Master 00 flour pizza: Pro Tips for Dough, Fermentation & Crust

Share

For any pizzeria serious about crafting an authentic Neapolitan-style 00 flour pizza, there's simply no substitute. This ultra-fine, soft wheat flour is the secret weapon behind a crust that hits all the right notes: soft, chewy, and light, all at once, with that classic leopard-spotted char that tells customers you know what you're doing. It’s the very foundation of a reputation built on quality.

The Professional Pizzeria’s Choice For Authentic Crust

In the pizza business, consistency is everything. Choosing 00 flour isn't just about sticking to tradition; it's a strategic move to control your final product and nail it every single time. Unlike your standard all-purpose or bread flour, 00 flour brings a unique combination of protein content and an incredibly fine grind that completely changes how the dough behaves.

This unique blend lets the dough absorb water more evenly, creating a smooth, supple texture that’s a dream to work with. For your pizza makers, this means they can stretch dough balls incredibly thin without tearing them—a non-negotiable step for a true Neapolitan base. It's also why a professional pizza prep table is so invaluable; its cold work surface keeps this delicate, high-hydration dough from sticking or getting overworked during service.

What Sets 00 Flour Apart

The real magic is in the milling process and the gluten structure. Italian flours are graded by their fineness, from the coarse 'tipo 2' all the way down to the finest 'tipo 00'. The texture is almost like talcum powder, and that's what delivers that distinctively soft crumb everyone loves.

A common misconception is that 00 flour is low in protein, but its content usually sits between 11-12.5%, which is right in line with all-purpose flour. The critical difference is the kind of gluten it produces. It’s less about brute strength and more about extensibility, creating a gluten network that stretches easily. This gives you a crust with a satisfying chew that never feels tough or dense.

For a restaurant, this isn't just about the eating experience. It’s about operational efficiency. Having a dough that's predictable, easy to handle, and performs flawlessly in a screaming-hot oven is essential for a fast-paced kitchen. Using 00 flour takes a lot of the guesswork out of the equation and ensures every single pizza lives up to your standard.

To really see why professionals are so committed to 00 flour, it helps to put it side-by-side with the alternatives you might find in a commercial kitchen.

Flour Comparison For Professional Pizza Making

Each flour type brings something different to the table, but for the specific demands of Neapolitan pizza, the characteristics of 00 flour are unmatched. This table breaks down why it stands out.

| Flour Type | Milling Fineness | Typical Protein % | Water Absorption | Best For |

|---|---|---|---|---|

| 00 Flour | Ultra-fine (powdery) | 11-12.5% | Moderate | Authentic Neapolitan pizza with a soft, airy, and slightly chewy crust. Stretches thin without tearing. |

| Bread Flour | Coarse | 12-14% | High | New York-style or thicker crust pizzas that need a very strong, chewy, and dense structure. |

| All-Purpose Flour | Medium | 10-12% | Moderate | Versatile for home use but lacks the specific gluten structure for a professional, authentic Neapolitan crust. Can be gummy. |

While bread flour can give you a great chew and all-purpose is a decent stand-in, neither can replicate the delicate, tender-yet-structured crust that only 00 flour can produce, especially under the intense heat of a proper pizza oven.

A Growing Market Demand

This isn't just a chef's preference anymore—it's a direct response to a booming market. In the competitive world of pizza restaurants, 00 flour has cemented its place as the gold standard for that perfect Neapolitan crust. The global 00 flour market soared to USD 1.2 billion in 2024 and is projected to grow at a CAGR of 4.11% from 2025 to 2034. That growth is being driven by a huge spike in demand for artisanal pizzas, particularly in North America. You can dig into the specifics in a recent market analysis from Polaris Market Research.

The data tells a clear story: customers are actively looking for higher-quality, authentic pizza experiences. For a pizza restaurant, getting on board with this trend means using premium ingredients like 00 flour and investing in the right gear, like pizza prep tables, is a direct line to building a loyal following and a powerful brand.

Crafting Your Commercial 00 Flour Dough Formula

Forget home-baking recipes. If you want to run a successful pizza restaurant, you need to think like a professional baker. That means ditching cups and spoons for the precision of baker’s percentages.

This system is the backbone of any serious pizzeria. Every ingredient is measured as a percentage of the total flour weight, which is always 100%. This simple shift in thinking is the key to scaling your 00 flour pizza dough with absolute consistency, whether you're prepping 10 dough balls for a slow lunch or 100 for a slammed Friday night.

Baker's percentages give you surgical control. Need a bit more salt to pop the flavor? Want to nudge the hydration up on a dry day? You can tweak a single number without wrecking the whole batch. This is the kind of control you need when you're managing large mixes, especially when you have a dedicated pizza prep table keeping everything organized and properly chilled.

The Foundation: A Baseline Formula

A truly great Neapolitan-style dough comes from just four basic ingredients. The real secret isn't what's in it, but the ratio between them. With flour as your 100% anchor, everything else falls into place.

Here’s a solid, professional baseline formula that works beautifully with 00 flour:

- Caputo 00 Flour: 100%

- Water: 65% (hydration)

- Fine Sea Salt: 2.8%

- Fresh Yeast: 0.3% (or 0.1% for instant dry yeast)

This formula lands you at a 65% hydration level—a sweet spot for 00 flour. It creates a dough that’s soft, easy to stretch, and manageable for your crew. The salt adds flavor while keeping the yeast in check, and the tiny amount of yeast is perfect for the long, cold fermentation that develops those deep, complex flavors your customers will crave.

For any pizzeria owner, your dough formula is your secret weapon. It’s what makes your pizza different from the guy’s down the street. Mastering baker's percentages gives you the power to perfect that signature crust and replicate it flawlessly, day after day. That's how you build a brand.

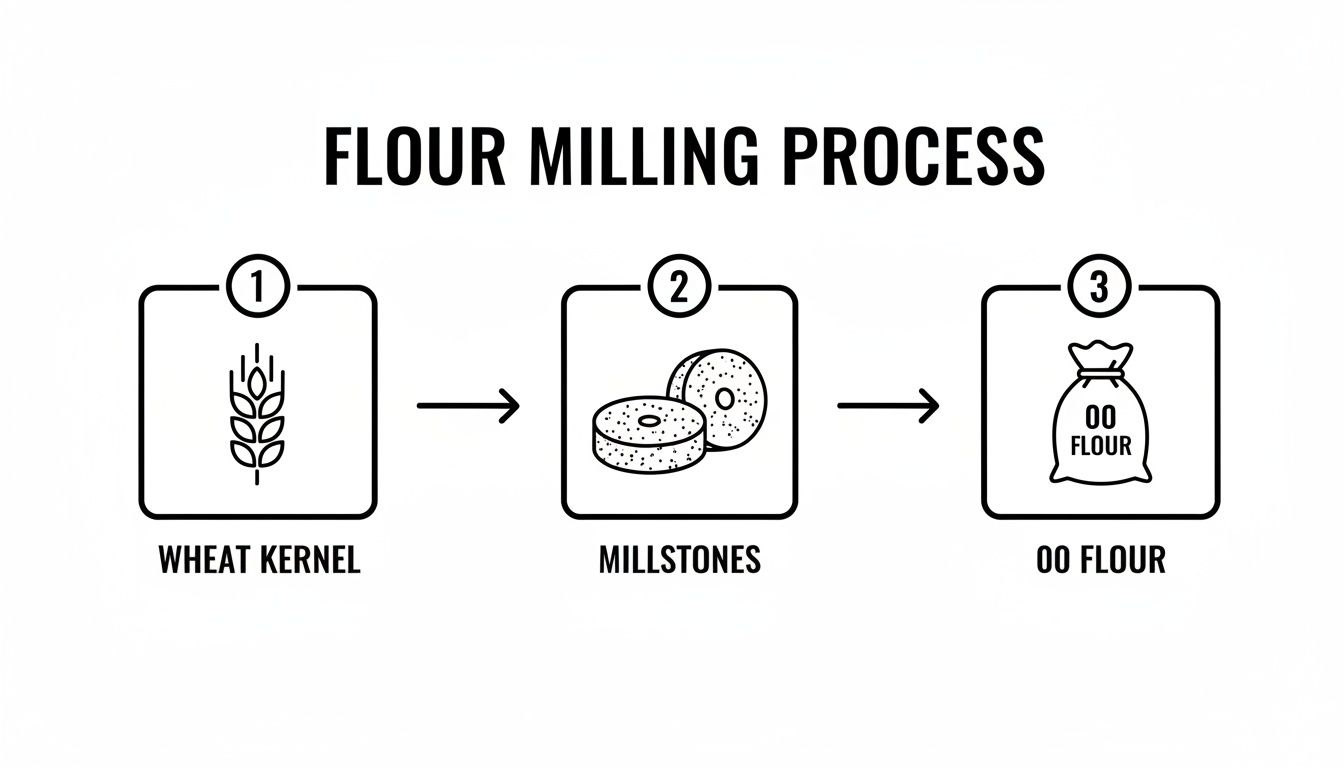

The diagram below shows the journey from a simple wheat kernel to the ultra-fine 00 flour that makes this formula possible.

This meticulous milling process is what gives the flour its powdery texture, which is absolutely essential for creating that classic, elastic dough.

From Small Test Batch To Full Production

Never commit to a huge batch without running a small test first. This lets you see how the dough behaves in your kitchen—the specific temperature and humidity in your prep area can and will affect the final product.

Let's walk through how this formula looks for a small test batch using 5,000g (5kg) of flour.

Example Small Test Batch (5kg Flour):

- 00 Flour: 5,000g (100%)

- Water: 3,250g (65% of 5000g)

- Fine Sea Salt: 140g (2.8% of 5000g)

- Fresh Yeast: 15g (0.3% of 5000g)

- Total Dough Weight: 8,405g

Once you’ve nailed the test batch and love the results, scaling up is just simple math. The percentages don't change, only the flour weight. Let's scale this up for a full 25kg bag of flour, a standard size for any commercial kitchen.

Scaling For A Busy Service

This is where the magic of baker's percentages really comes to life. A 25kg mix is a serious amount of dough where precision is everything. This is also where a high-quality pizza prep table becomes your best friend, giving you the refrigerated space to properly hold and proof dozens of dough trays.

Here’s the formula scaled for a full 25kg bag:

| Ingredient | Baker's Percentage | Weight for 25kg Flour |

|---|---|---|

| 00 Flour | 100% | 25,000g |

| Water | 65% | 16,250g |

| Fine Sea Salt | 2.8% | 700g |

| Fresh Yeast | 0.3% | 75g |

| Total Dough Weight | - | 42,025g |

With this single scaled-up batch, you can produce roughly 150 dough balls at a standard weight of 280g each. This systematic approach takes all the guesswork out of the equation. It cuts down on ingredient waste and guarantees that the last pizza of the night has the exact same incredible crust as the first. It's the only way to operate a serious pizzeria.

Mastering Dough Fermentation And Handling

A perfect formula is just the starting line. The real soul of your 00 flour pizza dough is developed during fermentation and handling—a hands-on process where your technique and workflow make all the difference. This is where a top-tier pizza prep table really starts to earn its keep, turning what could be a chaotic mess into a smooth, streamlined system.

It all begins with temperature control right out of the mixer. If you're using a spiral mixer, your goal is to hit a final dough temperature of around 75°F (24°C). This is the sweet spot for kicking off yeast activity, setting you up for a predictable and healthy fermentation from the get-go.

Many of the best pizzerias swear by an autolyse—a short rest period after mixing just the flour and water, before you add the salt and yeast. This simple pause lets the delicate 00 flour fully hydrate, which pays off big time later with a dough that's more extensible and a dream to handle.

Choosing Your Fermentation Strategy

Once your dough is mixed, you’ve got two main roads you can take for fermentation. Each one creates a totally different end product, both in flavor and how it fits into your kitchen's rhythm. Your choice will really depend on your pizza restaurant’s capacity, service schedule, and the kind of crust you're aiming for.

- Bulk Fermentation: This is the faster route. You let the entire mass of dough rise at room temperature, usually for 1-2 hours. It gets the job done quickly but doesn't build the same deep, complex flavors.

- Cold Fermentation: This is the method preferred by true artisans. You divide the dough into balls shortly after mixing and let them ferment slowly in the fridge for a good, long while.

Cold fermentation is where 00 flour really comes alive. A slow proof of 24 to 72 hours inside your prep table’s refrigerated base does so much more than just let the dough rise. It gives enzymes the time they need to break down complex sugars and proteins. The result? Incredible depth of flavor and a final crust that's noticeably more digestible for your customers.

The patience for a long, cold ferment is what separates a good pizza from a truly great one. It's a low-and-slow game that builds a rich, nuanced flavor you just can't fake or rush. This is the signature of a pizzeria that truly respects the craft.

Balling Dough For Service

After the initial mix, it's time to divide and ball the dough. Consistency is everything here if you want a uniform product. For a classic Neapolitan-style pizza, each dough ball should weigh between 250g and 280g. A digital scale isn't optional for this step; it's mandatory.

How you ball the dough is critical. You're trying to create a tight, smooth surface that will trap the gases produced during the final proof. That tension is what gives you that beautiful, airy cornicione when the pizza hits the hot oven.

Once balled, the dough goes into proofing boxes. These stackable, airtight containers are essential—they keep the dough from drying out while it undergoes that long cold ferment. A well-organized system of dated proofing boxes in your pizza prep table's refrigerated base creates a seamless "first in, first out" inventory system. You can get more pro tips in our guide on how to keep pizza dough fresh.

This organized workflow ensures you always have perfectly proofed dough ready for service, cutting down on waste and boosting efficiency when the dinner rush hits.

And the demand for this level of quality is exploding. The pizza industry's unstoppable growth is supercharging the need for 00 flour, making it a staple for any serious restaurant operation. The market for 00 flour was valued at a cool USD 2.0 billion in 2023 and is projected to hit USD 4.9 billion by 2033—that's a solid 9.1% CAGR. This boom is driven by global pizza sales, with B2B channels like yours owning a 59.3% market share in 2023, supplying restaurants that can't get enough of this finely milled powerhouse. You can dive deeper into these market trends on Fact.MR.

How a Pizza Prep Table Transforms Your Workflow

Once you've nailed your 00 flour pizza formula and fermentation schedule, the last thing you want is for all that hard work to fall apart on the assembly line. Great dough is delicate. This is where a dedicated pizza prep table stops being just a piece of equipment and becomes the absolute nerve center of a high-volume pizzeria.

Its real magic is in consolidating everything—dough, sauce, toppings—into one efficient, temperature-controlled station. That refrigerated rail, lined with cold pans, keeps your mozzarella, pepperoni, and fresh basil perfectly chilled and food-safe. This isn't just about making things easier for your restaurant; it's about strict quality control and cutting down on waste, ensuring every pizza that goes out is identical, even when you're slammed.

The Importance of a Cold Work Surface

With a delicate, high-hydration 00 flour dough, temperature control is everything. A cold work surface isn't a luxury; it's a non-negotiable part of the process. Whether it's classic marble or modern stainless steel, a chilled surface keeps the dough from getting sticky, overheating, and losing its structure while your pizzaiolos are trying to work.

- Stainless Steel: It's the industry standard for a reason. Stainless is tough as nails, non-porous, and a breeze to sanitize, hitting all the critical NSF food safety marks for your restaurant. It gets cold fast and stays cold, giving your crew a reliable surface for stretching.

- Marble: The traditional choice, prized for its natural ability to stay cool. It’s fantastic for dough work, but it's also more porous and needs some TLC to prevent stains and chips over time in a busy pizza restaurant setting.

Whichever material you have, that cold surface lets your team stretch dough balls consistently without fighting a sticky, frustrating mess. That translates directly to faster prep and a better crust.

Sizing Your Station for Peak Performance

The size of your pizza prep table directly dictates your restaurant's output. Picking the right model comes down to your sales volume and the physical space you have to work with.

A small café turning out a few dozen pizzas a day can get by just fine with a compact 44-inch unit, giving one person plenty of room to work. But a bustling pizza restaurant with a constant stream of tickets needs a much bigger stage—something like a spacious 93-inch model. These larger tables let multiple chefs work shoulder-to-shoulder, creating a genuine assembly line that can crush even the most intense dinner rush.

A well-chosen pizza prep table is an investment in consistency and speed. It becomes the central hub where quality control, food safety, and operational efficiency meet, allowing your team to perform at their best when the pressure is on.

The global pizza market hit a staggering USD 148.6 billion in 2023 and is on track to reach USD 219.9 billion by 2032. Just in the US, we're talking about USD 38 billion in annual pizza sales. That kind of growth means new pizza restaurants need professional gear like a 93-inch prep table to handle 00 flour prep in bulk just to keep up.

Ultimately, the right equipment allows your team to focus on the craft, not the chaos. You can explore a variety of sizes and configurations in our complete guide to the commercial pizza prep table. But don't stop there; optimizing the entire kitchen is crucial. It all starts from the ground up, so take a look at the various durable and hygienic commercial kitchen flooring options that can handle the demands of a busy pizzeria.

The Art Of Stretching And Baking 00 Flour Pizza

This is the moment of truth. All your careful prep work comes down to this. Your perfectly fermented dough is ready, the toppings are chilled and organized on the prep table, and the oven is roaring hot. Now it's time to turn that humble dough ball into a truly exceptional 00 flour pizza.

The journey from a proofed dough ball to a finished pizza is a fast, high-stakes sprint. In a professional kitchen, this whole sequence unfolds on or right next to the pizza prep table. This isn't just for convenience; it's a critical workflow that keeps every single ingredient at the perfect temperature until it hits the screaming hot deck of the oven.

Hand Stretching For The Perfect Cornicione

First things first: never use a rolling pin. Ever. A rolling pin is the enemy of good pizza. It crushes and destroys that beautiful, delicate network of air bubbles your long fermentation worked so hard to create. Those bubbles are the secret to the light, airy, and puffy outer crust—the cornicione.

The goal here is to gently persuade the dough into shape, not force it. Start by pressing down in the center with your fingertips, carefully pushing the air out toward the edges. You’re simultaneously forming the thin, sturdy base for the toppings while building up the foundation for that iconic puffy rim.

Once you’ve established the rim, you can lift the dough and use gravity and your knuckles to gently stretch it to its final size.

A perfectly stretched base is strong enough to hold toppings but thin enough to cook in under two minutes. This technique is a true craft that separates the pros from the amateurs, and it’s a skill that directly impacts the customer's experience.

Baking At Extreme Temperatures

Authentic 00 flour pizza demands blistering heat. The sweet spot is an oven raging between 800-950°F (425-510°C). This isn't just a suggestion; it’s non-negotiable if you want the signature characteristics of a Neapolitan-style crust.

In a pizzeria, this heat comes from a wood-fired or high-temp deck oven. That blast of heat causes an explosive oven spring, which rapidly inflates the cornicione and creates that amazing airy interior we all love.

This incredibly quick 60-90 second bake is also what produces the beautiful "leopard spotting"—those dark, charred blisters scattered across the crust. The rapid cooking locks in moisture, ensuring the crust stays tender and soft on the inside, never dry or cracker-like. You can learn more about finding the right gear in our guide to the best commercial pizza oven for your restaurant.

Troubleshooting Common Baking Issues

Even with perfect dough and a great oven, things can go wrong during a busy service. Here’s how to fix some common problems and make sure every pizza that goes out is perfect:

-

Soggy Center: This is usually the result of too much sauce or piling on wet ingredients like fresh mozzarella or raw veggies. Go easy on the toppings, apply them evenly, and always drain wet cheeses thoroughly before they hit the dough. A base stretched too thin in the middle will also cause this problem.

-

Unevenly Cooked Toppings: If your toppings are burning before the crust is done, or the other way around, your oven probably has hot spots. It's also absolutely critical to rotate the pizza about halfway through its short bake. A quick turn with a peel ensures every side gets equal exposure to the heat, giving you a perfectly uniform cook.

-

Dough Sticking to the Peel: This is a classic dinner-rush nightmare. It usually happens when the dough is too wet or it's been sitting on the peel too long before launching. Make sure your prep surface and peel are lightly dusted with flour or semolina. The real key is speed—build the pizza quickly on the peel. The longer it sits, the more it will stick. A cold marble or stainless steel work surface from a pizza prep table is a huge help here, as it keeps the dough from warming up and getting tacky.

Questions We Hear All The Time

Even with a killer dough recipe and the best equipment lined up, questions always pop up during the daily grind of a busy pizzeria. Let’s tackle some of the real-world problems that chefs and owners run into when dialing in their 00 flour pizza and sorting out their kitchen flow, especially around the prep table.

Can I Just Use Bread Flour If I Run Out Of 00?

You can, but you really shouldn't. It's a swap that completely changes the pizza you’re selling and definitely isn't the right move if your goal is an authentic Neapolitan-style pie. The two flours just don't play the same game. Bread flour is coarser and has more protein, which gives you a crust that’s dense, chewy, and tough—much closer to what you’d find in a New York slice shop.

That super-fine, almost powdery feel of 00 flour is what makes the magic happen. It absorbs water in a unique way, creating a dough that’s incredibly soft and easy to stretch paper-thin without tearing. Switch to bread flour, and your pizzaiolos will immediately feel the difference; the dough will be tougher and fight back more. To deliver that premium quality your customers expect from a 00 flour pizza, you have to stick with the right stuff.

What's The Best Hydration Percentage For 00 Flour?

For most Neapolitan-style doughs using 00 flour, the hydration sweet spot is somewhere between 60% and 68%. Finding your magic number depends on a few things specific to your restaurant, like your mixer, how hot your oven runs, and even the humidity in your prep area.

Here’s how I break it down for a commercial kitchen:

- 60-63% Hydration: This dough is a dream to handle and a great starting point when you're training new cooks. It’s less sticky and way more forgiving when it comes time to shape.

- 65-68% Hydration: Pushing the water content up here gets you a lighter, airier crust with a beautiful open crumb. But be warned—this wetter dough is stickier and takes a more experienced hand to manage on the prep table.

My advice? Start around 63-65% and tweak it by a percent or two until you hit that perfect balance for your kitchen and the exact crust you want to be known for.

Hydration is one of the most powerful levers you can pull. A tiny adjustment of just 1-2% can totally change the feel of your dough and the final bite of the crust. It’s absolutely worth the time to experiment and find what works for your brand.

How Long Can I Really Cold Ferment My Dough?

With good temperature control, you can let your 00 flour dough balls cold ferment for a good while, which is how you develop those deep, complex flavors. In a commercial fridge or the base of a pizza prep table holding a steady 36-40°F (2-4°C), you’re looking at an ideal window of 24 to 72 hours.

Trying to push it past that 72-hour mark is risky. The yeast eventually eats up all the available sugars, and the gluten network starts to break down. You end up with an over-proofed dough that’s slack, a nightmare to stretch, and bakes up into a sad, flat crust. This is where a tight "first-in, first-out" system with dated proofing trays is non-negotiable.

Is A Marble Top Really Better Than Stainless Steel For A Prep Table?

Ah, the classic debate. Honestly, both are fantastic surfaces for handling delicate 00 flour dough. The "better" one really boils down to your pizzeria's volume, workflow, and how much maintenance you’re willing to do.

Marble Prep Surfaces

Marble is the old-school choice, loved by generations of pizzaiolos because it stays cool to the touch all by itself. That's a massive plus when you're working with high-hydration doughs, as it helps keep them from getting warm and sticky during a long, busy service. The downside? Marble is porous, which means it can stain and needs more careful upkeep to stay looking good.

Stainless Steel Prep Surfaces

Stainless steel is the undisputed workhorse of the modern commercial kitchen. It’s tough as nails, non-porous, and incredibly easy to clean and sanitize—making it the go-to for meeting strict NSF health codes. While it doesn't stay cool on its own like marble, a quality refrigerated prep table will keep the entire work surface perfectly chilled anyway. For most high-volume pizzerias, stainless steel is simply the more practical, durable, and food-safe choice.

Ready to build the ultimate pizza-making station? At Pizza Prep Table, we provide the high-quality, NSF-certified equipment that powers successful pizzerias. From compact workstations to expansive models designed for the busiest kitchens, we have the tools you need to ensure consistency, efficiency, and food safety. Explore our full collection of professional pizza prep tables and find the perfect foundation for your culinary creations.