Choosing the Perfect Pizza Prep Table for Your Pizzeria

Share

Walk into any thriving pizzeria during the dinner rush, and you'll see it: the calm center in a storm of flying flour and sizzling toppings. That's the pizza prep table. This piece of equipment is far more than just some stainless steel with a fridge underneath; it's the command center for your entire pizza-making operation.

Think of it as the heart of your kitchen, dictating the pace, consistency, and ultimately, the profit of every single pie you sell. It's the assembly line and mission control, all rolled into one indispensable workstation.

This guide isn't about boring spec sheets. We're going to dive into how the right restaurant preparation table goes from being a simple surface to a powerful strategic tool for your pizzeria. It's all about creating a seamless workflow where every move is efficient and every ingredient is held at the perfect temperature for crafting the perfect pizza.

More Than Just a Countertop

A thoughtfully chosen pizza prep table does a lot more than just hold your pepperoni and cheese. It performs several critical jobs that have a direct impact on your product quality and your bottom line. A great setup will:

- Crank Up Your Workflow Efficiency: By putting every last ingredient within arm's reach, it slashes the time your pizza chefs spend running around the kitchen. Those saved seconds on each order add up fast during a rush.

- Guarantee Pizza Consistency: A well-organized station means every pizza gets the right amount of sauce, cheese, and toppings. This is how you deliver the same delicious experience to your customers, every single time.

- Uphold Food Safety Standards: The built-in refrigeration is non-negotiable for a pizzeria. It keeps perishable ingredients like meats and cheeses out of the temperature "danger zone," which is absolutely critical for passing health inspections and keeping your customers safe.

The real job of a pizza prep table is to make the journey from raw dough to a fully-loaded pizza—ready for the oven—as short and smooth as possible. It’s the essential link between your walk-in cooler and your oven, creating an unbroken chain of efficiency.

At the end of the day, this guide is here to help you turn this essential piece of equipment into the true command center of your pizzeria. We’ll show you how to optimize every step, from stretching the dough to the final sprinkle of oregano, making sure every pizza that leaves your kitchen is a perfect slice of your brand.

Anatomy of a High-Performance Pizza Prep Table

It’s easy to think of a pizza prep table as just another piece of kitchen furniture, but that’s like calling a race car just another car. A high-performance table is more like a pizzaiolo's cockpit. Every single component is engineered to work together, creating a seamless workflow that gets pizzas from dough to oven with lightning speed.

When you break down this essential restaurant preparation table, you see a system built for speed, consistency, and above all, food safety in a pizzeria environment.

This synergy is what makes or breaks a busy pizzeria where every second is precious. The anatomy of these tables is no accident; it’s the result of decades of refining what it takes to run an efficient pizza kitchen.

The Refrigerated Topping Rail

Think of the refrigerated topping rail as the front line of your pizza-making battle. This is where your entire arsenal of ingredients—pepperoni, mushrooms, olives, cheese—sits perfectly chilled and ready for action. Consistent, reliable cooling here isn't just a nice-to-have; it's completely non-negotiable.

A top-tier rail uses a forced-air refrigeration system to blanket every single pan, from front to back, in cold air. This keeps everything at a food-safe temperature below 40°F (4°C). No more worrying about ingredients creeping into the "danger zone"—just fresh toppings for every single pizza.

The Cold Storage Base

Right below the action is the cold storage base, your reserve of backup ingredients. This space is absolutely vital for restocking the topping rail during a chaotic dinner rush without having to constantly run to the walk-in cooler. You typically have two choices here:

- Doors: These are your best bet for maximum storage capacity. They’re perfect for bulky items like bags of shredded cheese, large sauce containers, and boxes of prepped veggies.

- Drawers: When speed is the name of the game, drawers win. They offer quick, organized access to smaller items, letting staff grab backup topping pans without bending down and rummaging through a big cabinet. Many pizzerias also opt for refrigerated dough drawers to keep proofs at the perfect temperature right at the station.

The right choice really boils down to your kitchen’s unique flow. Some larger units even come with a combination of doors and drawers, giving you the best of both worlds.

The Critical Work Surface

Finally, we get to the work surface itself—this is where the pizza magic really happens. It's the stage for stretching dough, saucing the base, and assembling the final masterpiece. The most critical element here is the integrated cutting board.

This isn't just any plastic board. It's typically made from a high-density, NSF-certified polyethylene. It’s deep enough to give you plenty of room for even the largest pizzas and is built to be durable, non-porous, and easy to pop out for cleaning.

The smart integration of refrigeration into these specialized pizza prep tables has become a cornerstone of the modern commercial kitchen. In fact, the global market for refrigerated prep tables was valued at a whopping US$7.67 billion in 2024 and is only expected to grow as more pizzerias optimize their operations.

How to Choose the Right Table for Your Pizzeria

Picking out a new pizza prep table isn't like buying a new shelf; it's a core operational decision that will dictate the entire rhythm of your kitchen. The right unit acts as a force multiplier for your team, making service smoother and faster. The wrong one? It becomes a constant bottleneck that frustrates your staff and slows down pizza orders. This choice demands an honest look at your specific needs, from your menu's complexity to the actual square footage you have to work with.

Your first decision point is the type of unit. Think about your topping variety. A standard refrigerated table is a solid all-rounder, but if your menu boasts a dozen or more fresh ingredients, a mega-top unit is a total game-changer. These models are built with extra rows in the topping rail, maximizing your capacity and keeping every single ingredient chilled and within arm's reach.

On the other hand, some specialized models are laser-focused on a specific workflow. For instance, tables with built-in, refrigerated dough drawers keep your proofed dough at the perfect temperature right where you need it. This saves your pizzaiolo crucial steps and seconds during a chaotic, high-volume rush.

Matching the Surface to Your Workflow

The work surface is where all the action happens, and the material you choose directly impacts both how your team handles dough and how easily they can keep things sanitized. The two main options each have their own distinct advantages for a pizzeria.

Thinking about which surface is right for you? Marble is the classic go-to for artisans who hand-stretch their dough, thanks to its naturally cool surface that prevents sticking. Stainless steel, however, is the undisputed champ for durability and food safety in high-speed pizza kitchens.

Here’s a quick rundown to help you decide.

Pizza Prep Table Surface Comparison

| Material | Best For | Pros | Cons |

|---|---|---|---|

| Marble | Pizzerias focused on hand-stretched, artisanal dough. | Naturally cool surface prevents sticking; classic, premium appearance. | Porous, so it can stain; requires careful maintenance to prevent chipping. |

| Stainless Steel | High-volume, fast-paced pizzerias where speed and sanitation are key. | Extremely durable, non-porous, and very easy to sanitize. | Can be slightly warmer to the touch than marble; dough may stick more without flour. |

Ultimately, the choice comes down to your pizzeria's philosophy. If you're all about craft and tradition, marble might be worth the extra care. But if you're built for speed and efficiency, stainless steel is the practical, bulletproof choice. The global market for food preparation tables is valued at roughly US$1.2 billion in 2024, a testament to how vital this equipment is for pizzerias and other restaurants.

Evaluating Your Kitchen's Reality

Before you pull the trigger, take a hard look at your operational reality. How many pizzas are you cranking out during your busiest hour? What are the exact dimensions of the space you have available? A table that’s too small will cripple your output, while one that’s too big will choke your kitchen’s traffic flow and create chaos.

And don't forget the electricals. When you're installing a new refrigerated prep table, it’s not always a simple plug-and-play situation. It's smart to find reliable commercial electrical contractors to handle any necessary wiring or power upgrades safely and correctly.

Choosing the right restaurant preparation table is an exercise in balancing ambition with reality. Your peak pizza volume, menu complexity, and physical space must all align to find the perfect fit.

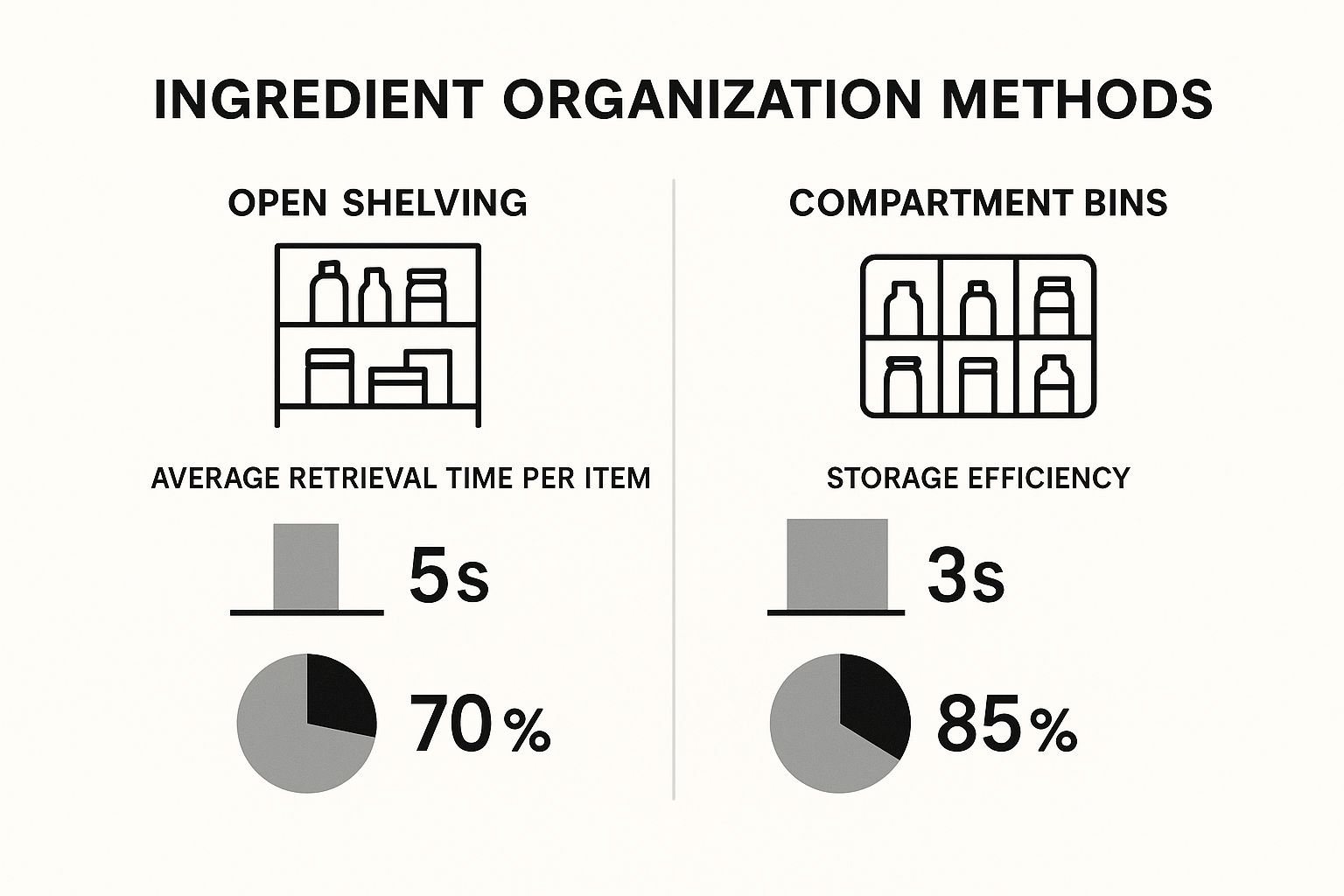

This image shows just how much impact different storage methods within your prep station can have on your team's speed and efficiency.

As you can see, organized compartment bins for toppings don't just look better—they can seriously cut down on ingredient retrieval time and make much better use of your storage space. It’s a clear argument for investing in a well-designed pizza station from the start.

Features That Directly Boost Speed and Consistency

The real difference between a good pizza prep table and a great one is all in the details. Certain features are engineered for more than just keeping things cold—they're designed to help you serve customers faster, cut down on waste, and make a more consistent pizza every single time. These aren't just bells and whistles; they're strategic tools that empower your crew during the craziest dinner rushes.

A truly effective restaurant preparation table is much more than a cold box with a cutting board on top. It's a fine-tuned machine where every single component has a purpose, from the way cold air circulates to how quickly your staff can grab backup ingredients. When you invest in the right features, you're really investing in a smoother, more profitable pizzeria.

Advanced Airflow for Perfect Toppings

The heart of any pizza prep station is its ability to keep toppings fresh and, most importantly, safe. A basic system might just blow cold air around, but the advanced airflow systems do so much more. They create a consistent "blanket" of cold air that wraps around every single ingredient pan in the rail, from the front to the very back.

This is what prevents "hot spots" where temperatures could creep into the danger zone—a massive concern for both health inspections and the quality of your pizza. It means the pepperoni on a slammed Friday night is just as fresh and safe as it was on a quiet Tuesday morning.

A superior airflow system is your pizzeria's silent guardian of quality. It ensures every topping, from the first scoop to the last, is held at a precise, food-safe temperature, guaranteeing consistency and safety in every single pizza.

This level of temperature control is what gives your team the confidence to work at full speed, knowing every ingredient they touch is at its peak. For more tips on getting your ingredient station set up for maximum flow, you can learn how to prep like a pizza pro with these topping stations.

Ergonomics That Shave Seconds Off Orders

In a pizzeria, ergonomics isn't about being comfortable—it's about being fast. The physical design of a prep table has a huge impact on how quickly your team can build a pizza. Two of the most important design choices to think about are the topping rail and the storage base below.

- Raised vs. Recessed Rails: A raised rail angles the topping pans toward your pizza maker, making it way easier to see and scoop ingredients. A recessed or flat rail keeps everything level with the cutting board. It might seem a subtle difference, but a raised rail can seriously reduce wrist strain and improve visibility over a long, busy shift.

- Drawers vs. Doors: Down in the base cabinet, doors are great for fitting bulky items like big bags of cheese or buckets of sauce. Drawers, on the other hand, give you faster, more organized access to backup pans of prepped toppings. Pulling out a drawer is much quicker than opening a door, bending down, and digging around for the right container.

Choosing drawers over doors can shave critical seconds off the restocking process. Over a night, that adds up to faster ticket times and a whole lot less chaos during a pizza rush. These small design choices are what separate a good workstation from a truly high-performance one.

Mastering Workflow and Food Safety at Your Pizza Prep Station

Owning a top-of-the-line restaurant preparation table is only half the battle. The real victory comes from building a smart, efficient process around it, because even the best equipment on the market can't fix a chaotic workflow. Mastering your prep station's organization and sanitation is what truly turns it into a profit-generating machine for your pizzeria.

It all starts with how you arrange your ingredients. A strategic setup can shave precious seconds off every single pizza order, which adds up to a massive advantage during a dinner rush. By organizing your topping rail logically, you create an intuitive, repeatable process that your entire team can follow without even thinking.

Organizing Your Topping Rail for Speed

The secret to a lightning-fast topping rail is minimizing movement and thought. Every single ingredient should have a permanent home, arranged to make the pizza-building process as smooth and natural as possible. Here are two core principles you need to implement right away:

- Arrange by Popularity: Place your heavy hitters—like mozzarella and pepperoni—in the most accessible, central spots. Toppings that get less action, like anchovies or pineapple, can live further to the sides. This simple trick reduces how far your crew has to reach and speeds up the most common pizza orders.

- Implement FIFO (First-In, First-Out): This is a non-negotiable rule for both food safety and quality control. When you refill a topping pan, always put the fresh product at the bottom and move the older product to the top. This ensures you’re consistently using the oldest ingredients first, which cuts down on food waste and guarantees every customer gets the freshest toppings.

A well-organized prep station is like a finely tuned instrument. When every ingredient is in its place and every motion is deliberate, your kitchen produces pizzas with the kind of speed and consistency that defines a professional operation.

Upholding Critical Cleaning Protocols

A pristine prep station is the foundation of food safety and customer trust in your pizzeria. Regular, thorough cleaning isn't just about appearances; it’s about preventing cross-contamination and making sure your equipment runs efficiently for years. Your team should be following a strict daily and weekly cleaning schedule. For a deep dive into the best practices, check out our comprehensive food safety guidelines for restaurants.

Here are a couple of key cleaning tasks that can't be skipped:

- Gaskets and Rails: Wiping down door gaskets every day prevents mold buildup and ensures a tight seal, keeping that precious cold air where it belongs. The topping rails should be completely emptied and sanitized daily.

- Condenser Coils: Regularly cleaning the condenser coils is vital for the refrigerator's health. When dust and grease build up, they force the unit to work harder, which drives up energy costs and puts you at risk for equipment failure during a Friday night rush.

Investing in equipment that boosts operational efficiency is a hallmark of successful pizzerias. This focus on specialized, high-performance prep tables is a major reason why the commercial food service equipment market continues to grow.

Your Smart Buyer's Checklist Before You Purchase

Making the final call on a new restaurant preparation table is a big moment for any pizzeria. This isn't just another piece of equipment; it's an investment that will dictate your kitchen's rhythm and efficiency for years. Before you pull the trigger, let's run through a quick pre-purchase checklist to make sure everything goes off without a hitch.

Think of this as your pre-flight check. Getting these details right now means your new pizza table becomes a workhorse asset from day one, not a logistical nightmare that costs you time and money.

Measure Twice, Buy Once

This sounds obvious, but you'd be surprised. The single most common—and costly—mistake is buying a prep table that simply doesn't fit your pizzeria. Before you do anything else, grab a tape measure and get real about your space.

- Kitchen Footprint: Get the exact dimensions of the spot where the table will live. Don’t forget to leave room for it to breathe. You need at least 6 inches of clearance at the back and sides for the condenser to get proper airflow and avoid overheating.

- Delivery Path: The table has to get from the truck to the kitchen. Measure every single doorway, hallway, and tight corner it needs to pass through. There's nothing more heartbreaking than watching your beautiful new unit get stuck in a hallway.

- Team Workflow: Once it's installed, will your team be able to move around it? Make sure there's enough space for staff to work without bumping into each other and creating a bottleneck on the pizza line.

A prep table is an investment in your pizzeria’s future success. Taking the time to verify every detail before purchase ensures that investment pays off from day one, empowering your team and protecting your bottom line.

Confirm Your Electrical and Service Needs

Beyond just the physical space, you’ve got to think about the technical side. A modern refrigerated pizza prep table is a powerful machine, and it has specific needs that you can't ignore. Make sure you have the right outlet and that your circuit can handle the electrical load without tripping a breaker in the middle of a Friday night service.

Finally, take a hard look at the warranty and any service agreements. A solid warranty is the manufacturer's way of saying they stand behind their product. You need to know exactly what’s covered (parts, labor, the compressor) and for how long. Knowing you have reliable support if something goes wrong is invaluable peace of mind. It's what turns a big purchase into a smart, long-term investment for your pizzeria.

Still Have Questions?

When you're looking at investing in a new restaurant preparation table, a few practical questions always come up. Here are some straight answers to the things pizzeria owners ask most often. Getting these details right is what separates a smooth-running kitchen from a chaotic one.

How Often Should I Clean My Condenser Coils?

This is probably the single most important maintenance task you can do for any refrigerated unit. Make it a habit to clean the condenser coils on your pizza prep table at least once every 90 days. No exceptions.

Now, if your kitchen has a lot of grease or flour dust flying around—common in any pizzeria—you'll need to bump that up to once a month. When coils get caked with dust and grease, they can't breathe. This forces the compressor to work overtime, jacking up your energy bills and dramatically shortening the life of your equipment.

What's the Right Temperature for the Topping Rail?

Your refrigerated topping rail needs to live at or below 40°F (4°C). Period. This keeps your ingredients safely out of the temperature "danger zone" where nasty bacteria can multiply.

Think of it this way: keeping that rail cold is non-negotiable. It's how you protect your customers, keep the health inspector happy, and make sure your toppings taste fresh and delicious on every pizza.

Honestly, maintaining this strict temperature is the most critical job of your pizza prep station's entire refrigeration system.

How Do I Pick the Right Size Table?

Choosing the right size really boils down to two things: how much space you've got and how many pizzas you're slinging during your busiest rush.

First, get out the tape measure. Figure out your exact footprint, but don't forget to leave at least six inches of breathing room around the unit for proper ventilation. Next, be honest about your peak sales volume. A smaller 44-inch table might be perfect for a cozy little shop, but a high-volume pizzeria cranking out pies on a Friday night will almost certainly need a 93-inch model to avoid a massive bottleneck at the prep line.

The goal is simple: give your team enough workspace and topping capacity to keep that pizza line humming along without a hitch.

Ready to find the perfect command center for your pizzeria? Explore a wide selection of high-quality, NSF-compliant pizza prep tables at Pizza Prep Table. Head over to https://pizzapreptable.com and find the ideal unit to boost your kitchen's speed and consistency.