Screen Time: Top Stainless Steel Pizza Screens Reviewed

Share

Why Pizza Screen Stainless Steel Matters for Your Kitchen

Pizza screen stainless steel options deliver superior durability and heat retention compared to aluminum alternatives. Here's what you need to know:

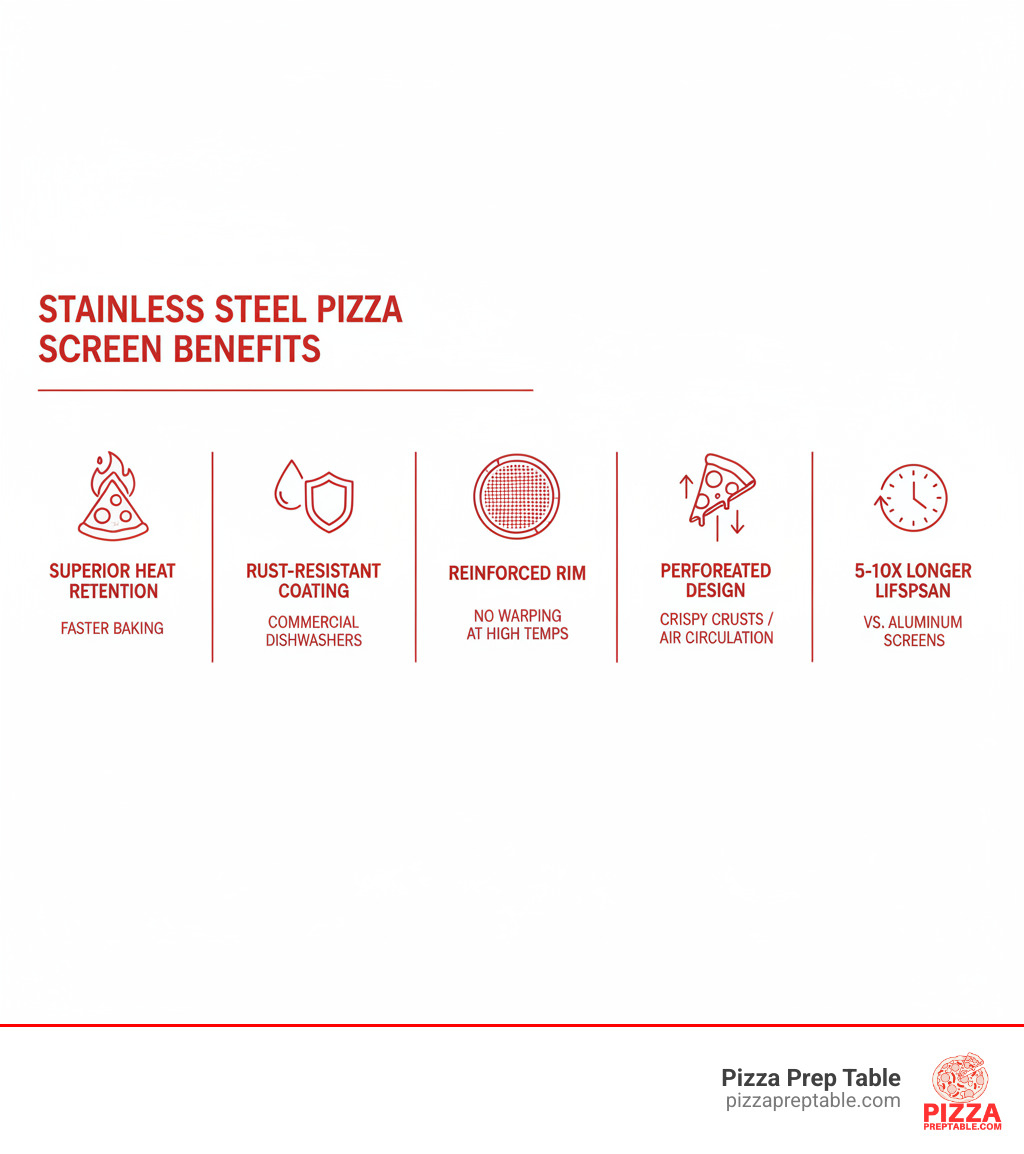

Key Benefits of Stainless Steel Pizza Screens:

- Stronger and Heavier - Better heat retention for well-cooked pizzas

- Rust and Corrosion Resistant - Ideal for heavy commercial use and frequent washing

- High-Temperature Performance - Perfect for very hot ovens without warping

- Long-Term Value - Can last 5-10x longer than standard aluminum screens

- Commercial-Grade Durability - Withstands constant intense heat in busy kitchens

As Sean Kearney from The Restaurant Warehouse notes in their comprehensive guide: "Some of the most valuable tools in a professional kitchen are the simplest. While a high-tech oven or mixer gets all the attention, a humble pizza screen can have a massive impact on your daily operations and the quality of your final product."

If you're tired of dealing with warped screens or soggy crusts, stainless steel pizza screens offer the solution. The open mesh design allows hot air to circulate beneath the crust, promoting thorough and uniform baking while preventing undercooked sections. Unlike traditional pizza pans, these screens facilitate maximum air ventilation for that perfectly browned, crispy crust every time.

The investment makes sense for both commercial kitchens and serious home pizza makers. While stainless steel screens cost more upfront than aluminum, they pay for themselves through longevity and consistent performance. You won't need to replace them annually like cheaper options - these screens are built to withstand multiple trips through a pizza oven daily without warping or degrading.

I'm Sean Kearney, and I've spent years helping restaurant owners outfit their kitchens with equipment that actually lasts. When it comes to pizza screen stainless steel options, I've seen how the right choice transforms both product quality and kitchen efficiency.

Why Choose Stainless Steel Pizza Screens?

If you've ever wondered whether the material of your pizza screen really matters, let me assure you—it absolutely does. While aluminum screens are everywhere and work fine for basic needs, pizza screen stainless steel options represent a significant upgrade in quality, especially when you're running a busy kitchen or simply want the best possible results at home.

The difference starts with the fundamentals. Stainless steel screens are heavier and more robust than aluminum, which might sound like a drawback until you understand what that weight means for your pizza. That extra mass translates directly into superior heat retention. When your screen holds onto heat better, your pizza cooks more evenly and thoroughly. The crust gets that perfect golden-brown color, and you avoid those disappointing soggy centers that can happen when heat dissipates too quickly.

But it's not just about heat. The real beauty of stainless steel becomes obvious when you consider the daily grind of kitchen work. These screens are remarkably resistant to rust and corrosion, which means they can handle the punishment of commercial dishwashers, frequent washing, and the humid environment of a busy pizzeria without breaking down. I've seen aluminum screens develop corrosion spots or require special seasoning to prevent sticking, but stainless steel? It just keeps working.

The durability at high temperatures is another crucial factor. Stainless steel won't warp when you're running your oven at maximum heat, day after day. This structural integrity means your pizzas cook consistently every single time—no more adjusting for a warped screen that's creating hot spots or uneven results.

Yes, stainless steel screens cost more upfront. But here's where the math works in your favor: these screens can last 5-10 times longer than standard alternatives. When you factor in replacement costs, downtime, and the frustration of dealing with degraded equipment, the investment pays for itself. For more guidance on equipping your kitchen with lasting quality, check out our guide on Commercial Kitchen Equipment.

| Feature | Stainless Steel Pizza Screens | Aluminum Pizza Screens |

|---|---|---|

| Durability | Excellent; highly resistant to warping, dents, and heavy use | Good; can warp at very high temperatures or with heavy use |

| Heat Performance | Superior heat retention; ideal for high temperatures | Good heat conductivity; can lose heat faster |

| Maintenance | Easy to clean; rust and corrosion-resistant | Can be prone to corrosion; may require seasoning |

| Average Cost | Higher initial investment, but excellent long-term value | Lower initial cost, but shorter lifespan and more replacements |

Durability for Demanding Kitchens

Let's be honest—commercial kitchens are tough environments. Equipment gets dropped, stacked carelessly during rushes, subjected to temperature swings that would make your home oven weep, and generally treated like the workhorses they need to be. This is where pizza screen stainless steel construction proves its worth every single day.

The warping resistance alone makes these screens invaluable. When you're cranking out pizzas during dinner rush, the last thing you need is a screen that's developed a subtle bowl shape from repeated heating and cooling. That warping creates uneven cooking surfaces, which means inconsistent results and unhappy customers. Stainless steel maintains its flat, true shape even after hundreds of trips through a blazing hot oven.

I've talked to pizzeria owners who were replacing their aluminum screens every few months because of wear and tear. The screens would develop rough edges, lose their shape, or simply fail under the constant stress of heavy use at high temperatures. When they switched to stainless steel, those replacement cycles stretched to years instead of months. That's not just cost savings—it's peace of mind.

The longevity of these screens is impressive. While quality aluminum screens from reputable manufacturers can last quite a while, stainless steel pizza screens consistently match or exceed those lifespans, often remaining in service for a decade or more with proper care. In a commercial setting where reliability directly impacts your ability to serve customers, that kind of durability is priceless.

Heat Performance: Consistent, Crispy Results

Every pizza maker knows the holy grail: that perfectly crispy crust with just the right amount of chew, golden-brown on the bottom, cooked evenly from edge to center. Achieving that consistency isn't magic—it's about having the right tools, and pizza screen stainless steel options deliver exactly the heat performance you need.

The secret lies in how these screens handle heat transfer. When you preheat a stainless steel screen (which I always recommend), it becomes a heat reservoir. Place your prepared pizza on that hot surface, and it immediately begins transferring consistent, sustained heat directly to the dough. This bottom-up heating is crucial for developing that crispy foundation we all love.

But here's where it gets even better: the perforated design of the screen allows hot air to circulate freely around and beneath the crust. You're getting heat from direct contact and from convection, which means faster cooking times without sacrificing quality. The pizza bakes thoroughly and evenly, eliminating those frustrating undercooked spots that sometimes plague solid pans.

The heat retention properties of stainless steel really shine when you're doing high-volume production. Unlike lighter materials that cool down quickly when you load a cold pizza onto them, stainless steel bounces back fast, maintaining the temperature you need for consistent results pizza after pizza. This is especially important in commercial ovens running at very high temperatures—the stainless steel handles that intense heat without flinching.

For pizzerias serious about quality, this consistency is everything. Your morning shift and evening shift will produce the same excellent results. Your new hire and your veteran pizza maker will get the same crispy crusts. That reliability builds your reputation. If you're thinking about upgrading your entire pizza operation, start with The Ultimate Guide to Choosing the Best Pizza Oven to ensure all your equipment works together perfectly.

Top Pizza Screen Stainless Steel Options for 2025

Finding the perfect pizza screen stainless steel shouldn't feel overwhelming. Whether you're running a high-volume pizzeria or perfecting your pizza game at home, we've done the legwork to bring you our top recommendations for 2025.

The market is flooded with aluminum options, but we know you're here because you want something better. Our selection at Pizza Prep Table focuses specifically on what matters most: robust construction, reliable heat performance, and screens that actually last. Let's walk through our favorite picks for commercial kitchens and home chefs alike.

Best for Overall Value: Pizza Prep Table Stainless Steel Screens

Sometimes you need equipment that simply works without emptying your wallet. Our standard Pizza Prep Table stainless steel pizza screens hit that sweet spot perfectly. We've designed these screens to deliver consistent, crispy results while keeping your budget intact.

These screens bring sturdy construction and dependable baking performance to your kitchen. They're built to handle regular use without warping or degrading, and they'll give you that perfectly browned crust you're after, every single time. The best part? You're getting professional-grade quality without the professional-grade price tag.

We stock these screens in all the sizes you'll need, from personal pizzas to large family pies: 8-inch for appetizers and individual servings, 10-inch, 12-inch, 13-inch, and 14-inch for standard pizzas, plus 16-inch, 18-inch, and 20-inch for those bigger orders. No matter what size pizza you're making, we've got you covered.

For more insights on choosing the right equipment, check out pizza screen reviews to see how different screens stack up in real-world testing.

The Heavy-Duty Workhorse: Pizza Prep Table 304 Stainless Steel Perforated Screens

When your kitchen runs at full throttle during dinner rush, you need equipment that won't let you down. Our Pizza Prep Table 304 stainless steel perforated pizza screens are built for exactly that scenario. These are the screens we recommend when durability isn't just nice to have—it's absolutely essential.

The secret is in the material: 304-grade stainless steel represents the gold standard for commercial kitchens. This premium grade offers exceptional resistance to corrosion, rust, and warping, even when you're running pizzas through a blazing hot oven all day long. It's the same quality you'll find in high-end restaurant equipment, and it's designed to outlast anything else on the market.

The perforated design ensures hot air circulates evenly around your pizza, creating that uniformly crisp and golden crust your customers expect. We've also incorporated seamless rim design into these screens, which means no rough edges to catch on your hands or harbor food particles. Cleaning becomes easier, handling becomes safer, and your dough won't get stuck in awkward seams.

These screens are an investment in consistency and reliability. The 304-grade stainless steel construction meets the highest professional standards for commercial kitchen equipment.

Best for Home Use: Pizza Prep Table 16" Stainless Steel Pizza Screen

You don't need to run a restaurant to appreciate the difference quality equipment makes. Our Pizza Prep Table 16" stainless steel pizza screen brings commercial-grade performance right to your home kitchen, and honestly, once you've used one, you'll wonder how you ever managed without it.

This screen is sized perfectly for most home ovens and handles everything from frozen pizzas to your from-scratch masterpieces. It works as an excellent crisper pan, allowing air to circulate beneath your pizza so you get that restaurant-quality crispy bottom every time. No more soggy centers or unevenly cooked crusts—just consistently delicious results.

The durability means this screen will be part of your kitchen for years to come, surviving countless pizza nights without showing its age. And when it comes time to clean up? A quick wash and you're done. It's the kind of affordability that makes sense: pay once for quality that lasts, rather than replacing cheaper options every year.

Our 16-inch screen brings professional performance to home kitchens, delivering the same quality and reliability that commercial pizzerias depend on every day.

How to Choose and Use Your Screen for Perfect Pizza

Getting the perfect pizza isn't just about the dough and toppings—it's also about having the right tools and knowing how to use them properly. Your pizza screen stainless steel choice and how you care for it will make a real difference in your baking results and overall kitchen efficiency.

Finding the Right Size and Oven Compatibility

The first step in choosing your pizza screen stainless steel is making sure it actually fits your oven and matches the size pizzas you typically make. This might sound obvious, but I've seen plenty of folks order screens that are just slightly too large for their oven, which defeats the whole purpose.

Pizza screens typically range from 8 inches for personal-sized pizzas all the way up to 20 or even 21 inches for those impressive family-style pies. You'll even find rectangular and square options if you're doing something specialized. The key is measuring your oven's interior dimensions before you buy—especially if you're working with commercial equipment.

This measurement step is particularly crucial if you're using conveyor ovens, deck ovens, or convection ovens, where airflow and clearance matter significantly. The beauty of stainless steel pizza screens is how well they work with forced air circulation. In conveyor and convection ovens especially, these screens really shine by allowing hot air to flow freely around the pizza, creating that perfectly even bake and crispy crust you're after. Just make sure there's enough clearance around the screen for air to circulate properly. If you're still deciding on your oven setup, our guide on The Ultimate Guide to Choosing the Best Pizza Oven can help you make the right choice.

How to Clean and Maintain Your Pizza Screen Stainless Steel

One of the best things about stainless steel pizza screens is how straightforward they are to maintain. Unlike some materials that demand careful seasoning rituals and delicate handling, stainless steel is refreshingly forgiving. That said, taking proper care of your screens will extend their life and keep them performing at their best.

You might wonder whether you need to season a pizza screen stainless steel like you would a cast iron pan. While it's not as critical as with aluminum screens, a light initial seasoning can still be beneficial. I recommend wiping your new screen with a thin layer of high-smoke-point oil and baking it at 350°F for about 30 minutes. This creates a natural non-stick barrier that makes everything easier down the line.

For everyday cleaning, simplicity is your friend. Once the screen cools down, wipe it with a cloth to remove loose bits of food and grease. When you encounter stubborn, baked-on cheese or dough—and you will—use a soft brush with hot water to work it free. Avoid harsh soaps and abrasive scrubbers, which can scratch the surface and strip away any seasoning you've built up.

The rust and corrosion resistance of stainless steel means you can wash these screens frequently without worry. While many stainless steel items are technically dishwasher safe, hand-washing is usually better for screens if you want to maintain their shape and finish over the long haul. For particularly stubborn residue, a gentle soak in hot water works wonders.

Storage matters too. Keep your screens in a cool, dry place, ideally stacked flat to prevent any warping. A dedicated pizza screen rack keeps them organized and protected, which is especially helpful if you're working with multiple screens in a commercial setting. And if you want more tips on maintaining stainless steel equipment in general, our article on Best to Clean Stainless Steel Refrigerator covers many of the same principles that apply to screens.

Frequently Asked Questions about Stainless Steel Pizza Screens

When you're investing in quality pizza equipment, it's natural to have questions. We've gathered the most common concerns we hear from both commercial operators and home pizza enthusiasts about pizza screen stainless steel options. Let's explore what you really need to know.

Do I need to season a pizza screen stainless steel?

Here's the thing about seasoning stainless steel screens: it's helpful, but not as absolutely essential as it is with cast iron or aluminum. Seasoning creates a thin layer of baked-on oil that makes the surface more non-stick and helps prevent dough from clinging to the mesh. While pizza screen stainless steel is naturally less prone to sticking than other materials, a light initial seasoning still gives you an edge.

The process is straightforward. After washing and thoroughly drying your new screen, brush both sides with a high-smoke-point oil like grapeseed or avocado oil. Pop it in your oven at 350 F for about thirty minutes, then let it cool and wipe away any excess oil. This simple step builds up a natural non-stick coating that makes dough release easier and cleanup faster.

If your pizza keeps sticking despite seasoning, the culprit is usually one of three things: your dough might be too wet, stretched too thin for the mesh size, or you need another round of seasoning. A light dusting of flour or cornmeal on the screen before placing your dough can also work wonders for preventing sticking.

Is a stainless steel screen better than a pizza stone?

This question comes up constantly, and honestly, it's like asking whether a fork is better than a spoon. They're both excellent tools that achieve different results, and neither is objectively "better" than the other.

A pizza stone or steel delivers intense, direct heat through contact. When your dough hits that scorching surface, you get a rapid burst of heat that creates a deeply crisp, sometimes slightly charred bottom crust. Many traditionalists swear this direct contact method is essential for achieving that perfect artisan texture.

Pizza screen stainless steel, by contrast, works through airflow rather than direct contact. The perforated design lets hot air circulate freely beneath your crust, creating an evenly crisp, uniformly browned base. This method excels at preventing soggy centers and delivering consistent results every single time, which is why it's invaluable in commercial settings and high-volume operations.

So which should you choose? If you're chasing that authentic wood-fired, slightly blistered crust, reach for your pizza stone. But if consistency, even crispiness, and ease of handling are your priorities, a pizza screen stainless steel is your best friend. Some experienced pizza makers actually use both, starting their pizza on a screen and then sliding it onto a stone for the final minutes to combine the benefits. For more on this classic debate, check out our guide on Cast Iron vs. Pizza Stone: The Grill-Off for Perfect Homemade Pizza.

How does the weight of stainless steel screens impact kitchen workflow?

The weight of stainless steel pizza screens is one of those trade-offs that's worth understanding before you commit. Yes, stainless steel screens are definitely heavier than aluminum alternatives, and that weight affects your daily operations in both positive and negative ways.

On the plus side, that extra weight translates directly into durability and stability. Heavier screens resist warping and bending even under intense heat and constant use, which means fewer replacements and more reliable performance over time. The mass also helps with heat retention, contributing to more even baking and better overall results.

The downside? In a busy kitchen during the dinner rush, repeatedly lifting and maneuvering heavier screens can be more physically demanding for your staff. It might slow down handling slightly compared to lighter aluminum options. Storage is another consideration a full stack of stainless steel pizza screens weighs considerably more than aluminum, so you'll need sturdy shelving that can handle the load.

For most commercial operations, though, the benefits far outweigh these minor inconveniences. The long-term reliability and superior baking performance actually contribute to smoother workflow overall because you're not constantly dealing with warped screens or inconsistent results. Understanding how your equipment fits into your overall kitchen workflow helps you maximize efficiency and keep your operation running smoothly.

Conclusion: The Superior Choice for Durability and Performance

After everything we've covered, one thing becomes crystal clear: pizza screen stainless steel options simply deliver results that other materials struggle to match. Whether you're running a busy pizzeria or perfecting your craft at home, these screens offer a combination of durability, performance, and reliability that transforms your pizza-making process.

Think about what matters most in your kitchen. Consistency? Check. Those perfectly crisp, evenly baked crusts that keep customers coming back? Absolutely. Equipment that stands up to the daily grind of commercial use without warping, rusting, or falling apart? That's exactly what stainless steel pizza screens bring to the table.

Yes, you'll invest a bit more upfront compared to aluminum screens. But here's the thing – you're not just buying a piece of equipment. You're making a long-term investment that pays dividends through years of reliable service. When you factor in the reduced replacement costs, the consistent quality of your pizzas, and the peace of mind that comes from using commercial-grade equipment, the value becomes undeniable.

We've seen countless kitchens make the switch and never look back. The heat retention ensures every pizza gets that perfect golden-brown base. The corrosion resistance means your screens keep looking and performing like new, even after countless trips through the oven and dishwasher. And that durability? It's the difference between replacing screens every few months and having equipment that lasts for years.

At Pizza Prep Table, we're passionate about helping you succeed. We know that the right equipment doesn't just make your job easier – it makes your pizza better. That's why we're committed to offering commercial-grade quality tools that actually perform in real-world conditions, whether that's a high-volume Saturday night rush or a relaxed Sunday afternoon of home pizza making.

Ready to experience the difference? Browse our complete selection of pizza screen stainless steel options and find how the right equipment can lift your entire operation. And if you're building out your pizza business from scratch or looking to upgrade your setup, don't miss our comprehensive resource: Everything You Need to Know to Buy Pizza Shop Supplies. We're here to help you create pizza perfection, one crispy crust at a time.