Undercounter Refrigerator Dimensions Guide for Pizza Shops

Share

When you're outfitting a commercial kitchen, especially a pizzeria, you quickly learn that every single inch counts. Getting the dimensions right on your undercounter refrigerators isn't just about making sure they slide into place—it's about creating a seamless, efficient workflow that keeps your pizza line moving during the dinner rush.

Standard undercounter units are designed to tuck neatly under a 36-inch countertop, which is the industry standard for pizza prep tables. This means their height usually falls between 32 to 34.5 inches. For width, you’ll commonly find models at 24, 48, and 60 inches, while depths hover around 24 inches to sit flush with your pizza prep tables and surrounding cabinets.

Why Refrigerator Dimensions Matter for Pizza Restaurants

In the tight quarters of a busy pizza kitchen, space is everything. Choosing the right undercounter refrigerator dimensions is about more than just filling a gap; it's a strategic decision that directly impacts your prep line's speed and ergonomics. The perfect unit allows your team to grab cheese, sauce, and toppings without taking a single extra step, which is a game-changer when orders are flying in.

Get the sizing wrong, and you're in for a world of headaches. A unit that’s even a half-inch too tall simply won't fit under your pizza prep table. One that's too shallow is just wasted space where you could be storing valuable ingredients like extra dough balls or prepped toppings. This guide is built specifically for pizzeria owners, focusing on how to pick equipment that integrates flawlessly into your kitchen's unique rhythm.

Before you start shopping, it's helpful to have a quick reference for the typical dimension ranges you'll encounter. This table breaks down what you can expect for standard commercial undercounter units designed for pizzerias.

Standard Undercounter Refrigerator Dimension Ranges

| Dimension Type | Common Range (Inches) | Key Consideration for Pizzerias |

|---|---|---|

| Height | 32" to 34.5" | Must fit comfortably under standard 36-inch pizza prep tables with room for airflow. |

| Width | 24", 48", 60", 72" | Varies by door/drawer configuration and how many topping pans you need to store. |

| Depth | 24" to 32" | 24-inch depths are common for flush installation with standard pizza prep tables. |

Remember, these are just the most common ranges. Always, always check the manufacturer's spec sheet for the exact dimensions before you place an order.

Key Dimensional Standards

The industry has settled on these dimensions for a reason: seamless integration into the pizza prep line. The height range of 32 to 34.5 inches (that's about 81 to 88 cm) is specifically designed to leave just enough clearance under a standard 36-inch pizza prep table for proper ventilation.

Widths are often built in convenient increments like 24 inches, which allows you to mix and match units to fill a specific length of counter space. Depths usually stick close to 24 inches to align perfectly with the depth of your prep tables and other equipment. If you want to dig deeper into the specifics, you can learn more about the nuances of under-counter refrigerator sizes and how they impact your kitchen's layout.

Mastering Standard Commercial Refrigerator Sizes

When you're outfitting a kitchen, especially one with a pizza prep table, the single most important measurement for an undercounter refrigerator is its width. It’s the dimension that really dictates your storage capacity and how the unit slots into your pizza prep line. Thankfully, manufacturers have standardized these widths, which makes planning a whole lot easier.

While you'll find that height and depth stay in a pretty tight range—most units are 32 to 34.5 inches high and 24 to 32 inches deep—the width is where you get to make the real choices. Let's break down the common sizes and see where each one shines in a busy pizzeria.

Compact Models (24-inch and 36-inch Widths)

The 24-inch undercounter refrigerator is your go-to problem solver. These single-door units are perfect for tucking into small gaps in your pizza line or dedicating to a specific task. We see them used all the time at drink stations or for stashing backup sauces, specialty cheeses, or even gluten-free dough away from the main prep line.

Moving up a notch, a 36-inch model gives you a bit more breathing room, usually around 9-11 cubic feet of storage. It’s a fantastic choice for a small, secondary sandwich or salad station within a pizzeria. It holds a respectable amount of prepped ingredients without eating up too much of your valuable prep space.

Workhorse Units (48-inch and 60-inch Widths)

Ask any seasoned pizzeria owner, and they'll tell you the 48-inch undercounter refrigerator is the undisputed workhorse. Offering 12-14 cubic feet of capacity, these two-door models strike the perfect balance between footprint and storage. They slide neatly under most standard pizza prep tables and are big enough to hold all your primary toppings—pepperoni, mushrooms, onions, and cheese—right where you need them most.

When business is booming, stepping up to a 60-inch unit is a smart move. This expands your refrigerated storage to roughly 16-18 cubic feet, which is ideal for high-volume pizzerias that burn through ingredients. That extra width makes a real difference in organization, ensuring your most popular toppings are always within reach during a chaotic dinner rush.

For a lot of growing pizzerias, that 48-inch unit is the sweet spot to start with. It offers plenty of accessible storage right under the main prep area, which is absolutely critical for keeping ticket times down and minimizing how much your pizza makers have to move around.

High-Capacity Solutions (72-inch Widths and Beyond)

For the largest and busiest pizzerias, nothing less than a 72-inch model will do. These three-door giants offer 20+ cubic feet of storage, making them a perfect match for long prep lines that handle a massive variety of toppings. A unit this size ensures you can keep bulk quantities of every ingredient chilled and ready, which means fewer time-wasting trips to the walk-in cooler.

Ultimately, picking the right width comes down to three simple questions:

- Available Space: What are the exact measurements of the opening under your pizza prep table?

- Ingredient Volume: How many different toppings do you need to keep chilled and ready during your busiest shift?

- Workflow: Where does this unit need to be placed to make your pizza makers as efficient as possible?

When you match your undercounter refrigerator's dimensions to your pizzeria's real-world needs, you're not just buying a piece of equipment—you're building a more organized and productive kitchen.

Integrating Refrigerators with Pizza Prep Tables

A pizza prep table is the command center of your production line, but its efficiency takes a nosedive if the refrigerated base doesn't fit right. The whole point is to create a seamless, unified workstation where ingredients are chilled directly below the action. This requires a perfect match between the undercounter refrigerator dimensions and the space built into the prep table's chassis.

When you nail this pairing, you kill wasted motion and keep your pizza makers focused on assembly, not fetching ingredients. A mismatched unit is a recipe for disaster, creating workflow bottlenecks as staff constantly walk to another cooler for cheese or pepperoni.

Matching Refrigerators to Common Prep Table Sizes

The secret to a perfect fit is measuring the open space underneath your prep table—what we call the under-chassis. Most commercial pizza prep tables are built with specific openings to accommodate standard refrigerator widths. You need to measure the height, width, and depth of this cavity, not the overall table.

Here's a pro tip: always subtract 1-2 inches from your measurements to leave room for essential ventilation clearance. For a full breakdown of what to look for, our guide on choosing the right commercial pizza prep table is a must-read.

Here’s how standard undercounter refrigerator widths typically line up with popular pizza prep table sizes:

- For 48-inch Prep Tables: These tables nearly always feature a cavity designed for a 24-inch wide undercounter refrigerator. This leaves enough room for the table's own condensing unit while giving you a compact, single-door refrigerated section for your core toppings.

- For 72-inch Prep Tables: A 72-inch table usually has enough under-chassis space for a 48-inch two-door undercounter refrigerator. This combo is a workhorse in countless pizzerias, offering plenty of cold storage for a wide variety of ingredients right where you need them.

- For 93-inch Prep Tables: The largest standard prep tables are built for serious volume. A 93-inch model can typically fit a 60-inch or even a 72-inch wide undercounter refrigerator, creating a massive, integrated cold storage station that drastically cuts down on trips to the walk-in.

A common mistake is assuming a 72-inch prep table can fit a 72-inch refrigerator. The prep table's own mechanical components often take up part of the under-chassis space, so the refrigerator's width must be smaller than the table's total width.

By carefully cross-referencing your prep table's specs with the available undercounter refrigerator dimensions, you can build a highly productive and ergonomic pizza line that just plain works.

Your Essential Measurement and Installation Checklist

Avoid the costly mistakes that can derail an installation before it even starts. Getting your new undercounter refrigerator to fit and work perfectly in a busy pizza kitchen really comes down to nailing three things: measuring your space accurately before you buy, planning for proper ventilation, and making sure your utilities are good to go.

Get this right, and you'll sidestep workflow nightmares, equipment damage, and the massive headache of trying to return a multi-hundred-pound appliance. A well-installed unit is the bedrock of an efficient pizza prep line.

Stage One: Pre-Purchase Space Measurement

Before you even start looking at models, grab a tape measure. The single most common installation error is buying a unit based on the manufacturer's specs without ever measuring the actual opening it's supposed to slide into. You have to measure the opening under your pizza prep table—height, width, and depth—and do it from a few different spots.

For instance, measure the height on the left, in the middle, and on the right. Floors and countertops are almost never perfectly level. Take the smallest of those three numbers; that's your real-world maximum height. Do the same thing for the width and depth to find the true undercounter refrigerator dimensions you have to work with.

Thinking ahead is key for a smooth installation. Before you try to fit in an undercounter refrigerator, learning how to plan a room layout effectively can make a huge difference in visualizing your entire kitchen workflow.

Stage Two: Clearance and Ventilation Planning

Commercial refrigerators kick out a surprising amount of heat, especially when they're working hard in a hot pizza kitchen. Without enough room to breathe, the compressor works itself to death, leading to an early breakdown and food that isn't kept at a safe temperature. This is why clearance isn't optional.

As a simple rule of thumb, plan on leaving 1-2 inches of clearance on the sides and back for most commercial units. But—and this is important—you absolutely must check the manufacturer's spec sheet for the exact model you're buying. Those requirements can and do vary.

Skimping on ventilation space doesn't just shorten the life of your equipment; it can also completely void your warranty. Keep these points in mind:

- Front-Breathing Units: These are lifesavers for tight pizza prep lines. They pull air in and push it out through a grille on the front, which means they need very little, if any, side or rear clearance.

- Rear-Breathing Units: These models need open space behind them so the coils can get rid of heat. Boxing one of these in too tightly is a guaranteed recipe for failure.

- Top and Side Vents: Some units have vents in less common places. Always figure out where the air flows before you decide on the final placement.

Stage Three: Utility and Final Placement

Last but not least, you need to confirm your utilities are in the right spot and are rated for commercial gear. A standard home outlet probably isn't going to cut it, especially in a pizzeria running heavy-duty equipment.

Double-check these items before your new unit shows up:

- Electrical Outlet: Is there a dedicated outlet within easy reach of the refrigerator's power cord? Using an extension cord is almost always a health code violation and a serious fire risk.

- Voltage and Amperage: Make sure the outlet matches the voltage and amperage specs listed on the refrigerator. Commercial units are power-hungry and often need more juice than residential models.

- Floor Leveling: Your floor needs to be level. Most refrigerators have adjustable legs or casters to help you get it perfect, which is critical for making sure the doors seal tightly to keep the cold air in.

Choosing Between Door and Drawer Models

Figuring out the right undercounter refrigerator dimensions is a huge step, but the real game-changer for your workflow is deciding between doors and drawers. This isn't just about how the unit looks—it's a critical operational choice that directly impacts how fast and organized your pizza line runs during the dinner rush.

Door models are the versatile workhorses of the kitchen. Their open, vertical shelving is perfect for stashing bulky or awkwardly shaped items. Think big containers of pizza sauce, gallons of milk for the coffee station, or those tall stacks of pre-portioned dough boxes. This flexibility makes them a solid all-around pick for general cold storage needs.

However, when it comes to speed and precision at a high-volume pizza station, drawer models are in a league of their own.

Workflow Speed with Drawer Models

Drawers are engineered from the ground up to hold standard-sized food pans, effectively turning your undercounter unit into a perfectly organized grid of toppings. Instead of opening a door, fumbling to pull out a shelf, and then grabbing a container of pepperoni, your pizza makers simply slide a drawer open. Everything is laid out with immediate, top-down access.

This design shaves precious seconds off every single pizza order by eliminating searching and fumbling.

In a busy pizzeria, saving just three seconds per pizza can add up to dozens of extra orders served during a packed service. Drawers optimize the most repetitive motions your team makes, directly boosting your throughput and, ultimately, your bottom line.

In a fast-paced kitchen, the benefits are crystal clear. Drawers encourage a systematic layout where pepperoni, mushrooms, and onions are always in the same spot, building muscle memory and slashing ticket times. You can see similar principles of rapid access in specialized equipment like refrigerated beverage drawers, which apply this same logic to other parts of your operation.

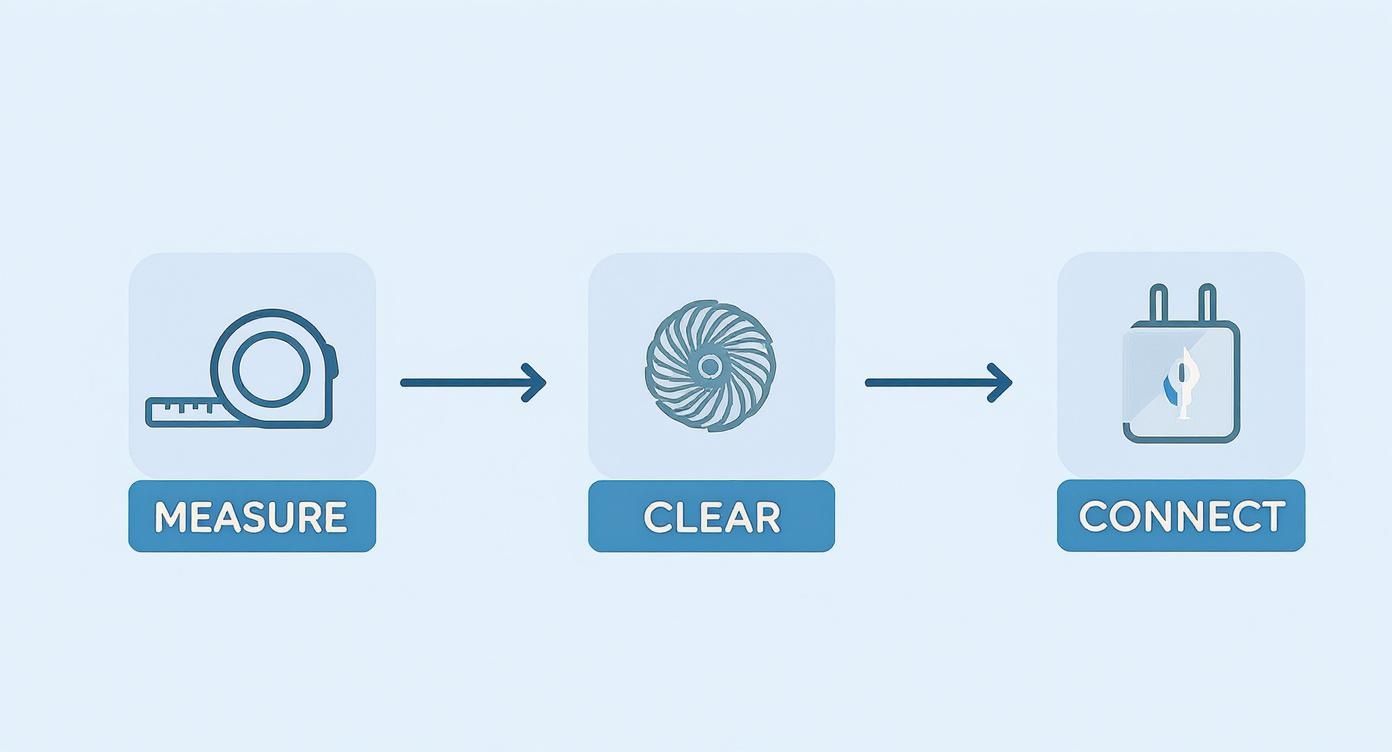

Of course, choosing the right model is just the first step. The infographic below breaks down the simple but crucial process for any successful installation.

This flow highlights that proper measurement and ensuring adequate clearance are non-negotiable prerequisites before you ever plug a unit in. It's the only way to guarantee your chosen door or drawer model performs as it should.

Door vs Drawer Comparison for Pizza Kitchens

To help you visualize how each configuration fits into a real pizza-making environment, I've put together a direct comparison. This table breaks down the key differences and best-use cases for both door and drawer models.

Door vs Drawer Undercounter Refrigerators

| Feature | Door Models | Drawer Models |

|---|---|---|

| Best For | Bulk storage (sauce tubs, dough boxes) and varied item sizes. | High-speed access to portioned toppings in food pans. |

| Organization | Flexible shelving, but can become cluttered without discipline. | Superior, with dedicated slots for specific ingredients. |

| Workflow | Requires opening a door and reaching in, a two-step process. | Single-motion drawer pull for immediate, top-down access. |

| Space Use | Bending down is often required to see and reach back items. | Ergonomic design reduces strain and improves visibility. |

Ultimately, the smartest pizzerias often use a combination of both. They'll place a drawer model directly under the main pizza prep table for instant access to toppings and keep a door model nearby for holding all the bulkier backup items. This hybrid approach gives you the best of both worlds: speed where it counts and flexibility where you need it.

Navigating ADA and Health Code Requirements

Getting your pizza kitchen compliant and safe is about more than just a smooth workflow. When you're picking out an undercounter refrigerator, you absolutely have to think about the Americans with Disabilities Act (ADA) and your local health codes. These rules touch everything from counter height to equipment certification, and they’re in place to protect both your crew and your customers.

For a pizzeria, ADA compliance usually comes down to making sure workstations are accessible. The act is pretty clear: work surfaces, including the sections of your pizza prep line, can't be higher than 34 inches. This is a big deal because most standard undercounter refrigerators are just a hair taller than that, meaning they simply won't fit. To build an inclusive kitchen, you'll likely need to hunt down specific ADA-compliant models built with a lower profile.

Health Codes and Food Safety

When it comes to the health department, there’s zero room for error, and your refrigeration is one of the first things an inspector will check. To make sure you pass inspection with flying colors and keep your food safe, always, always choose equipment that is NSF-certified (National Sanitation Foundation). This certification is your guarantee that the unit is made with food-safe materials and can hold ingredients at or below the required 40°F (4°C), even when the kitchen is blazing hot from the pizza ovens.

Ventilation is another huge hot-button issue for health inspectors. An undercounter fridge jammed in without enough clearance is going to overheat. When it overheats, it can't hold a safe temperature, and that puts your entire inventory of cheese and toppings at risk. That's a major red flag they won't miss.

Meeting these standards is non-negotiable for running a smooth operation. To get a really good handle on what inspectors are looking for, it helps to go through a comprehensive restaurant health inspection checklist. It'll help you make sure every corner of your pizzeria is up to code.

Finally, don't forget that your city or county might have its own specific rules. Always double-check with your local health department to see what codes apply to your business. Investing in a compliant, correctly-sized, and NSF-certified undercounter refrigerator isn't just an expense—it's a foundational step in building a safe, legal, and successful pizzeria. It protects you from fines and makes sure every pizza you send out the door is top-quality.

Common Questions About Refrigerator Dimensions

Even the most carefully planned kitchen layout can hit a snag. When it comes to fitting in new equipment, especially in the tight, high-heat environment of a pizzeria, a few common questions always pop up. Getting the right answers from the start saves you from headaches, costly returns, and workflow nightmares down the road.

Here are the straightforward answers to the questions we hear most often from pizzeria owners trying to nail their undercounter refrigerator setup.

What If My Counter Is Shorter Than 36 Inches?

If your pizza prep table or existing counter is lower than the standard 36 inches, you're not out of luck. You'll just need to look for models specifically labeled as "short" or "low-profile" undercounter refrigerators. These units are built with a shorter frame, typically around 32 inches high, to slide right into those non-standard spaces.

Before you even start shopping, grab a tape measure. Get the exact distance from your floor to the underside of the countertop. When you're looking at spec sheets, make sure you subtract at least 1 inch from your measurement to leave room for the essential top clearance for ventilation.

Can I Place an Undercounter Refrigerator Directly on the Floor?

Absolutely. Commercial undercounter refrigerators are designed to sit right on the floor. Most will come equipped with either casters (wheels) or adjustable leveling legs straight from the factory.

- Casters are a must-have in any pizza kitchen. They make it incredibly easy to roll the unit out for cleaning, which is a lifesaver when flour and cheese inevitably get underneath.

- Adjustable legs are your best friend if you have uneven floors. A perfectly level refrigerator is critical for making sure the door gaskets form a tight, complete seal to lock in the cold air.

Don't underestimate the importance of leveling. A poor door seal from an unlevel unit forces the compressor to run constantly, jacking up your energy bills and drastically shortening the life of the equipment. A few minutes with a level pays for itself.

How Much Clearance Do I Need Around the Refrigerator?

This is one area where you can't cut corners, especially in a hot pizza kitchen. Proper clearance is non-negotiable for the health of your refrigerator. Most manufacturers specify needing 1-2 inches of open space on the sides and back to allow the unit to breathe properly.

But in a real-world pizzeria, with ovens blasting heat all day, more space is always better. If you’re squeezed for room, front-breathing models are a brilliant solution. They pull air in and push it out through a grille on the front, meaning they need very little clearance on the sides and back. Always, always check the manufacturer's spec sheet for your specific model—failing to follow their clearance rules can void your warranty.

Will a Residential Undercounter Refrigerator Work in My Pizza Shop?

Let me be blunt: No, and it's not even close. Using a residential refrigerator in a commercial kitchen is a recipe for disaster. Its compressor is nowhere near powerful enough to keep food at safe temperatures when dealing with the ambient heat from pizza ovens and the constant door openings of a busy service.

You'll end up with spoiled ingredients, a failed health inspection, and a dead refrigerator in short order. For the safety of your customers and the reliability of your operation, you have to stick with NSF-certified commercial-grade refrigerators.

Ready to build the perfect pizza prep line? At Pizza Prep Table, we specialize in providing high-quality, NSF-certified undercounter refrigerators that fit seamlessly with your prep tables. Explore our collection today and find the ideal dimensions for your kitchen's workflow.