refrigerated storage. | $2,000 - $5,000 |

| Mega-Top Prep Table | Restaurants with a large number of fresh toppings. | An extra row of pan capacity in the rail, allowing for more ingredient variety without taking up more floor space. | $2,500 - $6,000 |

| Drawered Prep Table | Pizzerias focused on dough quality and organization. | Refrigerated drawers designed to hold standard dough boxes, keeping dough perfectly proofed and easily accessible. | $3,000 - $7,000 |

Ultimately, the goal is to create a seamless environment where your team can crank out a consistently amazing New York style pizza that New York customers expect, even when the kitchen is on fire. A thoughtfully chosen and organized prep table is the bedrock of that success.

The Perfect Bake From Launch to Slice

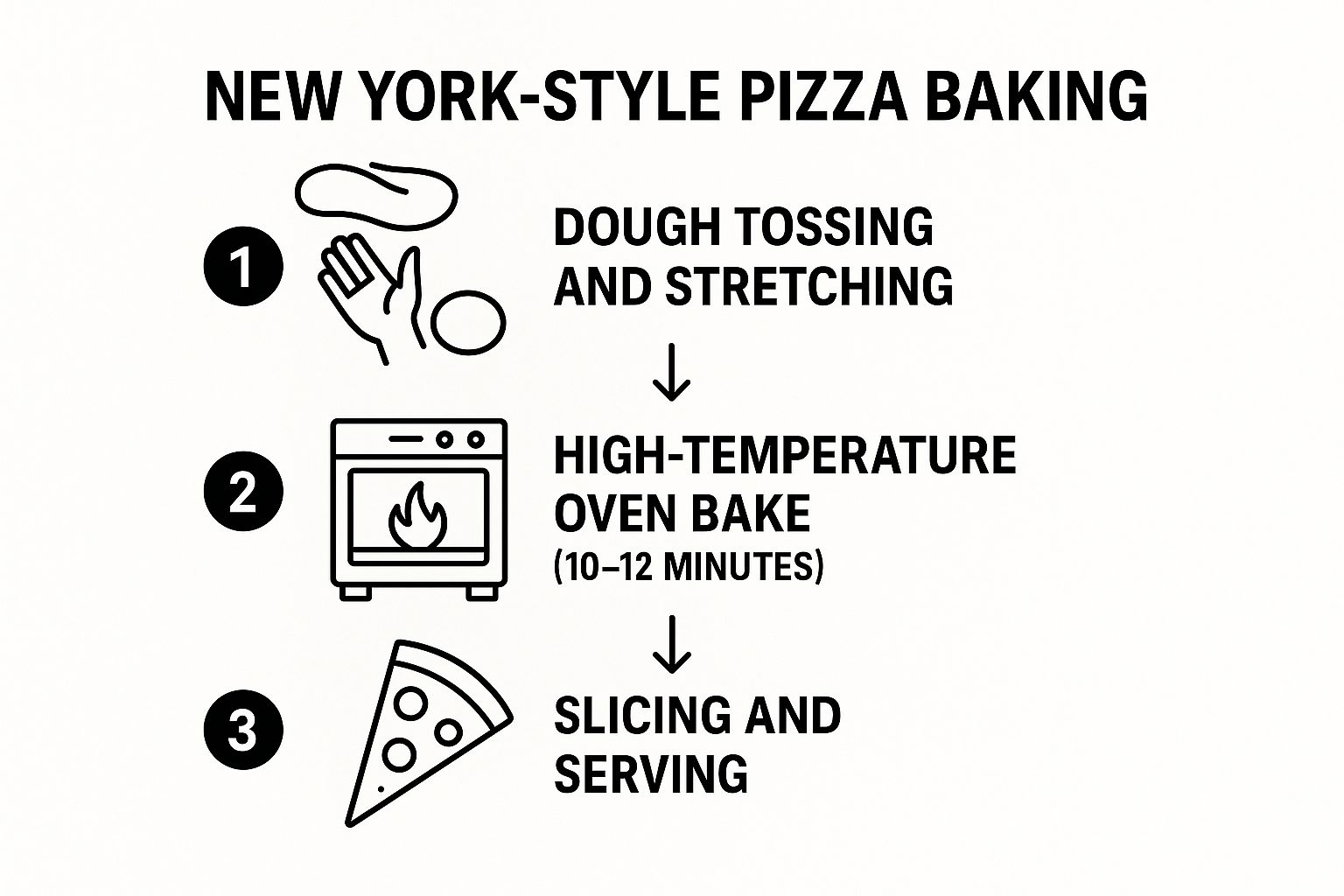

This is it. This is the moment where all that patient prep work—the long, cold fermentation of the dough, the perfectly organized mise en place on your pizza prep table—finally pays off. From launching the pie into a screaming-hot oven to that first, perfect slice, this final stretch is a high-speed ballet that makes or breaks your pizza.

Executing these last few steps flawlessly is what separates a good New York style pizza in New York from a truly legendary one. It all boils down to technique, temperature, and timing.

Mastering the Art of the Stretch

Before a single drop of sauce hits the dough, you have to nail the iconic New York stretch. This isn't about tossing it high in the air like in the movies; it's a specific, gentle technique. The goal is a uniformly thin center that can hold its own under toppings, leaving a puffy, airy edge we all know as the cornicione.

Start with a well-rested, room-temperature dough ball on a lightly floured surface. Using just your fingertips, gently press down in the center and work your way out, but be sure to leave about a one-inch border completely untouched. This is what will become your crust.

Now, the real work begins. The most effective method I've seen in countless pizzerias is the "knuckle stretch."

- Gently lift the dough and drape it over the backs of your hands.

- Using your knuckles, not your fingertips, slowly and carefully stretch the dough by moving your hands apart.

- Keep rotating the dough as you stretch to make sure it opens up into an even, thin circle.

This technique is crucial because it keeps your fingertips from poking holes or creating weak spots in the center, a super common mistake. You’re aiming for a large, almost translucent base that’s ready for the assembly line.

Applying Sauce and Cheese with Precision

With your perfectly stretched dough sitting on a lightly dusted pizza peel, it's go-time. You have to move quickly, but precision is what will save you from a soggy, floppy disaster.

The Sauce: Grab a ladle and pour on a thin, even layer of your simple, uncooked tomato sauce. Start in the center and spiral your way out, again leaving that one-inch border clean for the cornicione. If you use too much sauce, you'll get a wet, heavy crust. No one wants that.

The Cheese: The classic choice is low-moisture, whole-milk mozzarella. You want a generous layer, but don't go crazy. It’s all about balance. You're looking for that great coverage and signature cheese pull without creating a thick, greasy layer that smothers the flavor of the crust and sauce. Legendary pizza restaurants like John's of Bleecker Street are masters of this ratio.

The final build on the peel is a race against the clock. The longer a sauced-up pizza sits on that peel, the higher the risk of it sticking. A quick, confident assembly line that moves from your pizza prep table to the oven is essential for a clean launch.

Deck Oven Mastery for the Perfect Finish

For an authentic New York pie, a deck oven is the only way to go. That intense, radiant heat blasting up from the stone deck is what creates the signature crisp-yet-chewy crust. For the best results, your pizza restaurant needs to crank its oven to the highest setting, usually between 500°F and 550°F.

The launch is a make-or-break moment. You want to position the peel toward the back of the oven and, with one quick, confident jerk, slide that pizza right onto the hot stone. It’s a move that definitely takes some practice, but a clean launch is non-negotiable.

Baking a New York style pizza New York pizzerias would be proud of takes about 8 to 12 minutes. But don't just set a timer and walk away. You need to watch for the visual cues:

- The Rise: Within the first few minutes, that cornicione should puff up beautifully.

- The Melt: The cheese needs to be fully melted, bubbly, and just starting to get some nice golden-brown spots.

- The Turn: About halfway through the bake, use your peel to give the pizza a 180-degree turn. This guarantees an even bake, since pretty much every deck oven has hot spots.

- The Char: Keep an eye out for "leoparding"—those small, dark, charred spots on the crust's edge and, most importantly, the underside. This is the sign of a perfectly baked, flavorful crust.

Once you see that golden-brown cheese and perfectly spotted crust, use your peel to swiftly pull the pizza out. Let it rest for just a minute before slicing to let the cheese set up. This final, blistering-hot bake is what transforms all your hard work into a slice of pure New York perfection.

Equipping Your Pizzeria for Success

Your pizza restaurant is only as good as the workhorses in its kitchen. The right gear isn't just an expense; it's a direct investment in the quality, speed, and sanity of your operation. Outfitting your space is about building a system that can pump out perfect pies, especially when you're chasing that authentic New York style pizza New York customers line up for.

From the blistering heat of the oven to the consistent chill of your pizza prep table, every piece plays a critical role. Let's walk through the essential equipment that powers a high-volume pizza restaurant, focusing on making smart choices that balance your budget with your production goals.

The Heart of the Kitchen: The Pizza Oven

For a true New York-style crust—crispy on the bottom, with that signature chew and a beautifully puffed cornicione—a deck oven is the undisputed champion. There’s really no substitute. These ovens use super-hot stone or steel decks to blast heat directly into the bottom of the dough, creating a texture you just can't get any other way. Iconic pizza restaurants like John's of Bleecker Street and Joe's Pizza built their legacies on the intense, radiant heat that only a deck oven can provide.

Sure, other ovens exist, but for this specific style, they just don't measure up.

- Conveyor Ovens: These are fantastic for speed and consistency, which is why the big chains love them. But they bake with circulating hot air, which tends to dry out the crust and can't produce the signature char and crispness of a deck oven.

- Brick Ovens: Often tied to Neapolitan pizza, these wood-fired domes get incredibly hot. While they make an amazing pizza, the intense, smoky flavor and softer, more delicate crust are a world away from a classic New York slice.

A quality gas deck oven gives your restaurant the control and high temperatures you need, often pushing 550°F or higher. That heat is essential for getting the perfect bake in under 12 minutes.

The Unsung Heroes: Dough Mixer and Refrigeration

Behind every great pizza is a phenomenal dough, and behind that dough is a heavy-duty mixer and rock-solid refrigeration. Mixing by hand is a non-starter when you're doing any kind of volume, which makes a spiral dough mixer a must-have piece of equipment for any serious pizza restaurant. Unlike planetary mixers, spiral mixers are much gentler, developing the gluten network for that perfect New York chew without overworking or overheating the dough.

Just as vital is your refrigeration setup. Commercial-grade refrigeration is non-negotiable, and here’s why:

- Cold Fermentation: To get that deep, complex flavor that defines authentic New York dough, you need dedicated fridge space to hold stacks of dough boxes for 24-72 hours.

- Ingredient Safety: A powerful pizza prep table with refrigerated rails is your first line of defense. It keeps toppings like cheese, pepperoni, and fresh veggies at food-safe temperatures, even when you're in the weeds during a frantic dinner rush.

Your refrigeration system, especially your pizza prep table, is the backbone of your restaurant's workflow and food safety. Investing in a reliable unit with strong cooling power isn't just a good idea—it prevents ingredient spoilage and ensures every pizza is built with fresh, safe components.

Essential Smallwares and Prep Tools

While the big-ticket items get all the glory, it's the smallwares that make the daily grind feel smooth and efficient. A well-stocked pizza restaurant with the right tools empowers your crew to work faster, smarter, and with less stress.

Here’s a quick-hit list of the absolute must-haves:

- Pizza Peels: You’ll need both wooden peels for launching raw pizzas and metal peels for turning and retrieving the cooked pies. Don't skimp here.

- Dough Boxes: These stackable plastic containers are the only way to properly organize and store your dough balls during their long, cold nap in the fridge.

- Cutting Tools: A high-quality pizza rocker or a sharp wheel cutter is essential for clean, even slices. Nothing looks more amateur than a mangled slice.

- Ingredient Bins and Ladles: Using standardized containers for your pizza prep table rails and portion-control ladles for your sauce is the key to consistency. Every pizza gets the same love.

Putting your money into quality equipment, from a powerful deck oven to a well-organized pizza prep table, is fundamental. It creates a kitchen where you can consistently produce the high-caliber New York style pizza New York is famous for, turning out slice after perfect slice.

You've Got Questions, We've Got Pizza Answers

Opening a pizza restaurant anywhere is a grind, but trying to make it in New York? That’s like stepping into the ring at Madison Square Garden. You’re on the world’s biggest stage, and the pressure is intense. Aspiring restaurant owners always come to me with a similar set of questions, born from the city's fierce competition and sky-high expectations. Let's tackle a few of them.

So many new owners are obsessed with how to stand out. Look, the legendary pizza restaurants like Joe's Pizza or John's of Bleecker Street didn't just pop up overnight with a clever gimmick. They built their reputations on one thing: unwavering consistency. Your journey has to start with a laser focus on your product. Can you crank out a perfect New York slice every single time, even when the tickets are flying on a Friday night?

That consistency is born on your pizza prep table. It’s not just a fancy stainless steel counter; it's mission control for any serious pizza restaurant. This single piece of gear dictates your speed, your quality, and your sanity. Getting it right is everything.

What’s the Most Overlooked Part of Starting a Pizzeria?

Hands down, it’s the kitchen workflow. I see it all the time. Restaurant owners get romantic about the perfect sauce recipe but completely forget how that sauce will actually get onto a pizza during a rush. A poorly designed kitchen with a clunky pizza prep table can kill a business faster than a bad Yelp review.

Think about it in real terms. During the dinner rush, your team needs to stretch, top, and launch a pie in under a minute. If they're bumping elbows, walking across the kitchen for cheese, or fighting with a prep station that can’t hold temperature, you're bleeding money and time. The best pizza restaurants design their kitchens around a logical flow, with the prep table as the central hub connecting the dough, the toppings, and the oven.

A question I get a lot is whether a high-end, drawered pizza prep table is really worth the money. For an authentic New York pizza restaurant, the answer is almost always yes.

A game-changer. That's what having refrigerated drawers for your proofed dough balls directly under the prep surface is. It cuts out extra steps, protects your dough's hydration and temperature, and keeps the entire assembly line humming at top speed.

This isn't a luxury. It's a core component of making high-quality pizza at the volume New York demands.

How Do I Even Compete in This Market?

You don't try to be everything to everyone. You find your niche and you execute it better than anyone else. Many of the most successful new pizza restaurants started small, perfecting just a handful of items. Take Prince Street Pizza. They blew up because of their thick, spicy pepperoni-loaded Sicilian squares—a standout product in a city overflowing with classic thin-crust options.

Your equipment is your co-pilot here. A powerful spiral mixer and a reliable deck oven are non-negotiable. Just as critical is a durable pizza prep table that can take a beating night after night. You need a unit with a deep cutting board, rock-solid refrigeration, and enough topping storage to keep the line moving without sacrificing an ounce of quality.

The North American pizza market is a monster, valued at around USD 55.55 billion in 2024. That tells you people are always hungry for great pizza, but it also means the competition is everywhere. Your edge isn't a secret—it's delivering an authentic, top-quality slice, every single time. Dig into the latest market trends to see how pizzerias are staying sharp and growing in this massive industry.

Ready to build a kitchen that can handle the New York City rush? At Pizza Prep Table, we specialize in providing the high-quality, reliable equipment that powers successful pizzerias. From compact units to large workstations, we have the perfect prep table to anchor your operation. Equip your restaurant for success by visiting us at https://pizzapreptable.com.