The Ultimate Pizzeria Guide to Prep Stainless Steel Tables

Share

Think about the controlled chaos of a Friday night dinner rush. Pizzas are flying out, and your team is a blur of motion. At the very heart of this operation, there’s one piece of equipment holding it all together: the prep stainless steel table.

This isn't just furniture; it's the command center for your entire pizza-making operation. Every single pizza, from the initial stretch of the dough to the final sprinkle of mozzarella, starts right here. It’s far more than just a surface—it’s the central hub of your pizzeria’s entire production line.

Viewing this table as a foundational business investment is key. Its quality and design ripple through everything from your pizza prep speed to your food safety protocols, ultimately hitting your bottom line. In the high-volume world of a pizzeria—where flour clouds, acidic tomato sauce, and constant sanitizing are the norm—stainless steel is the undisputed champion.

Why Your Choice of Table Matters

The right prep table does more than just fill a space in your kitchen; it actively contributes to your success. Think of it this way:

- Unmatched Durability: Stainless steel is built to withstand the relentless abuse of a pizzeria. It resists the dents from dough boxes, scratches from pizza cutters, and corrosion from acidic sauces that would destroy lesser materials.

- Superior Hygiene: Its non-porous surface is a health inspector's dream. Bacteria have nowhere to hide, making it incredibly easy to clean and sanitize after a long shift of making pizzas.

- Workflow Enhancement: A well-chosen table creates a logical flow for the pizza-making process, streamlining every step from dough prep to topping assembly and the final slide into the oven.

The growing importance of this equipment is reflected in the numbers. The global market for stainless steel tables was valued at USD 1.2 billion in 2024 and is projected to hit USD 1.8 billion by 2033, largely driven by strict food safety regulations in restaurants like pizzerias.

Think of your prep table not as an expense, but as the stage where your pizzas are born. A flimsy, poorly designed stage leads to a chaotic performance. A solid, well-planned one ensures a smooth and successful service, night after night.

This guide will walk you through everything a pizzeria owner needs to know, from foundational choices like steel grades and table sizes to practical strategies for optimizing your pizza line. Our goal is to arm you with the knowledge to make an informed decision that pays dividends for years.

For a broader look at equipment that can round out your pizzeria's setup, you might explore suppliers like Yasutrading for commercial kitchen supplies.

Decoding Your Pizza Prep Table's Anatomy

A stainless steel prep table might look simple, but the best ones are engineered with details that make a huge difference in a busy pizzeria. Think of it like a perfectly crafted pizza—every single ingredient, from the type of steel to the shape of the edges, is chosen for performance. When you understand these elements, you can look at a spec sheet and see more than just a price tag. You see a tool designed to make your pizza production faster, safer, and way more efficient.

The foundation of any great prep table is the material itself. This is your first line of defense against the daily onslaught of acidic tomato sauce, briny olives, and constant scrubbing.

The Steel Showdown: Grades and Gauges

Not all stainless steel is created equal. The two numbers you’ll see tossed around are the grade and the gauge, and they tell you everything you need to know about a table's durability and its ability to fight off rust from pizza toppings.

For a pizzeria, the grade is especially important. You’ll typically run into two main types:

- 430-Series Stainless Steel: This is your budget-friendly option. While it's magnetic and holds up fine for general use, it lacks the nickel content needed to fight off serious corrosion from acidic and salty ingredients. Think of it for dry storage or boxing stations, not your main saucing and topping table.

- 304-Series Stainless Steel: This is the undisputed champion for pizzerias. It contains roughly 18% chromium and 8% nickel, creating a tough, non-porous barrier that stands up to tomato sauce, cleaning chemicals, and moisture without pitting or rusting.

Next up is the gauge, which is just a fancy way of saying "thickness." It works on an inverse scale, which can be a little confusing at first—the lower the number, the thicker and stronger the steel.

Think of the gauge like your pizza dough. A thin, flimsy base won't hold up to heavy toppings, just like a high-gauge (thinner) steel top will dent and warp under the weight of heavy dough boxes and equipment.

For a busy pizza kitchen, 16-gauge is the industry standard for tabletops. It hits that sweet spot between durability and cost. But if you plan on some heavy-duty action—like mounting a dough sheeter or dealing with massive dough batches—investing in a thicker 14-gauge top provides maximum strength and will probably outlast the pizza oven itself.

Essential Features for a Pizzeria Workflow

Beyond the steel itself, certain design features are what turn a basic table into a pizzeria workhorse. Each component is there to solve a common kitchen problem, from containing flour messes to keeping your pizza makers safe. A well-designed prep table should feel less like a piece of furniture and more like a member of your team.

Keep an eye out for these key anatomical parts when you're shopping:

- Backsplashes: An integrated backsplash is non-negotiable for any pizza prep table placed against a wall. It acts as a barrier, stopping flour, sauce, and stray bits of cheese from getting all over the wall. This makes cleanup way faster and keeps things more sanitary.

- Edge Types: The edge of the table matters more than you’d think. A square or "turndown" edge is simple and functional. But a rounded "bullnose" edge is a much safer bet, reducing the risk of bumps and bruises as your crew hustles through a tight space during a dinner rush.

- Undershelves: This is your prime real estate for storage. A solid undershelf is perfect for storing sealed containers, like extra sauce or toppings. A wire or slatted undershelf is better for promoting air circulation, making it a good choice for holding proofing dough boxes or cooling freshly baked crusts.

Each of these elements contributes directly to your pizzeria's rhythm. A backsplash saves precious minutes on cleanup, a bullnose edge prevents minor injuries, and the right undershelf keeps your most-used ingredients organized and within reach.

To make it even clearer, let's break down the best steel choices for different pizzeria needs.

Choosing the Right Stainless Steel for Your Pizzeria

Picking the right material is one of the biggest decisions you'll make. This table lays out the pros and cons of the most common options to help you match the steel to the job.

| Feature | 18-Gauge / 430-Series (Good for Light Duty) | 16-Gauge / 304-Series (The Pizzeria Standard) | 14-Gauge / 304-Series (Heavy-Duty Champion) |

|---|---|---|---|

| Best For | Light prep, dry storage, pizza boxing stations, or budget-conscious setups. | All-purpose pizza prep, dough stretching, and topping stations. | Heavy equipment mounting, high-volume dough work, and maximum durability. |

| Corrosion Resistance | Moderate. Vulnerable to acidic ingredients like tomato sauce over time. | Excellent. Resists corrosion from salts, acids, and cleaning agents. | Excellent. Offers the same high resistance with superior structural integrity. |

| Durability | Prone to dents and scratches from pizza cutters and pans. | Resists dents and warping from daily pizzeria abuse. | Extremely resistant to denting, bowing, and physical impact. |

| Cost | Most affordable option. | Mid-range investment with the best long-term value for pizzerias. | Highest upfront cost, but built to last a lifetime. |

Ultimately, your choice comes down to balancing your budget with how you plan to use the table. For front-line pizza prep stations, the durability and corrosion resistance of 16-gauge, 304-series steel is the smartest investment you can make for the long haul.

Refrigerated vs. Standard Tables for Peak Freshness

Picking the right stainless steel surface is a big decision, but what's happening underneath that surface is just as crucial for a pizzeria. Are you better off with a simple, open-base standard table for dough work, or do you need a refrigerated unit that keeps pepperoni and mozzarella perfectly chilled and right at your fingertips?

This choice hits your kitchen's speed, food safety, and overall sanity square in the jaw, especially when the Friday night pizza rush is in full swing.

A standard prep stainless steel table is your open workbench—uncluttered and ready for anything. It’s perfect for focused tasks where you just need space, like stretching dough. A refrigerated pizza prep table, on the other hand, is a high-performance workstation with its own climate-controlled inventory. All your toppings are exactly where you need them, when you need them.

The Case for the Standard Stainless Steel Table

The standard, non-refrigerated stainless steel table is the unsung hero of the pizzeria. Its biggest asset is its straightforward, versatile design. This is your go-to station for any pizza-making job that doesn't involve perishable ingredients needing constant temperature checks.

In most pizza kitchens, this table is all about the dough. It’s the perfect spot for:

- Dough Stretching and Slapping: You need a wide, clear runway to work your dough into the perfect crust without knocking over pans of pepperoni.

- Portioning and Balling: After it comes out of the mixer, dough gets weighed, portioned, and rolled on a clean, dedicated surface before it goes off to proof.

- Landing Zone for Hot Pies: Sticking a standard table near the oven gives you a heat-proof spot to land screaming hot pizzas for cutting and boxing.

Because there are no complex moving parts, standard tables are also easier on the wallet and a breeze to clean under. That open undershelf is perfect for stashing bulky items like flour bins or stacks of dough boxes.

When to Upgrade to a Refrigerated Prep Table

Standard tables are a must-have, but a refrigerated pizza prep table is what turns a good pizza line into a truly efficient one. These units are built from the ground up to speed up assembly while keeping the health inspector happy.

During a chaotic dinner service, the time you save by not running back and forth to a separate walk-in cooler for toppings is huge. One kitchen efficiency study found that centralizing ingredients this way can slash prep time by a whopping 20%.

A refrigerated prep table isn't just a table with a cooler slapped underneath; it's an ergonomic command center that merges your workspace with your cold storage. This fusion kills wasted steps and keeps your pizza toppings in the food-safe zone (below 40°F), even when the kitchen feels like a sauna.

This is the station where a simple stretched dough base gets loaded up and becomes a pizza. By keeping toppings like cheese, pepperoni, fresh veggies, and your house-made sauces chilled right where you build the pie, you drastically cut down on spoilage and guarantee every pizza goes out with the freshest ingredients possible.

If your menu goes beyond pizza, exploring different models can be a game-changer. You might be surprised to learn how a specialized refrigerated sandwich prep table can help you broaden your offerings.

Understanding Refrigerated Configurations for Pizzerias

Not all refrigerated tables are created equal. For pizzerias, a couple of specific designs have emerged to handle topping-heavy menus.

- Standard Top Units: These tables have a row of chilled ingredient pans that sit just a bit lower than the main work surface. They're great for a pizzeria with a basic set of toppings.

- Mega-Top Units: This is the undisputed champion for most pizzerias. Mega-tops feature a much larger refrigerated rail that can hold 30-50% more pans than a standard unit. If you offer a long list of toppings, this setup is a must. It lets you keep everything from mushrooms and olives to multiple types of cheese perfectly chilled and within arm's reach.

The decision tree is pretty simple. For dedicated dough work or a simple landing zone for hot pizzas, a standard prep stainless steel table is a smart, economical choice. But for the heart of your production line—the main topping and assembly station—a refrigerated mega-top table is a non-negotiable investment in speed, safety, and quality.

Optimizing Your Kitchen Workflow and Layout

A top-of-the-line pizza prep table can still cause chaos if it’s in the wrong spot. Having the right equipment is only half the battle; where you place it determines whether your pizzeria flows like a well-oiled machine or grinds to a halt during the dinner rush. Smart kitchen ergonomics aren't just a buzzword—they're critical for maximizing your pizzeria's output.

The goal here is to create a seamless, linear production path for your pizzas that cuts down on wasted steps and kills bottlenecks before they start. Think of your pizza-making process as an assembly line. It should move logically from one station to the next with zero backtracking.

The Pizzeria Production Flow

A well-designed layout guides your staff and ingredients through a natural progression. This doesn't just speed up pizza production—it also slashes the risk of cross-contamination and staff collisions during peak hours.

The ideal flow for most pizzerias generally looks something like this:

- Dough Management: The journey starts at the mixer, moves to a dedicated table for portioning and proofing, and then heads into the walk-in cooler.

- Stretching and Saucing: From the cooler, dough comes out to a standard prep table—dusted with flour—for stretching. This is usually where the sauce gets applied.

- Topping Assembly: The sauced base then slides over to a refrigerated pizza prep table, where all the chilled toppings are waiting and ready to go.

- Oven and Finishing: Finally, the fully assembled pizza moves to the oven. After baking, it lands on a nearby table for cutting, boxing, and getting out the door.

The most common workflow mistake I see is placing key stations too far apart. Every extra step your pizza maker takes between the walk-in, the prep table, and the oven adds up to lost seconds. Over a busy night, those seconds become lost minutes—and lost revenue.

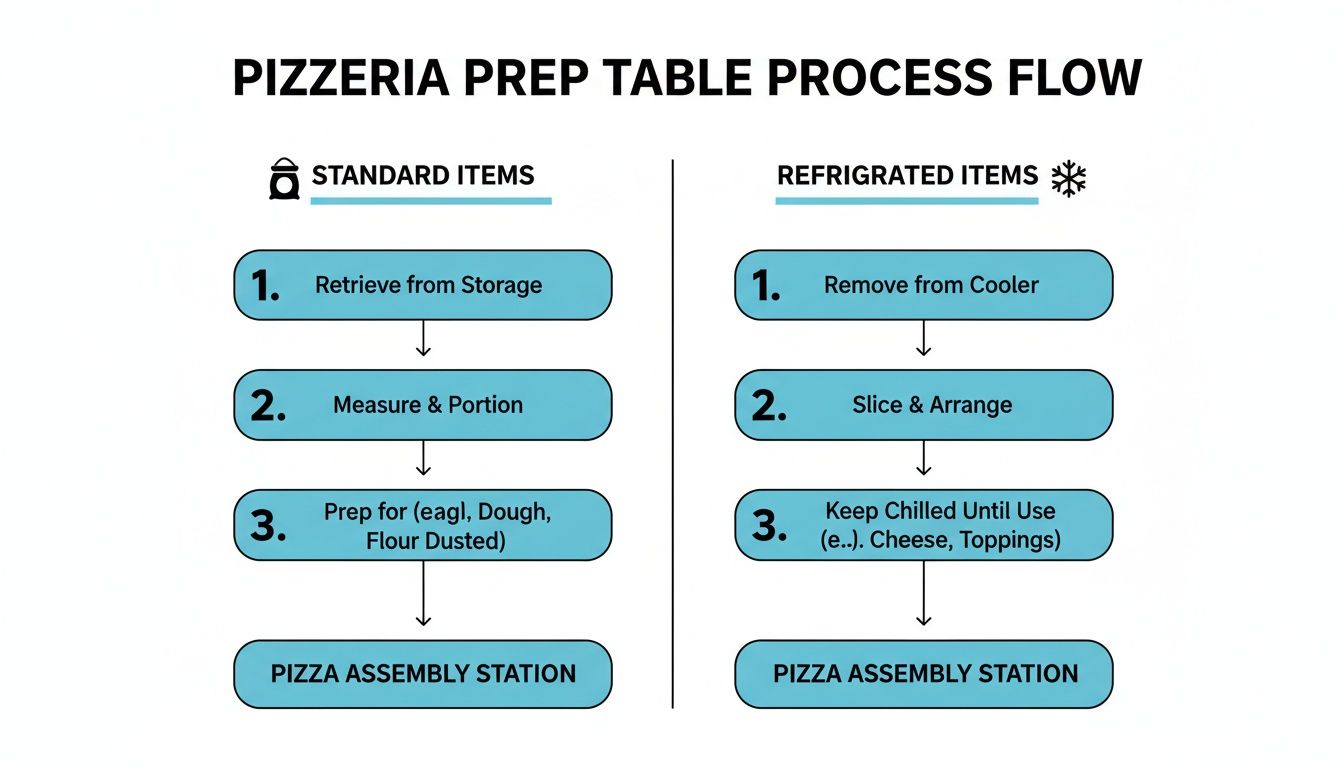

The flowchart below breaks down the distinct roles that both standard and refrigerated tables play in this essential pizza production sequence.

This visual really highlights how a standard table is perfect for dry, room-temperature tasks like dough work, while a refrigerated table is the indispensable hub for assembling fresh, temperature-sensitive pizza toppings.

Strategic Table Placement and Clearance

Positioning your primary pizza prep table is a huge strategic decision. You want to place it as centrally as possible between your main cold storage (the walk-in) and your primary cooking station (the pizza oven). This creates a tight "work triangle" that keeps your pizza maker's movements short and efficient.

For a deeper dive into kitchen design principles, check out our guide on commercial kitchen layout design.

Proper clearance around your tables is also vital. Aim for at least 36 inches of walkway space in lower-traffic areas and 48 inches in main thoroughfares. This allows for easy staff movement, cart passage, and efficient cleaning routines. A cramped pizzeria isn't just inefficient; it's a safety hazard.

The demand for durable, easy-to-clean equipment has driven a massive global market for a reason. Global trade for stainless steel kitchen articles, including these essential tables, hit $8.81 billion in 2023. Their non-porous surfaces are prized for reducing contamination risks—a non-negotiable in any serious pizzeria.

By thoughtfully placing each prep table to support a linear workflow, you can dramatically reduce prep times, eliminate kitchen congestion, and give your pizzeria's hourly output a significant boost.

Keeping Your Table Clean, Safe, and Ready for Action

Think of your stainless steel prep table as a long-term investment. It's built like a tank to handle the chaos of a busy pizzeria, but its lifespan—and your ability to ace health inspections—really comes down to how well you care for it. Consistent, proper maintenance is the only way to protect the steel's natural defenses and guarantee a safe surface for every single pizza you build.

This isn't just about a quick wipe-down at the end of the night. We're talking about a smart cleaning strategy that knows how to handle the specific messes of a pizza kitchen. Caked-on flour, stubborn grease, and acidic tomato sauce each present a unique challenge, and you need the right approach to tackle them without accidentally damaging the table itself.

The Daily Cleaning Playbook

Your daily cleaning routine is your best defense against bacteria and grime. The goal is simple: get food particles off the surface before they have a chance to harden or cause problems. It's a bit like seasoning a cast iron pan—regular care builds up a history of protection.

A solid cleaning regimen for your pizza prep station boils down to a few key steps:

- Scrape and Clear: First things first, grab a soft plastic or rubber scraper and clear away all the loose debris—flour, stray cheese, and bits of dough. Whatever you do, don't use a metal scraper; it will gouge the surface.

- Wash with the Right Soap: Use a mild detergent mixed with warm water. Apply it with a soft cloth or sponge, and always scrub in the direction of the steel's grain. This little trick helps you avoid creating tiny scratches.

- Rinse It All Off: Soap residue is a magnet for dirt and can leave ugly streaks. A thorough rinse with clean, warm water is crucial to wash away every last trace of the cleaner.

- Sanitize and Dry: After rinsing, hit the surface with a food-safe sanitizer, following the manufacturer's instructions to the letter. Finally, wipe the table completely dry with a clean microfiber cloth. This prevents water spots and stops bacteria from getting a foothold.

What's the Big Deal with NSF Certification?

When you spot that NSF (National Sanitation Foundation) certification on a piece of equipment, it's more than just a sticker. It's a guarantee—to you, your health inspector, and your customers—that your prep table was designed from the ground up for food safety and easy cleaning.

NSF certification means the table has been put through the wringer to ensure it has no tiny cracks, pits, or crevices where bacteria can set up shop. For a pizzeria, features like coved corners—those smooth, curved transitions where surfaces meet—are a direct result of NSF standards. They make it physically impossible for flour and grease to get trapped.

Of course, a safe kitchen is more than just one table. It’s about creating a complete system. Integrating things like NSF Certified shelving solutions ensures that every part of your pizzeria, from prep to storage, meets the same tough health standards.

Choosing the Right Cleaners (and Avoiding the Wrong Ones)

The chemicals you use on your table are a huge deal. The wrong cleaner can permanently wreck your stainless steel by stripping away its protective layer, leading to rust and pitting. This is especially true for the tough 304-series steel that's so common in pizzerias.

Stainless steel has become the backbone of the food service industry for a reason. In 2021, global stainless steel production jumped 10.6% to hit 56.3 million metric tons, with the U.S. alone seeing a 10.4% increase. This incredible demand is all about the material's amazing resistance to corrosion—a quality that proper cleaning is designed to protect.

Here’s a quick rundown of what to use and what to steer clear of:

-

Safe to Use:

- Mild dish soap and warm water

- Baking soda paste for tough spots like baked-on sauce

- A vinegar and water solution (just be sure to rinse well)

- Cleaners made specifically for stainless steel

-

Avoid at All Costs:

- Chloride-based cleaners: This is the big one. Bleach and many common sanitizers are loaded with chlorides, which are the absolute worst enemy of stainless steel. They will cause pitting, and there’s no going back.

- Abrasive powders: Harsh scouring powders will scratch the finish.

- Steel wool or brushes: Not only will these scratch your table, but they can also leave behind tiny iron particles that will rust on the surface.

For a deeper dive into tackling tough messes without causing damage, check out our guide on the best ways to clean a stainless steel refrigerator. Many of the same rules apply to your prep table.

Got Questions? We’ve Got Answers.

You’ve got the rundown on anatomy, workflow, and keeping your table spotless. But now it’s time for the rubber to meet the road—the practical questions that pop up when you’re about to buy a new pizza prep table. Let’s tackle the most common ones head-on, so you can choose your table with confidence and use it like a pro from day one.

What Is the Best Stainless Steel Grade for a Pizza Prep Table?

For any pizzeria, 304-series stainless steel is the undisputed champion. The reason is simple: it contains about 8% nickel, giving it superior armor against corrosion. Think about the daily reality of a pizza station—it’s a constant barrage of acidic tomato sauce, salty cured meats, and briny olives.

A cheaper 430-series table might look tempting on paper, but it’s missing the nickel needed to fend off that acidic assault. Over time, it’s far more likely to pit and rust, creating hygiene nightmares and forcing you to buy a replacement way sooner than you planned. Investing in 304-series steel is the smartest long-term move for any surface that will touch your pizza ingredients.

Should I Choose a Table with or Without a Backsplash?

This one almost always comes down to a simple question: where is your pizza table going?

-

With a Backsplash: If your prep table is going against a wall, a backsplash is non-negotiable. It’s a simple barrier that stops flour, water, and stray toppings from hitting the wall. This makes cleanup exponentially faster and boosts sanitation by closing the gap where gunk loves to hide.

-

Without a Backsplash: For an island-style or pass-through prep station, a flat top is the way to go. This design lets your team access the table from multiple sides, which is perfect for a pizza line where multiple people are working or creating a seamless handoff point between the prep line and the oven.

How Thick Should My Prep Table's Surface Be?

The thickness of the steel, known as its gauge, is a direct measure of its toughness. In the world of steel, the numbers work backward—a lower number means thicker, stronger steel.

For most pizzerias, 16-gauge is the industry standard and the perfect sweet spot. It’s built to handle the daily grind of sliding dough boxes, heavy ingredient pans, and constant leaning without denting or bowing.

If you plan on doing some seriously heavy-duty work—like mounting a dough sheeter or a commercial mixer directly on the table—upgrading to a beefier 14-gauge top is a smart investment for absolute stability. An 18-gauge top is generally too thin for a primary pizza station and is better suited for light-duty tasks or a boxing station.

Think of your table's gauge like the foundation of a house. A 16-gauge top is a strong, reliable foundation for your daily pizza making. A 14-gauge top is like reinforcing that foundation with steel beams—it's built to handle extreme loads without flinching.

Can I Put a Hot Pizza Pan Directly on a Stainless Steel Table?

Yes, absolutely. One of the biggest perks of a stainless steel work surface is its incredible heat resistance. It can easily take the heat from a pizza pan coming straight out of a 500°F+ oven without scorching, melting, or warping.

This makes a standard stainless steel table the perfect landing zone right next to your pizza oven. You can pull a pie, slide it onto the table for cutting and boxing, and never have to worry about damaging the surface. That’s a level of durability you just won’t get from wood or plastic.

Are Casters (Wheels) a Good Idea for a Pizzeria Prep Table?

Wheels can be a game-changer for a pizzeria, but it all depends on what the table is for.

-

Great for Utility Tables: For smaller, secondary tables used for temporary staging or wheeling ingredients like bulk flour around, casters are fantastic. They add a ton of flexibility to your layout and make deep cleaning under equipment a breeze.

-

Less Ideal for Main Prep Stations: For your primary dough stretching or topping station, stationary legs are usually the better call. A stationary table provides a much more stable, solid foundation for vigorous work like slapping dough. If you do opt for casters on a main prep table, make sure they are heavy-duty and have rock-solid locking mechanisms to prevent any movement while you work.

It’s all about balancing your pizzeria's need for flexibility with the demand for stability where it matters most.

Ready to build the perfect pizza-making station for your restaurant? At Pizza Prep Table, we specialize in high-quality, NSF-compliant equipment designed for the demands of a busy pizzeria. Explore our wide selection of refrigerated and standard prep tables to find the perfect fit for your workflow.

Browse Our Collection of Pizza Prep Tables at pizzapreptable.com