Reduce Food Waste in Restaurants & Boost Profits

Share

Reducing food waste in a pizzeria is more than just an operational goal; it's a critical part of running a profitable business. For us in the pizza world, this battle is often won or lost right at the prep table. The key is to stop thinking of your prep station as just a place to assemble pies and start seeing it as the command center for efficiency. It’s all about locking down precise portion control and smart ingredient management to cut waste before it ever has a chance to start.

The True Cost of Food Waste in Your Pizzeria

When you toss out an unsold slice or a tray of day-old toppings, you're throwing away a lot more than just the food itself. The real cost of waste is a sneaky profit killer. You have to account for all the hidden expenses that get thrown out along with that food. Think about the labor hours your prep cook spent chopping those mushrooms that spoiled, the electricity your walk-in used to chill dough that never got stretched, and even the fees you pay to have it all hauled away.

For a typical pizzeria, these "small" losses add up shockingly fast, often costing hundreds of dollars every single week. A slightly too-generous scoop of cheese on every pizza, a few extra slices of pepperoni, or an overfilled cambro of olives at the prep station—it all bleeds your bottom line. This isn't just an unavoidable cost of doing business; it's a manageable problem that you can, and should, fix.

Unpacking the Financial and Environmental Toll

The impact goes way beyond your P&L statement. The entire foodservice industry has a massive environmental footprint. In 2023, full-service restaurants in the U.S. were the single biggest source of food waste in the sector, generating a staggering 5.76 million tons. Limited-service restaurants, which includes most of us in the pizza game, added another 2.45 million tons to that pile. This isn't just a financial disaster; it’s a serious environmental issue, as all that wasted food contributes heavily to greenhouse gas emissions.

The real cost of a wasted ingredient is its purchase price plus the labor, energy, and disposal costs associated with it. A $5 bag of basil that spoils can easily represent a $15 loss to your bottom line.

Shifting from Waste to Profit

The first step is a mental one: start seeing food waste as a solvable problem, not just a line item. This guide is all about practical, real-world solutions that work in the unique chaos of a pizza kitchen. We’re going to dig into the strategies that hit the most common waste hotspots head-on, including:

- Optimizing the Pizza Prep Table: Getting serious about systems like "First-In, First-Out" (FIFO) and using the right size containers to keep every topping at its peak freshness.

- Smart Inventory Control: Ordering based on hard data, not just gut feelings, to prevent over-buying toppings and dough.

- Strategic Menu Design: Building a menu where pizza ingredients pull double-duty, ensuring nothing sits on the shelf collecting dust.

- Engaging Your Pizza Crew: Training your team to be your eyes and ears on the floor, making them active partners in the fight against waste.

Understanding the financial hit from food waste is crucial. To take it a step further and protect your ingredient investment, you can explore how a chest freezer can save you money by preventing spoilage. By tackling these key areas, you can turn what was once a drain on your operation into a new source of profit and a point of pride.

Conducting a Pizzeria Waste Audit

You can't fix a problem you can't see. To really get a handle on food waste in your pizzeria, you first have to know exactly what you’re tossing, how much of it there is, and why it’s ending up in the bin. Guessing is just throwing money away, but a systematic waste audit gives you the hard data you need to make smart, targeted changes. For a pizzeria, this process is surprisingly straightforward—and incredibly revealing.

The basic idea is to separate and track your kitchen's waste over a set period. I usually recommend a full week to see the natural ups and downs of your business cycle. This isn't about just weighing the big dumpster at the end of the night. It's about getting granular to find the hidden profit leaks.

Setting Up Your Audit Bins

First things first, you need a simple, easy-to-use system for your pizza crew. This means getting a few dedicated, clearly labeled bins to separate waste into a few key categories. This is how you pinpoint precisely where the waste is happening in your workflow, from the moment a topping is prepped to when a customer's crust comes back.

For a pizza kitchen, your main categories should be:

- Pre-Consumer Prep Waste: This is all the stuff from initial prep—think vegetable peels, dough off-cuts, and any trimmings from getting toppings ready.

- Pre-Consumer Spoilage Waste: This bin is for any ingredient that expires or goes bad before it ever sees a pizza. We're talking about that case of cheese that went past its date, wilted basil, or mushrooms that started to turn.

- Post-Consumer Plate Waste: This is everything that comes back from the dining room uneaten. Crusts, abandoned toppings, half-eaten slices—it all goes here.

Set these bins up in a logical spot, maybe near the dish pit or your main trash area. All you need is a simple kitchen scale to weigh the contents of each bin at the end of every shift. A basic spreadsheet or even a dedicated notebook is perfect for logging the daily weights for each category.

From Data Collection to Actionable Insights

After a week of tracking, you’ll have a clear snapshot of your pizzeria’s waste habits. Now the real work begins: digging into that data to find the story it's telling you. Are you seeing a mountain of spoiled mushrooms every Tuesday? That could mean you're over-ordering for a historically slow day or your pizza prep table's refrigeration isn't quite right. Is one specific specialty pizza constantly coming back to the kitchen half-eaten? That’s a huge red flag that the topping combination just isn't landing with customers.

Don't just look at the total weight. Focus on the specifics. Knowing you threw out 10 pounds of spoiled mozzarella is far more actionable than knowing you had 50 pounds of total waste.

This process turns vague worries about waste into concrete problems you can actually solve. For instance, a lot of prep waste might point to inefficient cutting techniques for toppings. Excessive plate waste often means your pizza sizes are too generous. Every number is a clue. This first audit creates your baseline, the starting point you'll use to measure how well any new waste-reduction strategies are working.

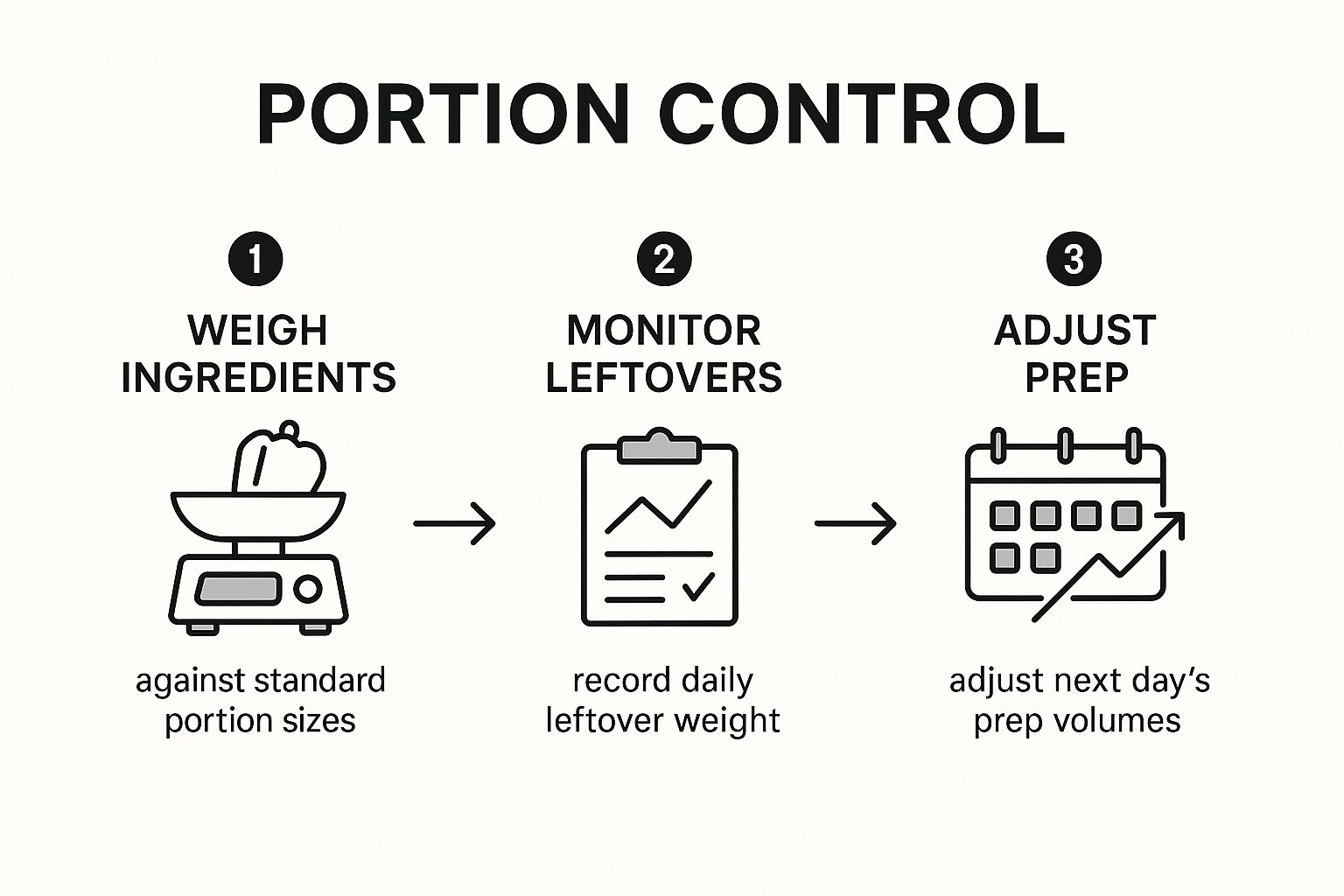

This simple diagram shows how data from an audit can directly influence your daily portion control, creating a powerful feedback loop.

The key takeaway here is that waste reduction is a cycle: you weigh pizza toppings, monitor what comes back as plate waste, and then tweak your future prep. It's a continuous loop of improvement.

The data you gather is especially powerful when it comes to fine-tuning your pizza prep line. If you notice a lot of spoilage for certain toppings, it’s a clear sign your prep table setup needs a second look. The efficiency of that station is everything, directly impacting both your speed and your waste. For a deeper dive, our guide on selecting commercial food prep equipment can show you how the right tools create a leaner operation. With solid data from your audit, you can finally stop guessing and start making informed decisions that go straight to your bottom line.

Building a High-Efficiency Pizza Prep Station

Your pizza prep line is the heart of your operation, but let’s be honest—it’s also ground zero for pre-consumer food waste. Every topping that misses the mark, every bit of spilled sauce, and every spoiled ingredient comes directly from this station, silently chipping away at your profits.

If you want to make a real dent in your food waste, turning your pizza prep table into a lean, efficient hub is one of the most direct ways to do it. The goal is to create a workflow so smooth and logical that waste becomes the exception, not the rule. This all starts with a non-negotiable principle every seasoned pizza pro swears by: First-In, First-Out (FIFO). It's a simple but powerful method that ensures older ingredients always get used before new ones, which can drastically cut down on spoilage.

Mastering FIFO and Smart Container Use

Implementing FIFO at the pizza prep table means more than just rotating stock in the walk-in. You need a visual, physical system right where the action is. Every ingredient container, or cambro, should be clearly labeled with the date it was prepped. When it's time to refill, the new product always goes to the back or bottom, pushing the older product forward for immediate use. Simple.

This brings us to another critical point: container size. I've seen it a thousand times—kitchens fill massive bins with popular toppings like mozzarella or pepperoni to avoid refilling during a rush. But this is a classic waste trap, especially for your more delicate items.

For perishables like fresh basil, sliced mushrooms, or prosciutto, using smaller, shallow cambros in your pizza prep table is far more effective. A smaller container means less exposure to air and temperature fluctuations, preserving that precious freshness. It also forces your team to refill more often from the main refrigerated stock, ensuring the ingredients on the line are always at their peak.

A common mistake is treating all toppings the same. A large, deep bin of shredded cheese might last a shift just fine. But that same-sized bin filled with fresh-cut bell peppers will likely see significant quality loss and waste by the end of the night.

Think of it this way: a shallow, frequently refilled pan of basil ensures every pizza gets vibrant, fresh leaves. A deep, slowly depleted bin guarantees the last few handfuls will be wilted and brown, destined for the compost pile.

Strategic Layout and Portion Control Tools

How you arrange your pizza prep table ingredients has a direct impact on waste. A smart layout minimizes cross-contamination, spills, and costly errors during a hectic service. Your most popular items—sauce, cheese, pepperoni—should be in the most accessible, ergonomic positions to cut down on reaching and spillage.

Picture this real-world scenario: if your pizzaiolo has to constantly reach over the olive container to get to the mushrooms, spills are inevitable. Over time, those little spills add up to pounds of wasted product. A logical layout makes the right choice the easy choice.

Beyond layout, precise tools are your best defense against the heavy hand of over-portioning.

- Portion-Control Ladles: Using a specific, measured ladle for sauce is non-negotiable. It ensures every single pizza gets the exact same amount, enforcing consistency and eliminating guesswork.

- Color-Coded Scoops: Assign different colored scoops or spoodles for different toppings. A red scoop for pepperoni, a green one for peppers—this visual cue helps staff grab the correct portion size instantly, even when the kitchen is slammed.

- Pre-Portioning High-Cost Items: For expensive ingredients like prosciutto, fresh mozzarella, or truffle oil, pre-portioning is a must. During slower prep periods, have staff weigh and separate these items into individual portions in small deli cups. When an order comes in, they just grab one pre-portioned unit. This completely eliminates guesswork and prevents a $20/lb ingredient from being used too generously.

To help you pinpoint exactly where waste might be happening on your line, I've put together a quick guide to some of the most common trouble spots and how to fix them.

Prep Table Ingredient Waste Hotspots and Solutions

This table breaks down some of the most common ingredients that get wasted at the pizza prep table and offers practical, actionable solutions to minimize spoilage and over-portioning.

| Waste Hotspot (Ingredient) | Common Problem | Waste Reduction Solution |

|---|---|---|

| Fresh Basil/Herbs | Wilting and browning from air exposure in large containers. | Use small, shallow pans. Store bulk herbs with damp paper towels in the main cooler and refill the line frequently. |

| Sliced Mushrooms | Turning slimy and brown due to excess moisture and long exposure on the line. | Prep in smaller batches. Store in a container with a perforated bottom to allow moisture to drain. |

| Shredded Mozzarella | Over-portioning and spills from reaching across the prep area. | Place cheese in the most ergonomic spot. Use a designated portion scoop or cup to ensure consistency. |

| Prosciutto/Cured Meats | Drying out or becoming oily. Over-portioning due to high cost. | Pre-portion slices between parchment paper during slow periods. Use smaller cambros on the line. |

| Bell Peppers/Onions | Losing crispness and becoming limp by the end of a shift. | Use smaller, shallow containers refilled more often. Ensure the prep table's cooling system is functioning optimally. |

| Pizza Sauce | Inconsistent application from pizza to pizza, leading to waste and variable quality. | Mandate the use of a specific portion-control ladle for every pizza. No free-handing. |

By focusing on these specific hotspots, you can make targeted changes that have a big impact on your bottom line. It's all about creating systems that make it easy for your team to do the right thing.

Of course, none of these strategies work without the right foundation. A well-chosen table provides the refrigerated storage and ergonomic workspace needed to make these systems flow. For an in-depth look at how different models can support your waste reduction goals, explore our breakdown of prep tables for restaurant efficiency.

By combining a smart layout with the right tools and equipment, you build a system that champions consistency and makes reducing food waste an automatic part of your daily workflow.

Driving Down Waste with Smart Menu Engineering

Let's be honest, serious waste reduction in a pizzeria doesn't start with the compost bin. It starts long before your crew even preps a single ingredient. It begins with your menu—the very blueprint for every order you place and every pizza you serve. By getting smart about your menu design and inventory, you can stop waste before it even gets a chance to happen.

Let's be honest, serious waste reduction in a pizzeria doesn't start with the compost bin. It starts long before your crew even preps a single ingredient. It begins with your menu—the very blueprint for every order you place and every pizza you serve. By getting smart about your menu design and inventory, you can stop waste before it even gets a chance to happen.

This is where that waste audit data you gathered becomes your secret weapon. It’s the hard proof you need to shift from "gut-feel" ordering to truly data-driven purchasing. This data is the key to setting smart par levels—the absolute minimum amount of any topping you need on hand to sail through a service period. Nailing your pars keeps you from over-ordering those low-use items that just end up spoiling on the shelf.

The Power of Ingredient Cross-Utilization

If there's one golden rule in engineering a waste-free menu, it's ingredient cross-utilization. Put simply, it’s the art of making sure your pizza toppings are multi-talented. Every single item in your walk-in should have more than one job.

Think about it. If you have a specialty pizza that calls for roasted red peppers, but that's the only thing on your menu that uses them, you've created a high-risk situation. If that particular pizza has a slow week, those peppers are on a one-way trip to the trash.

The smarter play? Find other homes for those peppers. Can they be an add-on for a house salad? What about tossing them into a meatball sub or blending them into a specialty dipping sauce for your breadsticks? The goal is to create multiple paths for every single ingredient to leave your kitchen on a customer's plate.

A core principle of a waste-conscious menu is that no ingredient should be a one-hit wonder. Every item you buy should have at least two, and ideally three, potential uses across your menu.

This approach doesn't just crush your spoilage rates; it also simplifies your ordering, streamlines your inventory, and makes prep work a breeze. It's a true win-win that boosts your kitchen's efficiency and fattens up your profit margins.

Case Study: Trimming Waste by 15%

Let me share a real-world story. A pizzeria I consulted with was constantly tossing out artichoke hearts. They were a key ingredient on their "Tuscan Sun" specialty pizza, but sales for that pie were all over the map. After we ran a waste audit, the numbers were grim: they confirmed that nearly 40% of the artichoke hearts they bought were hitting the bin every single week.

Diving into their sales data, we saw the Tuscan Sun pizza was a low-performer, making up less than 2% of their total pizza sales. It was a textbook case of a unique, slow-moving ingredient creating a steady financial bleed. The solution was blunt but effective: they axed the pizza from the menu entirely.

The result was immediate. They slashed their weekly spoilage by over 15% and freed up precious real estate on their busy pizza prep table. This single, data-informed move directly padded their bottom line without hurting overall sales. It's a perfect example of how optimizing your kitchen's flow, much like the best sustainable supply chain examples, drives real efficiency.

Designing a Leaner, More Profitable Menu

Ready to apply this thinking to your own pizzeria? Grab your POS sales reports and your waste audit results, and start scrutinizing your menu. For every single item, ask yourself these tough questions:

- Which toppings are unique to this one pizza? Put a red flag next to any pizza that relies on a single-use ingredient.

- How can I cross-utilize my top five most expensive ingredients? Focus your energy on high-cost items like prosciutto, fresh mozzarella, or fancy cheeses to squeeze every last drop of value out of them.

- Can I run Limited-Time Offers (LTOs) to burn through surplus stock? If you notice you're heavy on bell peppers, launch a weekend special for a sausage and pepper calzone.

When you design a menu where every component works hard, you build resilience right into your operation. You create a system that's not just less wasteful but also more profitable and much easier for your team to execute—especially when things get crazy at the pizza prep table where speed is everything.

Turning Your Crew into Waste Reduction Champions

Your equipment and menu are the foundation, but let's be honest—the real power to slash food waste comes from the people on your team. An efficient pizza prep table is only as good as the pizzaiolo using it. Your crew members are your single most powerful asset in this fight, and turning them into waste reduction champions starts by building a culture where everyone gets how their actions directly hit the bottom line.

This has to start on day one. During onboarding, waste reduction training needs to be as fundamental as learning how to stretch dough. But don't just show them what to do; take the time to explain the why behind every single step.

Building a Waste-Conscious Culture from Day One

Instead of just telling a new hire, "Hey, follow FIFO," show them what happens when you don't. Put a tray of slimy, spoiled mushrooms right next to a fresh one and explain how proper rotation prevents that loss. This kind of hands-on, visual lesson makes the abstract idea of "waste" real and tangible. The goal is to connect their daily habits to the pizzeria's health and its commitment to sustainability.

This is more important than ever. In the United States, restaurants and consumers toss nearly 35 million tons of food every year. The crazy part? This problem has actually gotten worse, even as food prices climb. When you give your team this knowledge, you're not just training employees; you're making them part of the solution to a massive issue.

Building a team that's skilled and aware is your best defense against waste. For more on creating a solid training program, you can find great resources on effective restaurant employee training.

Making Waste Visible and Personal

Numbers on a spreadsheet don't inspire anyone. To get your team fired up about this, you have to make the cost of waste painfully obvious. Next time you're in a team huddle, don't just say, "We wasted $100 in cheese last week." Try this instead:

- Get a clear bucket. Take a scoop of shredded mozzarella—the amount that easily gets spilled or over-portioned during a rush—and drop it right in.

- Connect it to something real. Tell them, "This little scoop costs us $0.50. If every one of us does this just ten times a shift, that's $5. In a week, that’s what we’d spend on a brand-new stack of pizza screens."

Suddenly, "waste" isn't some vague concept. It's a real, measurable loss that everyone can see and understand. It helps your staff connect their own actions at the pizza prep table directly to the shop's success.

A wasted ladle of sauce isn't just wasted tomatoes. It's wasted labor, wasted energy from the stove, and wasted cooler space. When your team sees the full picture, their perspective changes.

A well-organized kitchen makes all of this easier, by the way. A workspace where every tool and ingredient has a logical home naturally cuts down on mistakes and spills. You can find some great layouts and practical inspiration by exploring different pizza shop design ideas that are built for efficiency.

Fostering Friendly Competition with Incentives

Nothing gets a team moving like a little friendly competition. Forget about punishing mistakes and focus on rewarding wins. This creates a positive, proactive vibe where everyone is pulling in the same direction.

Here are a few ideas that I've seen work wonders in pizzerias:

- The "Cleanest Bin" Challenge: Track pre-consumer waste (like veggie trim and spoilage) for each shift over a week. The shift with the lowest total gets a small bonus, a team lunch, or first pick of next week's schedule.

- "Waste-Free Hero" of the Month: Give a shout-out to one employee who consistently nails waste reduction—think perfect portioning, smart ingredient rotation, or coming up with creative ways to use up extras.

- Team-Based Goals: Set a monthly target for reducing overall food waste by a specific percentage. If the whole team hits the goal, everybody shares in a reward, like a bonus or a catered staff party.

These kinds of programs do more than just cut costs; they build camaraderie and make your staff feel valued. When your crew sees that their careful work at the pizza prep table is noticed and rewarded, they stop being just employees. They become true partners in your business.

Answering Your Toughest Pizzeria Waste Questions

Getting a handle on food waste is a journey. It’s one thing to read about tracking spoilage and another thing entirely to implement new systems during a chaotic Friday night dinner rush. Once you dive in, you’re bound to have some questions.

Think of this as your practical, no-nonsense troubleshooting guide. I’ve heard these same questions from countless pizzeria owners, so let’s tackle them head-on, focusing on the real-world challenges you face in your kitchen, right down to the setup of your pizza prep table.

How Much Waste Is Too Much in a Pizzeria?

This is the big one, but the answer isn’t a magic number. Forget about chasing some arbitrary industry percentage. The real goal is continuous improvement measured against your own starting point.

A truly dialed-in pizzeria with great systems might get its pre-consumer waste (that’s spoilage and prep trim) as low as 2-4% of what they spend on food. If you're seeing numbers creeping up toward 10%, that's a flashing red light. It means serious profits are leaking out of your operation every single day.

Here's the key: Use your first waste audit as your benchmark. If you start at 8%, your first goal is simply to get to 6%. It’s all about making steady, incremental progress, not trying to hit perfection overnight. The only number that truly matters is that your waste percentage is consistently trending downward.

What if My Staff Resists These New Changes?

Pushback from the crew is a classic hurdle, but it's almost always fixable. Resistance rarely comes from a bad attitude; it usually stems from a lack of understanding or the feeling that new rules are just more work for no reason. The solution is all about communication and empowerment, not just posting a new sign.

- Hammer Home the "Why": Don't just hold one staff meeting and call it a day. You have to constantly connect the dots for them. Show your team how wasted cheese is money that could have gone toward a new mixer, a staff party, or even performance bonuses.

- Make It Effortless: Your new systems have to be practical. If the portion cups are stored across the kitchen from the pizza prep table, nobody is going to use them when the tickets are flying. You have to design your workflow for maximum efficiency during a rush, not just when it's quiet.

- Create Waste Champions: Look for a couple of team members who are genuinely on board with the changes. Make them your official "Waste Champions" on each shift. Give them a little authority to lead by example and coach their peers. It’s far more effective than having a manager constantly looking over everyone's shoulder.

When your team understands that cutting waste isn't about being cheap but about making the business stronger for everyone, their mindset shifts. It goes from "I have to do this" to "We want to do this." They become your biggest allies.

Is Investing in Technology Really Necessary?

Look, you can absolutely make progress with a good old-fashioned clipboard and a spreadsheet. But technology can be a massive shortcut. Modern AI-powered tools and advanced POS systems aren't just for the big chains anymore, and they offer a huge leg up for independent pizzerias trying to tame the waste beast.

Take a system like ClearCOGS, for example. It analyzes your sales data to create shockingly accurate forecasts for every single topping you carry. This means you can prep exactly the right amount of sliced mushrooms for a Tuesday, which is very different from a Saturday. You virtually eliminate spoilage.

I saw a case study where a restaurant using this kind of tech saved as much as three racks of ribs every single day just by improving its forecasts. For a pizzeria, that could easily translate to saving pounds of expensive cheese or prosciutto daily.

These tools take the gut-feel guesswork out of ordering and prepping. You start making critical decisions based on hard data, not just intuition. It's a fundamental step in professionalizing how you reduce food waste in your restaurant and turns a reactive problem into a proactive strategy.

At Pizza Prep Table, we know that running an efficient kitchen starts with the right foundation. A well-designed, reliable refrigerated prep table is the command center for all your waste reduction efforts. It keeps your ingredients perfectly fresh and makes a smooth workflow possible. Explore our collection of high-quality prep tables and find the perfect centerpiece for a more profitable, less wasteful kitchen at https://pizzapreptable.com.