Top Food Prep Table Guide for Perfect Pizza Stations

Share

Picture your busiest night. Is it a smooth, rhythmic dance of orders flowing out of the kitchen, or a frantic scramble for space and ingredients? The difference often boils down to one critical piece of equipment: the pizza prep table. This isn't just a slab of stainless steel; it's the command center for your entire pizza-making operation.

The Secret to a Faster Pizza Workflow

For any pizzeria owner, efficiency isn't just a buzzword—it's the key to staying profitable. During the dinner rush, every single second counts. A well-chosen food prep table can single-handedly transform kitchen chaos into a streamlined production line, ensuring every pizza is built with speed, consistency, and top-tier food safety.

Think of it as the heart of your kitchen's assembly line. It’s where raw dough becomes a perfectly topped masterpiece, ready for the oven. Without the right station, your team is stuck making extra trips, reaching for distant ingredients, or fighting for a clean spot to stretch dough. All that wasted motion adds up, slowing down ticket times and frustrating hungry customers.

From Chaos to Command Center

An optimized pizza prep station is specifically engineered to eliminate these bottlenecks. It’s a purpose-built workstation that puts everything your pizza maker needs squarely within arm's reach.

- Ergonomic Design: Refrigerated wells hold toppings at the perfect height, which reduces strain on your staff and speeds up the entire assembly process.

- Integrated Workflow: The flow is completely logical—from the refrigerated base holding your dough, to the cutting board for prep, and right up to the ingredient rail for topping.

- Enhanced Food Safety: Keeping all your perishable ingredients properly chilled in integrated, covered pans is absolutely critical for acing health inspections and serving a safe product.

This integrated approach means a single employee can manage the entire prep process from one spot. The result? A more organized kitchen, a less stressed team, and a much faster journey from the order ticket to the oven.

A dedicated pizza prep table is a strategic investment in your operational excellence. It creates a predictable, repeatable process that serves as the foundation for consistent quality and service, especially when you're slammed.

More Than Just a Surface

Sure, a standard table gives you a flat surface. But a specialized pizza prep table provides a complete system. It combines a durable work surface, organized ingredient storage, and essential refrigeration into a single, compact unit. This consolidation frees up precious kitchen real estate and creates a focused zone for your most critical task: making amazing pizza.

This guide will walk you through everything you need to know about choosing the perfect food prep table for your pizzeria. We’ll cover the unique features that set pizza tables apart, how to pick the right size, what features are non-negotiable, and how to maintain your investment for years of peak performance. With these insights, you can truly transform your kitchen's output.

Why a Pizza Prep Table Beats a Standard Station

If you've ever tried making pizzas on a standard sandwich station, you know the struggle. It’s like trying to paint a masterpiece on a Post-it note—you might get the job done, but it’s messy, cramped, and just plain frustrating. For any pizzeria that takes its craft seriously, a dedicated pizza prep table isn't just a nice-to-have; it's the engine of your entire operation.

The difference comes down to purpose-built design. These tables are engineered from the ground up to support the unique, often chaotic, workflow of a busy pizza kitchen. They solve problems a generic prep table doesn't even know exist.

A Deeper Workspace for a Better Pie

The first thing you’ll notice is the cutting board. A real pizza prep table boasts an extra-deep cutting board, often 19 inches or more. This gives your crew plenty of real estate to stretch, flour, and top even the biggest pies without sending ingredients flying.

Trying to manage a large pizza on a narrow, 10-inch sandwich board is a recipe for disaster. Flour gets everywhere, toppings spill over the sides, and the whole process feels clumsy. That extra space isn't a luxury; it's what allows for a clean, fast, and organized workflow, which directly impacts the quality of every single pizza that goes out the door.

A purpose-built pizza prep table is designed to create a seamless, ergonomic workflow. It directly translates into a faster, more organized kitchen, preventing costly mistakes and ensuring every single pizza meets your high standards.

The Raised Rail and Refrigerated Base Advantage

Here’s another game-changer: the raised pan rail. Unlike the flat or recessed pan setup you see on a standard sandwich station, a pizza table’s rail is elevated. This smart, ergonomic design lifts all your topping pans closer, reducing back strain and letting your team top pizzas in record time.

These rails are also built to hold full-size, third-pan containers, which are essential for bulky items like pepperoni, sausage, and mountains of cheese. A sandwich station’s smaller pans just can’t keep up.

Below the workspace, the refrigerated base is specifically designed to hold dough boxes. This means you can store and proof your dough at the perfect temperature right where you need it, eliminating constant trips to a separate cooler. This integrated system—deep surface, easy-access ingredients, and on-demand dough storage—is the secret to a seriously efficient production line.

To get a better sense of how these features come together, take a look at our guide on choosing the right commercial pizza prep table.

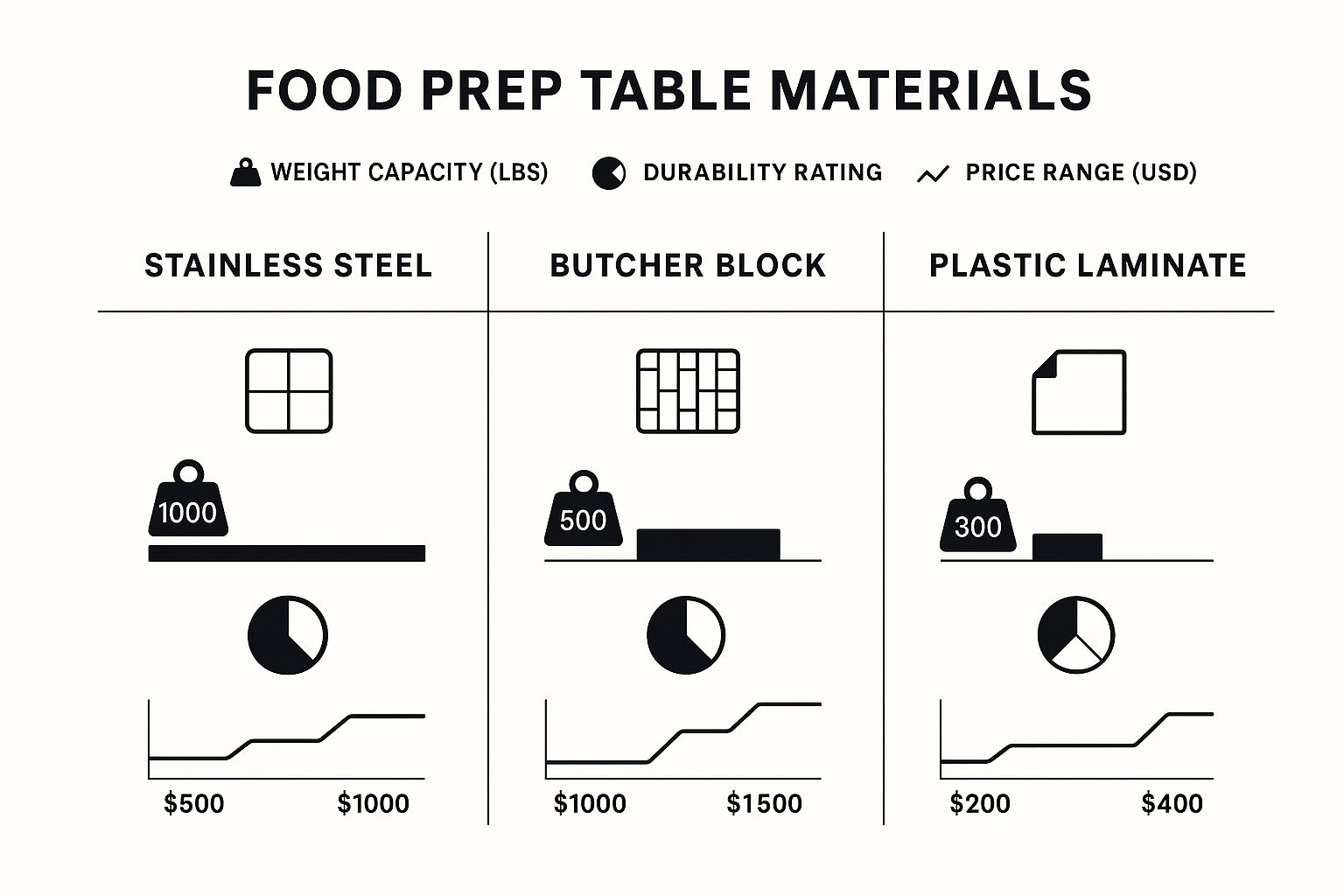

While the design is critical, the materials used are just as important. Here’s a quick look at how different materials stack up.

As you can see, investing in the right materials from the start isn't just about looks; it's a strategic decision that affects durability, capacity, and the long-term success of your kitchen.

This laser focus on specialized equipment is why the global market for food prep tables was recently valued at $1.18 billion and is expected to hit $1.62 billion. That growth is fueled by restaurant owners who understand that efficiency and food safety are everything.

Choosing the Right Size and Layout for Your Kitchen

Picking the right size and layout for your pizza prep table isn't about getting the biggest unit you can find. It’s about finding the smartest fit for your kitchen’s unique dance. Think of it like tailoring a suit; a perfect fit makes you look sharp and move freely, while a bad one is just a constant, restrictive headache. An improperly sized table will create bottlenecks, throw your team's rhythm off, and bring your whole operation to a crawl on a busy Friday night.

First things first: break out the measuring tape. You absolutely need to know the exact footprint you have to work with, but don't just measure the empty floor. You have to account for the real world—the swing of the oven door, the path to the walk-in, and your team's main traffic lanes. A solid rule of thumb is to leave at least 36 inches of clearance around the table. This gives your staff enough room to move safely and efficiently without constantly bumping into each other or hot equipment.

Matching Table Width to Pizza Output

Once you have your measurements, you can start connecting the physical size of the food prep table to your pizzeria's actual production needs. The width of the table is the most direct clue to its output capacity. Each size is engineered for a different level of volume, which helps you scale your investment to match your sales.

Here’s a practical breakdown of how standard table sizes translate to real-world pizza-making:

- Compact (44" - 52"): This is your starter unit. It's perfect for small cafes that have added pizza to the menu, brand-new pizzerias, or food trucks where every inch is prime real estate. These tables can comfortably support making 10-15 pizzas per hour, ideal for lower-volume spots.

- Standard (60" - 72"): The workhorse. This is the sweet spot for most independent pizzerias. A table in this range, like a popular 67-inch model, gives one or two pizza makers enough elbow room and ingredient storage to crank out 20-30+ pizzas per hour.

- High-Volume (87" - 119"): Now we're talking about a full-scale production line. A massive 93-inch or larger table is built for the busiest shops, allowing multiple staff to work side-by-side without getting in each other's way. These beasts can handle 50 or more pizzas per hour, easily meeting the demand of a high-traffic restaurant.

This link between size and output is a huge deal for managing efficiency across the entire foodservice industry. In fact, the humble food prep table is a core part of the global food service market, a sector valued at a staggering $3,486.58 billion that's projected to nearly double. The efficiency of these stations is a major reason restaurants can keep up with that growth. You can explore more data on the enormous foodservice market to see just how big the picture is.

Drawers vs. Doors: What's Right for Your Workflow?

The base of your pizza prep table is some of the most valuable real estate in your kitchen. The choice you make between drawers and cabinet doors will have a massive impact on your team's speed and organization. This isn't just about looks; it's a critical functional decision that has to match how your kitchen actually operates.

Choosing between drawers and doors depends entirely on what you need to store. Drawers excel at organizing portioned items, while doors are necessary for bulky supplies.

Let's break down the primary use for your refrigerated base:

Choose Drawers If: Your main goal is organizing smaller, pre-portioned ingredients. Drawers are absolutely perfect for holding containers of sliced mushrooms, diced onions, or different cheese blends. They keep every single thing neatly separated and ready to grab, which cuts down on search time and keeps the line moving smoothly.

Choose Cabinet Doors If: You need to store bulky items that simply won't fit in a standard drawer. Cabinet-style bases are a must-have for holding large dough proofing boxes, stacks of pizza screens, or big backup containers of high-volume ingredients like sauce and cheese. For oversized supplies, that open, flexible space is unbeatable.

Many pizzerias I've worked with land on a combination unit—one that has both drawers and doors—as the perfect compromise. This setup gives you the best of both worlds. You can stash your bulky dough boxes behind the cabinet door while keeping all your perfectly portioned toppings neatly organized in the drawers, creating a workstation that’s truly optimized for speed and efficiency.

Essential Features That Boost Pizzeria Performance

Once you've nailed down the size and layout, it's time to get into the details that separate a high-performance pizza prep table from a constant headache. Think of these features as the engine under the hood. They dictate your table's power, reliability, and how long it'll last through the nightly dinner rush.

This is your buyer's checklist for quality. We’ll break down the non-negotiables that turn your investment into a true kitchen workhorse, starting with the certifications that guarantee you’re running a safe and compliant operation.

Decoding NSF Certification for Pizzerias

When you spot that NSF (National Sanitation Foundation) logo on a prep table, it's more than just a sticker. It’s your rock-solid guarantee that the equipment meets strict public health and safety standards. An NSF-certified table has been put through the wringer, tested to ensure it's easy to clean, sanitize, and built with food-safe, non-porous materials that won't harbor bacteria.

For any pizzeria, this is non-negotiable. Health inspectors look for this certification, and having it can be the difference between a passing grade and a costly shutdown. It’s a clear signal that your equipment is designed to prevent foodborne illness and uphold the highest hygiene standards, protecting both your customers and your reputation.

The Heart of the Machine: Refrigeration Systems

The refrigeration system is, without a doubt, the most critical part of your pizza prep table. It's what keeps your cheese, meats, and veggies fresh and safe, directly impacting your food costs and the quality of every pizza that goes out the door. Not all systems are created equal, and the difference can be dramatic.

- Forced-Air Refrigeration: This is the technology you want for a pizza station. A fan actively circulates cold air throughout the cabinet and across the topping rail, hitting every single ingredient pan with consistent, even cooling. This prevents dangerous "hot spots" and keeps every topping in the safe zone, even when the lids are open during a rush.

- Cold-Wall (or Static) Refrigeration: This system uses cooling lines embedded in the unit's walls. While it's often quieter and more energy-efficient, it can lead to uneven temperatures—items near the walls get colder than those in the middle. For a busy pizzeria where food safety is everything, forced-air is the more reliable choice.

Built to Last: The Importance of Stainless Steel

A pizzeria is one of the toughest environments for kitchen equipment. The constant exposure to acidic tomato sauce, salty olives, and harsh cleaning chemicals will test any material. This is where your table’s construction becomes incredibly important.

The grade of stainless steel used in your food prep table is a direct indicator of its ability to resist corrosion and maintain its structural integrity over years of heavy use.

You’ll generally run into two main grades of stainless steel:

- Type 304 Stainless Steel: This is the premium choice for any pizza prep table. It has a higher nickel content, giving it superior resistance to rust and corrosion, especially from the salts and acids found in pizza toppings. For any surface that touches food, 304-grade steel is the industry gold standard.

- Type 430 Stainless Steel: This is a more budget-friendly option you'll often see on the sides, back, and legs of a unit. While it's still durable, it's more susceptible to rust over time, especially in a high-moisture kitchen. A quality table will often use 304 for the top and interior and 430 for less critical exterior panels.

This focus on durable, specialized equipment is a key driver in the foodservice industry. In the U.S. alone, the market was valued at $1,515.5 billion and is projected to grow significantly as more kitchens adopt innovative equipment to boost efficiency.

Ergonomic and Energy-Saving Details

Finally, a few smaller features add up to make a huge difference in a table's daily performance and long-term value. A thick, durable polyethylene cutting board is a must-have. It provides a forgiving surface that won't dull your pizza cutters and is easy to remove for deep cleaning and sanitizing. For even more ways to organize your workspace, you can prep like a pizza pro with these topping stations.

Also, keep an eye out for an ENERGY STAR rating. These certified units use advanced compressors, better insulation, and more effective gaskets to be more energy-efficient. They might cost a little more upfront, but they can save you hundreds of dollars a year in electricity bills, making them a much smarter investment in the long run.

Proper Care to Maximize Your Table's Lifespan

Think of your pizza prep table less like an appliance and more like a high-performance vehicle; it needs routine care and the right handling to perform at its peak. You wouldn't skip an oil change on a prized car, and neglecting your table is just asking for poor performance and eventual breakdowns. A little proactive attention to installation and maintenance is the secret to protecting this critical investment.

Right from the moment it arrives, proper setup is everything. Your first move should be ensuring the unit has enough room to breathe. The refrigeration compressor is the heart of your food prep table, and it needs proper ventilation. Shoving it too close to a wall or right next to a hot oven will cause it to overheat, work way harder than necessary, and burn out long before its time.

Once it's in position, leveling the unit is a small step that makes a huge difference. An unbalanced table can prevent the doors and drawers from sealing correctly. Even a tiny gap lets cold air escape and warm air creep in, forcing the compressor to run nonstop and creating a potential hotspot for food safety issues.

The Foundation of Performance: Installation

Getting the installation right isn't just about plugging it in—it's about setting your table up for a long, efficient life. A few initial checks will save you from major headaches down the road.

Before you even think about loading it up with valuable ingredients, take a moment to calibrate the thermostat. Grab an external thermometer and verify that the internal temperature actually matches what the display says. This simple check ensures your ingredients are held at a safe, consistent temperature from day one, protecting both your customers and your bottom line.

Your Practical Maintenance Schedule

Consistent maintenance is what separates a table that lasts for years from one that dies a sudden, dramatic death during a Friday night rush. By breaking down tasks into a simple schedule, you can keep your unit in peak condition without overwhelming your staff.

Daily Tasks (5-10 Minutes):

- Wipe Down All Surfaces: At the end of every single shift, use a food-safe cleaner to wipe down the stainless steel exterior, interior, and cutting board. No exceptions.

- Clean Door Gaskets: Crumbs and grease love to build up on gaskets, preventing a tight seal. A quick wipe-down with a damp cloth keeps them effective and helps them last longer.

Weekly Tasks (15-20 Minutes):

- Clear the Condenser Coils: Dust and grease are the mortal enemies of refrigeration efficiency. Gently brush or vacuum the condenser coils to get rid of any buildup. This one task allows the unit to cool more effectively and noticeably lowers your energy bill.

- Deep Clean Ingredient Pans: Pull out and thoroughly wash all your topping pans and the entire pan rail area. This prevents cross-contamination and keeps nasty bacteria from getting a foothold.

A disciplined maintenance routine does more than just keep your food prep table clean. It's a proactive strategy that prevents the vast majority of costly emergency repairs and ensures your station remains a reliable pillar of your pizzeria's operation.

Monthly Checks (20-30 Minutes):

- Inspect Seals and Gaskets: Go beyond just wiping them down. Carefully check all door and drawer gaskets for any signs of cracking, tearing, or brittleness. A damaged gasket is a huge energy waster and should be replaced immediately.

- Verify Temperature Accuracy: Time to re-calibrate. Use that independent thermometer again to make sure it’s still holding the correct temperature. This is how you catch cooling problems before you end up with spoiled food.

- Check and Tighten Hardware: Casters, legs, and door hinges take a beating and can loosen over time. A quick inspection and a few turns of a wrench will keep the unit stable and secure.

For further insights into the benefits of durable materials in commercial settings, considering their impact on equipment lifespan is crucial. You can find helpful insights on durable materials that highlight why quality construction matters for long-term performance. This commitment to both initial quality and ongoing care will ensure your food prep table serves your pizzeria faithfully for years to come.

Building a Better Pizzeria One Pizza at a Time

If there's one thing to take away from this guide, it's this: the right pizza prep table isn't just another expense. It's a foundational investment in your pizzeria's success. Think of it as the undisputed heart of your kitchen—the command center where speed, quality, and safety all come together.

We've walked through exactly why a purpose-built food prep table is a must-have for any serious pizzeria, leaving standard sandwich stations in the dust. A specialized pizza table is simply built differently, engineered from the ground up for the unique rhythm of making pies, from its deep cutting board to its ergonomic topping rail.

Your Blueprint for Success

Choosing the right table is all about matching its size and layout to your kitchen's real-world flow. Whether you need a nimble 48-inch unit for a cozy cafe or a massive 93-inch workstation for a high-volume powerhouse, the goal is always the same: create a seamless workflow that crushes bottlenecks and lets your team fly.

The critical features we've covered—like NSF certification for hygiene, forced-air refrigeration for bone-chilling consistency, and durable 304-grade stainless steel—are your guarantee of quality. They ensure your station can take a beating in a busy kitchen and keep on performing.

Armed with this knowledge, you're ready to confidently size up your current setup or invest in a new table that will pay for itself. The returns show up in a smoother workflow, rock-solid product quality, and unwavering food safety.

And it doesn't stop there. A real commitment to proper installation and routine maintenance ensures that your investment remains a reliable workhorse for years. For those looking to go even deeper, our guide to prep tables that work as hard as you do covers more advanced strategies.

By optimizing the heart of your kitchen, you’re setting the stage for greater efficiency, happier customers, and a healthier bottom line. You're not just buying a piece of steel; you're building a better pizzeria, one perfect pizza at a time.

Frequently Asked Questions About Pizza Prep Tables

When you’re looking at a new pizza prep table, a lot of questions can pop up. It’s a big investment, and you want to get it right. Here are some straightforward answers to the most common things pizzeria owners ask, so you can feel good about your choice and get the most out of your new workhorse.

Can I Use a Pizza Prep Table for Other Foods?

You absolutely can. While these tables are built with pizza in mind, their heavy-duty design makes them a powerhouse for all sorts of prep work in a busy kitchen. The deep cutting board and serious refrigerated storage are perfect for assembling massive deli sandwiches, complex salads, or even appetizer platters.

Think of it as the ultimate prep station that just happens to be a pizza-making expert. Its real strength is handling high-volume ingredients and large items, which makes it a versatile, multi-purpose tool that can adapt to whatever your menu throws at it.

How Often Should I Clean the Condenser Coils?

For a busy pizzeria, you should be cleaning the condenser coils on your refrigerated prep table at least once a month. If your kitchen is a hot zone for grease and flour dust—and let's be honest, most are—bumping that up to a bi-weekly cleaning is a much smarter move.

Ignoring this simple task is one of the fastest ways to kill your equipment. When coils get clogged, the compressor has to work overtime, jacking up your energy bills and heading straight for burnout. A quick once-over with a vacuum or brush takes just a few minutes and is easily the best preventive maintenance you can do.

The temperature setting on your pizza prep table isn't just about food quality; it's a critical control point for food safety. Maintaining the right temperature prevents bacterial growth and ensures you are always serving a safe product to your customers.

What Is the Ideal Temperature for a Pizza Prep Table?

For rock-solid food safety, you need to keep the refrigerated base and the topping rail of your pizza prep table between 33°F and 40°F (0.5°C to 4.4°C). This is the sweet spot that keeps perishable ingredients like cheese, meats, and veggies safely out of the temperature "danger zone" where bacteria love to multiply.

Most modern units come with a digital thermostat, which makes setting and monitoring the temperature a breeze. It’s still a great habit to double-check it with an external thermometer every now and then, just to make sure the display is telling you the truth.

Are Drawers or Doors Better for a Pizza Station?

The classic "drawers vs. doors" debate really comes down to your kitchen's workflow and what you’re storing. Neither one is better than the other, but one will definitely be a better fit for your specific operation.

- Doors are essential for: Storing bulky, awkward items. Think large dough-proofing boxes, stacks of pizza screens, or those big backup tubs of sauce and cheese. The open cabinet gives you maximum flexibility for anything oversized.

- Drawers are perfect for: Organizing smaller, pre-portioned ingredients. They’re fantastic for keeping sliced veggies, different meats, and various cheese blends neatly separated and easy to grab, which can seriously speed up your topping process.

In my experience, a lot of operators find that a combination unit—one with both doors and drawers—gives them the best of both worlds and the most efficient setup.

Ready to build a more efficient and productive pizzeria? At Pizza Prep Table, we provide the high-quality, NSF-compliant equipment you need to streamline your workflow and master the perfect pie. Explore our selection of top-rated pizza prep tables today. Find your perfect fit at https://pizzapreptable.com.