Slice, Dice, and Store: Top Prep Tables for Every Kitchen

Share

The Heart of the Kitchen: Why a Great Prep Table is Non-Negotiable

A prep table is a work surface designed for food preparation in commercial kitchens, available in standard stainless steel, wood-top, and refrigerated models. Here are the main types to consider:

- Standard Work Tables: Basic stainless steel or wood surfaces for general prep work

- Refrigerated Prep Tables: Include built-in cooling with ingredient rails for sandwiches and salads

- Pizza Prep Tables: Feature deep cutting boards and raised rails specifically for pizza assembly

- Mega Top Tables: Wider refrigerated units with maximum pan capacity for high-volume operations

Price ranges from $1,249 for basic 29" models to over $4,000 for large 3-door units.

The key to good cooking starts with organized, methodical preparation. As one industry expert puts it: "A properly prepped station is the foundation upon which a successful service period is built."

Your prep table isn't just furniture - it's the command center of your kitchen. Whether you're assembling pizzas during the dinner rush or prepping sandwiches for lunch service, the right prep table keeps ingredients at safe temperatures while giving you the workspace to work efficiently.

Without proper prep surfaces, even the best restaurants struggle. Too little prep space leads to chaos during busy periods. The wrong equipment can slow down service, waste ingredients, and even create food safety issues.

Stainless steel construction dominates commercial kitchens for good reason. It's durable, easy to clean, and resistant to corrosion. Refrigerated models add temperature control to keep ingredients fresh and safe throughout service.

I'm Sean Kearney, and I've spent years helping restaurant owners choose the right equipment for their kitchens, including finding the perfect prep table for their specific needs. My experience in sales and deep understanding of the foodservice industry has taught me that the right prep table can make or break your kitchen's efficiency.

Must-know prep table terms:

Types of Prep Tables: Finding Your Perfect Match

Every commercial kitchen has its own personality, and finding the right prep table is like finding the perfect dance partner. Whether you're running a busy pizzeria or a cozy sandwich shop, your workstations need to match your rhythm and style.

The beauty of modern foodservice equipment is that there's truly a prep table for every need. From the simplest stainless steel surface to sophisticated refrigerated units, each type serves a specific purpose in creating an efficient kitchen workflow. More detailed information about restaurant kitchen tables can help you understand the full range of options available.

Standard Work Tables (Stainless Steel & Wood Top)

Think of standard work tables as the reliable workhorses of any kitchen. These stainless steel beauties can handle whatever you throw at them - literally. Need to tenderize meat? No problem. Chopping vegetables for the dinner rush? They've got you covered.

Stainless steel tables shine because they're practically indestructible. They resist stains, don't harbor bacteria, and clean up with just a quick wipe-down. Most come with an undershelf that gives you extra storage space for those bulky items that always seem to clutter up your workspace.

But sometimes you need something gentler. Wood top tables and butcher block surfaces are perfect when you're working with dough or need a knife-friendly surface. The wood won't dull your blades as quickly, and dough just behaves better on wood - it doesn't stick and tear like it might on metal.

These general purpose tables might seem basic, but their versatility makes them essential. They're the foundation pieces that let you tackle any prep task with confidence.

Refrigerated Prep Tables

Here's where things get exciting. Refrigerated prep tables are like having a personal assistant who never forgets to keep your ingredients fresh and perfectly organized.

Picture this: it's lunch rush, orders are flying in, and you need to make twelve different sandwiches in five minutes. With a refrigerated prep table, all your cold ingredients are right there at the perfect temperature. No running to the walk-in cooler, no worrying about food safety - everything stays consistently cold and ready to use.

The magic happens with temperature control that keeps ingredients in that sweet spot between fresh and frozen. Digital displays let you monitor temperatures at a glance, so you always know your food is safe. This kind of efficiency can transform how smoothly your kitchen operates during busy periods.

Most units feature individual ingredient pans that fit perfectly into refrigerated rails, keeping everything organized and easily accessible. For more detailed information, check out our guide on sandwich prep table refrigerators.

Specialized Prep Tables (Pizza & Sandwich/Salad)

Sometimes you need equipment that's built for one specific job - and does it perfectly.

Pizza prep stations are engineered with pizza makers in mind. They feature deeper cutting boards that can handle even the largest pizza doughs, plus raised ingredient rails that keep your toppings at eye level and easy to reach. Many include dough storage compartments below, so you can keep extra dough balls perfectly chilled and ready for the next rush.

Sandwich prep units take a different approach. They're usually designed with standard-depth cutting boards but offer more individual ingredient compartments. Mega Top tables are the superstars here - they provide an extra row of ingredient pans, giving you maximum variety and capacity for high-volume operations.

These specialized tables include smart features like condensation management systems that keep ingredient pans dry and fresh-looking, even during the busiest service periods.

If you're serious about pizza, you won't want to miss our comprehensive guide: Don't Miss Out on These Pizza Prep Tables.

Top Prep Tables for Your Needs: A Comparative Look

Finding the perfect prep table for your kitchen is like finding the right tool for any job - it needs to match exactly what you're trying to accomplish. Whether you're slinging pizzas in Brooklyn or crafting gourmet sandwiches in Portland, the wrong table can slow you down when you need speed most.

Let me break down the key differences between the main types so you can see which one fits your operation best:

| Feature | Pizza Prep Table | Sandwich Prep Table | Standard Work Table |

|---|---|---|---|

| Size (Common) | 44" to 90" wide | 27" to 72" wide | 24" to 120" wide |

| Refrigeration | Yes (pans & base) | Yes (pans & base) | No (unless a chef base) |

| Cutting Board | Wider & Deeper (e.g., 19" wide) | Standard Depth (e.g., 9-10" wide) | N/A (separate cutting board needed) |

| Ingredient Rail | Raised, accommodates larger pans | Flush or slightly raised, accommodates smaller pans | N/A |

| Best For | High-volume pizza assembly, dough storage | Rapid sandwich/salad assembly, diverse toppings | General food prep, heavy-duty tasks, storage |

| Average Price Range | $1,500 - $4,000+ | $1,200 - $3,500+ | $150 - $1,000+ |

Think of it this way: a pizza prep table is like a sports car built for one thing - making pizzas fast and efficiently. A sandwich prep table is more like a versatile SUV, handling lots of different ingredients with ease. And a standard work table? That's your reliable pickup truck, ready for whatever heavy-duty task you throw at it.

Best for Pizza Making: Refrigerated Pizza Prep Tables

If you're running a pizzeria, a dedicated pizza prep table isn't just nice to have - it's absolutely essential. I've seen too many pizza shops try to get by with regular tables, and it always slows them down during the dinner rush.

Maxx Cold, Chef AAA, and Dukers make some of the best pizza prep tables in the business. The numbers tell the story: Maxx Cold V-Series 1 Door models average around $2,039, while their larger 3-door units can reach over $4,000. Chef AAA's 70" Pizza Prep Table with 9 pans and 2 doors runs about $1,990.

What makes these tables so special? The raised rail keeps your cheese, pepperoni, and toppings perfectly chilled right at eye level. No more bending down to grab ingredients or worrying about them warming up during busy periods.

The deep cutting board is where the magic happens. At 19" or wider, you've got plenty of room to stretch dough, assemble pizzas, and cut them before they head to the oven. Compare that to a standard prep table, and you'll immediately see why pizza makers swear by these specialized surfaces.

Don't forget about dough storage either. The refrigerated base keeps your pre-portioned dough balls at the perfect temperature until you're ready to use them. No more trips to the walk-in cooler every few minutes.

For the complete breakdown on these game-changing units, check out our guide on commercial pizza prep tables.

Best for Sandwiches & Salads: Mega Top & Standard Top Tables

When your menu focuses on custom sandwiches and fresh salads, you need a different kind of prep table - one that gives you access to lots of different ingredients quickly. That's where sandwich and salad prep tables shine.

Migali and Chef AAA lead the pack here. Migali's 27" model with 8 pans averages $1,832, while their 48" table with 12 pans runs around $2,560. Chef AAA offers great value too - their 48" 12-pan model comes in at about $1,600, and their 60" 24-pan Mega Top hits $1,990.

The pan capacity is what sets these apart. Instead of a few large pans like pizza tables, these hold numerous smaller 1/6th or 1/9th size pans. Mega Top models take this even further with an extra row of pans, giving you twice the ingredient options without taking up more floor space.

Condensation management might sound boring, but it's crucial. Quality units use insulated roll covers and R290 refrigerant (which can save you up to 40% on energy costs) to keep everything at the right temperature without creating that annoying condensation that makes ingredients soggy.

The beauty is in the easy access. During the lunch rush at a busy deli, your staff can grab what they need, build the order, and move on without missing a beat. It's like having a perfectly organized toolbox where every tool is exactly where you expect it.

Speaking of organization, the importance of kitchen prep sheets can't be overstated when you're managing this many ingredients!

Best All-Purpose Workhorse: Stainless Steel Work Tables

Sometimes you don't need bells and whistles - you just need a solid, dependable surface that can handle whatever you throw at it. That's where stainless steel work tables earn their keep in kitchens from coast to coast.

Gridmann and John Boos build some of the toughest work tables around. While prices vary widely based on size and features, you're typically looking at $150 to $1,000+ - making them the most budget-friendly option for most operations.

Look for NSF Certified models every time. This certification means the table meets strict health and safety standards, so you know it's easy to clean and won't harbor bacteria. In a commercial kitchen, this isn't optional.

Most quality tables come with undershelves that you can adjust to fit your needs. Whether you're storing pots and pans, bulk ingredients, or small appliances, that extra storage keeps your work surface clear and your kitchen organized.

The heavy-duty construction is what really sets these apart. Built from 18-gauge or even 14-gauge stainless steel, these tables can handle everything from pounding meat to supporting heavy mixers. They're built to last for years, even with constant daily use.

For new restaurants or expanding kitchens, these tables offer incredible value. You get professional-grade equipment that can grow with your business without breaking the bank.

Want to see how stainless steel tables can work specifically for pizza operations? Our guide to stainless steel pizza prep tables has all the details.

Choosing the Right Prep Table: A Buyer's Guide

Picking the perfect prep table for your kitchen is more than just shopping – it's about making a smart investment that will serve your business for years to come. Think of it as choosing the right partner for your daily operations. You want something reliable, efficient, and built to handle whatever your kitchen throws at it.

When I work with restaurant owners, I always tell them to consider their specific needs first. How's your kitchen layout? Are your staff comfortable at their current work height? These aren't just nice-to-have considerations – they directly impact your bottom line through improved efficiency and reduced staff fatigue.

Key Features of a High-Quality Prep Table

Let's talk about what really matters when you're investing in a prep table. The material quality is your foundation – literally. 304-type stainless steel is what you want to see on the spec sheet. It's the commercial kitchen standard because it fights off corrosion like a champ.

Now, here's where thickness comes into play. 18-gauge stainless steel handles most kitchen tasks beautifully, but if you're doing heavy-duty work like tenderizing meat or supporting heavy equipment, 14-gauge is your friend. It's thicker, stronger, and won't budge when you need stability most.

Size and dimensions can make or break your kitchen flow. I've seen too many restaurants squeeze in tables that seemed like a good deal, only to create bottlenecks during rush periods. Measure twice, buy once – and don't forget about comfortable working height. Most commercial prep tables sit around 34-36 inches high, which works well for most staff.

Storage options are where you can really boost efficiency. Undershelves give you instant access to frequently used items without extra trips across the kitchen. Some models offer cabinets or drawers – perfect for keeping smaller tools and ingredients organized and within arm's reach.

Think about mobility too. Casters are fantastic if you need to move your prep table for cleaning or rearranging during catering events. But if you want rock-solid stability, adjustable leveling feet will keep your table steady even on uneven floors.

Don't overlook the details like backsplashes and marine edges. A backsplash protects your walls from splashes and makes cleanup easier. A marine edge – that raised rim around the table's perimeter – is a lifesaver that contains spills before they hit the floor.

Food Safety and Sanitation

Here's where your prep table becomes a food safety superhero. NSF certification isn't just a nice badge – it's your guarantee that the table meets strict public health standards. Health inspectors look for this certification, and for good reason.

The beauty of stainless steel lies in its non-porous surface. Unlike wood or plastic, it doesn't absorb liquids, odors, or bacteria. This makes preventing cross-contamination much easier, especially when you're switching between different types of ingredients.

Easy-to-clean surfaces aren't just convenient – they're essential for maintaining the high standards your customers expect. A quick wipe-down with sanitizer between tasks keeps your workspace safe and your reputation intact.

For detailed insights on maintaining food safety standards with your equipment, check out our guide on food prep tables and safety.

Maintaining Your Stainless Steel Prep Table

Taking care of your prep table is like maintaining any valuable tool – a little attention goes a long way. Daily cleaning is straightforward: warm water, mild dish soap, and a soft cloth. Always wipe with the grain of the stainless steel to avoid streaks that make your beautiful table look tired.

For tougher spots, a dedicated stainless steel cleaner works wonders. Just avoid abrasive scrubbers or harsh chemicals that can scratch the surface or leave unwanted residues.

Polishing your table after cleaning brings back that professional shine. A dry microfiber cloth usually does the trick, but for special occasions, a light application of food-grade mineral oil can make your prep table gleam like new.

Avoiding rust is mostly about good habits. While stainless steel resists corrosion, it's not completely rust-proof. Dry your table thoroughly after cleaning, and don't let acidic foods or cleaning agents sit on the surface too long.

With proper care, your stainless steel prep table becomes a true kitchen workhorse that can serve your business for decades. Regular cleaning, quick spill cleanup, and gentle treatment ensure your investment keeps paying dividends year after year.

Frequently Asked Questions about Prep Tables

Restaurant owners call us all the time with questions about prep tables. After years in this business, I've noticed the same concerns come up again and again. Let me share the answers to the questions I hear most often - they'll help you understand why the right prep table can transform your kitchen.

How do prep tables improve kitchen efficiency?

Think about your busiest dinner rush. Orders are flying in, tickets are backing up, and your staff is running around like crazy. This is exactly when a well-designed prep table proves its worth.

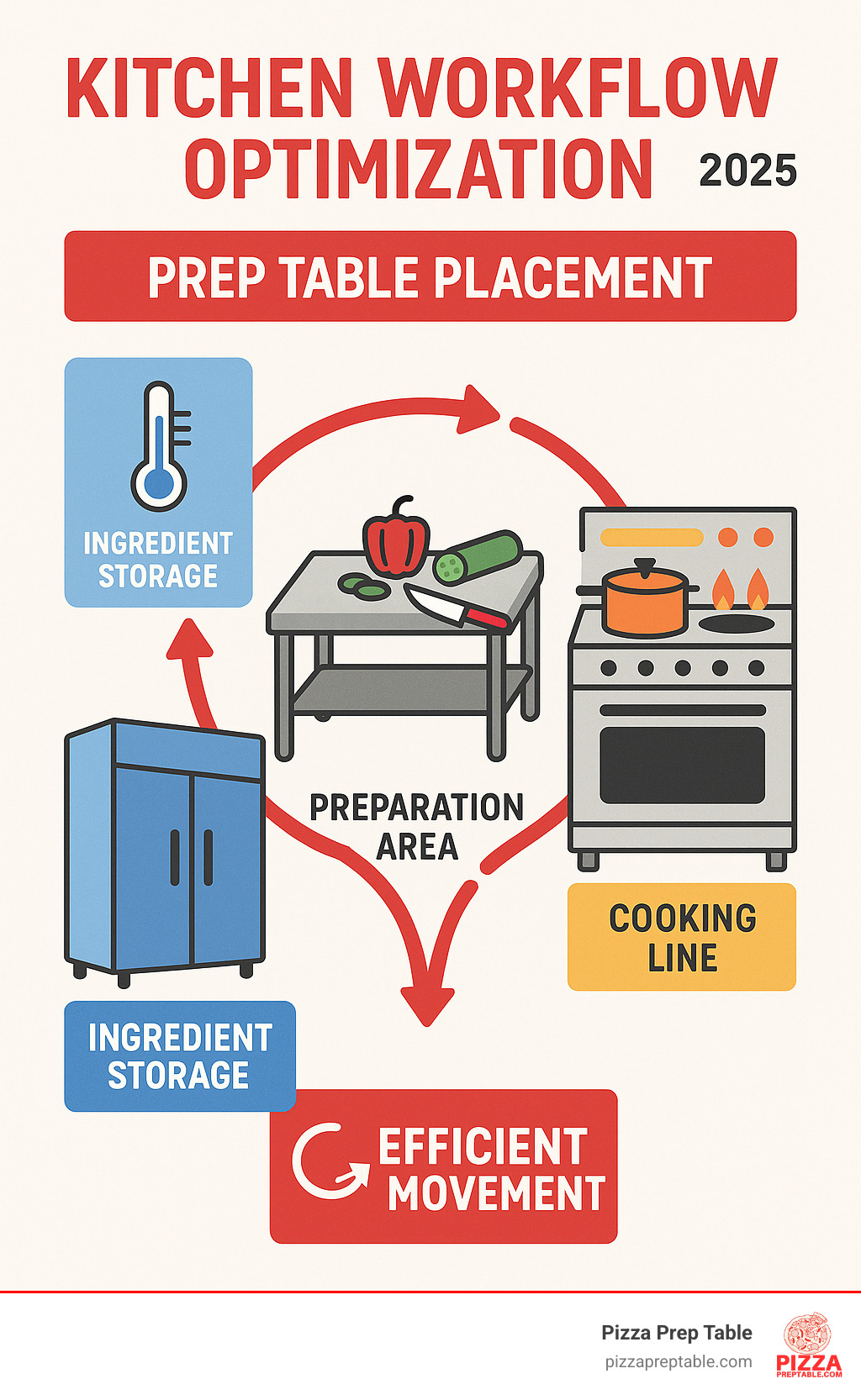

The magic happens through workflow optimization. Instead of your team zigzagging across the kitchen grabbing ingredients, everything they need is right at their fingertips. I've watched pizzerias in busy Vegas casinos cut their assembly time in half just by switching to a proper pizza prep table.

Mise en place - that French term meaning "everything in its place" - becomes reality with the right setup. Your ingredients are pre-portioned in chilled pans, tools hang within arm's reach, and the cutting surface stays clear and ready. It's like having a perfectly organized toolbox, but for food.

The reduced movement alone makes a huge difference. When your staff isn't constantly walking back and forth to the walk-in cooler, they're fresher at the end of their shift and much faster during service. Every saved step adds up to faster ticket times and happier customers.

Good organization isn't just about looking neat - it's about safety and speed. With undershelves for storage and integrated refrigeration keeping ingredients at perfect temperatures, your kitchen runs like a well-oiled machine.

What is the main difference between a pizza prep table and a sandwich prep table?

While both are refrigerated prep tables designed for quick assembly, they're built for completely different jobs.

The most obvious difference is the cutting board depth. Pizza prep tables need serious real estate - usually 19 inches or more - because you're stretching dough and assembling large pies. Sandwich prep tables work fine with 9-10 inches since you're building vertically, not spreading horizontally.

Refrigerated rail design tells the real story though. Pizza tables often feature a raised rail that lifts ingredient pans higher above the work surface. This design accommodates deeper pans and provides better insulation for cheese, pepperoni, and other toppings that need to stay perfectly chilled. Sandwich tables typically have flush or slightly raised rails for easy access to smaller portions.

The pan configuration reflects what you're making. Pizza tables might have fewer, larger pans to hold bulk toppings. Sandwich and salad tables shine with lots of smaller 1/6 or 1/9 size pans - perfect for the variety of ingredients that make a great deli operation. Mega Top models take this even further with double rows of pans.

It all comes down to your intended food product. Pizza tables are engineered for handling dough and quickly topping large, flat surfaces. Sandwich tables excel at rapid assembly of layered items with diverse components.

What does NSF certified mean and why is it important?

NSF certification is like a gold star for commercial kitchen equipment, and I always tell customers to look for it first.

NSF International is an independent organization that puts equipment through rigorous testing to meet strict public health standards. When a prep table earns NSF certification, it means the materials are safe for food contact, the construction is solid enough for commercial use, and the design allows for proper cleaning and sanitization.

Food safety is where this really matters. Health inspectors know what NSF certification means, and they look for it during inspections. It tells them that your equipment won't contaminate food and can be properly cleaned to prevent bacterial growth.

The durability testing aspect often surprises people. NSF certification isn't just about hygiene - it also means the equipment can handle the daily beating of a commercial kitchen. That's important when you're investing thousands of dollars in a prep table.

For commercial use requirement, NSF certification is often mandatory. From San Francisco to Charlotte, health departments typically require NSF-certified equipment in foodservice operations. It keeps you compliant with regulations and gives you peace of mind that you've invested in equipment that meets professional standards.

When you see that NSF mark on a prep table, you know it's built right and will keep your operation running safely for years to come.

Boost Your Kitchen's Performance Today

We've taken quite a journey together exploring prep tables today! From understanding why they're the heart of every successful kitchen to comparing pizza prep stations with sandwich units, we've covered the essential knowledge you need to make a smart choice.

Let me recap what makes a quality prep table such a game-changer for your operation. Efficiency jumps to the top of the list - having everything organized and within arm's reach transforms chaotic dinner rushes into smooth, coordinated service. Safety follows close behind, with proper refrigeration keeping ingredients at safe temperatures while NSF-certified surfaces prevent contamination. And let's not forget organization - there's something beautiful about a well-set prep station where every ingredient has its place and every tool is exactly where it should be.

At PizzaPrepTable.com, we've seen how the right equipment transforms kitchens. Whether you're running a cozy neighborhood pizzeria in Portland or managing a high-volume operation in Miami, we understand the unique challenges you face. That's why we've built our reputation on supplying commercial pizza prep tables, restaurant equipment, and kitchen appliances that actually work for real foodservice businesses.

Here's something I really appreciate about working in this industry - the right equipment isn't just an expense; it's an investment in your business's success. I've watched small independent shops double their output after upgrading to a proper refrigerated prep table. I've seen larger establishments cut their food waste in half simply by having better organization and temperature control.

We even offer financing options because we know that cash flow matters, especially when you're growing your business. Whether you're just starting out or expanding to multiple locations, we want to help you get the equipment that will make a real difference.

The best part? You don't have to take my word for it. The proof is in the pudding (or should I say, the pizza?). Faster service leads to happier customers, which leads to better reviews, repeat business, and ultimately, a more profitable operation.

Ready to transform your kitchen's performance? Explore our full collection of Pizza Prep Tables and let us help you slice, dice, and store your way to culinary excellence! Your future self - and your staff - will thank you for making the investment in quality equipment that truly works.