The Ultimate Pizzeria Stainless Steel Kitchen Work Table Guide

Share

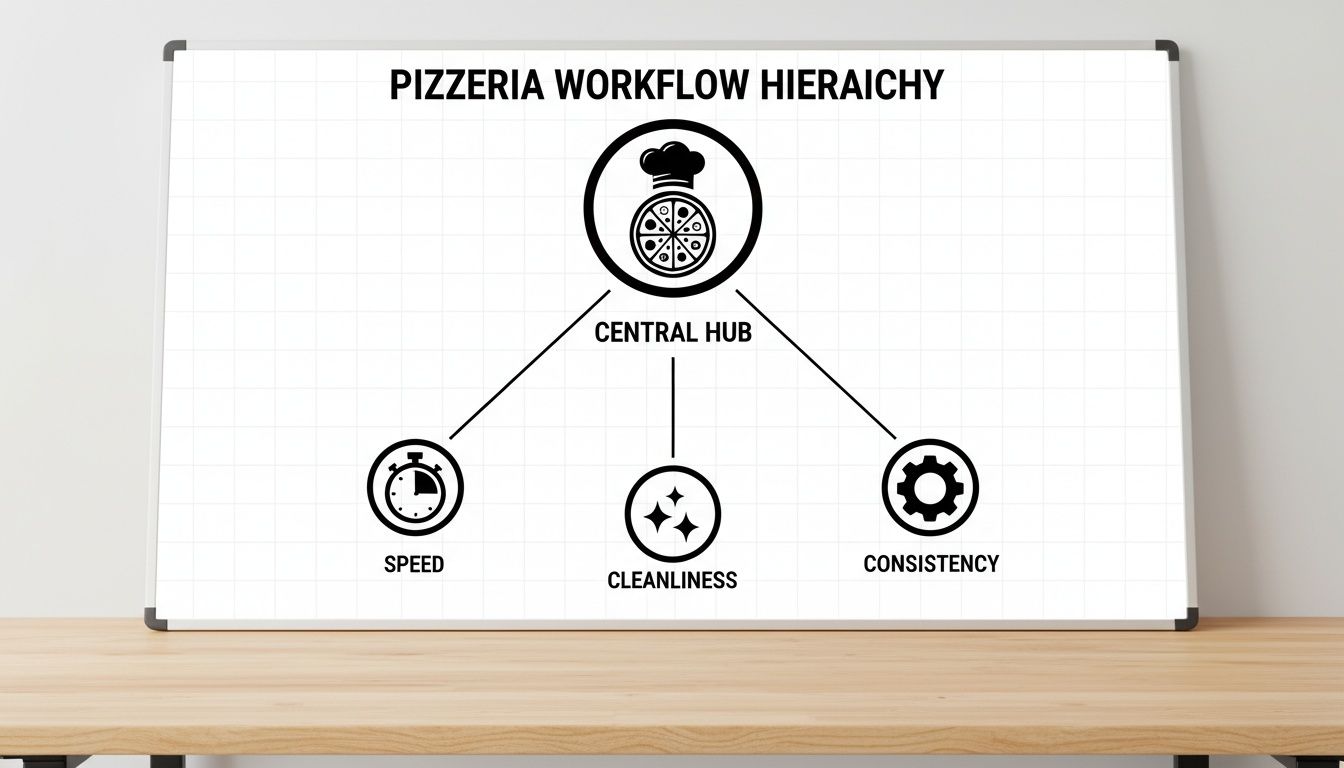

A top-notch stainless steel kitchen work table isn't just a piece of furniture—it's the operational heart of any successful pizzeria. This is where the magic happens, from dough prep and topping assembly to final plating. The right pizza prep table directly impacts your kitchen's speed, cleanliness, and consistency—the three pillars of a profitable pizza business.

Choosing the right one isn't just about buying a surface; it's an investment in your entire pizza-making workflow.

The Foundation of Every Great Pizza

In the fast-paced world of a pizzeria, every single second counts. The right work table is more than just a place to put ingredients; it's a strategic tool that defines your production line. Think of it as the stage where your culinary performance unfolds. A poorly chosen table creates bottlenecks, slows down your pizzaiolos, and compromises food safety, which hits your final product and your reputation right where it hurts.

A dedicated pizza prep table is built to handle the unique abuse of a pizzeria. From the constant dusting of flour to acidic tomato sauce and the relentless chopping and scraping, the surface has to be durable, non-porous, and incredibly easy to clean. This is where stainless steel really proves its worth.

More Than Just a Countertop

An optimized work surface contributes directly to your bottom line by making your team more efficient. When your crew has an organized, dedicated space for pizza prep, the entire process just flows better.

- Speed and Efficiency: A well-placed table creates a logical path from dough stretching to topping to the oven. It cuts out unnecessary steps and dramatically speeds up order times during that chaotic dinner rush.

- Hygiene and Safety: There's a reason stainless steel is the industry standard for food safety. Its non-porous surface fights off bacteria, odors, and stains from troublemakers like tomato sauce and oils, making it a breeze to sanitize and keep the health inspector happy.

- Consistency is Key: A stable, spacious work area is your secret weapon for consistency. It gives your team the room they need to stretch dough to the perfect size and apply toppings evenly, ensuring every customer gets that same high-quality pizza, every single time.

The right stainless steel kitchen work table acts as the command center for your entire pizza operation. It's not an expense—it's a critical investment in your pizzeria's ability to produce quality food quickly and safely. That’s the real recipe for long-term success.

Decoding Steel Gauges and Grades for Pizzerias

When you're shopping for a stainless steel kitchen work table, it's easy to think all steel is the same. But that’s a rookie mistake. The specs on that steel will make or break how well your table holds up in the chaos of a real pizzeria. Two numbers matter more than anything else: the gauge and the grade.

Think of steel gauge like you think about your pizza dough—the lower the number, the thicker and tougher the steel. A thicker table is your first line of defense against dents, warping, and the day-in, day-out abuse of a busy pizzeria.

What Is Stainless Steel Gauge?

The gauge tells you exactly how thick the sheet of stainless steel is. In a commercial kitchen, especially for a pizza prep line where all the action happens, a lower gauge means you're getting a more durable, long-lasting surface.

- 14-Gauge: This is the heavyweight champion. It’s incredibly thick and built like a tank, making it the perfect choice for heavy-duty work like pounding out large batches of dough or holding up a heavy mixer. It’s a true long-term investment.

- 16-Gauge: This is the sweet spot for most pizzerias. 16-gauge steel strikes a fantastic balance between serious durability and cost. It's tough enough for just about any pizza prep task, from stretching dough to chopping toppings, making it a reliable workhorse.

- 18-Gauge: This is your lighter-duty option. While it's still good commercial-grade steel, it's better suited for less intense jobs, like holding lightweight appliances or as a simple storage surface, not your main pizza prep area.

For your primary pizza prep line, dropping the extra cash on a 14 or 16-gauge table is a no-brainer. It will pay for itself over and over again in sheer longevity.

A lower gauge number means a thicker, more resilient work surface. For the constant pounding, chopping, and leaning that happens in a pizzeria, a thicker gauge is your best defense against dents and damage.

The Critical Difference Between 304 and 430 Grade Steel

Beyond thickness, the grade of the steel is what really separates the good from the great. This number tells you about the steel's chemical makeup and, most importantly, how well it fights off rust and corrosion. A lot of pizzeria owners get this wrong, and it costs them. The two grades you'll see most often are 304 and 430.

The key difference is nickel. 304 grade, often called "18/8" steel, has both chromium and nickel in the mix. That little bit of nickel is what gives it superior protection against rust, which is absolutely essential in a pizzeria environment.

This diagram shows how the right table becomes the central hub for your entire workflow, directly impacting your speed, cleanliness, and consistency.

As you can see, a quality work table isn't just a piece of furniture—it supports the three pillars of a successful pizza operation.

For your main pizza prep table, 304 grade is the undisputed champion. Why? It stands up to the constant attack from acidic ingredients like tomato sauce, salty olives, and harsh cleaning chemicals without pitting or rusting. The market knows this, too; the stainless steel tables market is projected to hit USD 2.3 billion by 2032, and the 304-grade segment is the dominant force because of its proven toughness.

On the other hand, 430 grade is the more budget-friendly choice because it doesn't have nickel. While it's still food-safe and perfectly fine for certain jobs, its lower corrosion resistance makes it a risky choice for wet or acidic prep areas. Over time, it will start to show wear. A 430-grade table is much better suited for dry storage, holding equipment, or prep tasks that don't involve corrosive pizza toppings.

To make this crystal clear, here’s a quick cheat sheet to help you decide.

Stainless Steel Gauge and Grade Quick Reference

| Specification | What It Means | Best Use in a Pizzeria |

|---|---|---|

| 14-Gauge | The thickest, most durable option available. Built for extreme abuse. | Main dough prep area, supporting heavy mixers or ovens. |

| 16-Gauge | The industry standard workhorse. Great balance of strength and cost. | Primary pizza prep and topping station, general-purpose work surfaces. |

| 18-Gauge | Lighter-duty steel. Good for less demanding applications. | Dry storage shelves, holding light appliances, dish-drying area. |

| 304 Grade | Contains nickel, offering superior rust and corrosion resistance. | Any surface that touches acidic foods (tomato sauce, citrus) or harsh cleaners. |

| 430 Grade | No nickel, making it more affordable but less corrosion-resistant. | Equipment stands, dry goods storage, work areas with minimal moisture. |

Getting the right combination of gauge and grade is the secret to buying a pizza prep table that lasts.

To really get into the weeds of steel composition, A Cook's Guide to Stainless Steel for Cookware is a fantastic resource. Our own guide also digs deeper into choosing the right https://pizzapreptable.com/blogs/pizza/commercial-stainless-steel-tables for your pizzeria's specific needs.

Essential Features of a High-Performance Pizza Prep Table

Getting the right gauge and grade of steel is the foundation, but the specific features are what really turn a basic stainless steel kitchen work table into a pizzeria powerhouse. These aren't just bells and whistles; they're strategic upgrades designed to solve the real-world problems of pizza making, from containing flying flour to keeping dough boxes within arm's reach.

Picking the right features has a direct impact on your kitchen's workflow, organization, and how you handle the dinner rush. Each one plays a part in creating a prep station where your team can build perfect pizzas faster and more consistently.

The Backsplash: Your First Line of Defense

A backsplash is a simple raised edge along the back of the work table, but don't underestimate its importance in a pizzeria. Think of it as a defensive wall for your kitchen. When your pizzaiolos are in the zone, stretching dough and topping pies, flour, cornmeal, and sauce inevitably go flying.

Without a backsplash, that mess ends up all over your walls, creating a constant cleaning headache and a potential sanitation nightmare. A standard 4 to 6-inch backsplash contains all that chaos, keeping your prep area tidy and your walls clean. This small feature saves countless hours of cleanup and helps you maintain a more professional, hygienic kitchen.

A stainless steel table with an integrated backsplash is one of the smartest investments a pizzeria can make. It contains the chaos of pizza prep, protecting your walls from grease, sauce, and flour, which simplifies daily cleaning routines and helps you maintain a sanitary workspace.

Mobility vs. Stability: Legs and Casters

The foundation of your pizza prep table dictates how it lives in your kitchen. You really have two choices: stationary legs for a permanent, rock-solid setup or casters (wheels) for mobility. The right decision comes down to how your pizzeria actually operates day-to-day.

- Stationary Legs: These give you maximum stability, which is non-negotiable for heavy-duty work like kneading huge batches of dough or running a heavy countertop mixer. If you have a dedicated pizza prep zone that isn't going to move, legs with adjustable bullet feet are perfect for leveling the table on uneven floors.

- Casters (Wheels): These offer incredible flexibility. Tables on wheels can be easily moved for deep cleaning underneath or to reconfigure your kitchen for a special event. For pizzerias with tight spaces, a mobile stainless steel kitchen work table can be a total game-changer. Just make sure at least two of the casters are lockable to keep the table securely in place during prep.

This choice is a strategic one. A stationary table provides a rock-solid foundation for your main pizza prep line, while a smaller table on casters can serve as a versatile utility player, rolling wherever it's needed most.

Maximizing Space with an Undershelf

In any commercial kitchen, storage space is prime real estate. An undershelf isn't just a nice-to-have; it's a non-negotiable feature for a pizza prep table. It effectively doubles your storage capacity without taking up a single extra inch of floor space, and it's the perfect spot to keep bulky but essential items organized and easy to grab.

An undershelf turns that empty void beneath your work surface into a highly functional storage zone. This is where you can neatly stack your dough boxes, store extra pizza screens, or keep containers of prepped toppings ready to go. By keeping these items off the main work surface and, more importantly, off the floor, you create a safer, more organized, and far more efficient prep station.

The result is a streamlined workflow where everything your pizza makers need is just a quick reach away. That means fewer unnecessary steps and precious time saved on every single order.

Choosing the Right Size and Layout for Your Pizzeria

The most bulletproof stainless steel kitchen work table on the market is totally useless if it doesn't actually fit your kitchen. A table that’s even a few inches too big can create a disastrous bottleneck during a dinner rush, while one that’s too small will absolutely cripple your team's efficiency.

Finding that sweet spot isn't just about measuring an empty patch of floor; it’s about mapping the table’s dimensions to your pizzeria’s unique workflow.

Think of your kitchen layout like a strategic roadmap. Every piece of equipment, from the oven to the walk-in, is a key destination. Your new pizza prep table has to slot into this map without creating frustrating traffic jams. Before you even start browsing, grab a tape measure and get precise measurements of your space, paying close attention to door swings, appliance clearances, and the main walking paths your crew uses a hundred times a shift.

Matching Table Size to Pizzeria Output

The right table size is directly tied to how many pies you're slinging. A small slice shop has vastly different needs than a high-volume restaurant pumping out hundreds of pizzas a night. The most common table lengths—48, 60, and 72 inches—each play a specific role in a pizzeria.

- 48-Inch Tables: These are the compact workhorses. They're perfect for smaller pizzerias or for dedicated tasks, like a final plating station or an auxiliary surface for chopping veggies.

- 60-Inch Tables: This is the go-to, versatile size that works beautifully as a primary pizza prep station in a small or medium-sized pizzeria. It gives one person plenty of room to stretch dough and build a pizza without feeling cramped.

- 72-Inch (and Larger) Tables: For high-volume operations, a 72-inch or even a 93-inch table is non-negotiable. This much real estate allows multiple pizzaiolos to work side-by-side, creating an efficient assembly line from dough to toppings.

The growing demand for durable equipment isn't just a feeling; it's a major driver of the stainless steel market. In fact, the commercial stainless steel cookware market is projected to hit USD 12.46 billion by 2030. You can get more insights on this trend by exploring the full market research on Grand View Research.

A Pro Tip for Visualizing Your Space

Numbers on a tape measure can be deceiving. To really get a feel for how a new pizza prep table will impact your kitchen's flow, try this simple but incredibly effective trick.

Grab some cardboard and painter's tape to create a life-sized cutout of the table's footprint right on your floor. Leave it there for a full shift and have your team walk and work around it. This test run will instantly reveal any potential bottlenecks or awkward movements before you spend a single dime.

This practical step helps you see how the new piece will integrate into your existing setup. A well-planned kitchen is the foundation of a successful pizzeria, and you can learn more by checking out our guide on commercial kitchen layout and design. The goal isn't just to choose a table that fits the space, but one that actively helps your team make amazing pizza, faster.

Why NSF Certification and Food Safety Matter

In a bustling pizzeria, cleanliness isn’t just about looking good for the health inspector—it’s the bedrock of your business. This is where the NSF (National Sanitation Foundation) certification for your stainless steel kitchen work table becomes absolutely non-negotiable.

Think of that little NSF seal as more than just a sticker. It's a guarantee. It tells you, your staff, and your customers that the table was built from the ground up to fight foodborne illness.

This certification means the table has been put through the wringer, tested to meet strict public health standards. It’s a critical investment in your restaurant's reputation and a frontline defense in keeping your food safe.

What That NSF Seal Really Guarantees

An NSF-certified table is engineered specifically for food safety, designed to eliminate the nooks and crannies where bacteria love to hide. This makes sanitation simpler and way more effective for your team.

It’s this focus on hygiene and durability that’s fueling a huge demand for quality kitchen gear. The global stainless steel tableware and kitchenware market was valued at around USD 23.5 billion and is expected to hit USD 35.7 billion by 2032. Pizzeria owners are tired of equipment that can't handle the daily grind.

So, what are you actually getting with that seal?

- Non-Porous Surfaces: The steel is perfectly smooth. There are no microscopic cracks or pits for food particles, moisture, or germs to get trapped in.

- Coved Corners: All the joints and corners are rounded and sealed. This gets rid of those sharp 90-degree angles that are a nightmare to clean, preventing grime from building up.

- Corrosion Resistance: The table is proven to stand up to constant contact with acidic foods (hello, tomato sauce!) and harsh cleaning chemicals without breaking down.

Basically, the NSF seal lets you breathe easier, knowing your main pizza prep surface is actively helping you run a clean kitchen and will make passing health inspections a whole lot less stressful.

Keeping Your Surface Compliant and Sanitary

Getting an NSF-certified table is step one. Keeping it that way is a daily commitment. A solid cleaning routine is what preserves the steel’s protective qualities and keeps you in compliance.

A consistent cleaning schedule stops food residue and grease from building up, which can weaken the passive chromium layer that fights off rust and corrosion. For a deeper dive into what this means for your daily operations, check out our guide on essential food safety guidelines for restaurants.

An NSF-certified work table is your silent partner in food safety. Its design makes cleaning easier and more effective, directly translating to a safer kitchen, happier customers, and a stronger business reputation. It's a fundamental requirement for any serious pizzeria.

To keep your tables in top shape, you need the right tools for the job. This guide to professional cleaning chemicals is a great resource.

A simple daily cleaning protocol can make all the difference:

- Clear the Surface: Get everything off the table—tools, containers, and food scraps.

- Wash It Down: Use a soft cloth or sponge with warm water and a mild detergent. Always wipe with the grain of the steel to avoid tiny scratches.

- Rinse Thoroughly: Use clean, warm water to get all the soap residue off. If left to dry, soap can tarnish the steel.

- Sanitize: Apply a food-safe sanitizer, following the manufacturer’s instructions to the letter.

- Air Dry or Towel Dry: Let the surface air dry, or use a clean, soft towel to wipe it down. This prevents those annoying water spots and streaks.

Following these simple steps ensures your stainless steel kitchen work table remains a safe, compliant, and reliable asset in your pizzeria for years to come.

Making a Smart Purchase for Your Pizzeria

Outfitting your pizzeria with a quality stainless steel kitchen work table is a serious investment, but it doesn’t have to drain your bank account. Making smart moves here can free up cash for other things that keep the lights on, like top-notch ingredients or a killer marketing campaign. By looking at new vs. used and getting creative with financing, you can land the perfect pizza prep station without overspending.

This is especially true when you're just starting out and every dollar counts. The name of the game is getting durable, reliable gear that’ll pull its weight from day one.

New vs. Used: Which Is Right for You?

It’s the classic kitchen dilemma: spring for a brand-new table or hunt down a pre-owned bargain? A new table is flawless—it comes with a full warranty, a pristine surface, and that peace of mind knowing you're the first owner. On the flip side, a used table can be an absolute steal, often costing 50-70% less than a new one. For a startup pizzeria, those savings are huge.

But buying used means you have to do your homework. You're swapping that warranty for a lower price, so a thorough inspection is non-negotiable. You don't want to inherit someone else's headache.

Your Used Table Inspection Checklist

Before you hand over cash for a used pizza prep table, you need to put on your detective hat. A few minutes of hands-on inspection can save you from a world of regret.

- Check for Stability: Get a good grip on the table and give it a hard shake. Does it wobble or feel like it’s about to collapse? Unsteady legs are a major safety hazard in the middle of a busy dinner rush.

- Inspect the Surface: Scan for deep scratches, major dents, or any hints of rust or pitting. A few minor scuffs are normal, but deep gouges are a nightmare to clean and can become breeding grounds for bacteria.

- Examine Welds and Joints: Look closely at the corners and where the legs meet the tabletop. If you see weak or cracked welds, walk away. That's a huge red flag for a poorly made or seriously abused table.

- Test Adjustable Parts: If the table has an adjustable undershelf or bullet feet, make sure they still move smoothly and can be locked down tight.

A great deal on a used stainless steel table is only a great deal if it's structurally sound and safe for food prep. Never skip the hands-on inspection; what you save upfront could be lost to future repairs or replacement costs.

Smart Financing and Shipping Strategies

For most pizzerias, dropping thousands of dollars on new equipment all at once just isn't realistic. This is where lease-to-own programs can be a lifesaver. These plans let you get the pizza prep table you need now with monthly payments that won’t cripple your cash flow. And at the end of the term, you own it.

Finally, don't get tripped up by logistics. Shipping a heavy stainless steel kitchen work table can easily add a few hundred bucks to your final bill. Always hunt for suppliers that offer free freight shipping. It's a simple move that cuts down your total cost and makes your budget stretch that much further.

Got Questions About Pizza Prep Tables? We've Got Answers.

Choosing the right stainless steel table involves a lot of little details. To cut through the noise, we've put together some straight answers to the questions we hear most from pizzeria owners. Think of this as your cheat sheet for making a smart, confident decision.

We're covering everything from the nitty-gritty of steel types to the practical realities of a fast-paced pizza kitchen. Getting these details right from the start means you end up with a table that works just as hard as you do.

What's the Best Stainless Steel for a Pizza Prep Table?

Hands down, you want 304 grade stainless steel for any surface that will see action with tomato sauce, olives, or cleaning chemicals. The nickel in 304 grade gives it superior armor against the rust and corrosion that acidic ingredients love to cause.

Sure, 430 grade is easier on the wallet, but it's best left for dry storage or equipment stands—not the front lines where your pizzas are made.

How Much Weight Can These Tables Actually Hold?

It really depends on the table's build quality and steel gauge. A standard heavy-duty table can typically handle between 500 and 700 pounds of evenly distributed weight. As a rule of thumb, a thicker 14-gauge table will support more than an 18-gauge one.

Always double-check the manufacturer's specs, especially if you plan on parking a heavy countertop mixer on it.

A table's stability is just as critical as its raw strength. Make sure the legs are locked in tight and perfectly level, particularly if you're putting vibrating equipment like a dough mixer on top. An unsteady table is a major safety hazard when your kitchen is in full swing.

Should I Go with Wheels or Stationary Legs?

This one comes down to your kitchen's flow and how you use the space.

- Stationary Legs: Pick these for your main prep station, no question. They provide rock-solid stability, which is a must for heavy work like kneading dough or serious chopping. They're the permanent foundation of your pizza production line.

- Casters (Wheels): Wheels are fantastic for smaller, secondary tables. They give you the flexibility to move things around for deep cleaning or to reconfigure your layout for a special event. Just make sure at least two of the casters lock firmly to keep the table from rolling away during use.

Can I Throw a Hot Pan Directly on My Stainless Steel Table?

You can, but you really shouldn't. While stainless steel handles heat well, slamming a scorching hot pizza pan directly onto the surface can cause it to warp over time—a nasty surprise called thermal shock. Do your investment a favor and use trivets or even a spare cutting board as a buffer. It'll keep your work surface perfectly flat for years to come.

How Do I Keep My Pizza Prep Table Looking Brand New?

The secret is regular, simple cleaning. This keeps the protective chromium layer on the steel intact and happy. For daily grime, a soft cloth with a little mild soap and warm water is all you need—just be sure to wipe in the direction of the steel's grain.

For stubborn, baked-on grease, a simple paste of baking soda and water works wonders. Whatever you do, stay away from abrasive stuff like steel wool or harsh cleaners with chlorine. They'll scratch the surface and open the door for rust to move in.

Ready to build the perfect foundation for your pizzeria? Pizza Prep Table has a huge selection of NSF-certified stainless steel work tables built for the grind of a commercial kitchen. Check out our collection to find the exact size and setup to make your workflow sing. Head over to https://pizzapreptable.com to get started.